Positive tab connection structure of battery and welding method

A battery positive electrode and tab technology, applied in structural parts, welding equipment, laser welding equipment, etc., can solve the problems of ineffective control of product quality, poor reliability of aluminum tab transfer, inconvenient transfer operation, etc. It is not easy to achieve Unstable welding, good transfer reliability, and convenient transfer operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

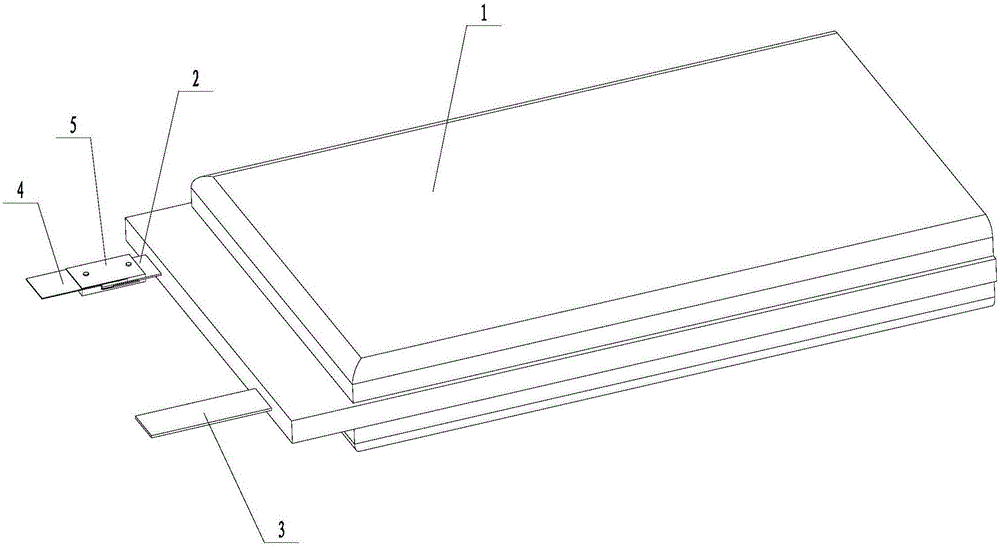

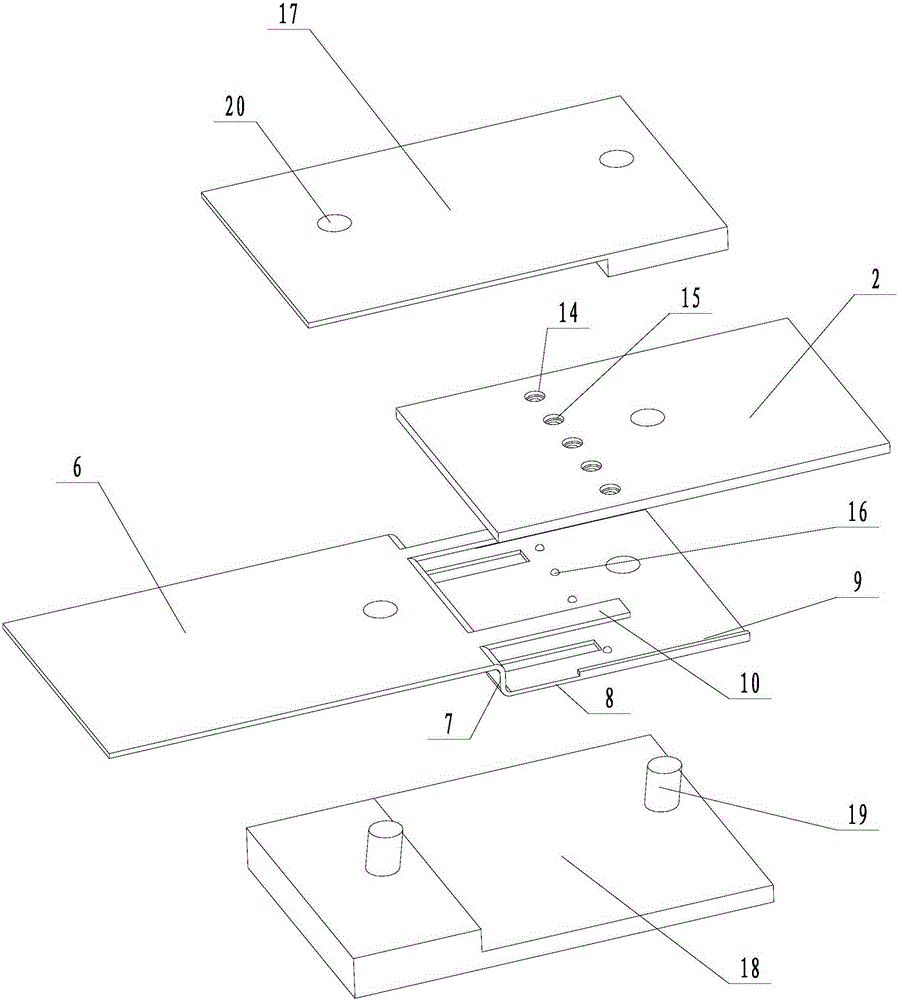

[0025] Example 1: A battery positive tab transfer structure (see attached figure 1 , attached figure 2 ), including the battery body 1, the battery body is provided with a positive pole lug 2, a negative pole lug 3, the positive pole lug is an aluminum lug, a nickel current carrier 4 is welded on the positive pole lug, the nickel current carrier and the positive pole A metal conductive clip 5 is detachably connected between the ears. The nickel current carrier has a Z-shaped stepped structure. The nickel current carrier includes an output terminal part 6, a transition part 7, and a welding part 8. A positioning groove 9 is arranged on the upper surface of the welding part, and the positive pole lug is inserted into the positioning groove. The end of the tab of the positive electrode abuts on the transition part. An elastic clip 10 is provided at the connection position between the output terminal part and the transition part, and the positive electrode tab is arranged betwe...

Embodiment 2

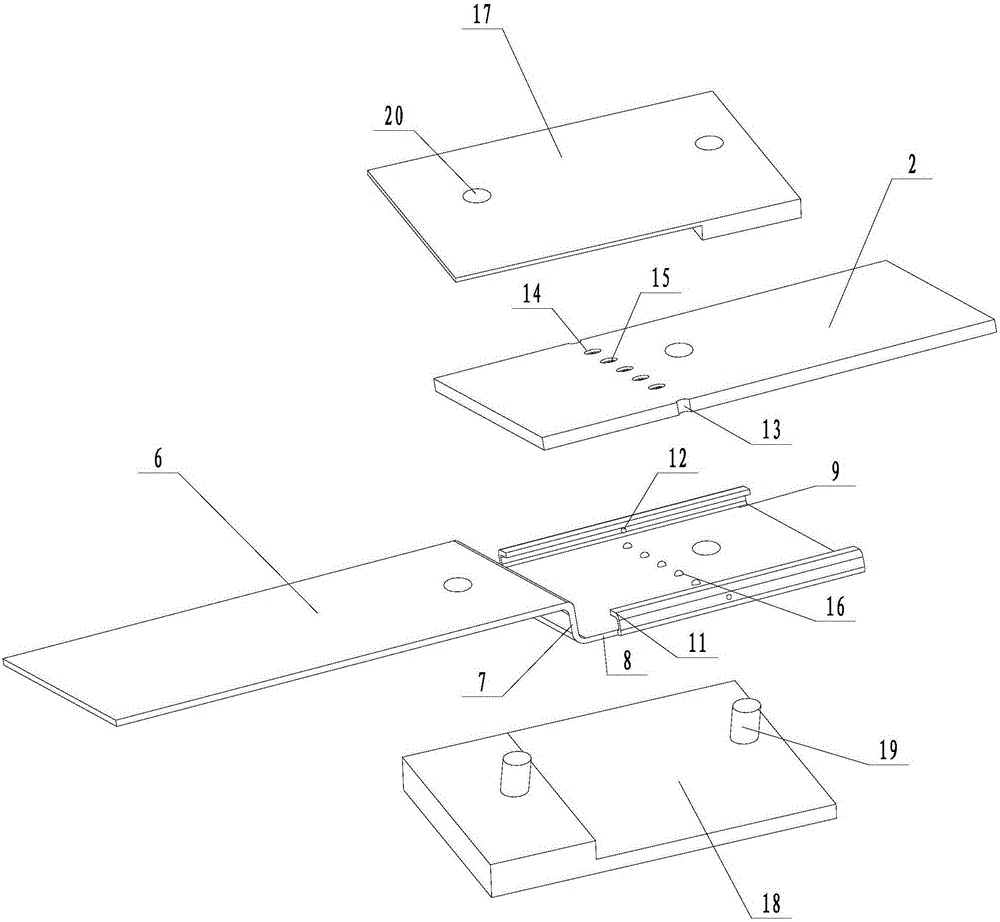

[0028] Example 2: A battery positive tab transfer structure (see attached image 3 ), its structure is similar to Embodiment 1, the main difference is that in this embodiment, both sides of the positioning groove on the upper surface of the welding part are provided with inwardly turned flanges 11, and the opening width between the upper ends of the two flanges is smaller than that of the positive electrode. The width of the lug, the two sides of the positive pole lug are clamped between the flange and the welding part. Elastic stamping heads 12 punched inward are provided on both flanges, and clamping grooves 13 are provided on both sides of the positive electrode lug, and the elastic stamping heads are snapped into the clamping grooves. Other structures are the same as in Embodiment 1. The nickel current carrier is clamped on the positive pole lug by flanging to realize reliable connection between the nickel current carrier and the positive pole lug, and the insertion and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com