Beam column connection piece, building framework structure and mounting method

A beam-column connection and column technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of affecting the connection strength and stiffness of the joint, the shaking of the beam and beam-column connector, and the lack of connection and fixing positions. Achieve the effect of stable and reliable connection nodes, multiple connection and fixing positions, and convenient connection and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

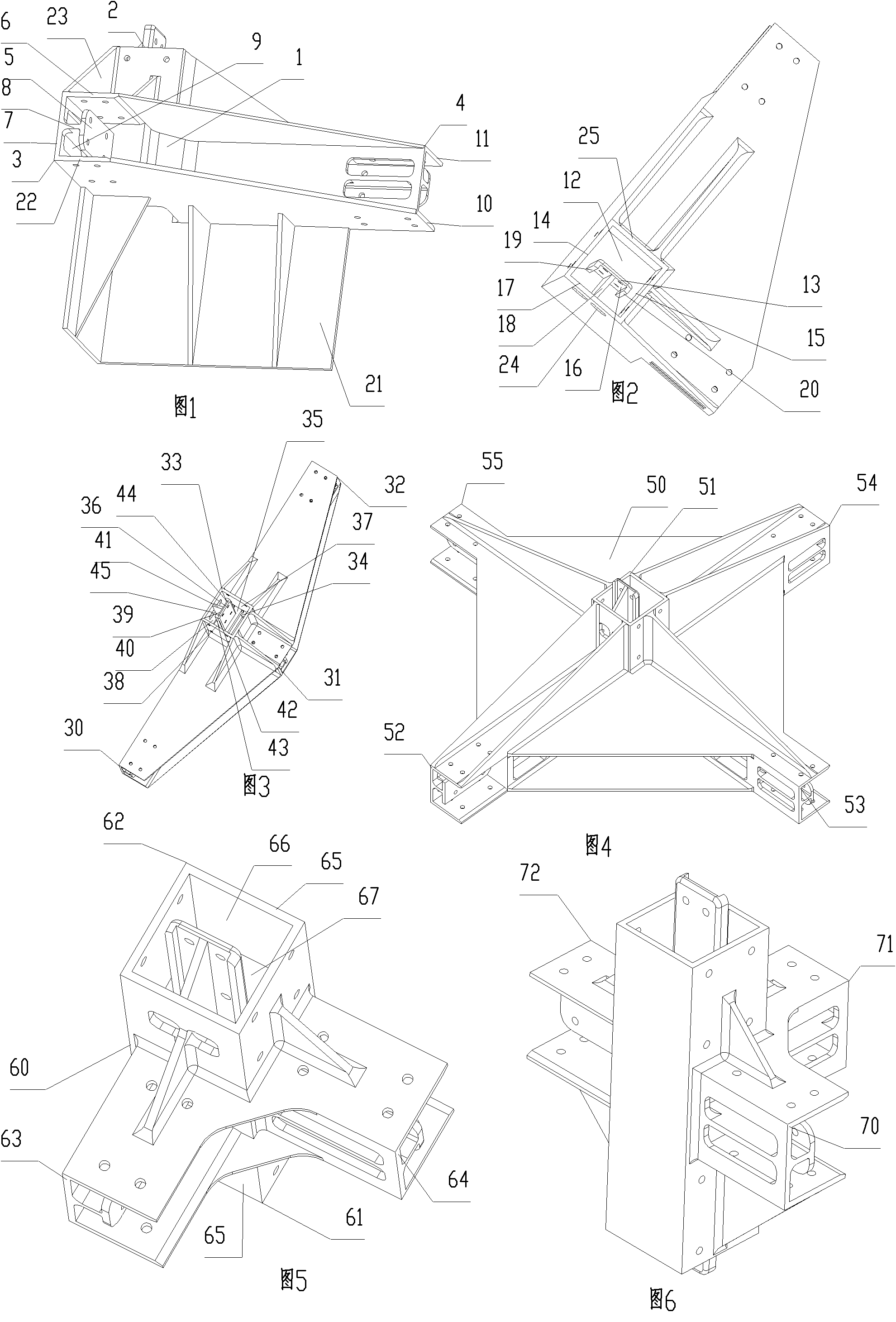

[0064] Such as figure 1 , figure 2 As shown, the beam-column connector is the bottom beam-column connector, including an integrally formed beam-column connector body 1, an upper column plug joint 2 that needs to be plugged and fixed with the end of the H-shaped steel column in the vertical horizontal direction, and two Directly support the H-shaped steel beam parallel to the horizontal plane, and the beam plug joint 3 and the beam plug joint 4 connected and fixed to the end of the beam.

[0065] The beam plug joint 3 retains the first support part 22 that is horizontally protruded from the side of the beam-column connector body 1 and directly supports the lower wing of the beam, placed directly above the first support part 22, and the side of the vertical beam-column connector body 1 is horizontal The first fixing part 5 fixed to the web of the beam is protrudingly provided, and the first fixing part 5 is arranged directly above the first fixing part 5 and horizontally protr...

Embodiment 2

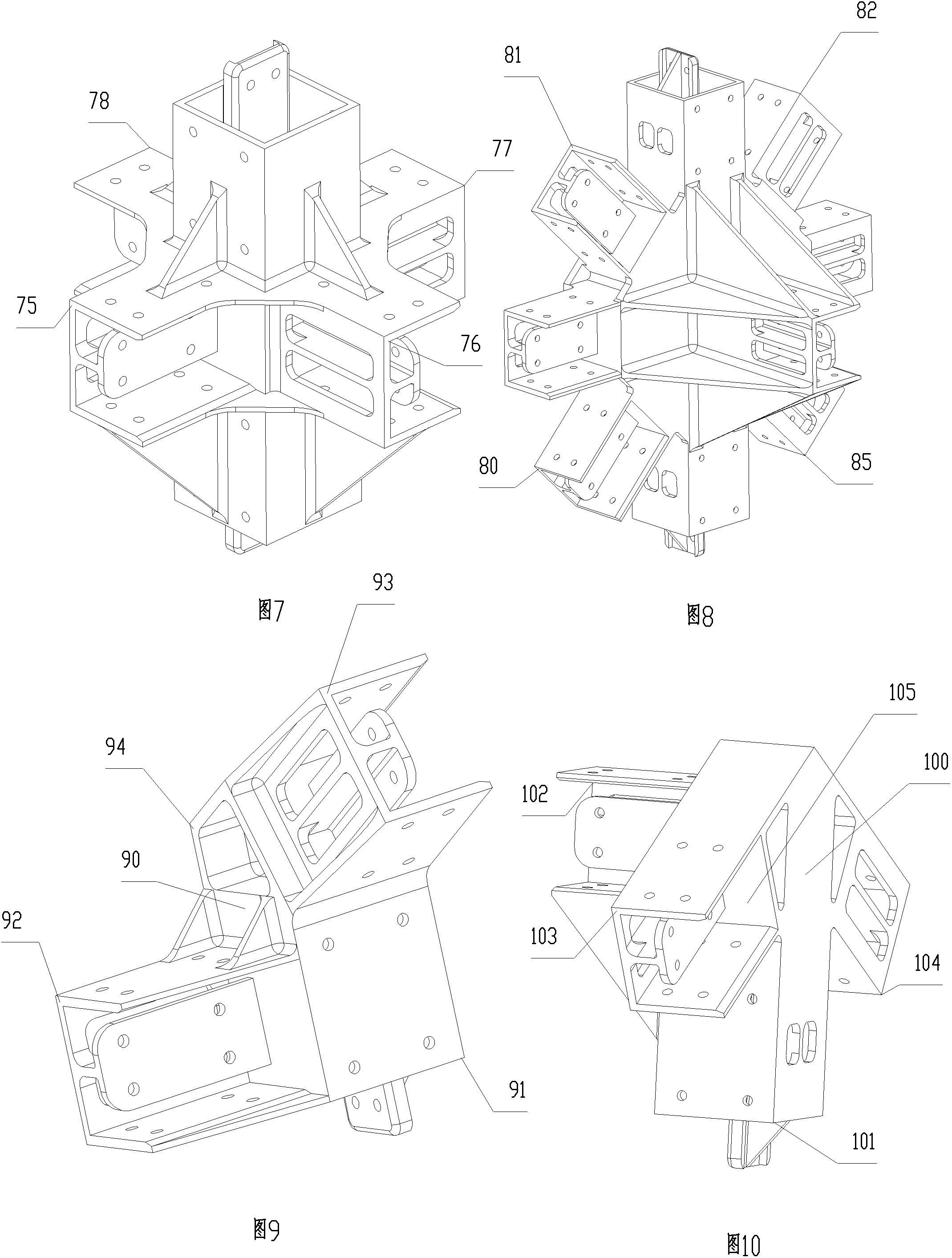

[0070] Such as image 3As shown, different from Embodiment 1, there are three beam plug joints, namely beam plug joint 30, beam plug joint 31, beam plug joint 32, and beam plug joint 30, beam plug joint 31, and beam plug joint 32 are perpendicular to each other. , into a T-shape. Two rows of disconnected resisting ribs 34 that resist the end of the column are horizontally protruded at the corresponding positions on the two inner sides opposite to the accommodation hole 33, and a resisting rib 35 is connected at the middle position of the two inner sides opposite to the accommodation hole 33. . The upper column plug joint includes a vertical resisting rib 35, a third fixed portion 36 fixed to the web of the column, and a reinforcing rib 41 connecting one side 39 of the third fixed portion 36 and one side 40 of the accommodating hole 33. The reinforcing ribs 43 and 44 on the side surface 42 of the third fixing part 36 and near the two ends of the third fixing part 36 . The di...

Embodiment 3

[0072] Such as Figure 4 As shown, the beam-column connector is the bottom beam-column connector, including an integrally formed beam-column connector body 50, an upper column plug joint 51 that needs to be plugged and fixed with the end of the vertical column in the direction of the vertical horizontal plane, four in ten The glyph directly supports the cross beam parallel to the horizontal plane, the beam plug joint 52, the beam plug joint 53, the beam plug joint 54, and the beam plug joint 55 that are fixedly connected with the end of the cross beam. The bottom surface of the beam-to-column connector body 50 is a plane. The structure of the upper column plug joint 51 is the same as that of the upper column plug joint in Embodiment 1, and the structure of the four beam plug joints is the same as that of the beam plug joint in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com