A large aperture ceramic ferrule

A ceramic ferrule and large aperture technology, applied in the field of optical fiber communication, can solve the problems of large optical attenuation loss, large range, and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

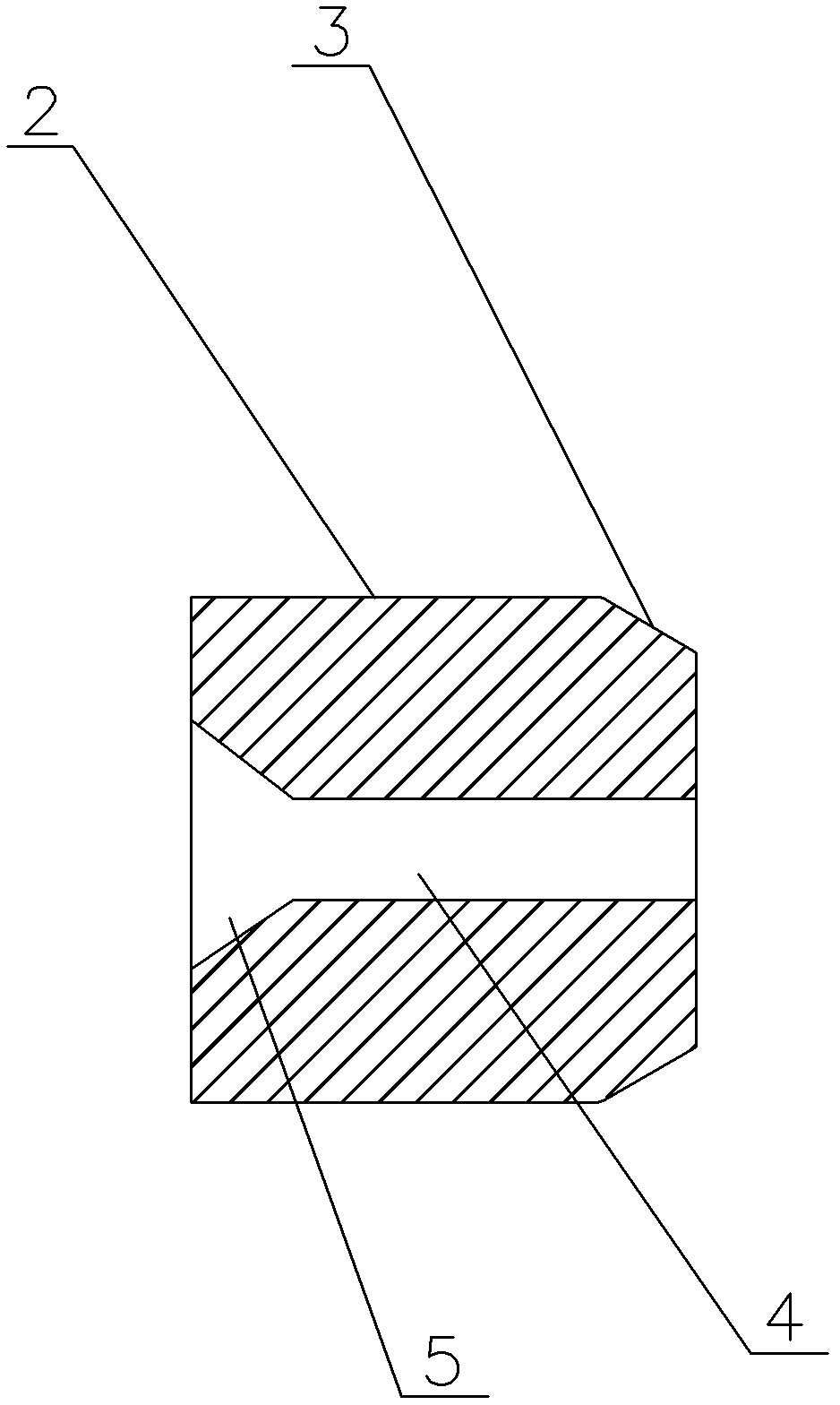

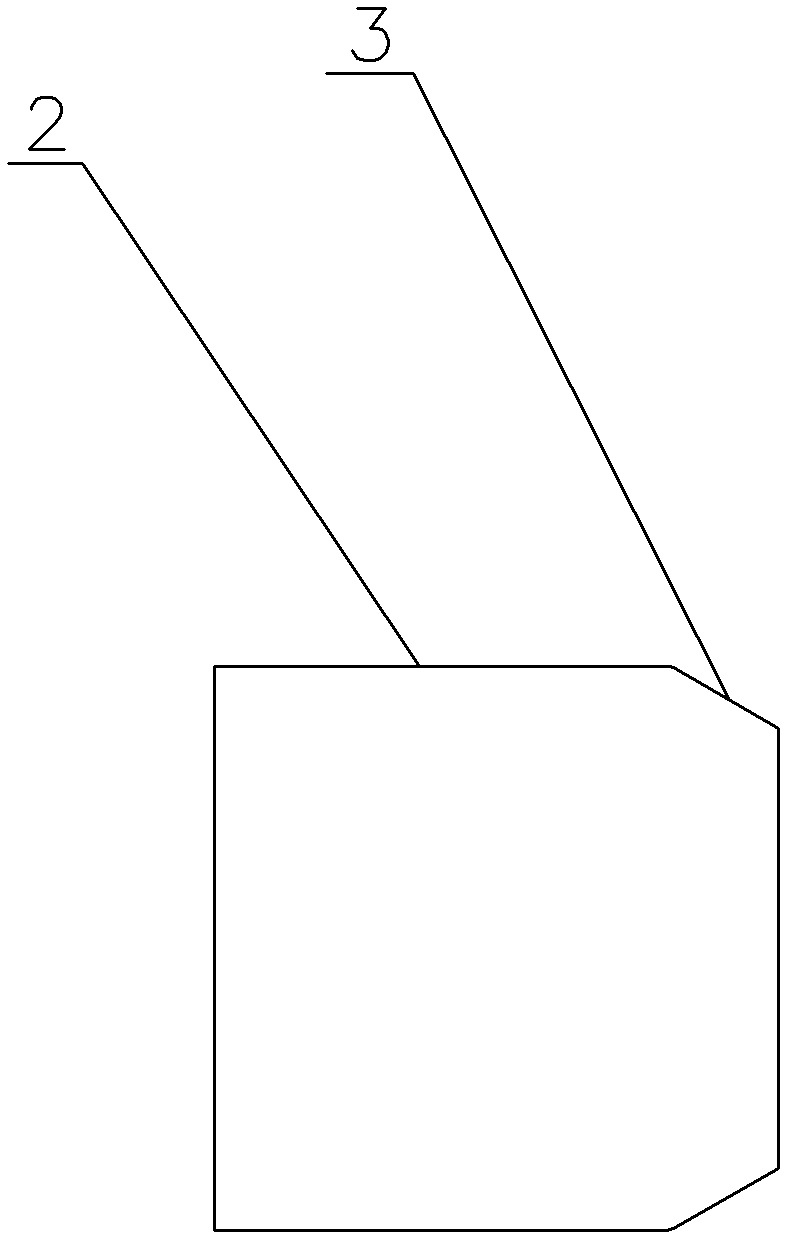

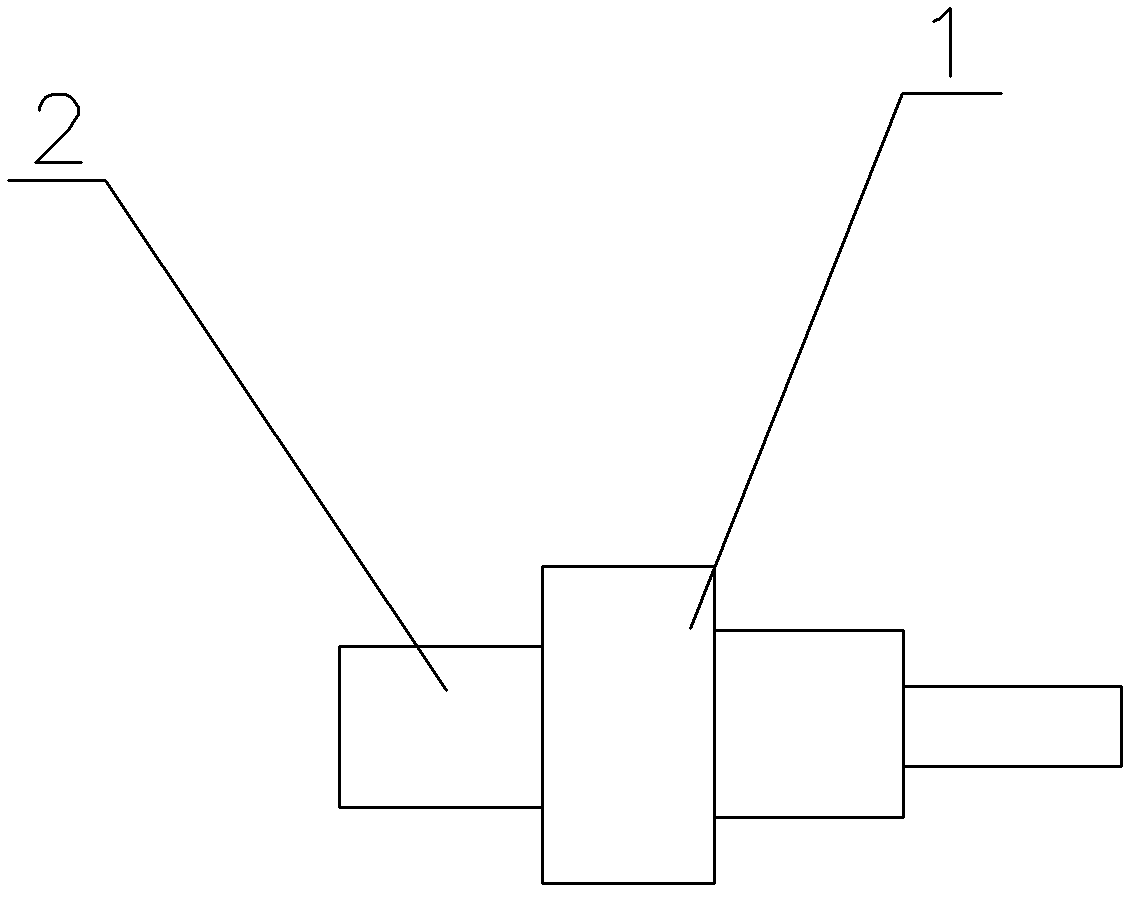

[0018] Such as figure 1 , figure 2 and image 3 As shown, a large-aperture ceramic ferrule is installed in the center of the optical fiber connector and used with a metal seat 1. The main body 2 of the ceramic ferrule is in the shape of a cylinder; one end of the ceramic ferrule is tapered. 3; the tapered end 3 is in the shape of a truncated cone. Wherein, the inner hole 4 of the other end of the ceramic ferrule is provided with a conical groove 5; the length of the ceramic ferrule is 2.5±0.05mm, the inner diameter is 0.5±0.02mm, the outer diameter is 2.499±0.0005mm, concentric The degree is not greater than 1 μm.

[0019] When installing a large-aperture ceramic ferrule of the present invention, such as image 3 As shown, one end of the ceramic ferrule provided with a tapered end 3 is placed in the center of the metal seat 1, and the inner cavity of the metal seat 1 is adapted to the outer surface of the ceramic ferrule provided with a tapered end 3, Because one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com