Patents

Literature

43results about How to "Improve precision quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

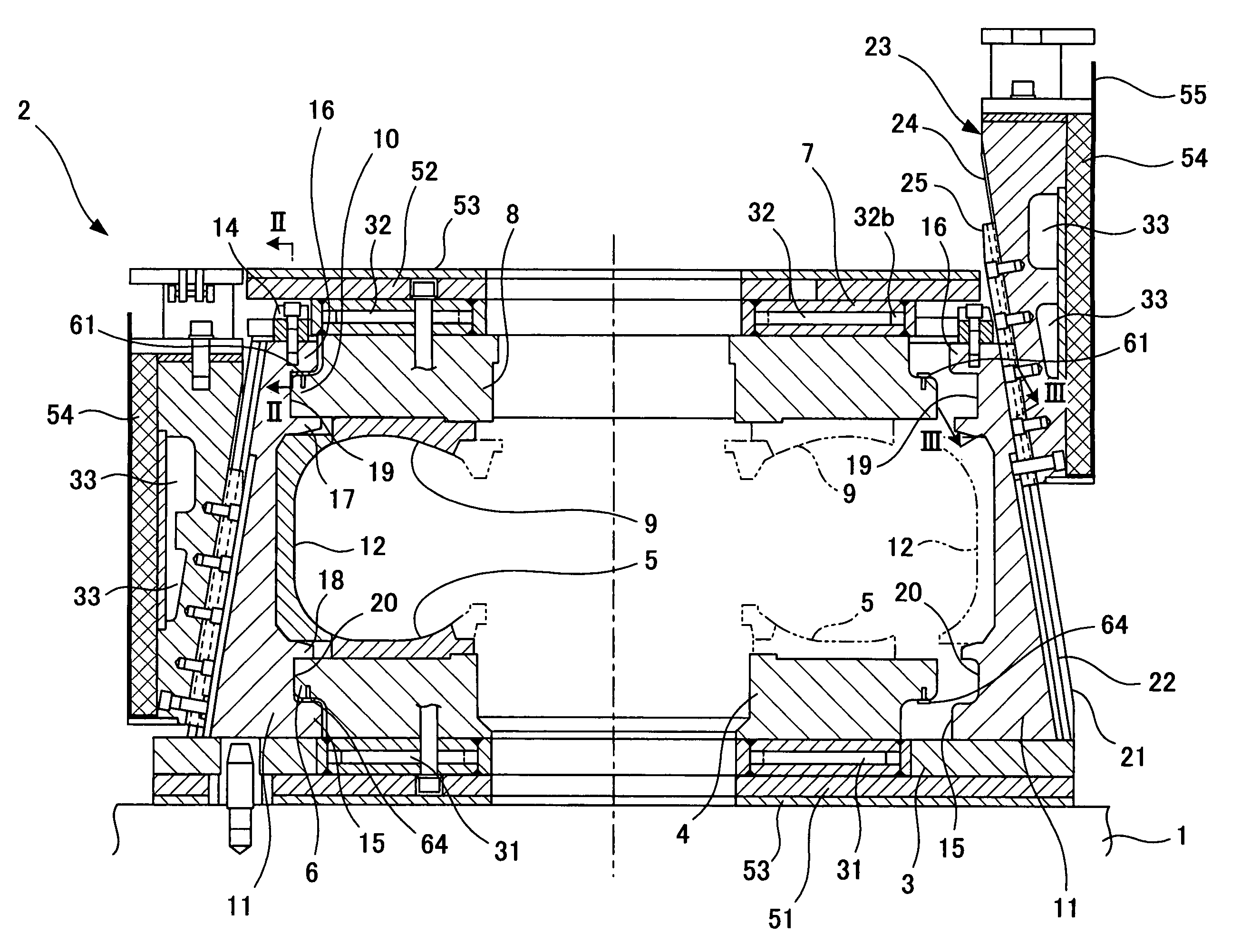

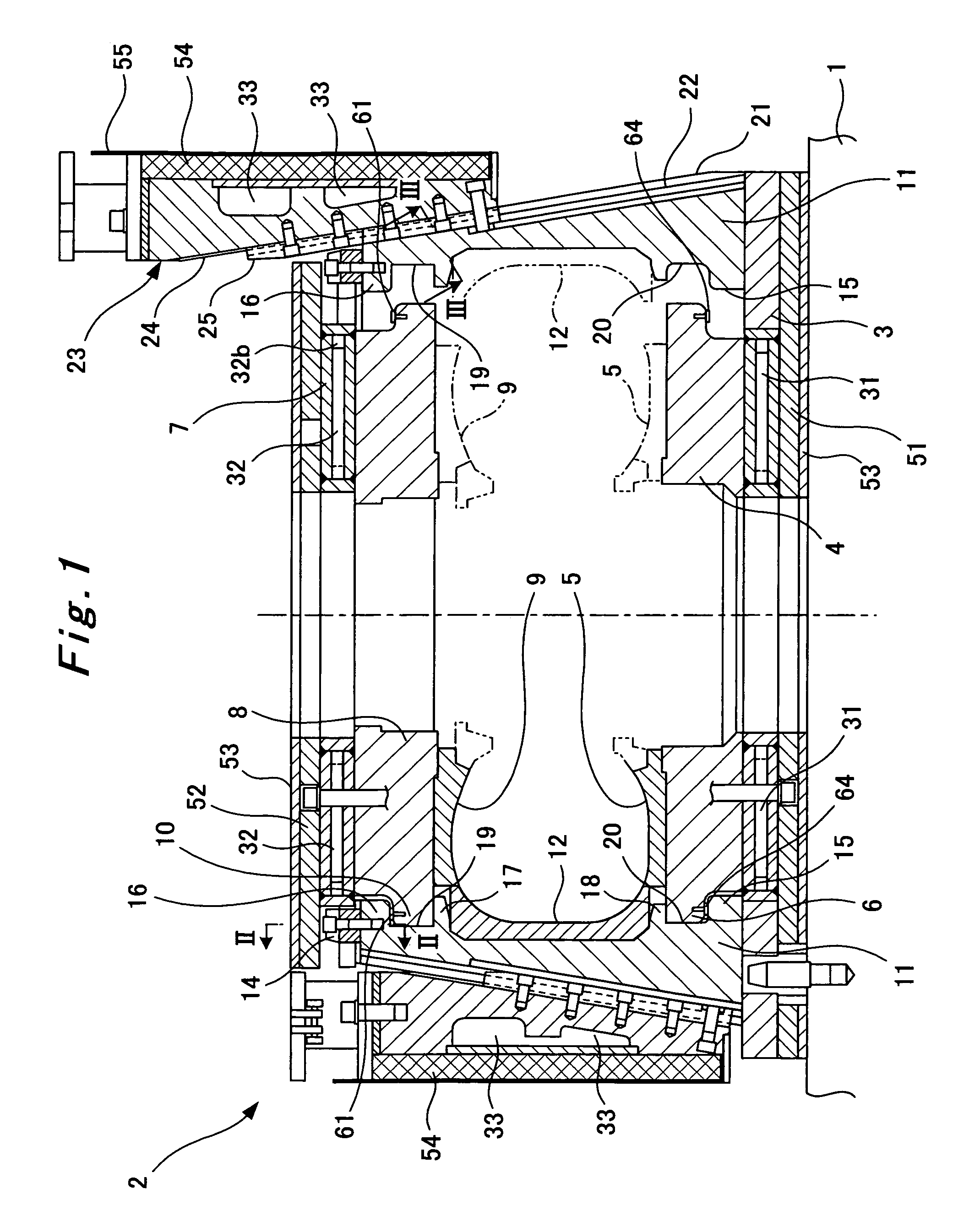

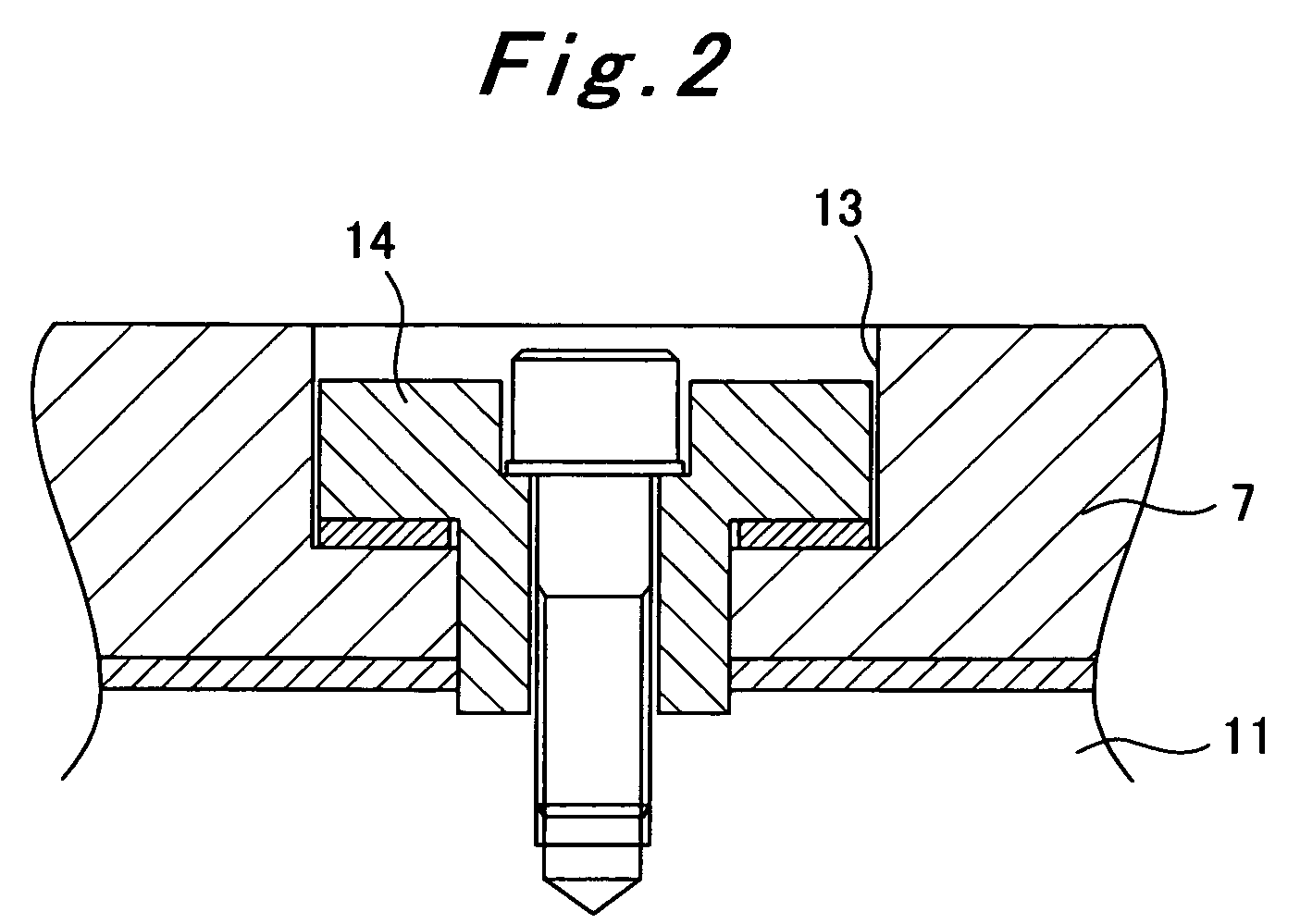

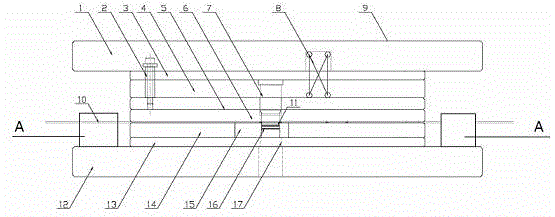

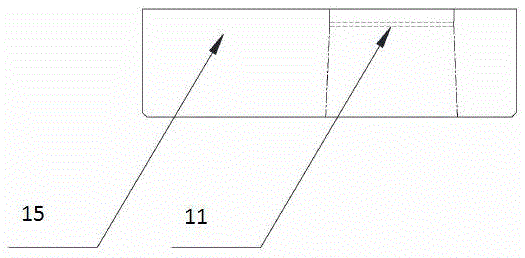

Tire vulcanizing apparatus

Disclosed is a tire vulcanizing apparatus including: upper and lower circular plates, to which sidewall dies for forming side portions of a tire are attached; respectively; and plural segments, to which tread dies separated as plural pieces for forming a tread portion of the tire are attached; respectively, in which apparatus, the upper and lower circular plates are held by engagement of lug portions, formed respectively on upper and lower portions of the segments, with protrusions on outer circumferential portions of the upper and lower circular plates so as to prevent the upper and lower circular plates from moving away from each other, the apparatus being constituted by providing adjustment plates, used for maintaining a measurement between the upper and lower circular plates, to an interface between the protrusion of each of the upper and lower circular plates and a corresponding one of the lug portions of each segment.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

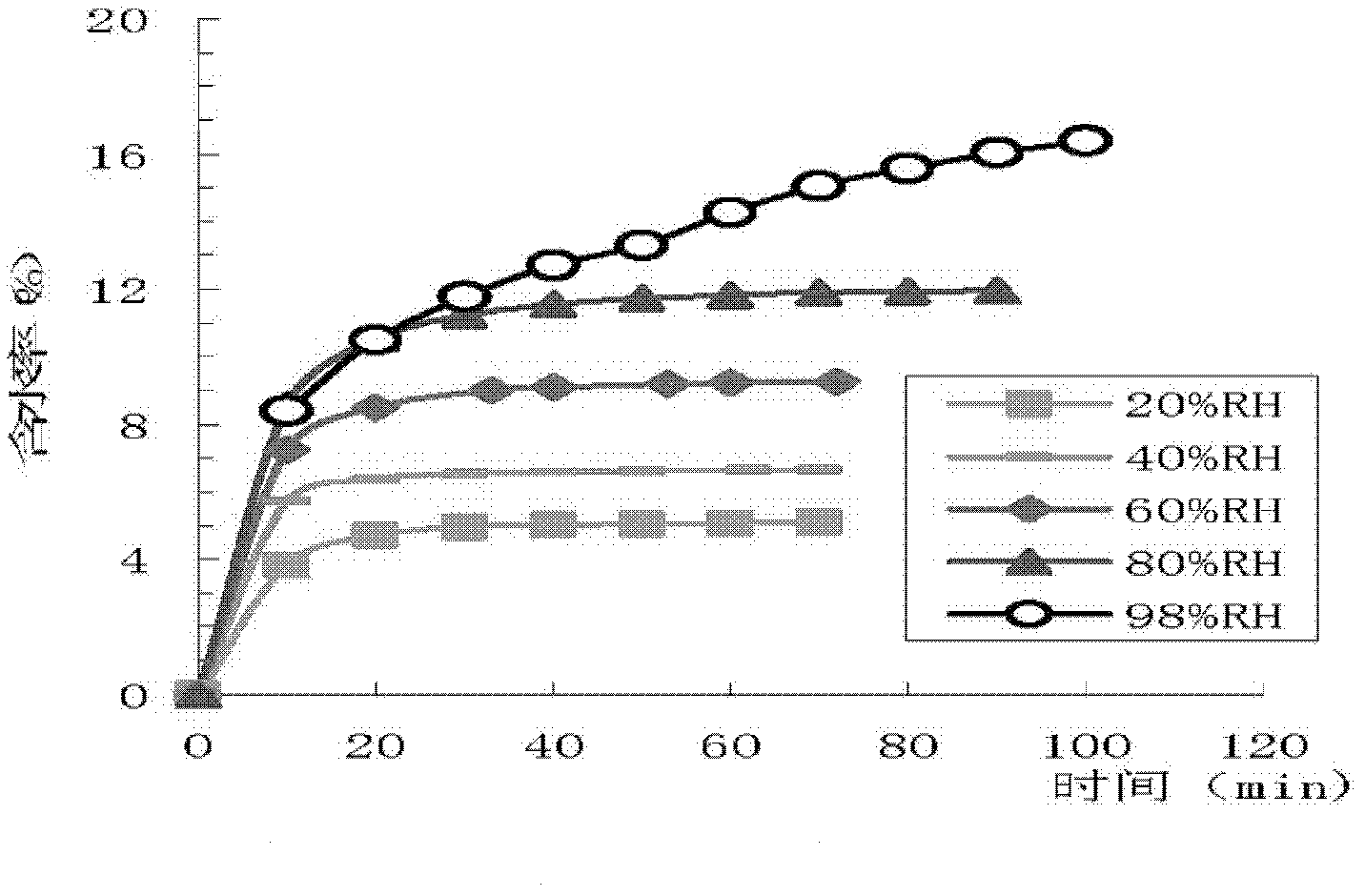

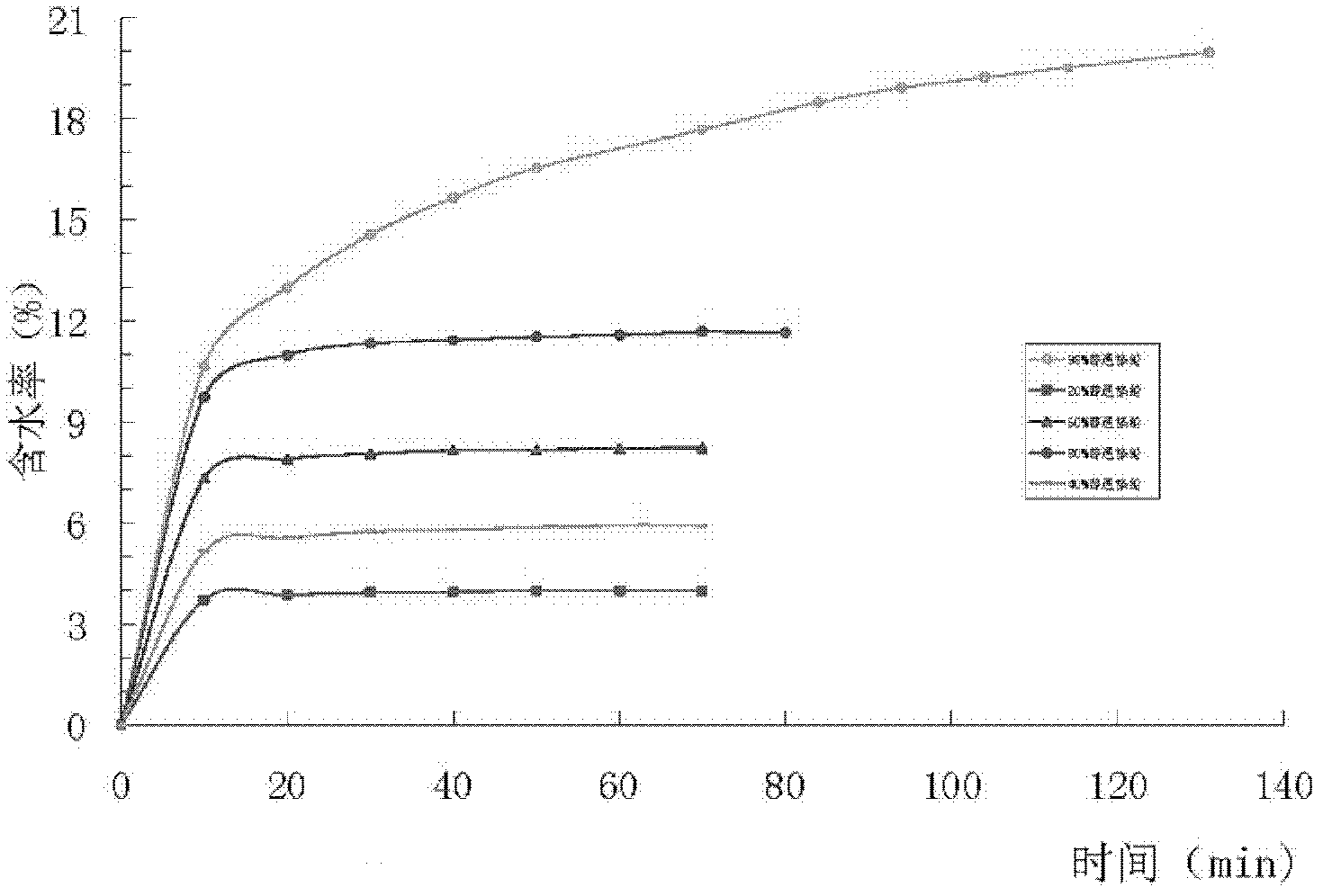

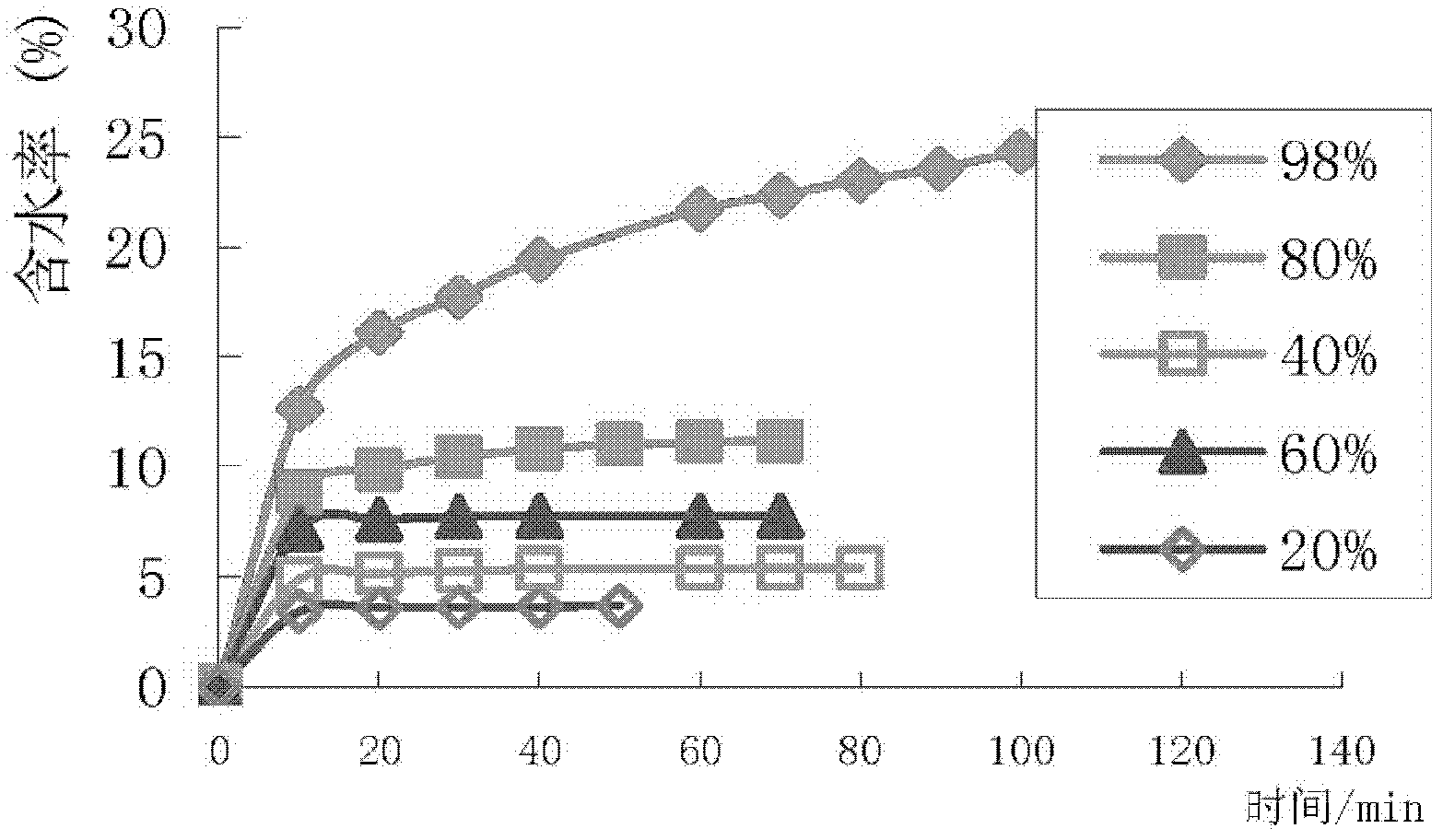

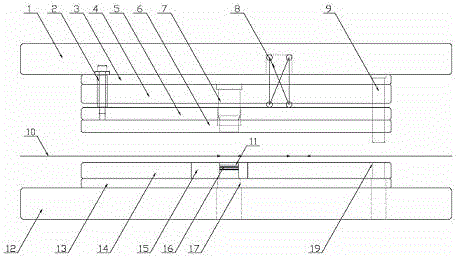

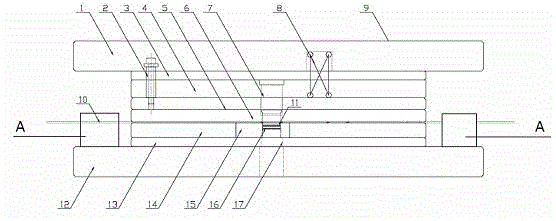

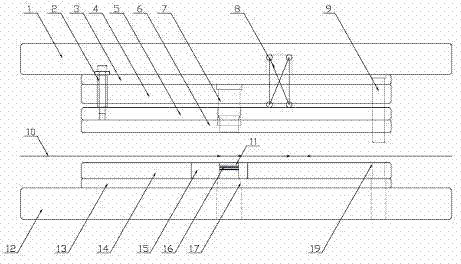

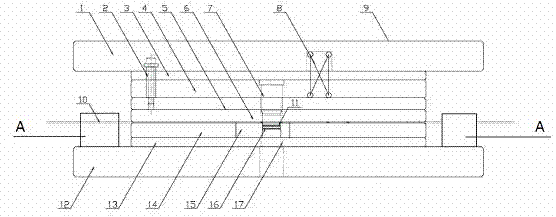

Device and method for testing dynamic moisture absorption data of fabric

InactiveCN102252934AEasy to prepareEasy to operateWeighing by absorbing componentTest fixtureEngineering

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

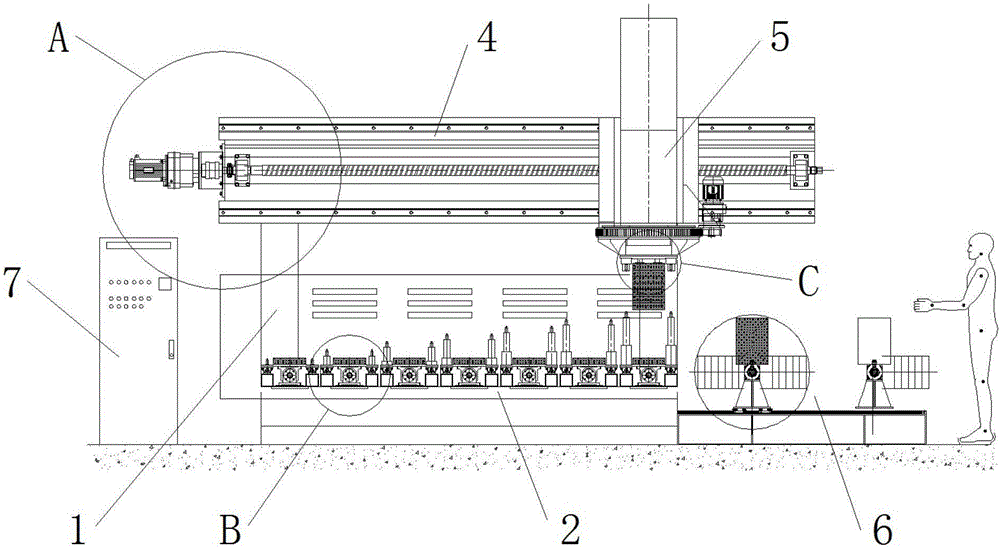

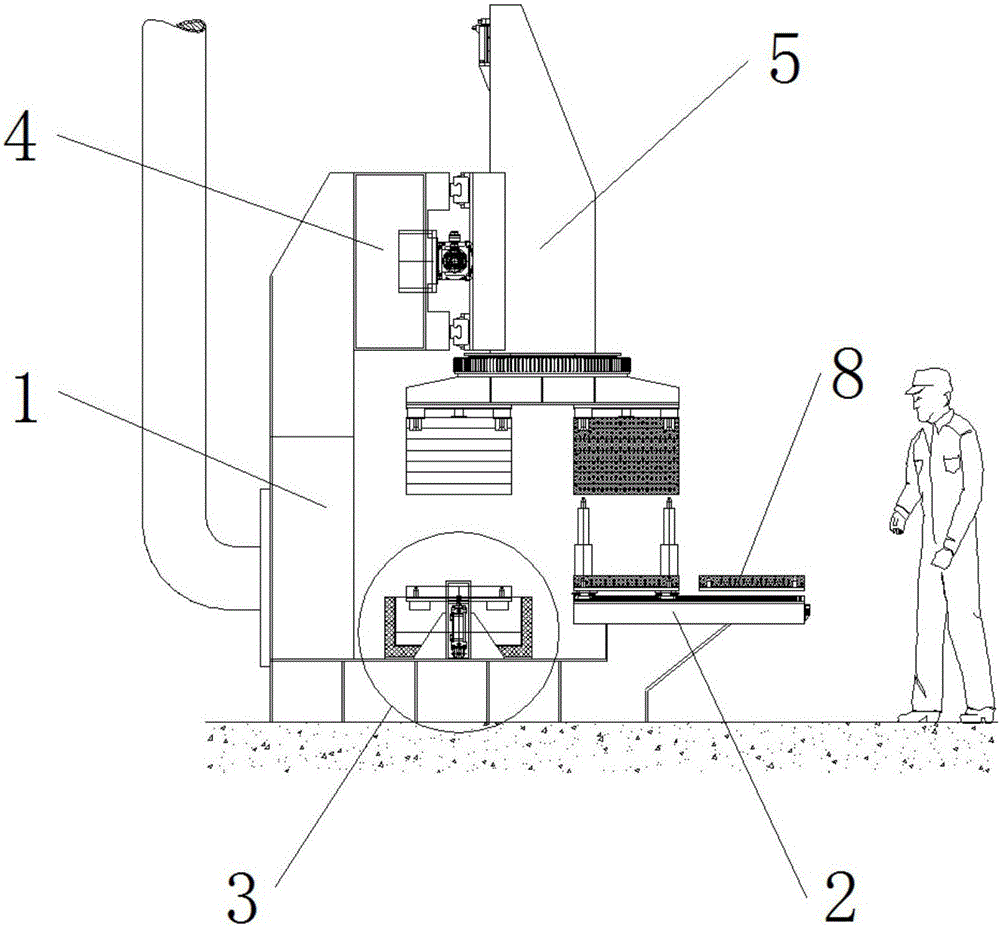

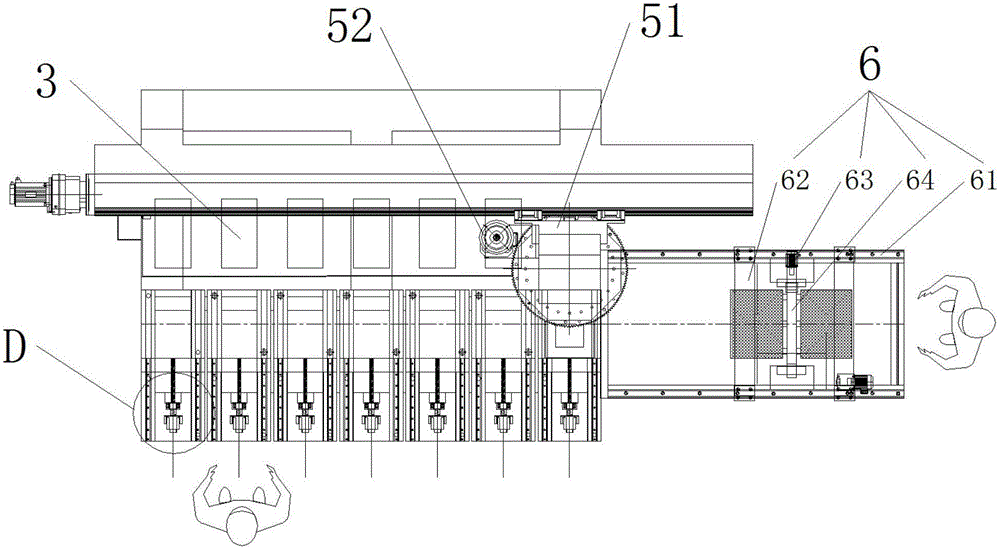

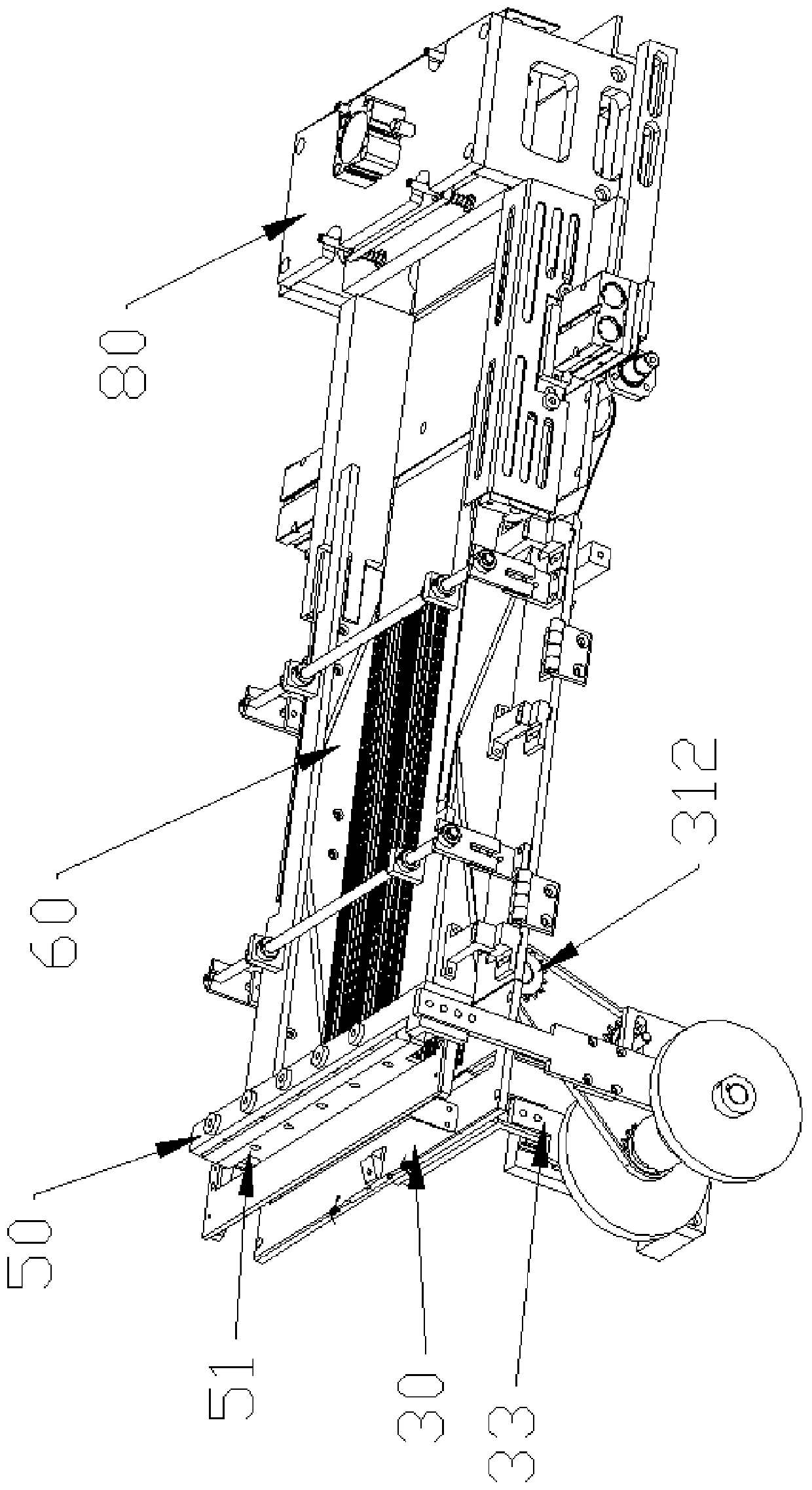

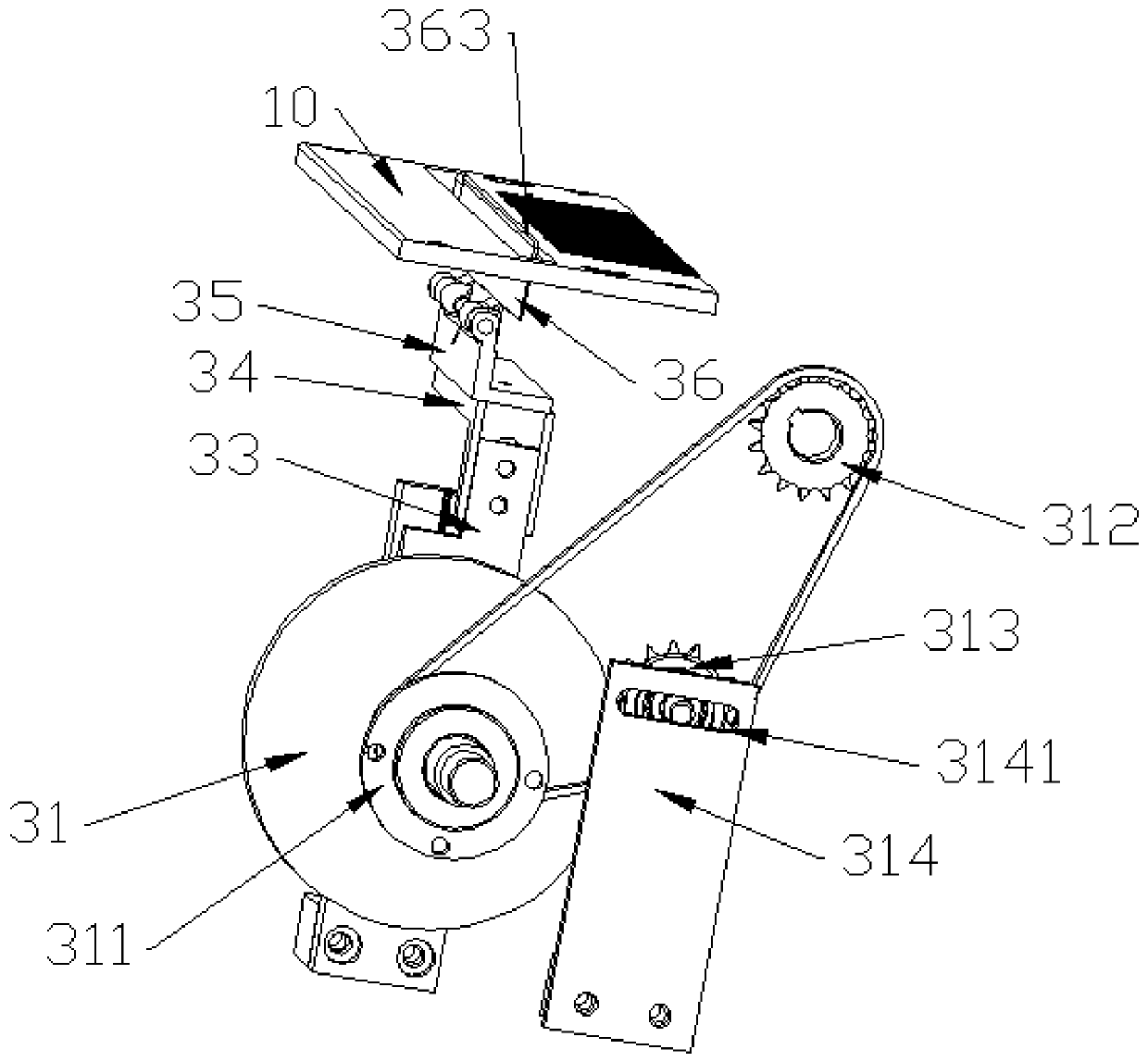

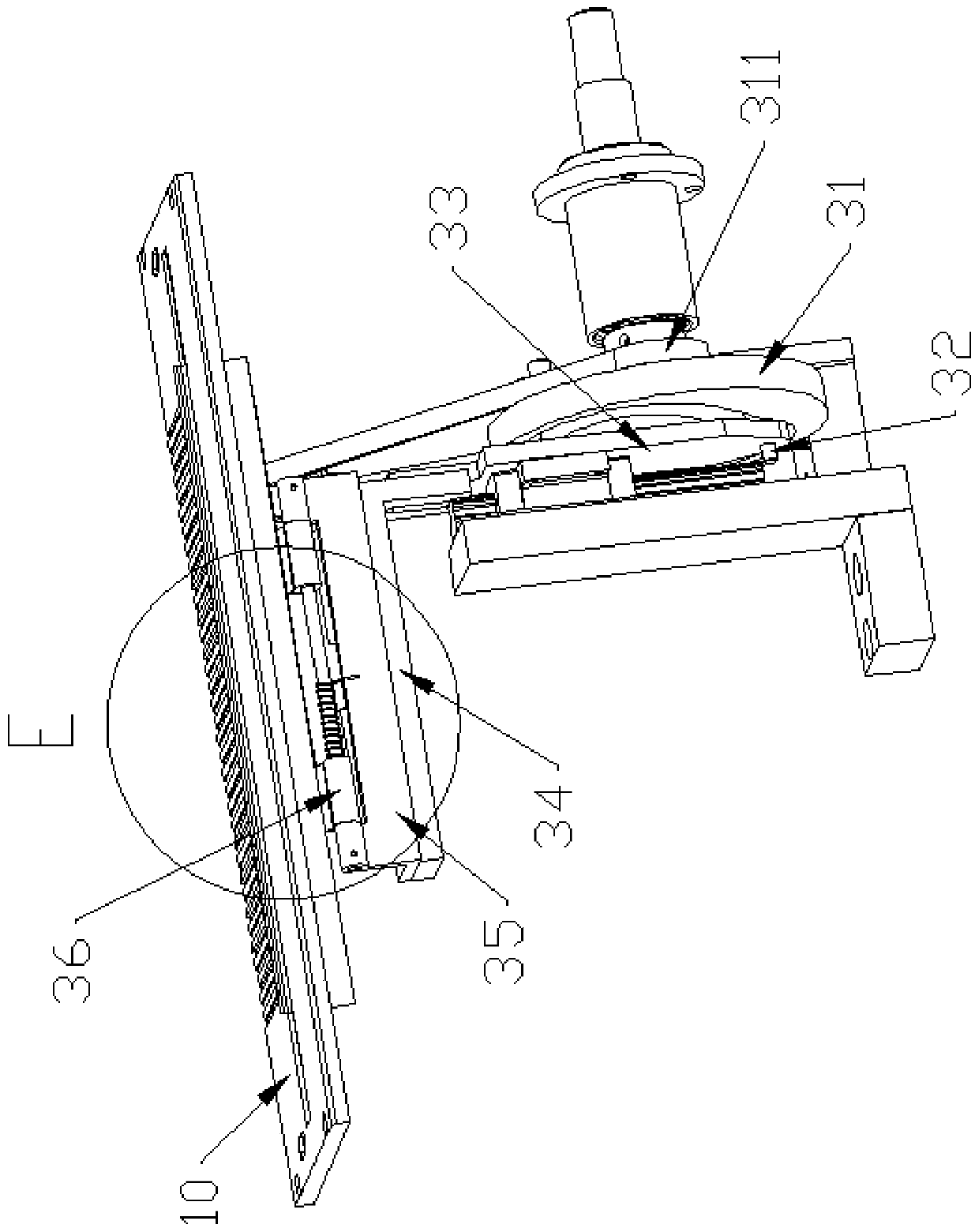

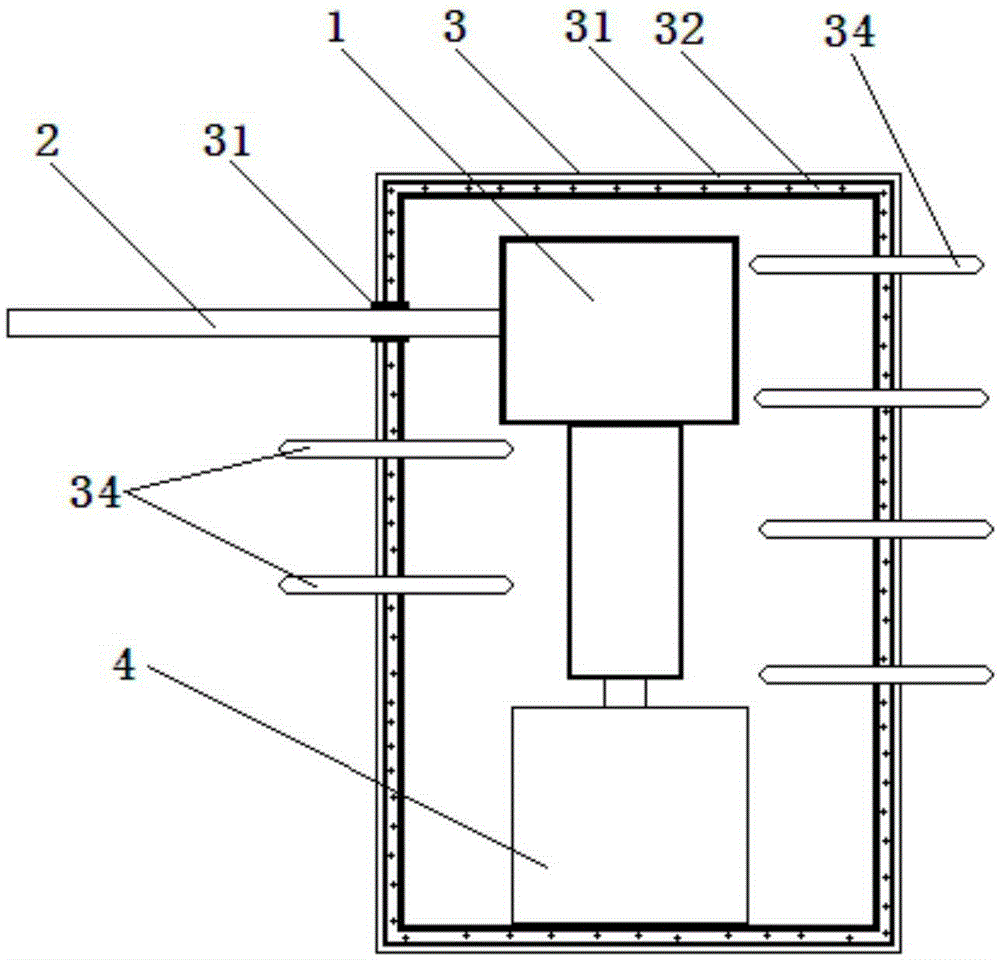

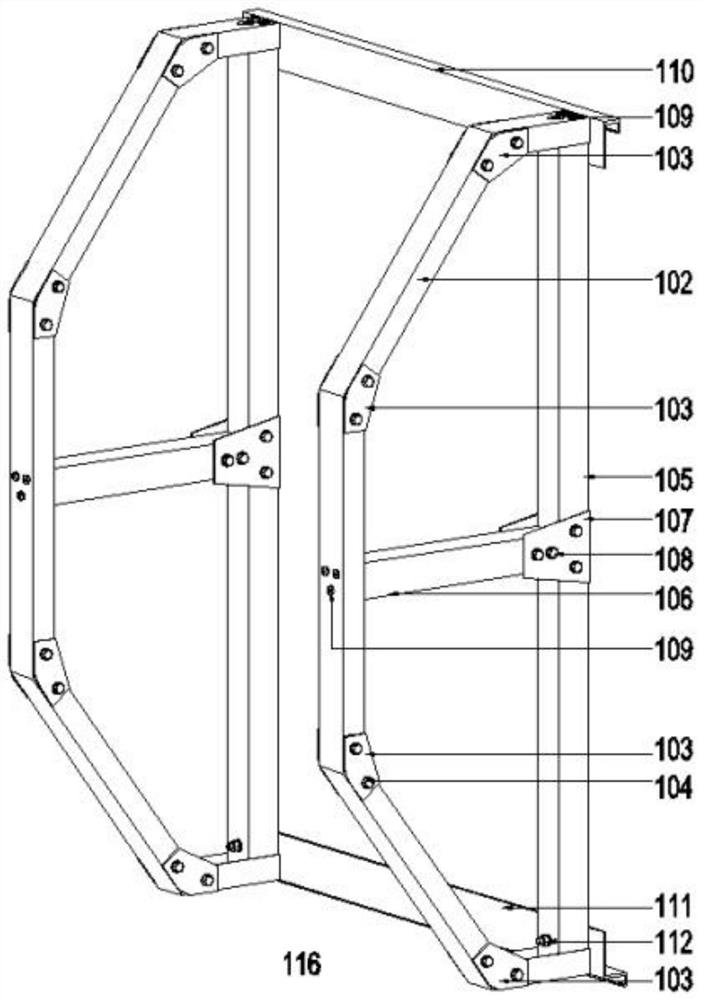

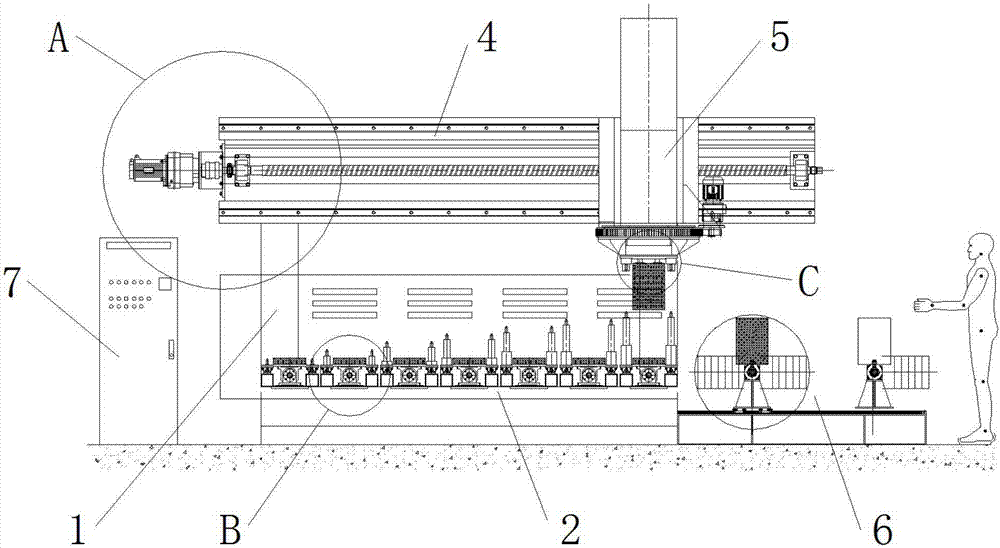

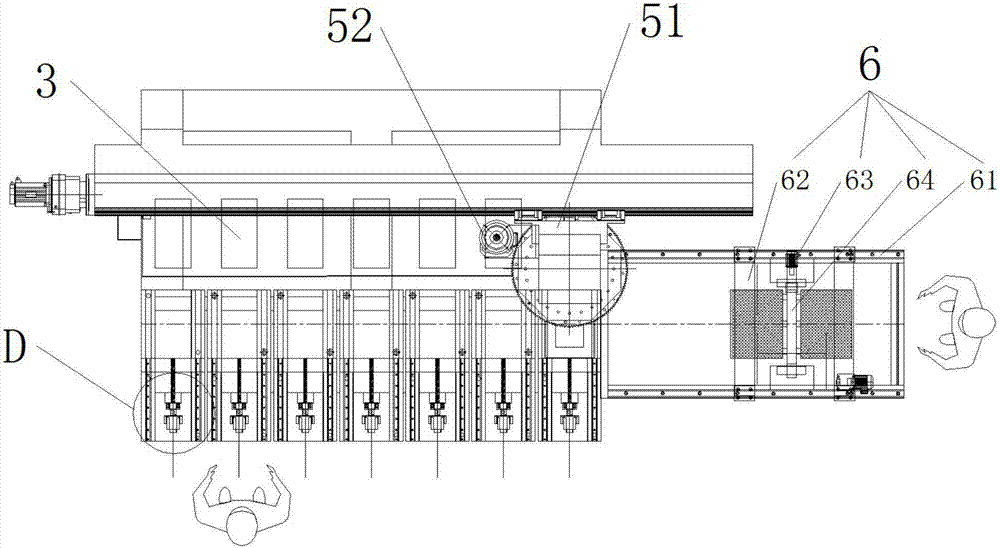

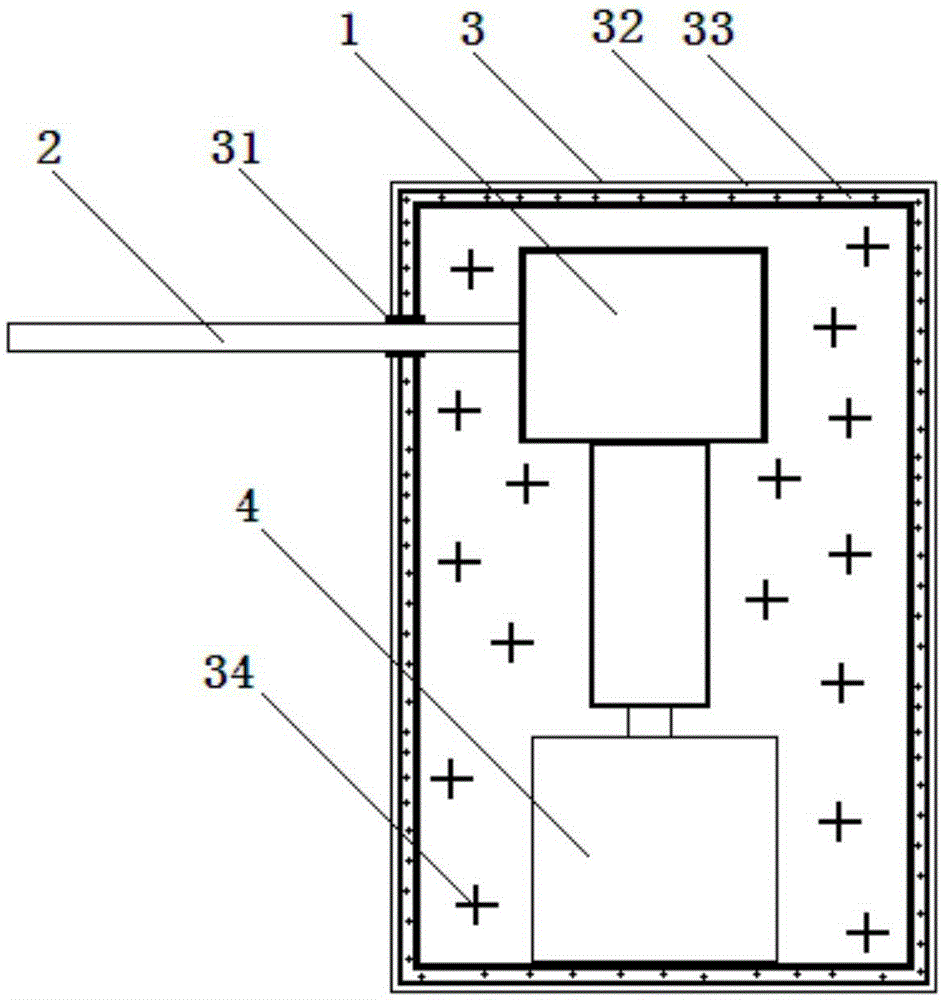

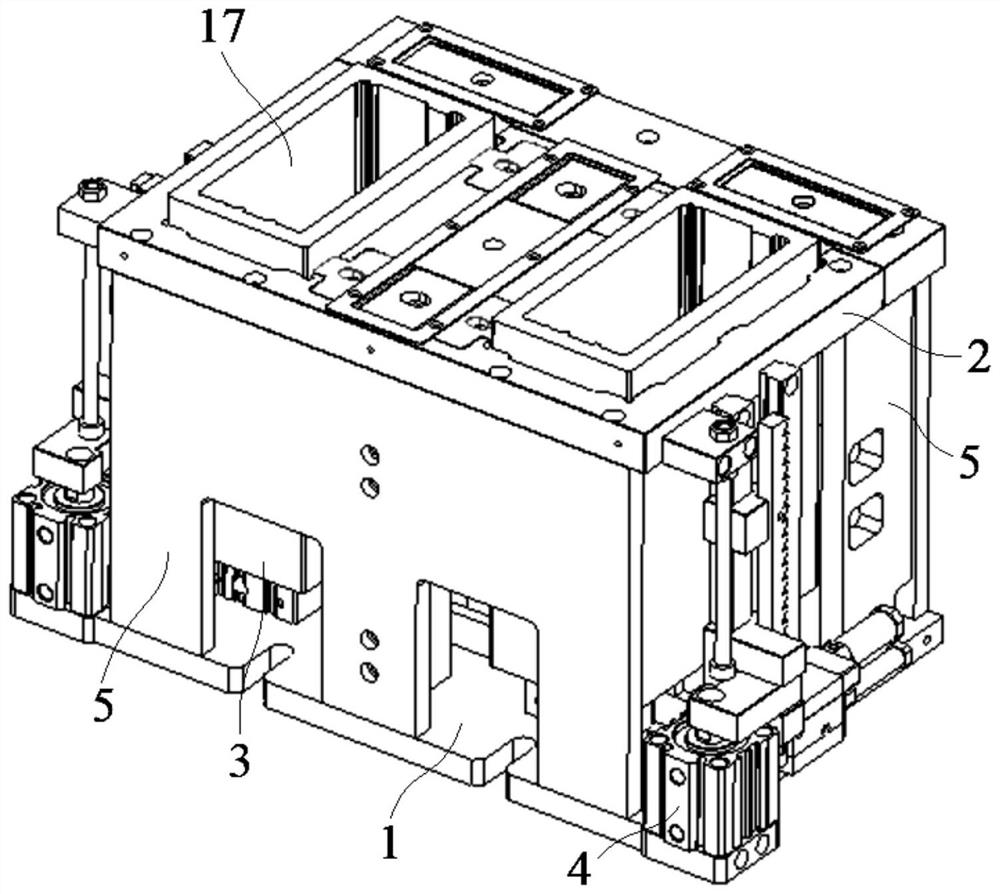

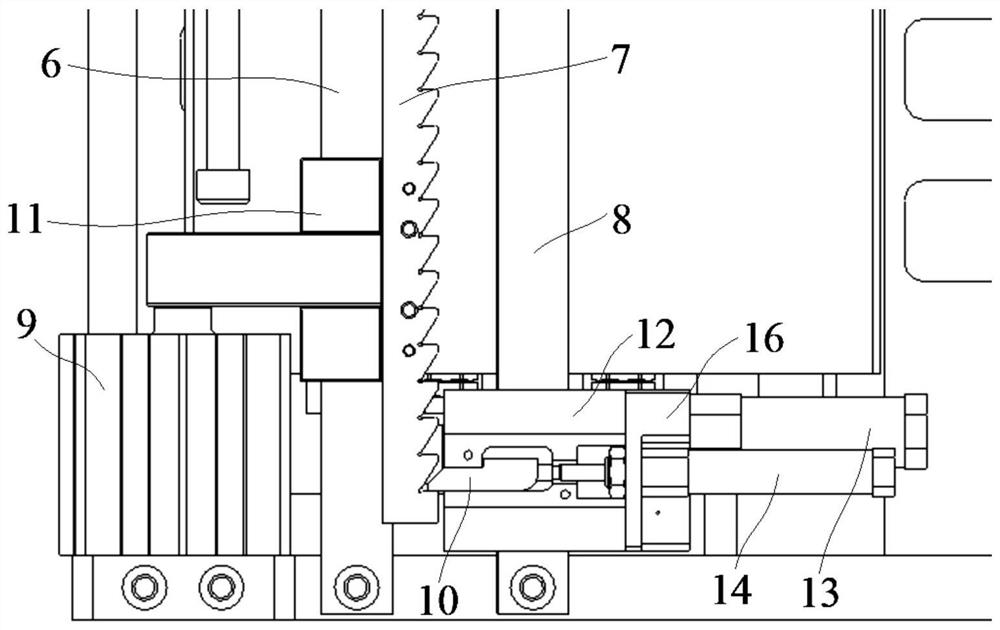

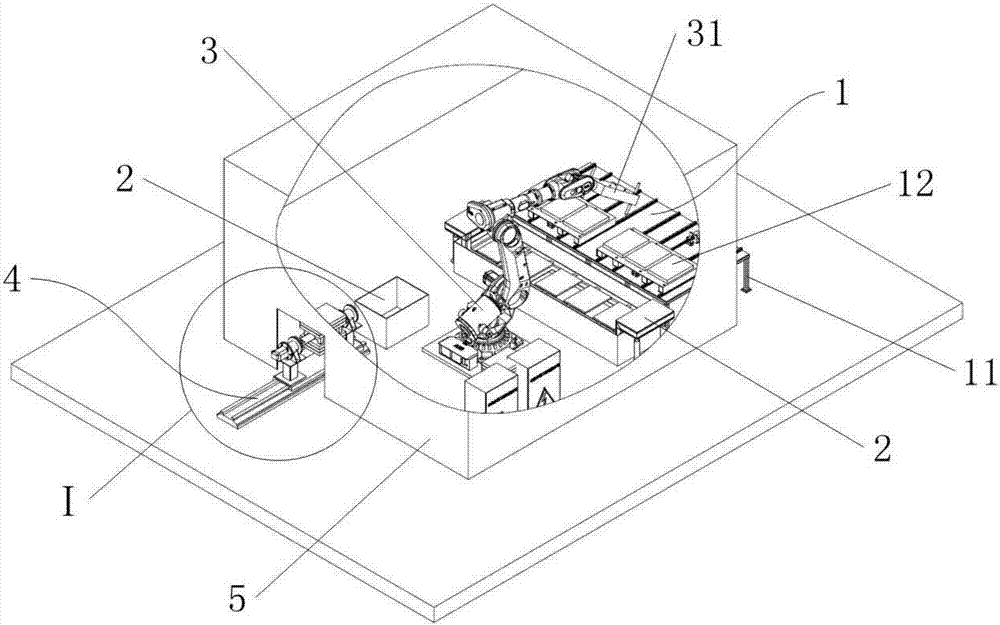

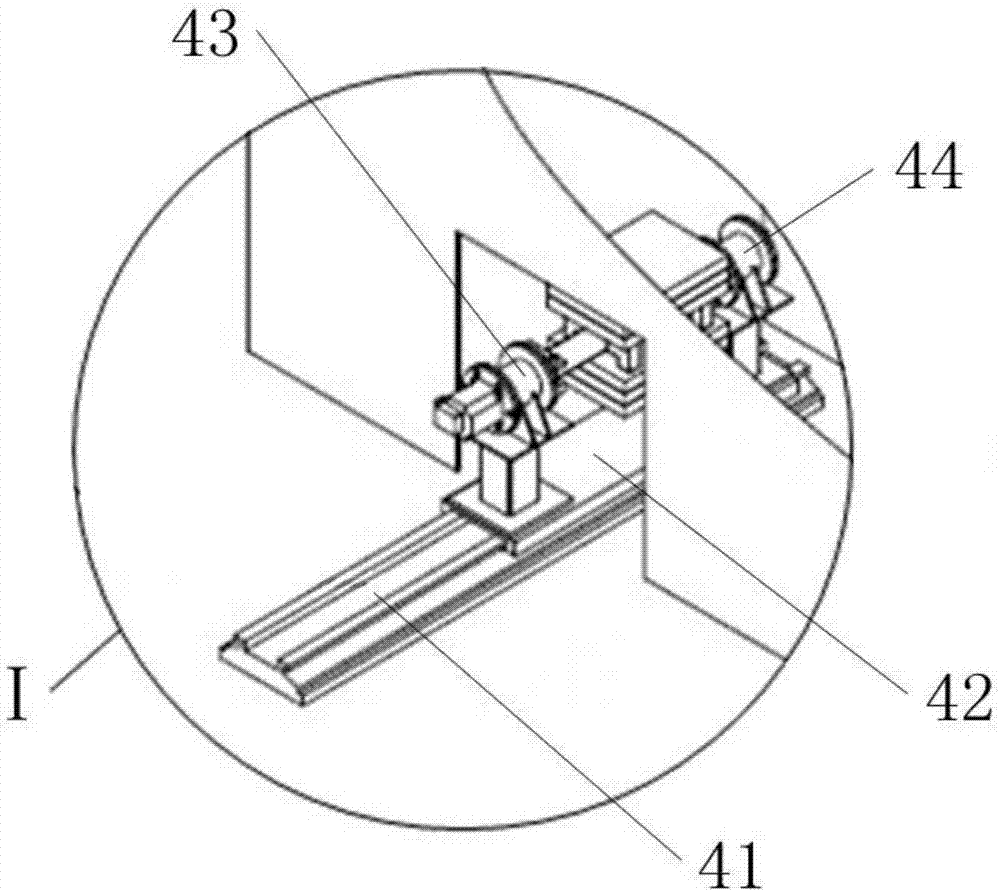

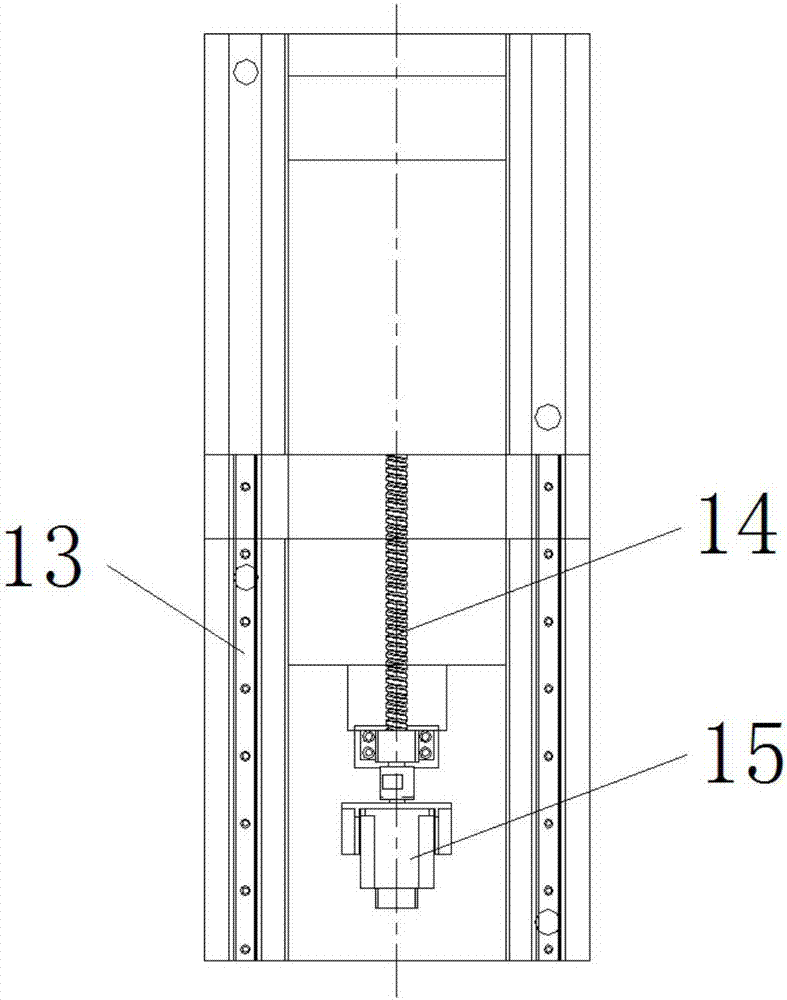

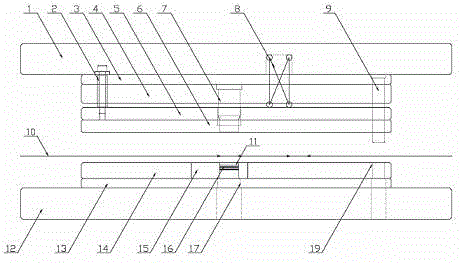

Multi-station digital pasting system for lost foam and pasting method of multi-station digital pasting system

ActiveCN105909639ASimplify equipment structureSimplify the installation processLiquid surface applicatorsMaterial gluingNumerical controlState of art

The invention discloses a multi-station digital pasting system for a lost foam and a pasting method of the multi-station digital pasting system. The multi-station digital pasting system mainly comprises a main rack, numerical control sliding table devices, a pasting system, a transverse movement driving system, a lifting rotating table, a main pouring gate pasting position changing device and an electric system connected with all the parts; by using the system, continuous pasting of a plurality of stations and automatic pouring gate pasting can be realized at one time, and corresponding moulds can be automatically switched according to the combination demand of templates to mount different templates; and compared with the prior art, the pasting system and method are high in automation degree and are used for reducing the cost while reducing the labor intensity of workers, and not only improving the pasting quality of the templates of the lost foam, but also remarkably increasing the pasting efficiency of the templates so as to have a considerable promotional value in the current trend of enterprise technological innovation transformation.

Owner:CMCU ENG

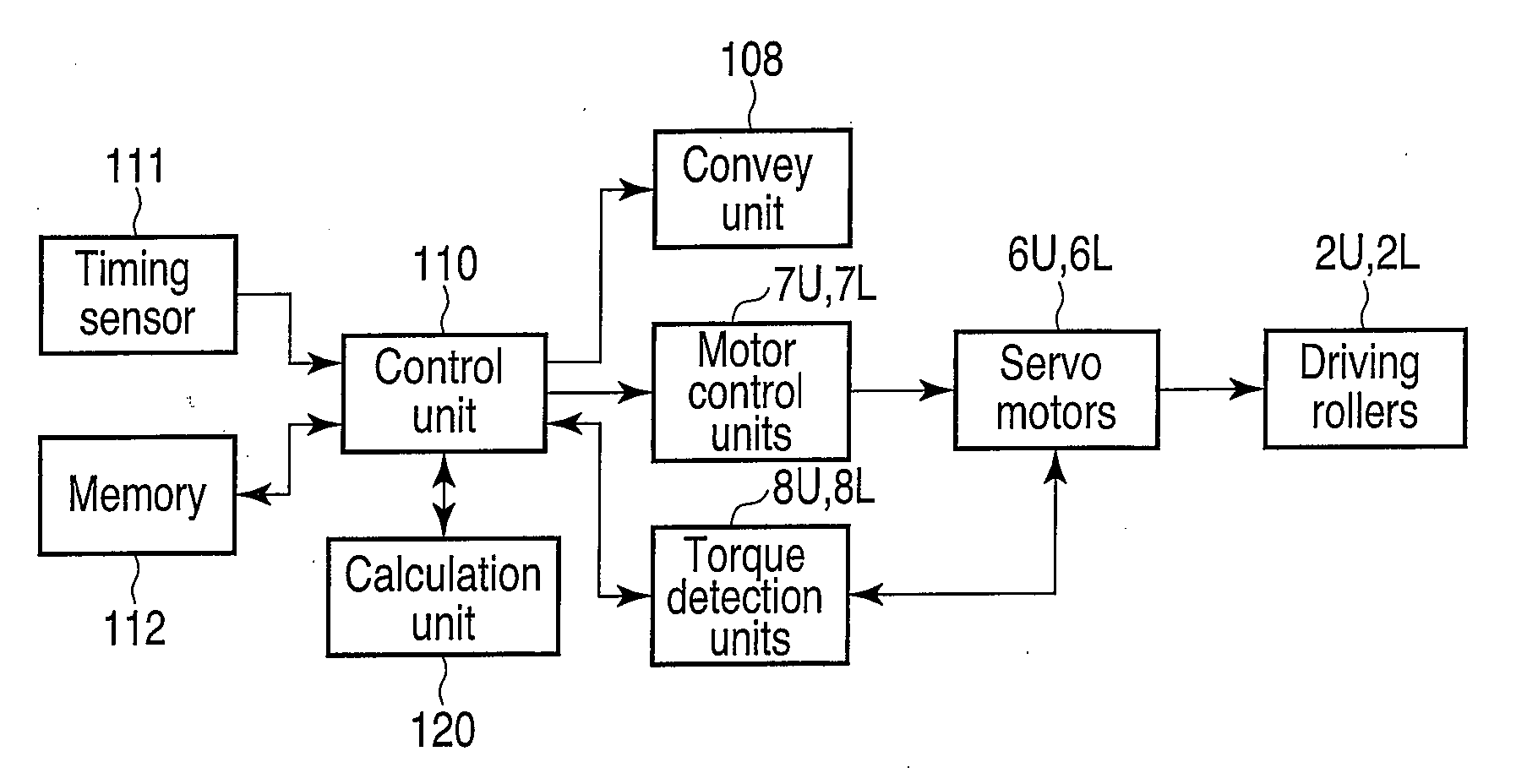

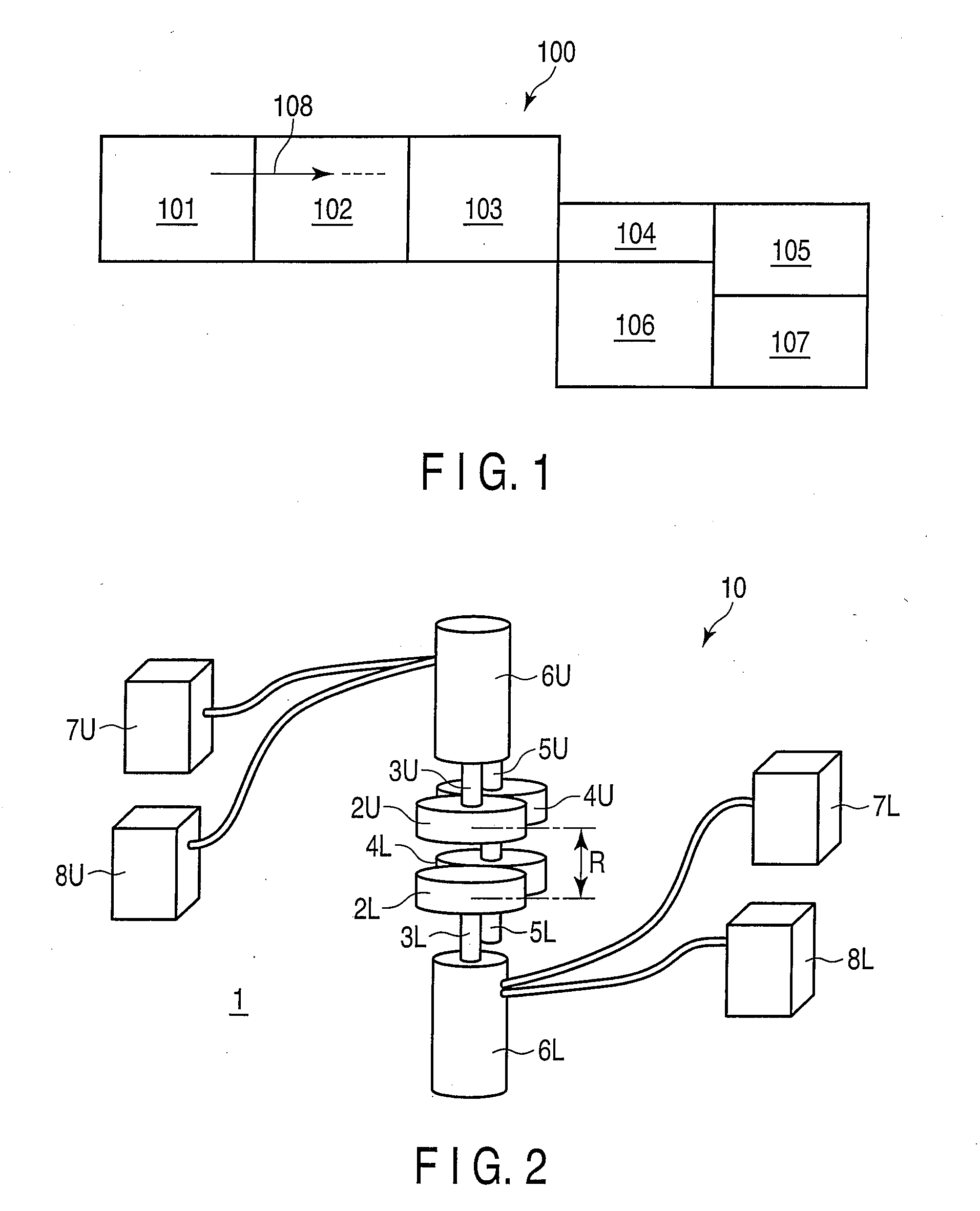

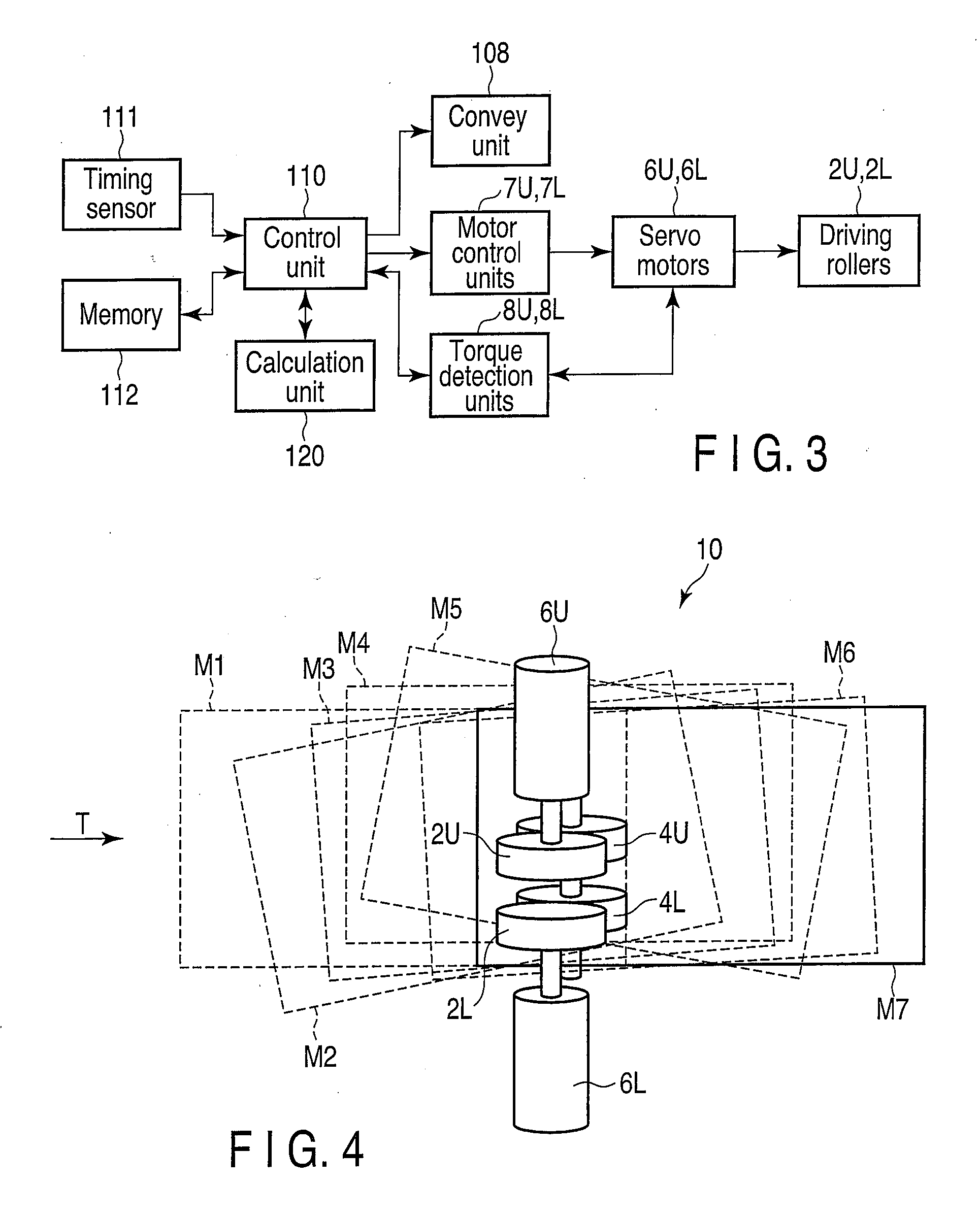

Sheet mass measuring unit

InactiveUS20110031683A1Improve precision qualityImprove throughputElectrographic process apparatusWeighing apparatus for materials with special property/formEngineeringMotor control

A mass measuring unit includes two driving rollers vertically separate from each other and intersecting the direction of conveyance of a mail matter. Servo motors for driving the driving rollers are connected to torque detection units. A control unit controls motor control units to cause them to impart a rate difference between the driving rollers to rotate the mail matter during its conveyance, and to cause the torque detection units to detect the torque values of the servo motors. The control unit compares the thus detected torque values with the torque values of the servo motors detected when the servo motors are idling without rotating the mail matter, thereby measuring the mass of the mail matter using a calculation unit.

Owner:KK TOSHIBA

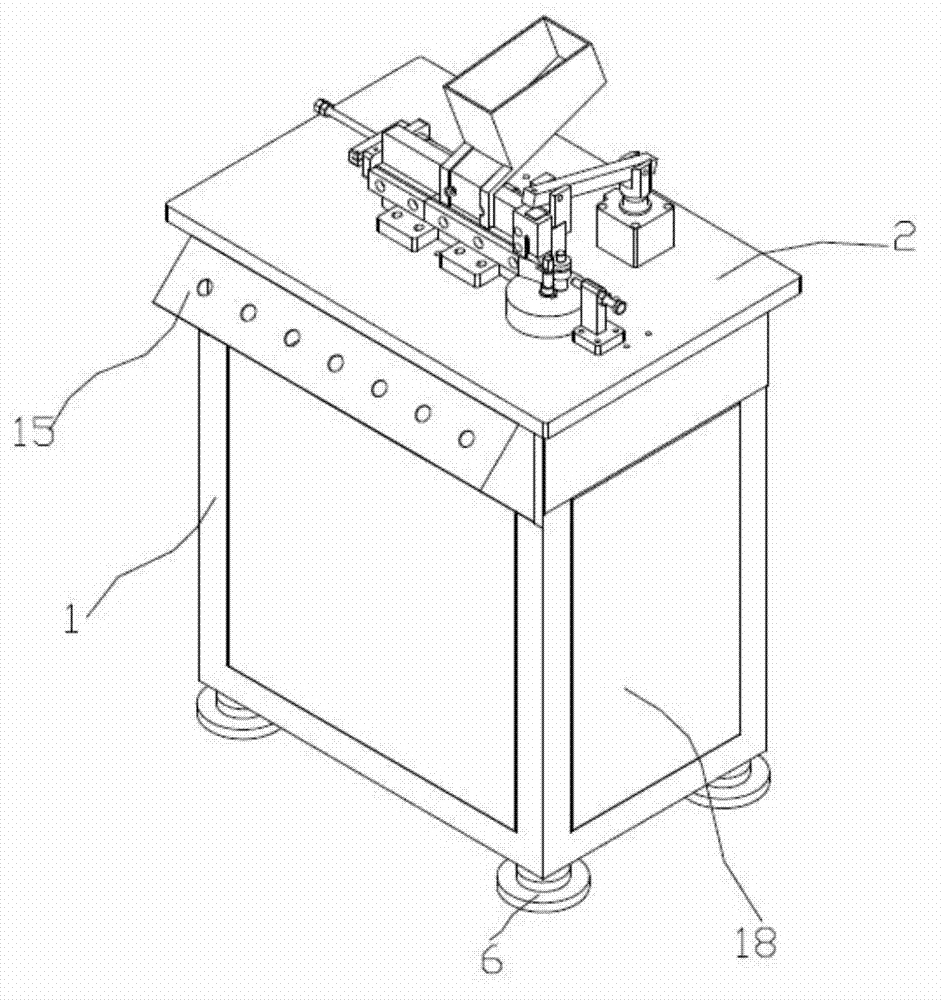

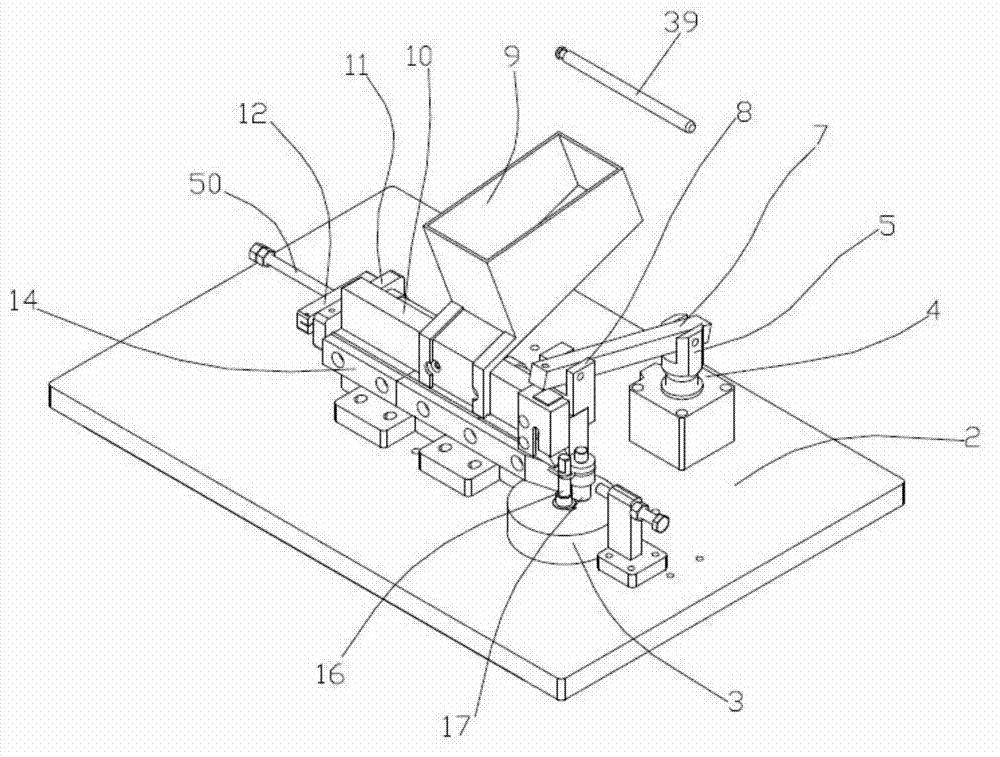

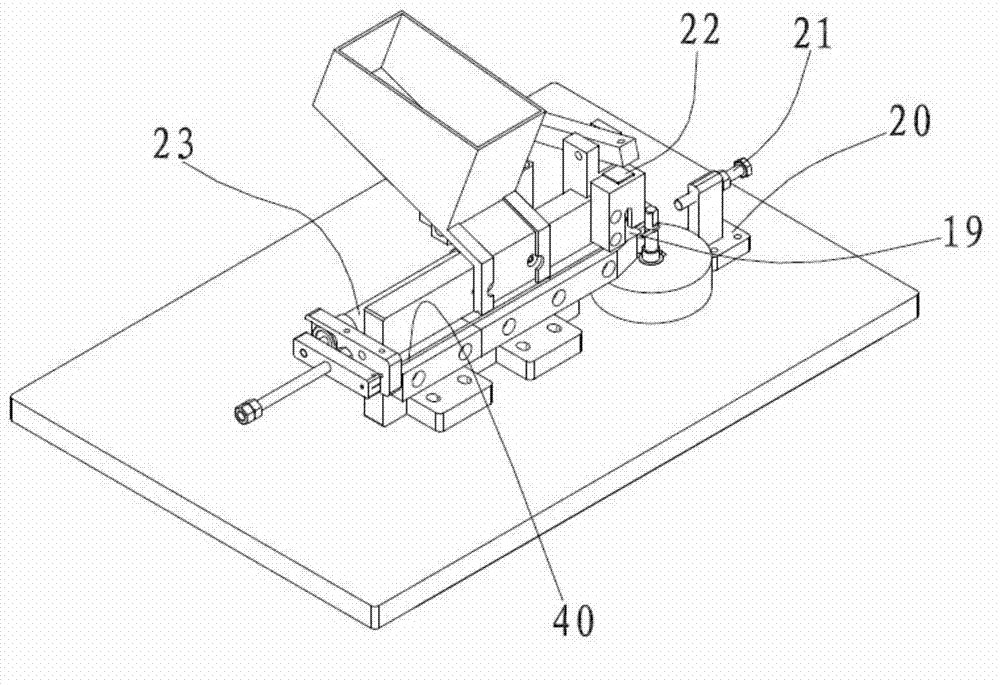

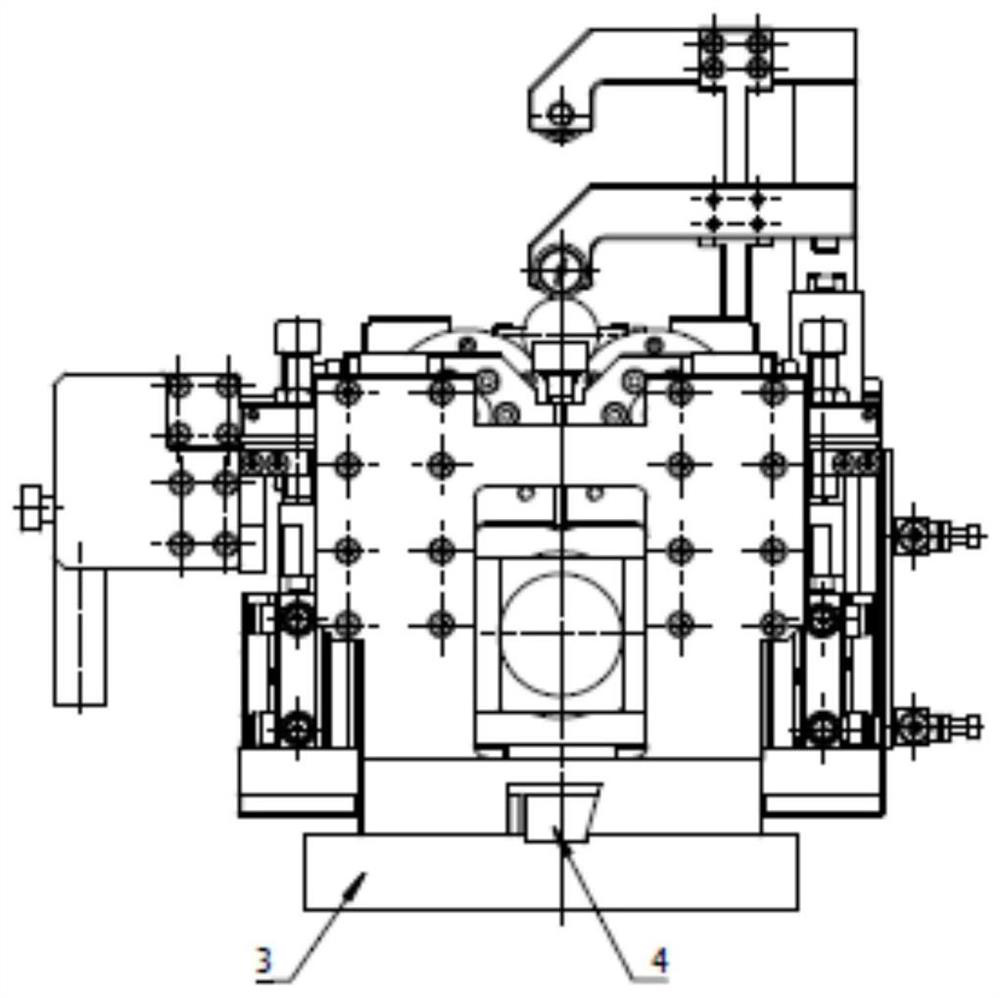

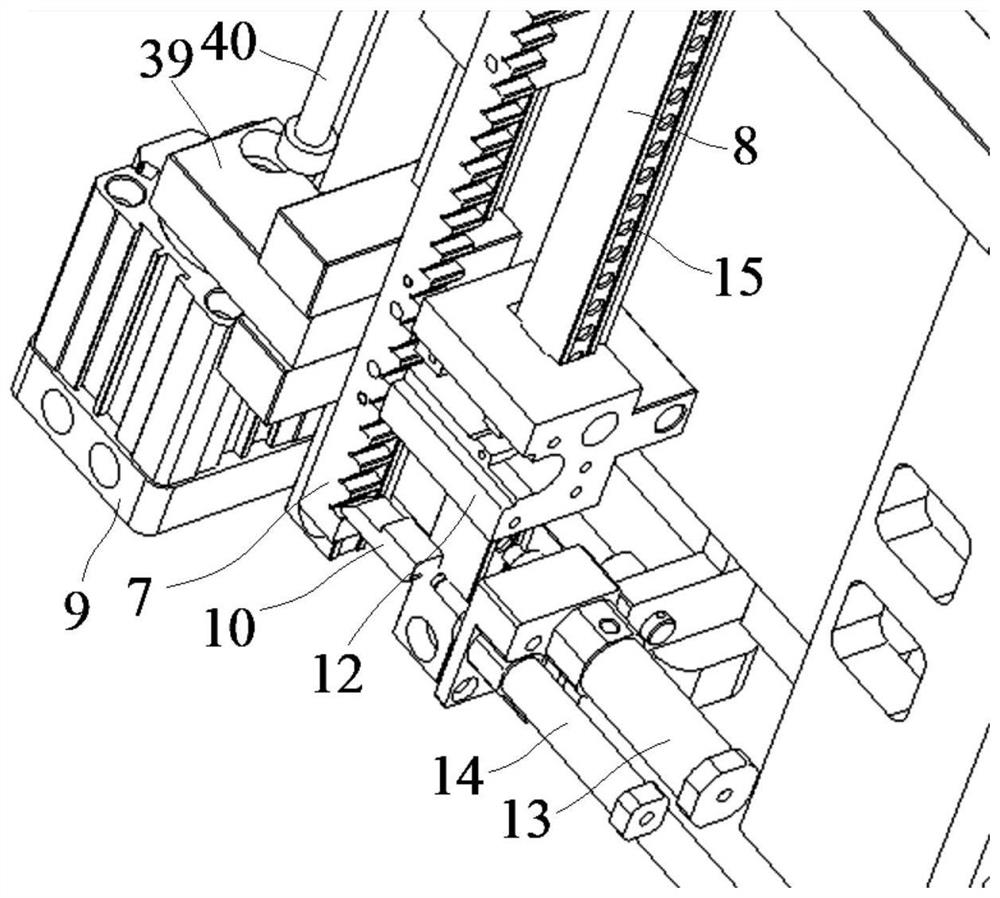

Machine tool of bending machine for bending lock beam

ActiveCN103028643AImprove precision qualityOvercome time-consuming, labor-intensive and low-efficiency shortcomingsMetal-working feeding devicesPositioning devicesEngineeringMachine tool

The invention discloses a machine tool of a bending machine for bending a lock beam, and the machine tool comprises a machine tool body (1), a frame bench (2), a feeding mechanism, a clamping mechanism and a bending mechanism; the frame bench (2) is fixedly arranged on the top of the machine tool body (1); the feeding mechanism, the clamping mechanism and the bending mechanism are fixedly arranged with the frame bench (2); according to the machine tool of the bending machine for bending the lock beam, a traditional manual lock beam processing method is mechanized, so that the defects of manual processing that time and labor are consumed and the efficiency is low are overcome; and the invention provides a good-quality and feasible technical scheme for the batch and high-quality processing of lock beams.

Owner:ZHEJIANG PUJIANG HUATONG MECHANICAL TECH CO LTD

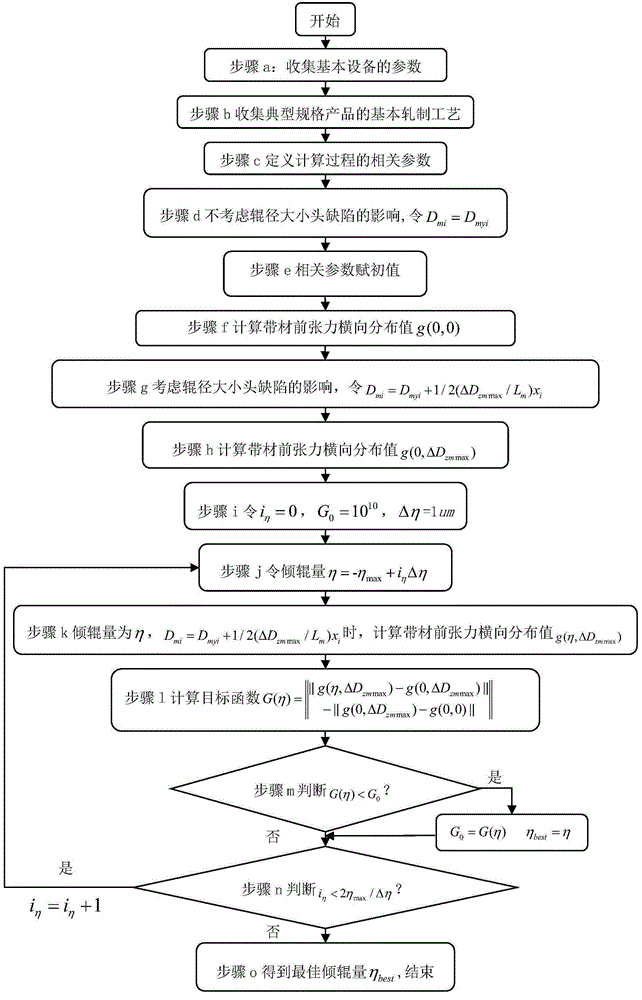

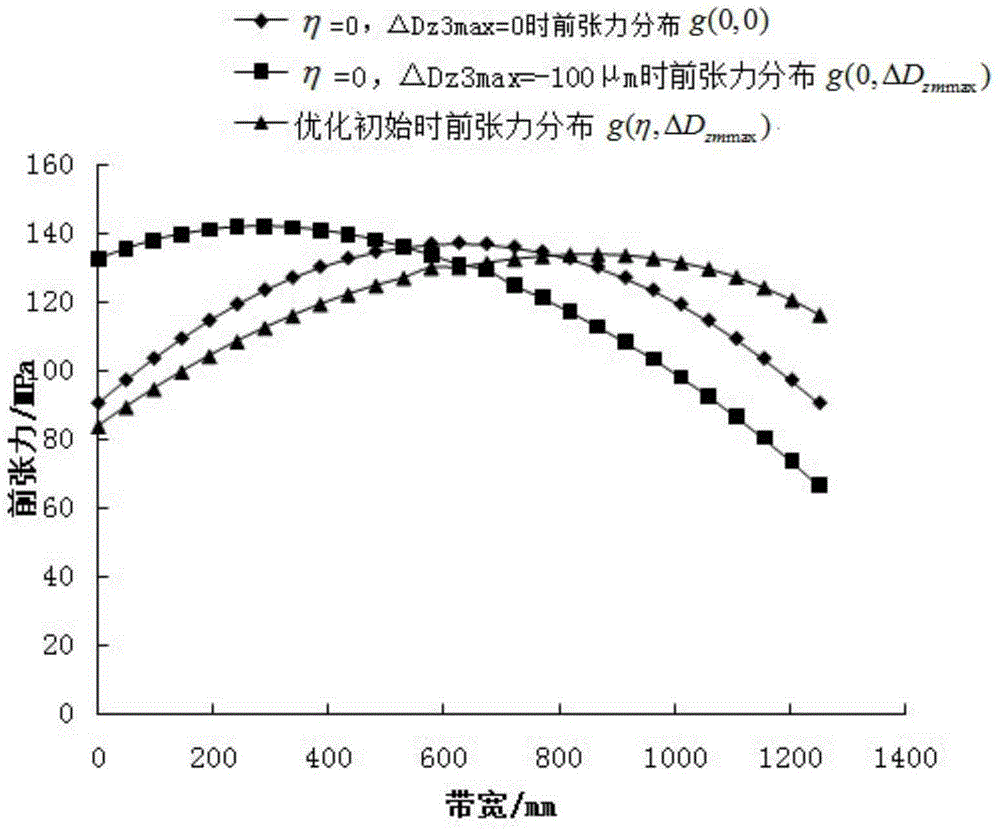

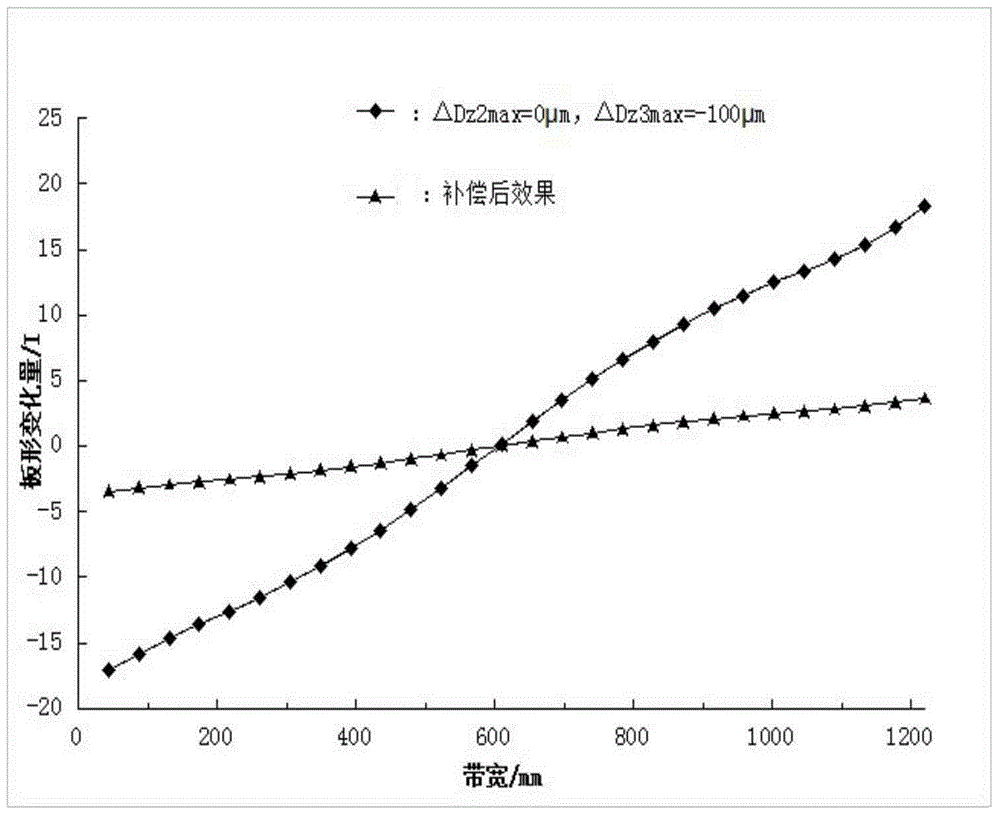

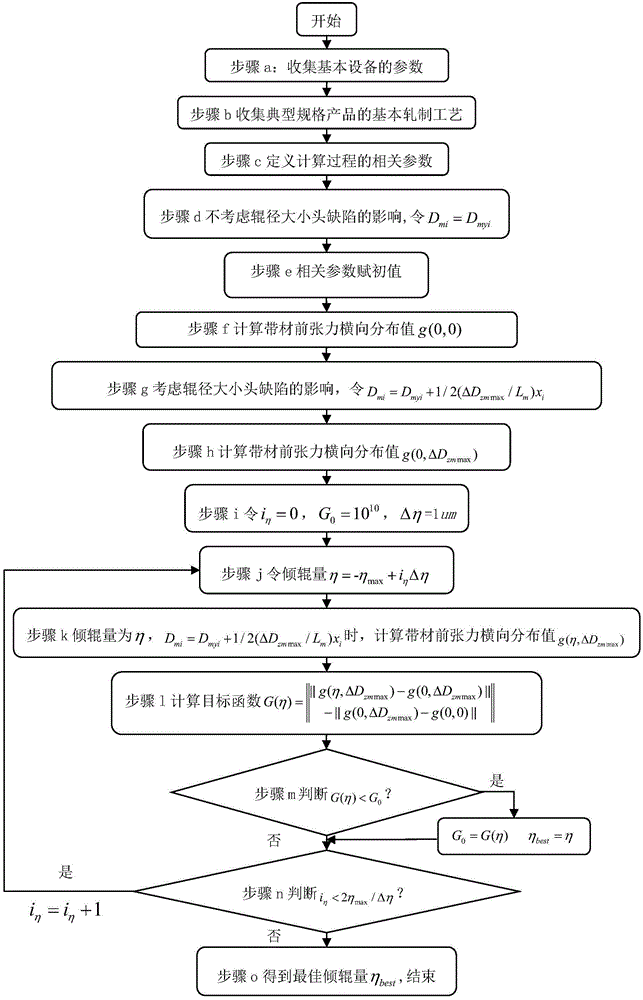

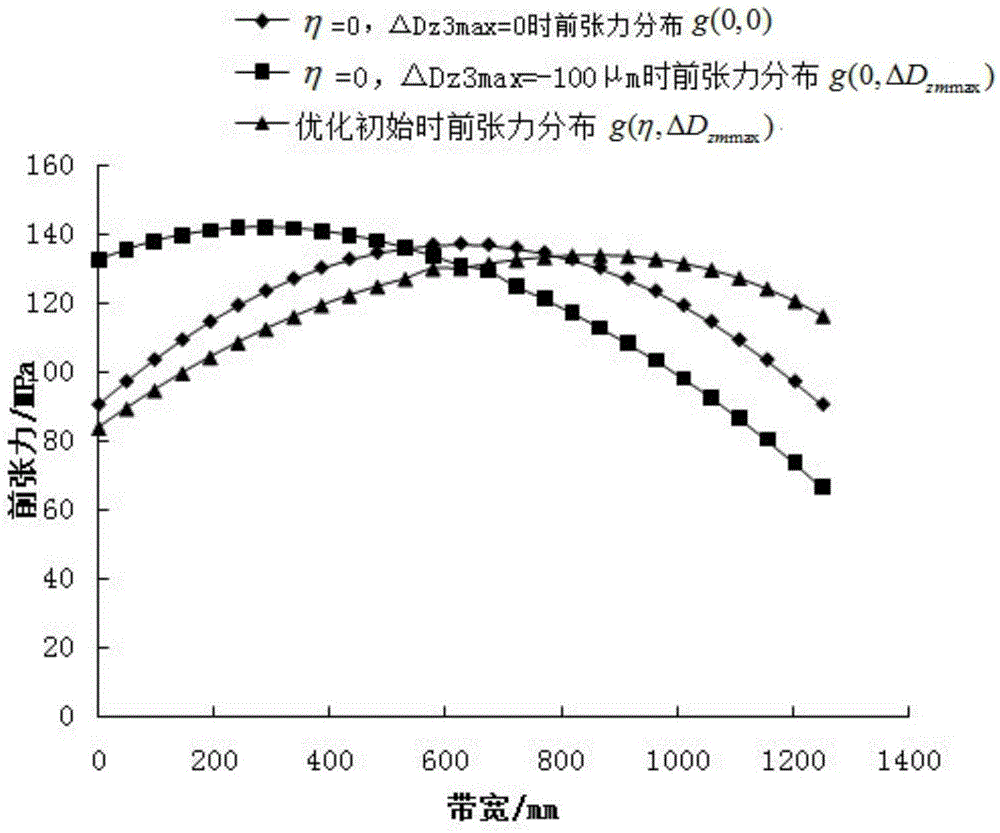

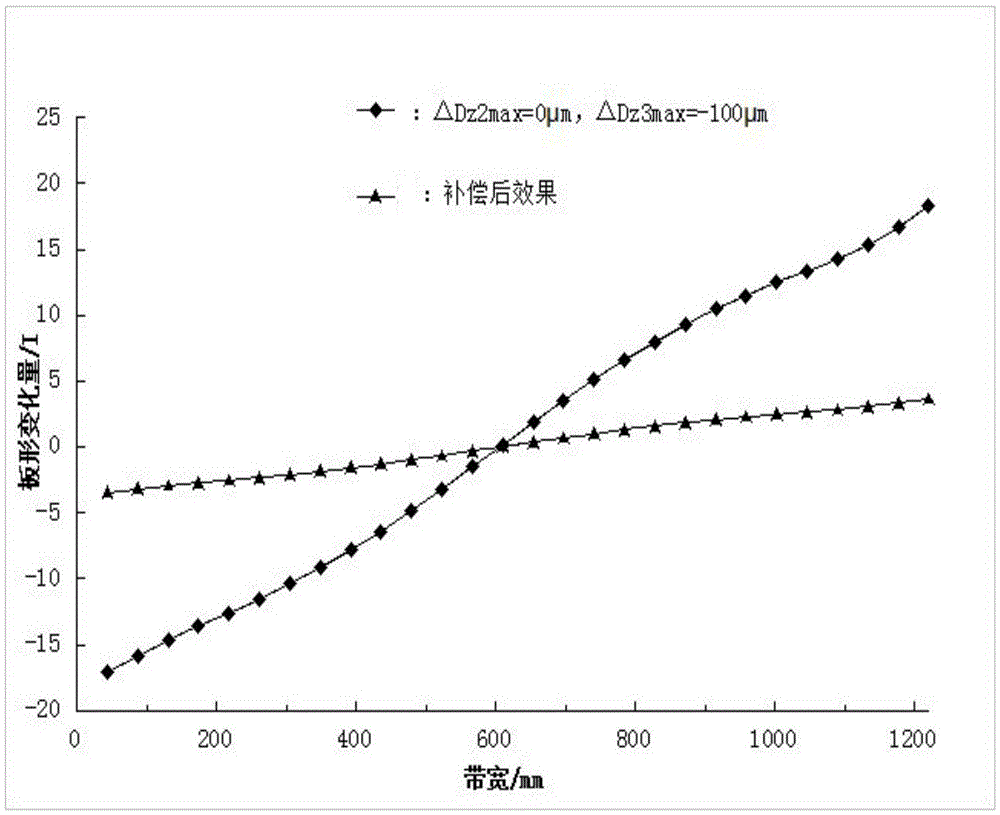

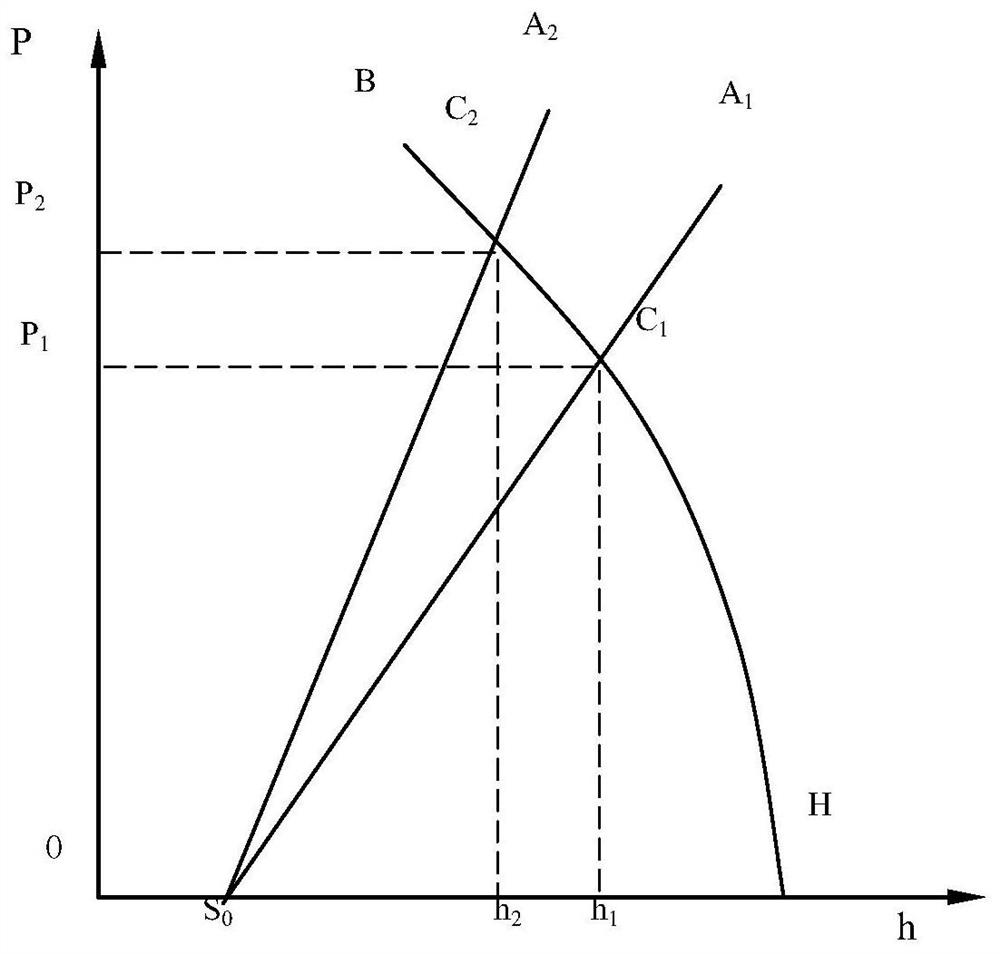

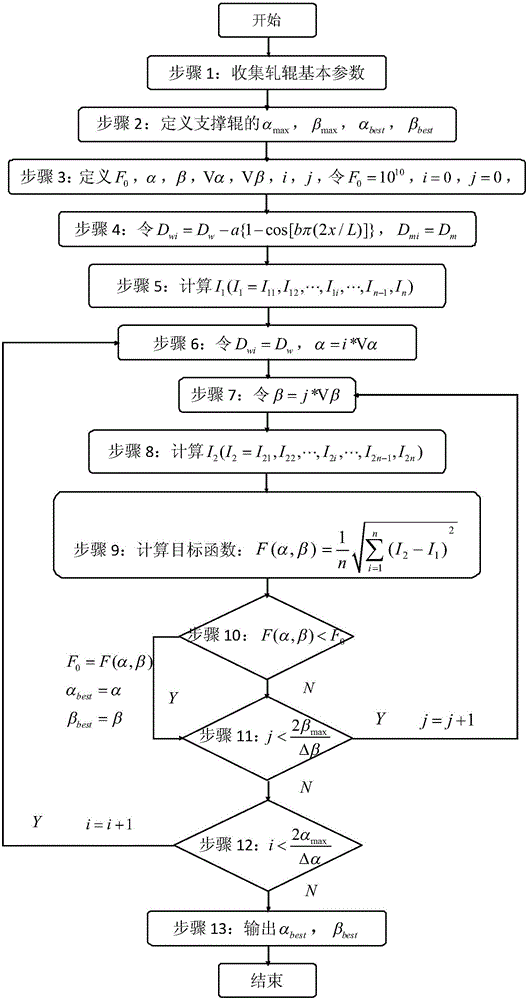

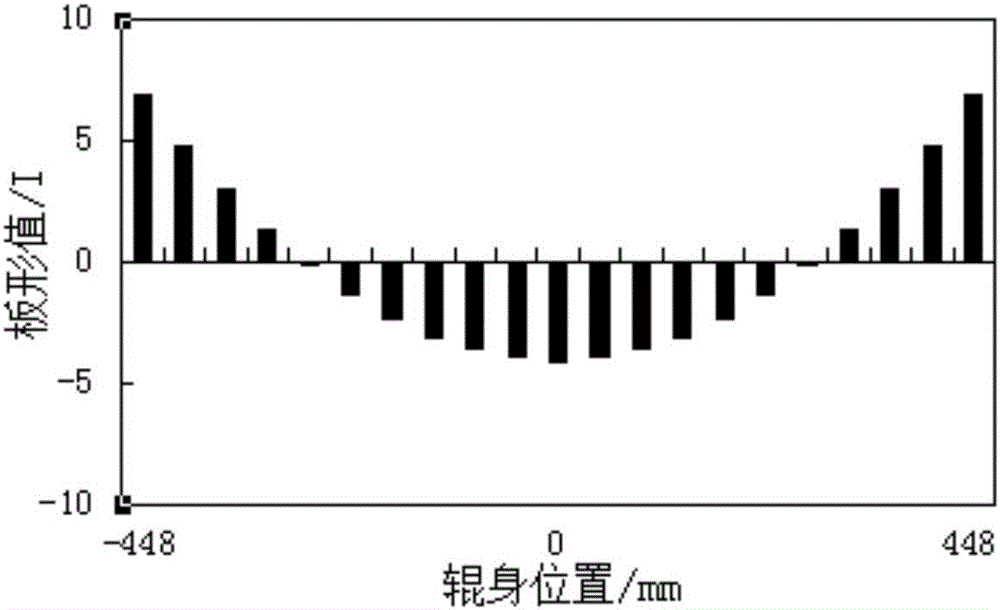

Roller taper defect treatment method for four-high rolling mill

InactiveCN104525579AAchieving Quantitative CompensationReduce or even eliminate the impactMetal rolling stand detailsProfile control deviceBending forceObject function

A roller taper defect treatment method for a four-high rolling mill mainly includes the following steps executed by a computer of 1 collecting basic device parameters; 2 collecting basic rolling process parameters of products of typical specifications; 3 defining an optimal roller inclining calculation process variable, a roller inclining amount, a roller inclining optimal step size, an objective function, an initial value of the objective function, a working roller channeling amount, a working roller bending force and an optimal roller inclining amount; 4 calculating the working roller channeling amount, the working roller bending force, the roller inclining amount and lateral distribution values of front tension of strips at an outlet of the rolling mill; 5 calculating the objective function; 6 completing the calculation after obtaining the roller inclining amount. The roller taper defect treatment method for the four-high rolling mill can achieve quantitative compensation for roller taper defects, minimizes or even eliminates the impact of the roller taper defects on the shape of the strips, solves the problem that the treatment of strip shape defects caused by roller taper is almost entirely dependent on experience of field operators and improves the accuracy quality of rolled strips.

Owner:山东冠洲股份有限公司

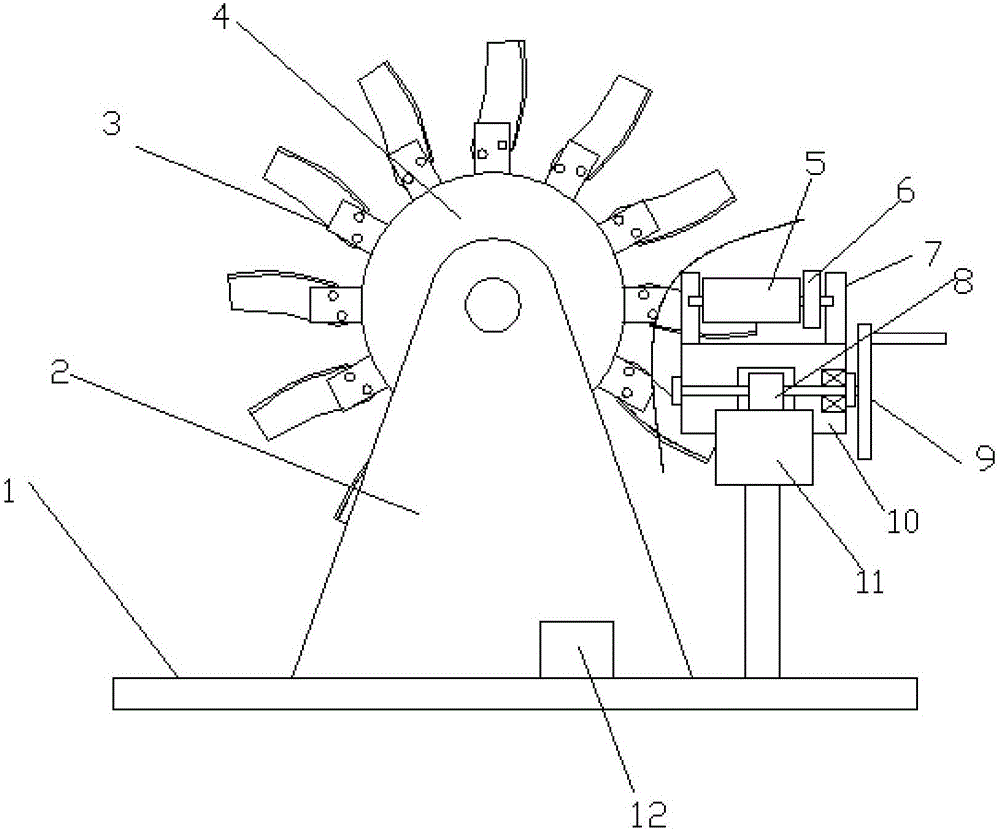

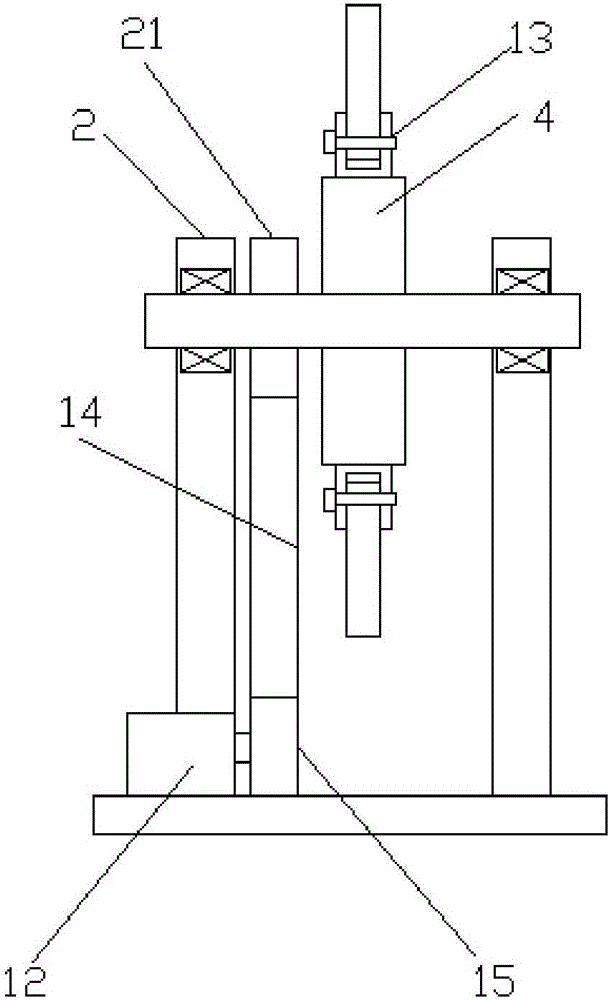

Coulter grinding correction device

InactiveCN106736893AReduce labor intensityImprove work efficiencyGrinding carriagesGrinding drivesDrive wheelEngineering

The invention relates to the technical field of correction devices, in particular to a coulter grinding correction device. The coulter grinding correction device comprises a fixing mechanism and a grinding machine; the fixing mechanism comprises a base plate, a chuck support is fixed to the base plate, a chuck is rotatably installed on the chuck support, a driven wheel is coaxially and fixedly connected to the chuck, a rotating motor is fixed to the base plate and connected with the driven wheel through a rotating mechanism, and holding frames are circumferentially and evenly distributed on the edge of the chuck. According to the coulter grinding correction device, by adopting automated grinding correction, grinding correction can be conducted on multiple coulters simultaneously, the working efficiency is greatly improved, and the labor intensity of workers is reduced; in addition, due to the fact that mechanical positioning is adopted, the product precision and quality are improved.

Owner:SHIZUSN JINHUI TECH & TRADE

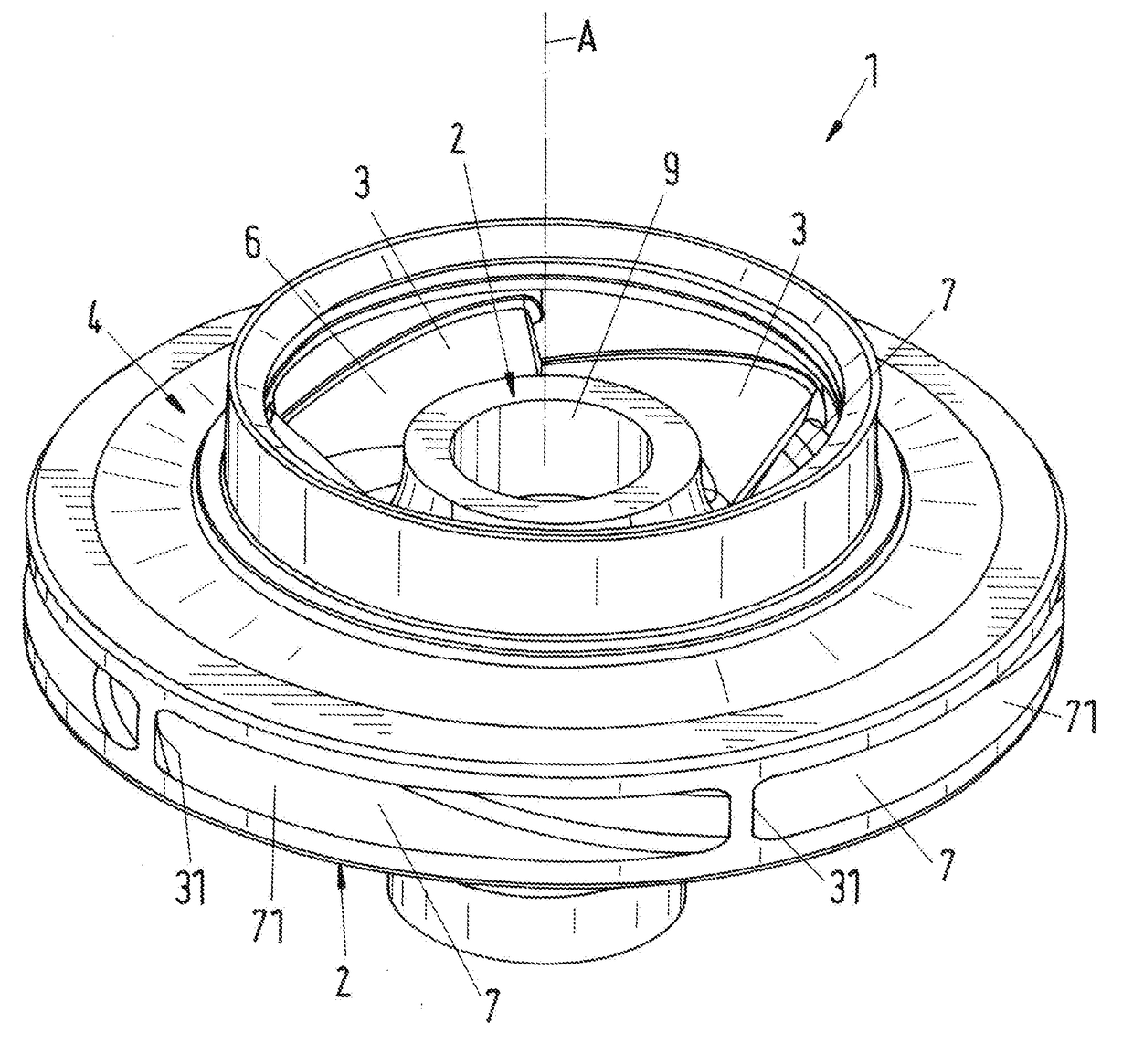

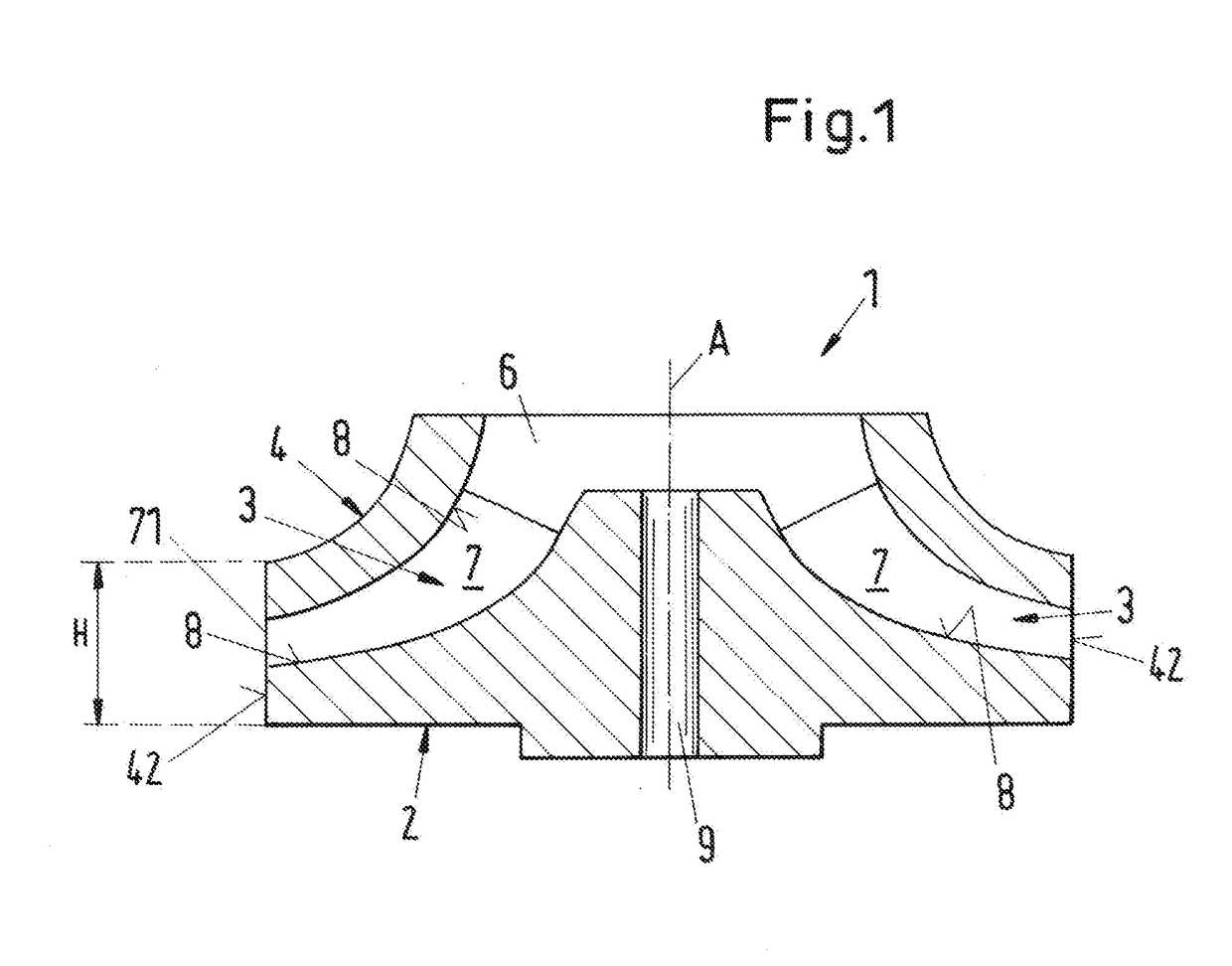

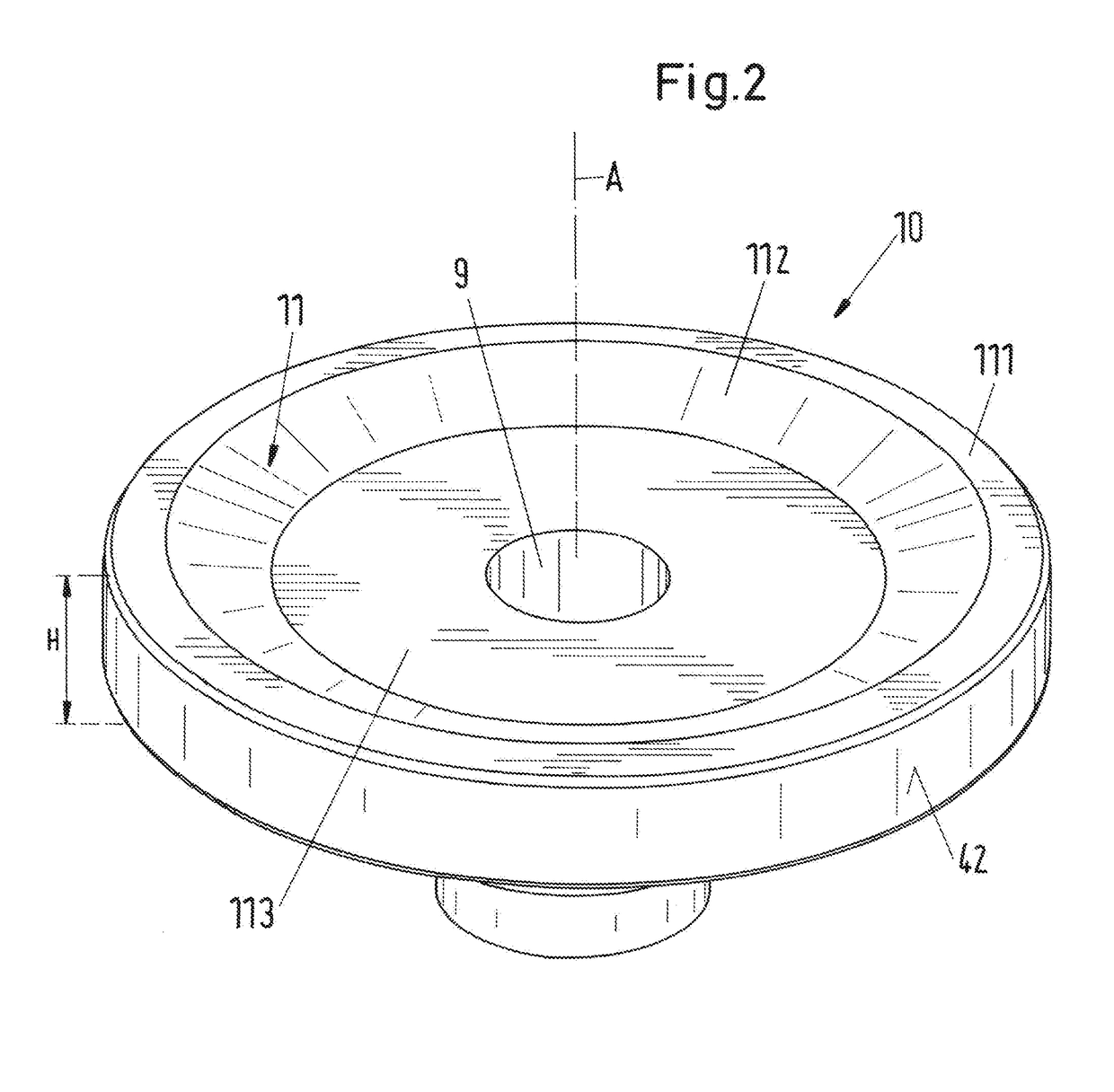

Method of manufacturing a component of a rotary machine and component manufactured using said method

ActiveUS20170341178A1Improve precision qualityImprove surface qualityTurbinesPump componentsMachiningRotary machine

A method of manufacturing a component of a rotary machine, the component has at least one inner passage that extends from a center up to a boundary surface of the component and is at least partly closed, and a blank is provided that includes the boundary surface and a top surface. The Method includes a first subtractive machining step that is carried out in which a part of the passage that at least includes an opening of the passage into the boundary surface as well as a cut-out in the top surface are manufactured by machining production, and subsequently the passage is completed by build-up production on the blank.

Owner:SULZER MANAGEMENT AG

Film laminating and heat sealing integrated production line

ActiveCN109941485ASave on transshipmentSave positioningConveyor wrappingWrapper twisting/gatheringProduction lineAssembly line

The invention provides a film laminating and heat sealing integrated production line, belongs to the field of packaging equipment. The film laminating and heat sealing integrated production line comprises a lower shovel flattening assembly, a corner folding assembly and an end surface flattening assembly which are sequentially arranged along the assembly line, wherein a heat sealing assembly is arranged over the lower shovel flattening assembly, and the heat sealing assembly and the lower shovel flattening assembly share a power source and move up and down relative to the corner folding assembly. A packaging box is coated with a film and then passes through the lower shoveling flattening assembly and the heat sealing assembly for connection after film laminating, the packaging box enters the corner folding assembly for the end face corner folding action and the end face sealing action after corner folding while the packaging box is continuously pushed, then the packaging box enters theend face flattening assembly for flattening and hot covering of the upper and lower sections, and finally the package box is discharged for the next procedure. The film laminating and heat sealing integrated production line integrates film laminating and heat sealing, the intermediate transfer link of the packaging box is omitted, the secondary feeding and repeated positioning are also avoided, therefore, the working efficiency is improved, and the manpower is saved.

Owner:天津树达科技发展有限公司

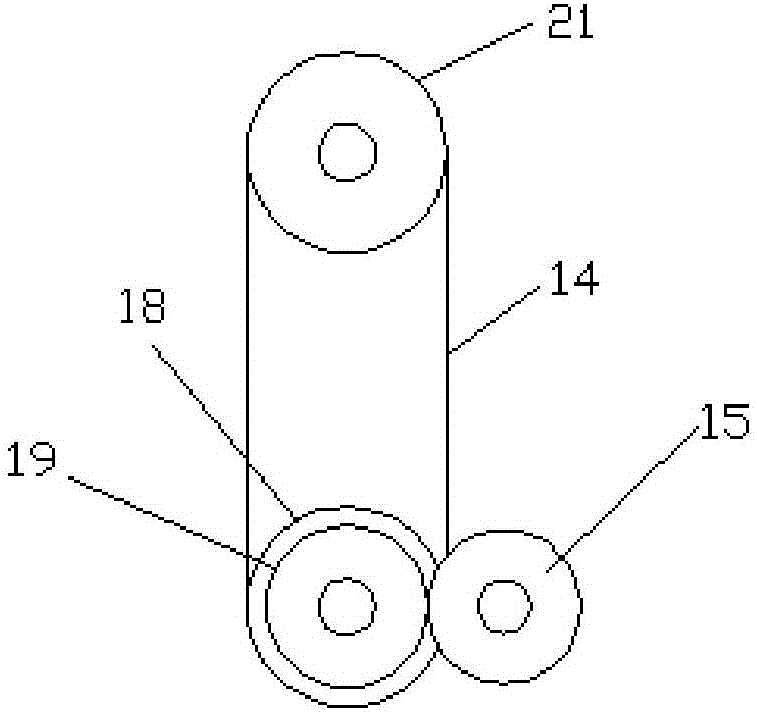

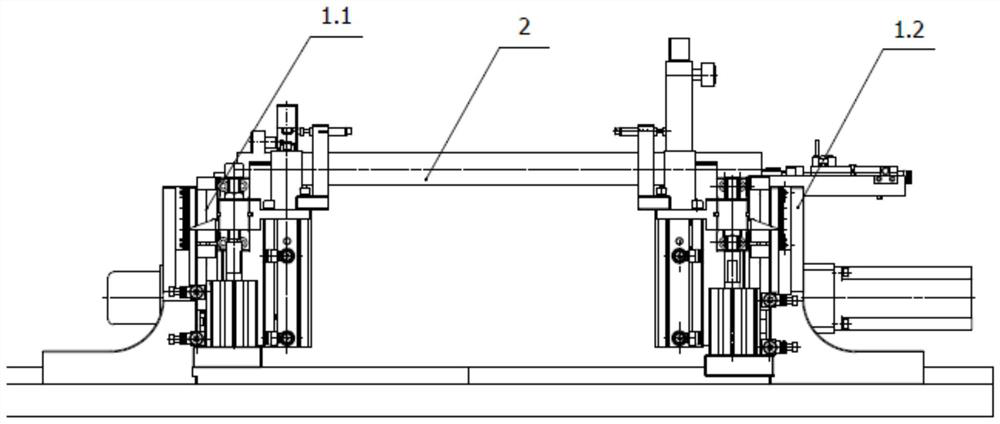

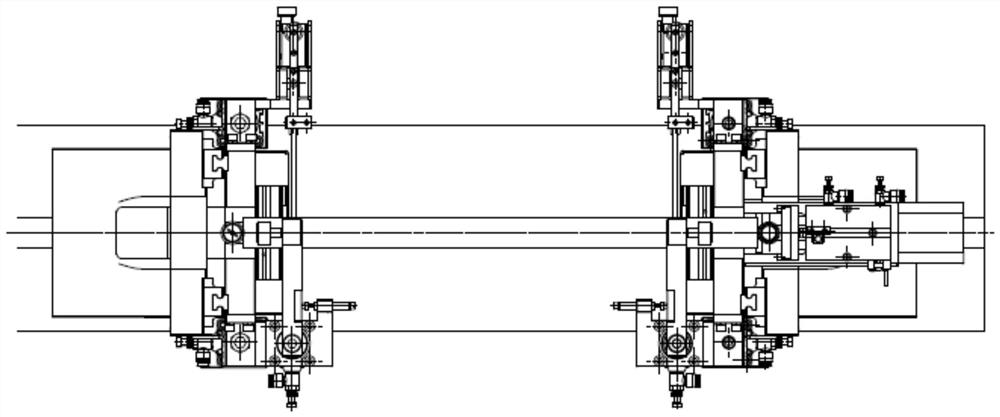

High-precision lower drive type roller driving mechanism

ActiveCN112547847ANovel structureCompact structureMechanical thickness measurementsUsing optical meansWorkbenchControl engineering

The invention relates to a high-precision lower drive type roller driving mechanism, and belongs to the field of shaft lever correction. The high-precision lower drive type roller driving mechanism comprises a high-precision roller lower drive mechanism driven end and a high-precision roller lower drive mechanism driving end, the lower surfaces of the high-precision roller lower drive mechanism driven end and the high-precision roller lower drive mechanism driving end are planes, and the planes are matched with the upper surface of a workbench and can slide on the surface of the workbench. Themechanism can achieve rotation driving of various shaft rod parts such as polished shafts and lead screws which are equal in diameter, variable in diameter, free of center holes, different in lengthand different in diameter. Compared with a conventional roller device, the high-precision lower drive type roller driving mechanism overcomes a series of technical defects of low precision, easy slipping, poor adaptability and the like when rotating measurement is carried out by taking a roller as a reference. The mechanism has the advantages of being high in rotation reference precision, wide inapplication range of workpieces, flexible and convenient to operate, convenient to adjust, capable of breaking through automatic shaft straightening with the outer circle as the reference and meetingthe high-precision straightness requirement, easy to assemble, compact in structure, convenient to produce and the like.

Owner:中机试验装备股份有限公司

Scrap-jumping prevention stamping die stamping method

ActiveCN104438552AGuarantee stamping qualityPlay the role of automatic safe unloadingStripping-off devicesScrapEngineering

The invention relates to a scrap-jumping prevention stamping die stamping method. A blanking tool edge is provided with a blanking section in the shape of an inverted circular truncated cone. The scrap-jumping prevention stamping die stamping method is characterized in that an inlet and an outlet are each provided with a stamped part compaction limiting mechanism (A), wherein each stamped part compaction limiting mechanism (A) acts on a stamped part (10). The stamped part compaction limiting mechanisms are arranged on a lower die base, and the stamped part compaction limiting mechanisms can not only position the stamped parts but also compact the stamped parts, guarantee the stamping quality of the stamped parts, and even play an automatic safe discharge role after stamping is completed.

Owner:佛山市高明德健五金有限公司

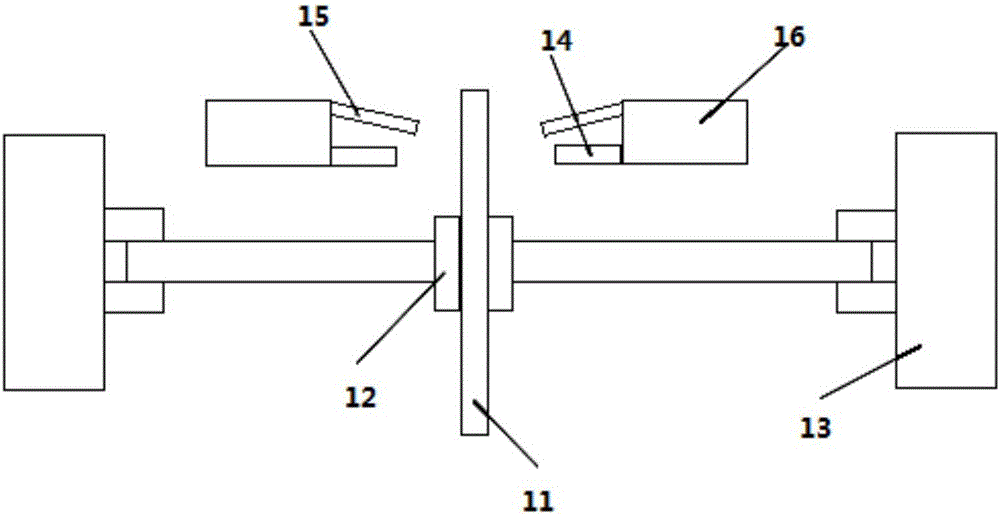

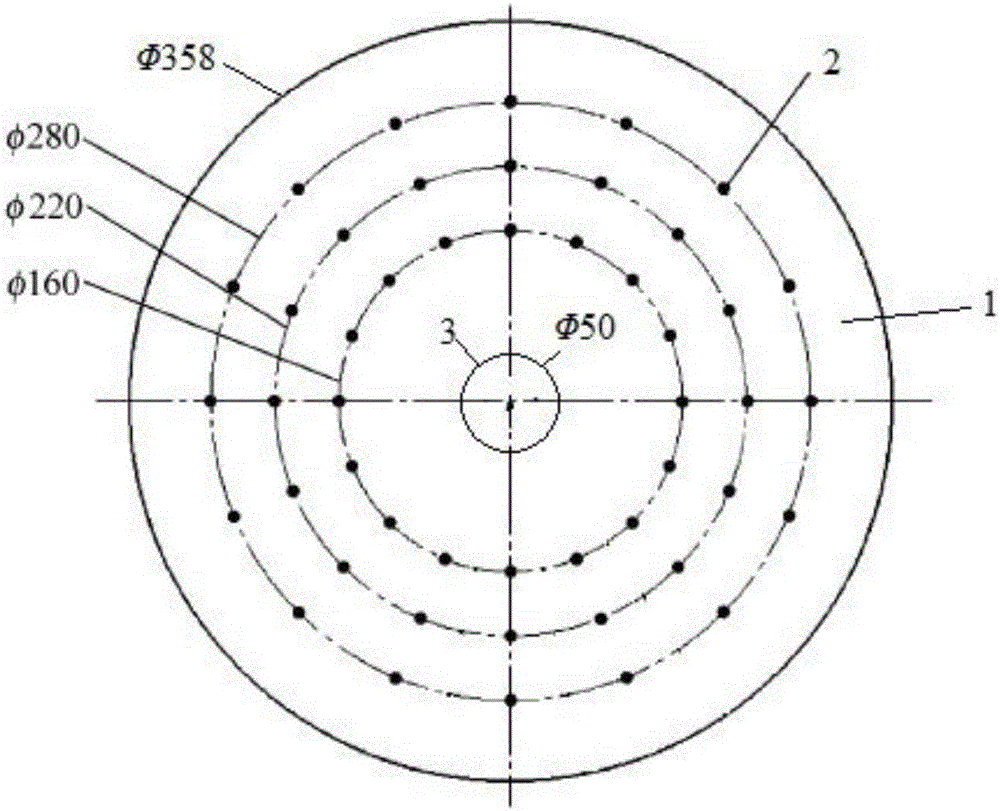

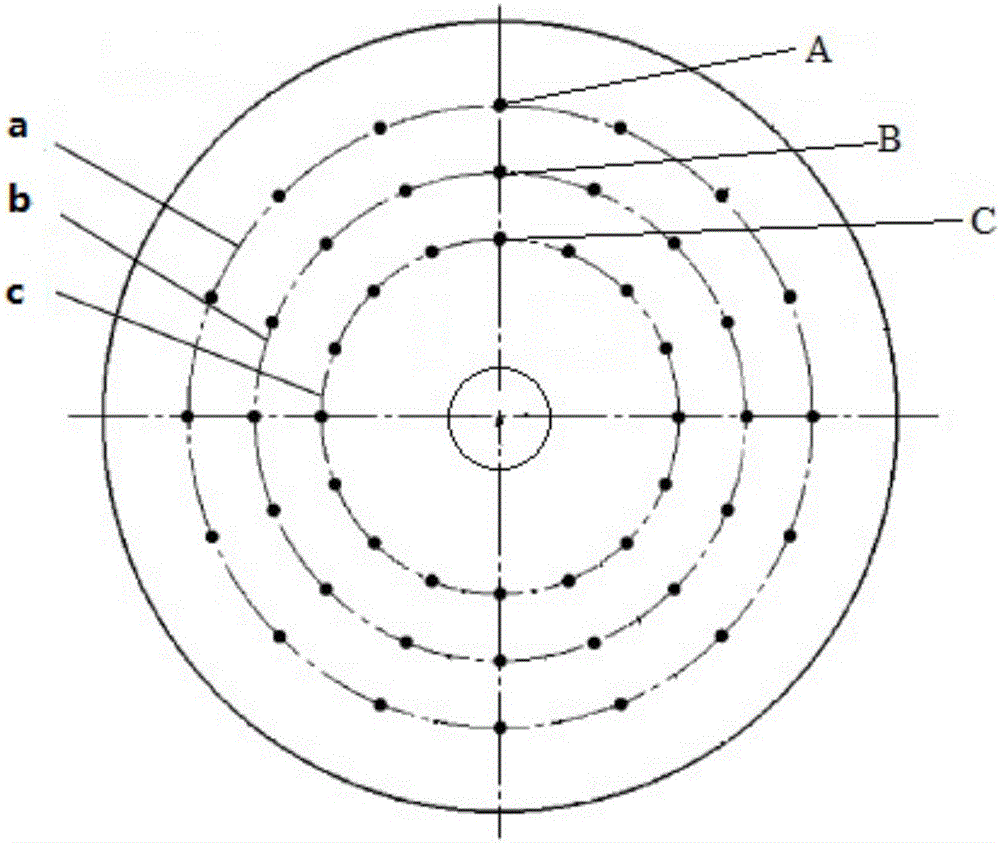

Laser impact tensioning device and method for circular saw web

ActiveCN105671250APrecise regulationImprove precision qualityFurnace typesHeat treatment furnacesCircular sawEngineering

The invention discloses a laser impact tensioning device and method for a circular saw web. The device comprises a clamp, a rotatable clamping device, a driving device, a laser device and a laser device displacement device. The method includes the steps that the end faces of the two sides of the circular saw web are coated with an absorbing protection layer material; the end faces of the two sides of the circular saw web are coated or sprayed with a restraint layer material; and laser beams are used for synchronously and symmetrically applying laser impact to the end faces of the two sides of the circular saw web. According to the laser impact tensioning device and method, the problems that existing tensioning methods such as hammering and roller pressing are low in efficiency, poor in accuracy, low in automatic degree, not ideal in tensioning effect and the like can be solved, promotion of the manufacturing level, the yield, the performance and the quality stability of the ultra-thin circular saw web is facilitated, the service life of a cutter can be prolonged, wood sawing losses are reduced, and the environmental pollution is reduced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A kind of anti-jump waste stamping die

InactiveCN104289587BGuarantee stamping qualityPlay the role of automatic safe unloadingStripping-off devicesEngineeringFrustum

The invention relates to an anti-bouncing waste stamping die. A blanking knife edge is provided with an inverted-frustum-shaped blanking segment. The anti-bouncing waste stamping die is characterized in that an inlet and an outlet of the anti-bouncing waste stamping die are each provided with a stamping piece pressing limiting mechanism (A) acting on a stamping piece (10). The stamping piece pressing limiting mechanisms are arranged on a lower die base. The stamping piece pressing limiting mechanisms can not only position the stamping piece, but also press the stamping piece tightly, the stamping quality of the stamping piece is guaranteed, and even automatic safe discharging is achieved after stamping is finished.

Owner:东莞市中霸电子制品有限公司

Servo motor capable of efficiently shielding high-frequency interference

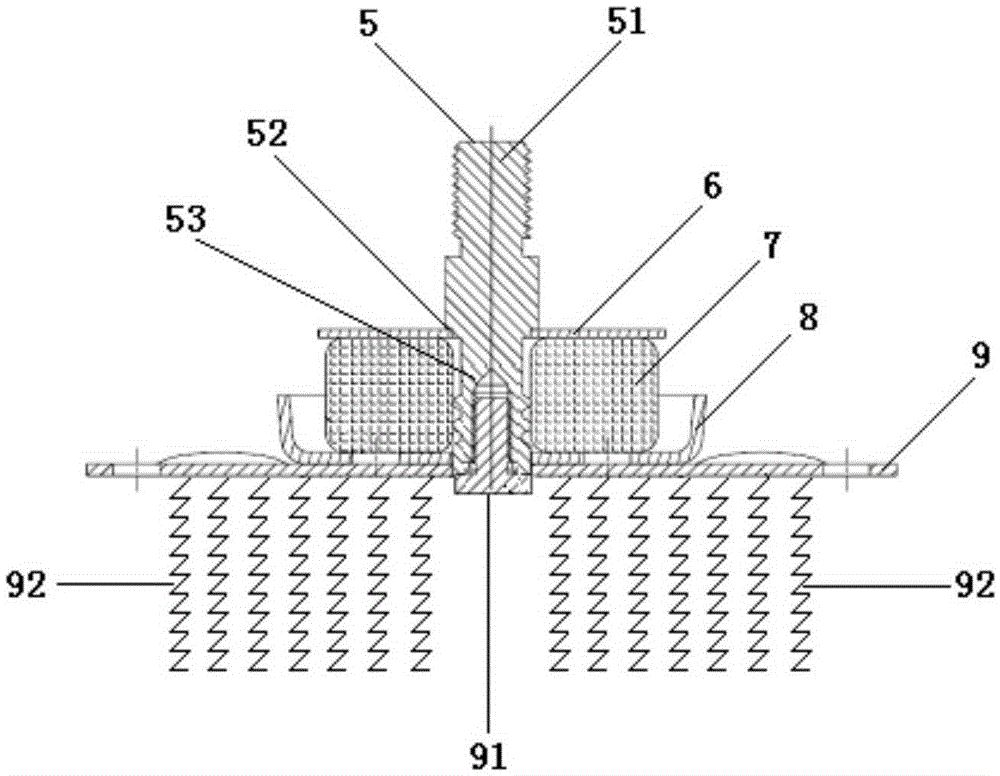

InactiveCN105262283AImprove shielding effectImprove precision qualitySupports/enclosures/casingsSuppressing electromagnetic interferenceMetal rubberControl theory

The invention discloses a servo motor capable of efficiently shielding high-frequency interference. The servo motor comprises a servo driver, a screw rod and an anti-high-frequency interference box, wherein the screw rod is driven by the servo driver; the anti-high-frequency interference box covers the outside of the servo driver; a through hole is formed in the box wall of the anti-high-frequency interference box; the screw rod extends out of the anti-high-frequency interference box through penetrating through the through hole; the servo driver is arranged on the inner bottom surface of the anti-high-frequency interference box through a shock-resistant suspension assembly; the shock-resistant suspension assembly comprises a connection screw rod; a mounting part, a convex shoulder and a sleeve part are sequentially arranged on a rod body of the connection screw rod; the mounting part is connected with the bottom of the servo driver; the sleeve part is sequentially sleeved with a cover board, a metal rubber spring ring, a mounting base and a mounting plate; the cover board and the metal rubber spring ring are sequentially clamped and pressed between the convex shoulder and the mounting base; the mounting plate is connected with the tail end of the sleeve part through a fastener; a plurality of springs are arranged at the bottom surface of the mounting plate; and the plurality of springs vertically extend and are connected to the inner bottom surface of the anti-high-frequency interference box. The servo motor has high shielding property and high accuracy and quality, and is low in cost, efficient and energy-saving.

Owner:SUZHOU KUNK & SAM LIGHTING TECH CO LTD

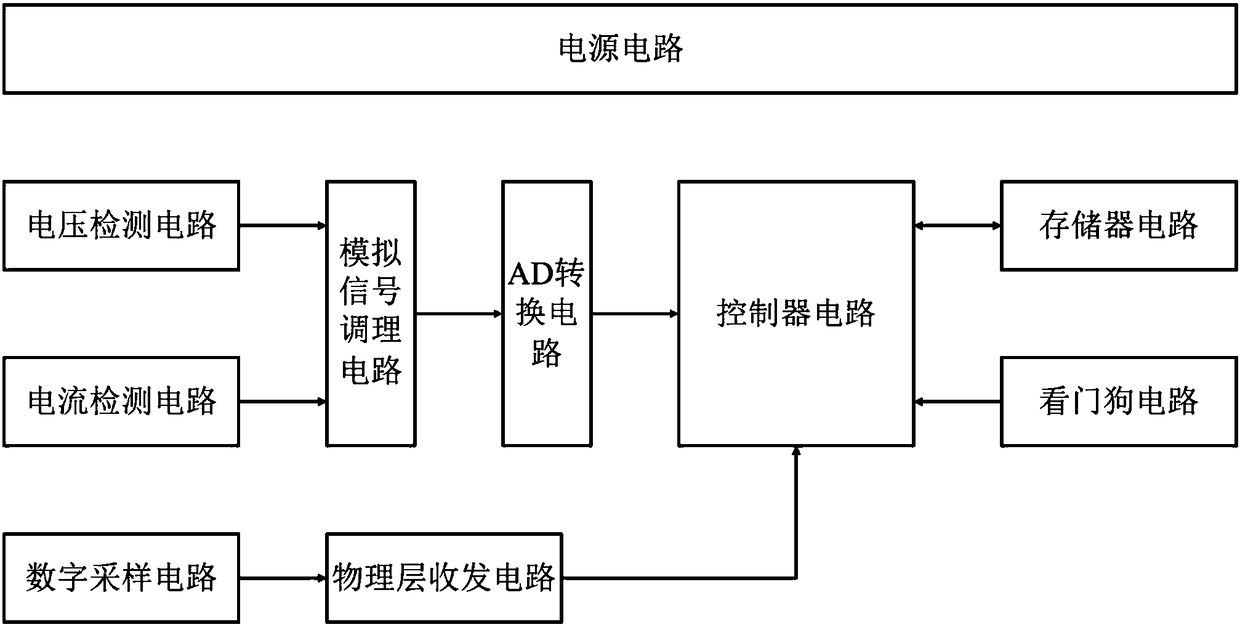

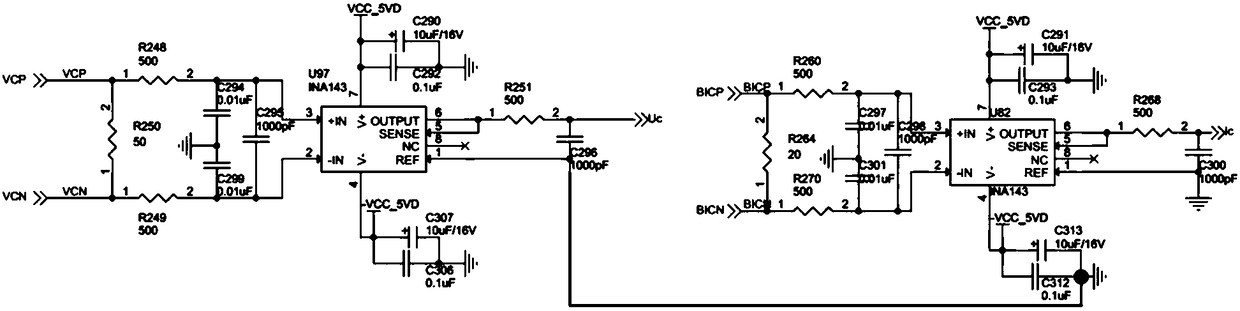

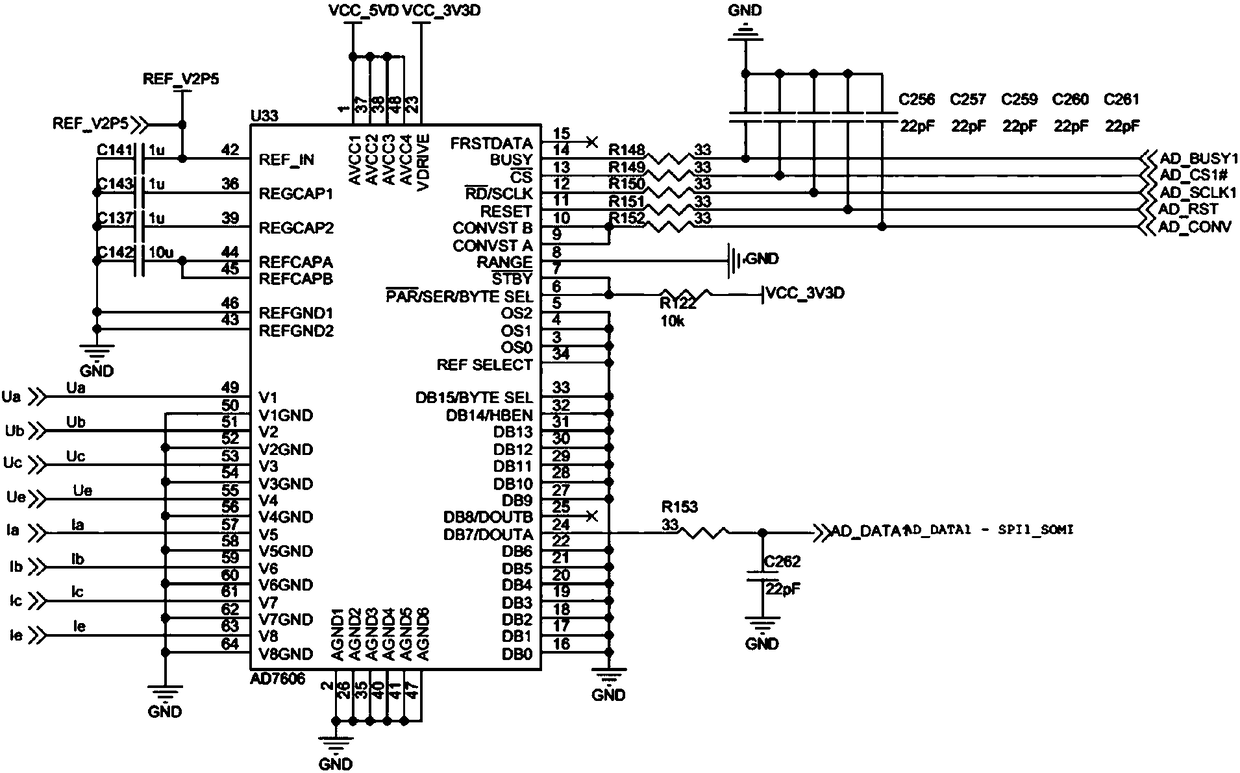

Novel electric energy measuring and electric energy quality monitoring device and monitoring method thereof

PendingCN108414828AIncrease storage spaceImprove precision qualityElectrical testingMeasurement using digital techniquesPower qualityPhysical layer

The invention discloses a novel electric energy measuring and electric energy quality monitoring device. The device comprises a voltage detection circuit, a current detection circuit, an analog signalconditioning circuit, an AD conversion circuit, a digital sampling circuit, a physical layer transceiving circuit, a controller circuit, a storage circuit, a watchdog circuit and a power circuit; thepower circuit supplies power; the voltage and current detection circuits detect voltage and current signals and upload the signals to the controller circuit through the analog signal conditioning circuit and the AD conversion circuit; the digital sampling circuit samples digital signals and uploads the signals to the controller circuit through the physical layer transceiving circuit; the storagecircuit stores parameters; the watchdog circuit provides reset signals; the controller circuit measures electric energy and monitors electric energy quality. The invention further provides a monitoring method of the novel electric energy measuring and electric energy quality monitoring device. The method comprises the steps of performing initialization, obtaining analog quantity and digital quantity signals, measuring electric energy, monitoring electric energy quality and storing parameters. Electric energy metering and electric energy quality monitoring can be performed at the same time.

Owner:WILLFAR INFORMATION TECH CO LTD

High-precision stamping method for anti-tripping waster material stamping die

ActiveCN104275382AEasy to limitEasy to fixMetal-working feeding devicesPositioning devicesEngineeringFrustum

The invention relates to a high-precision stamping method for an anti-tripping waster material stamping die. A stamping cutter edge is provided with an inverse frustum-shaped stamping section. The method is characterized in that a stamping component compressing and limiting mechanism (A) which acts on a stamping component (10) is arranged at each of an inlet and an outlet of the anti-tripping waster material stamping die. Due to the fact that one stamping component compressing and limiting mechanism is arranged at each of the inlet and the outlet of the anti-tripping waster material stamping die and can act on the stamping component in both the horizontal direction and the vertical direction, the stamping component can be well limited and fixed, and a stamped product is higher in precision and quality.

Owner:深圳钜宝精密模具有限公司

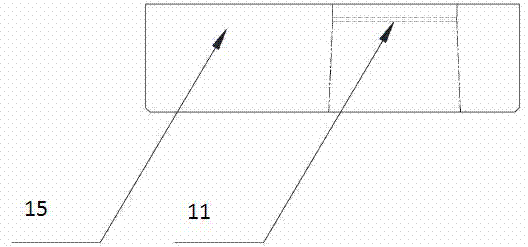

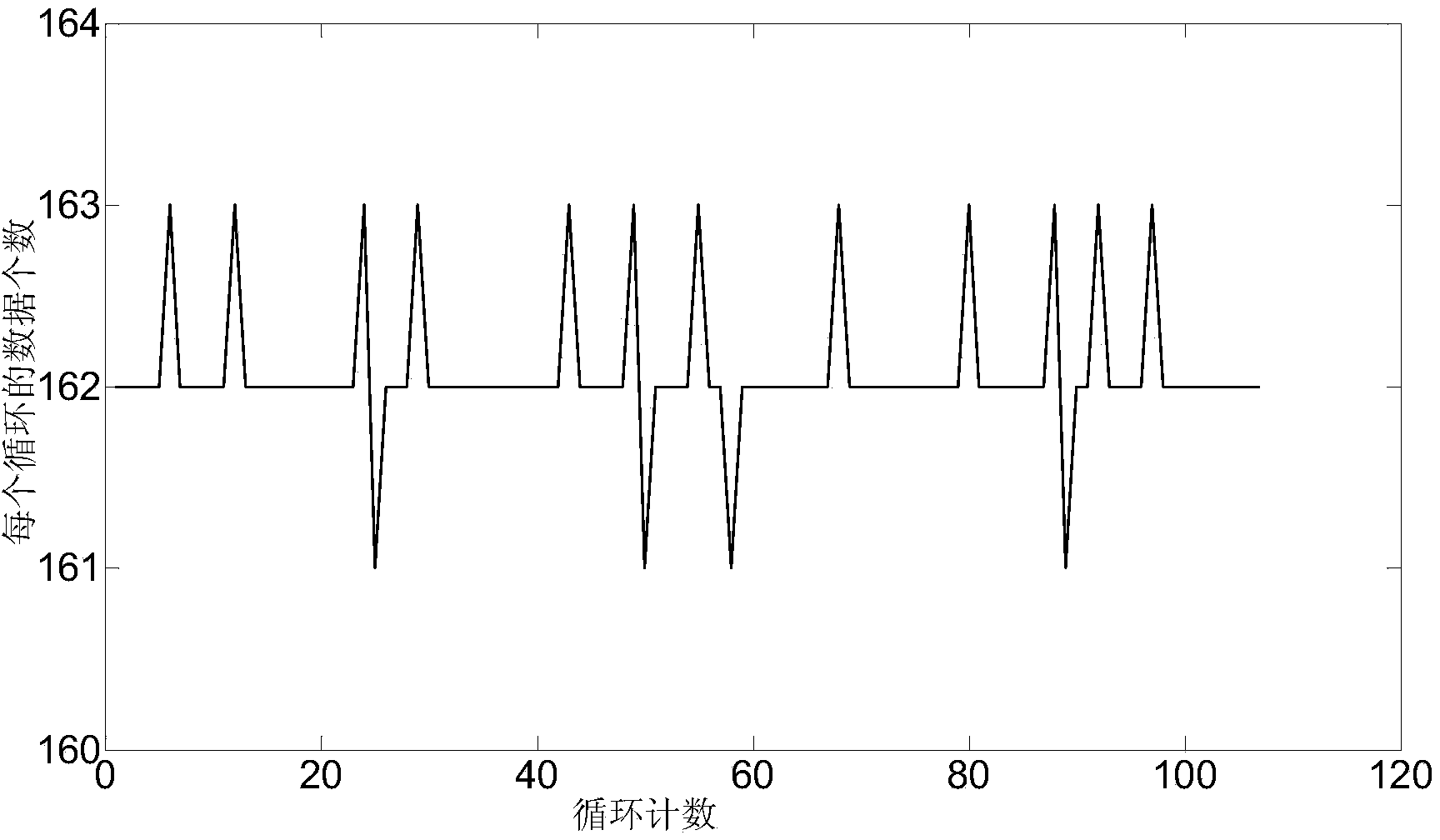

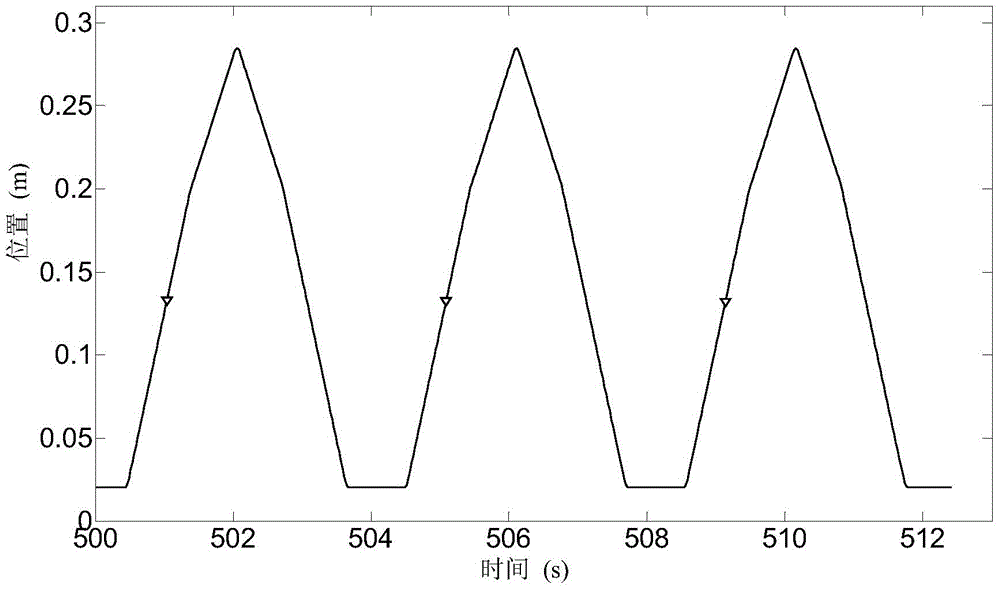

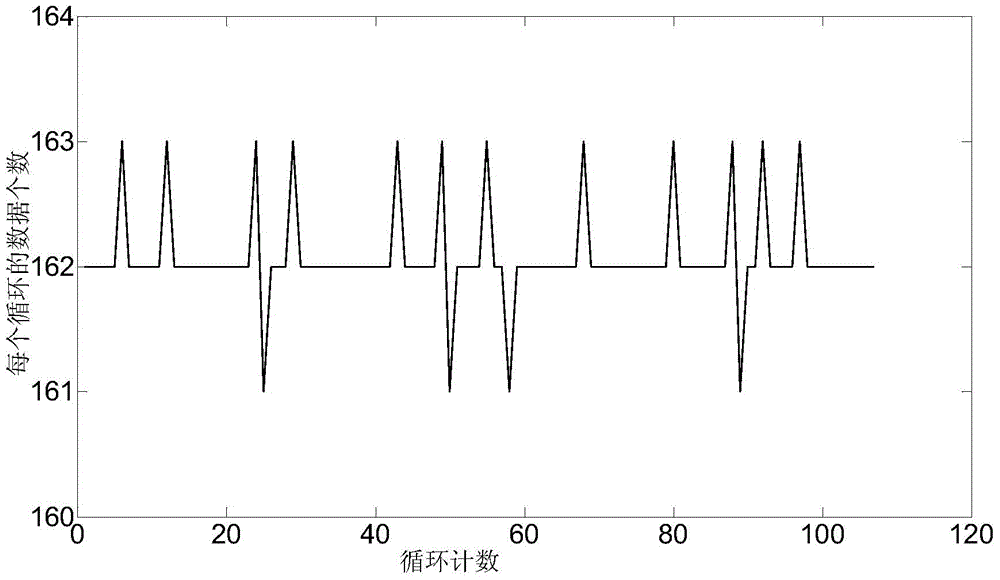

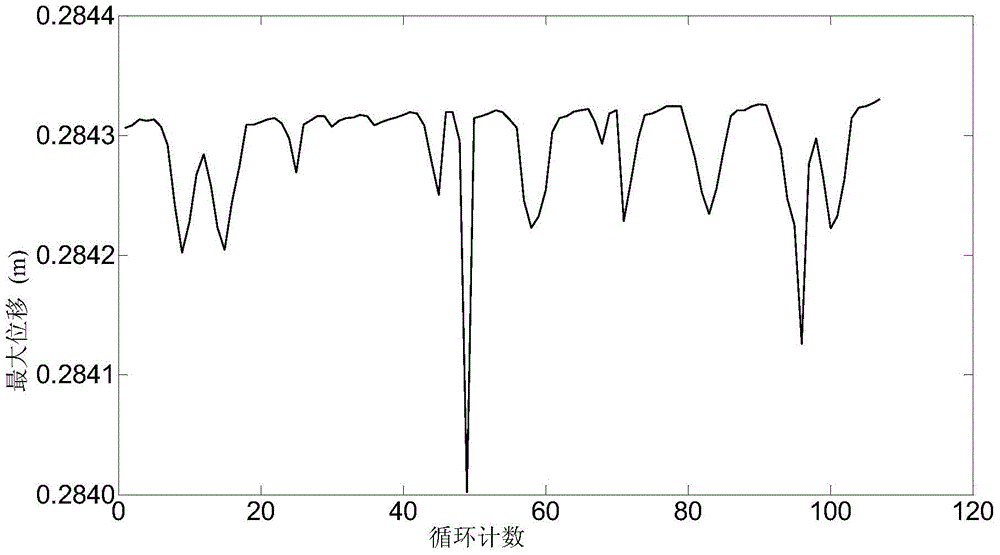

Injection molding machine die assembly thrust seat linear displacement measuring data processing method

InactiveCN103902823AImprove precision qualityMeasurement devicesSpecial data processing applicationsData seriesHorizontal axis

The invention discloses an injection molding machine die assembly thrust seat linear displacement measuring data processing method. The method includes: acquiring measured linear displacement data series and corresponding time data series, determining the total length of the data series, taking one section of effective data, allocating a serial number to each datum, using the time data series as horizontal axis value and the linear displacement data series as longitudinal axis value, displaying a displacement-time curve, and calculating the average value of all effective displacement data; traversing the displacement data series, segmenting circulation by using the displacement location closest to the average value as the starting point and in the displacement ascending direction, and recording the displacement vale, time value and data serial number information of the location; traversing the displacement data series, counting circulation number and datum number in each circulation according to the circulation segmenting point, searching for the maximum displacement valve and die assembly displacement value of each circulation, and calculating stroke value. The method has the advantages that relations among data are found according to measured discrete data series, and the motion features of the thrust seat can be analyzed.

Owner:ZHEJIANG UNIV

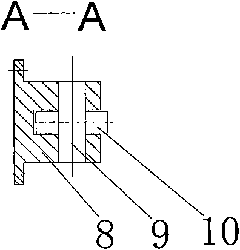

Support sheet mechanism of numerical control servo high-speed puncher

The invention discloses a support sheet mechanism of a numerical control servo high-speed puncher, which comprises a support sheet board. The lower part of the support sheet board is provided with an actuating cylinder; and a limit mechanism which is concentric with the support sheet board and avoids sheet fling when processing a material sheet, the limit mechanism comprises a support frame, a positioning plate which is arranged on the support frame, and the positioning plate is provided with a group of positioning blocks in circumference distribution which can be movably adjusted in radial direction; and the end part of the positioning blocks is provided with an idler wheel. The movably adjusting structure is as follows: the positioning blocks or the positioning plate are / is provided with a chute in radial direction, and a bolt passes through the chute and connects the positioning blocks and the positioning plate firmly. The positioning plate is also provided with a group of rolling devices which enable the material sheet to rotate smoothly. By adopting the adjustable limit structure and the rolling devices, when the puncher punches the last punching grooves, sheet fling of the material sheet is avoided, and the rotary friction of the material sheet is reduced. The material sheet can be punched more accurately, thus improving the accuracy quality of the punching material sheet. And moreover, radial adjustment can be carried out according to the size of the processed material sheet.

Owner:芜湖市申力电工专用机械制造有限公司

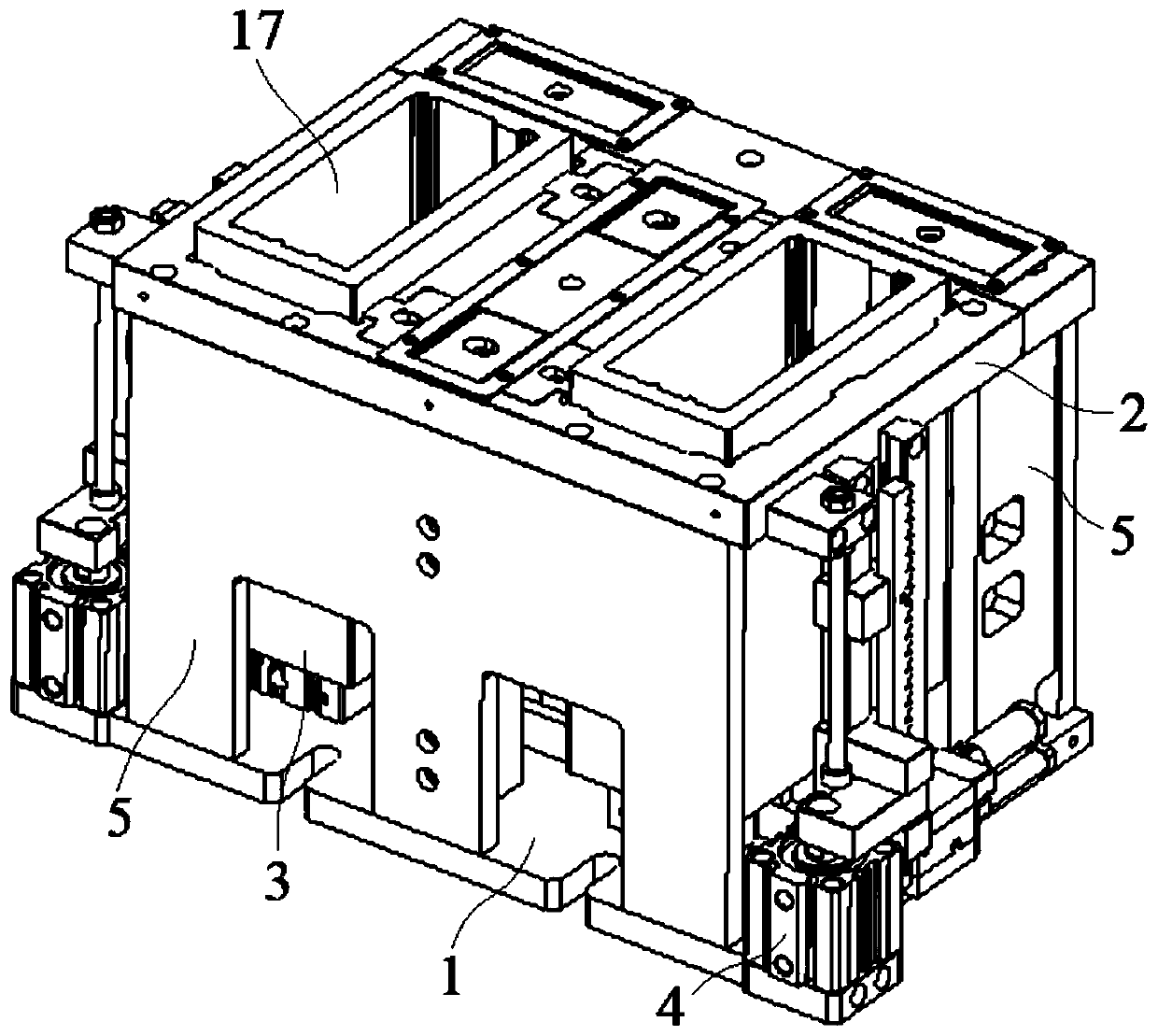

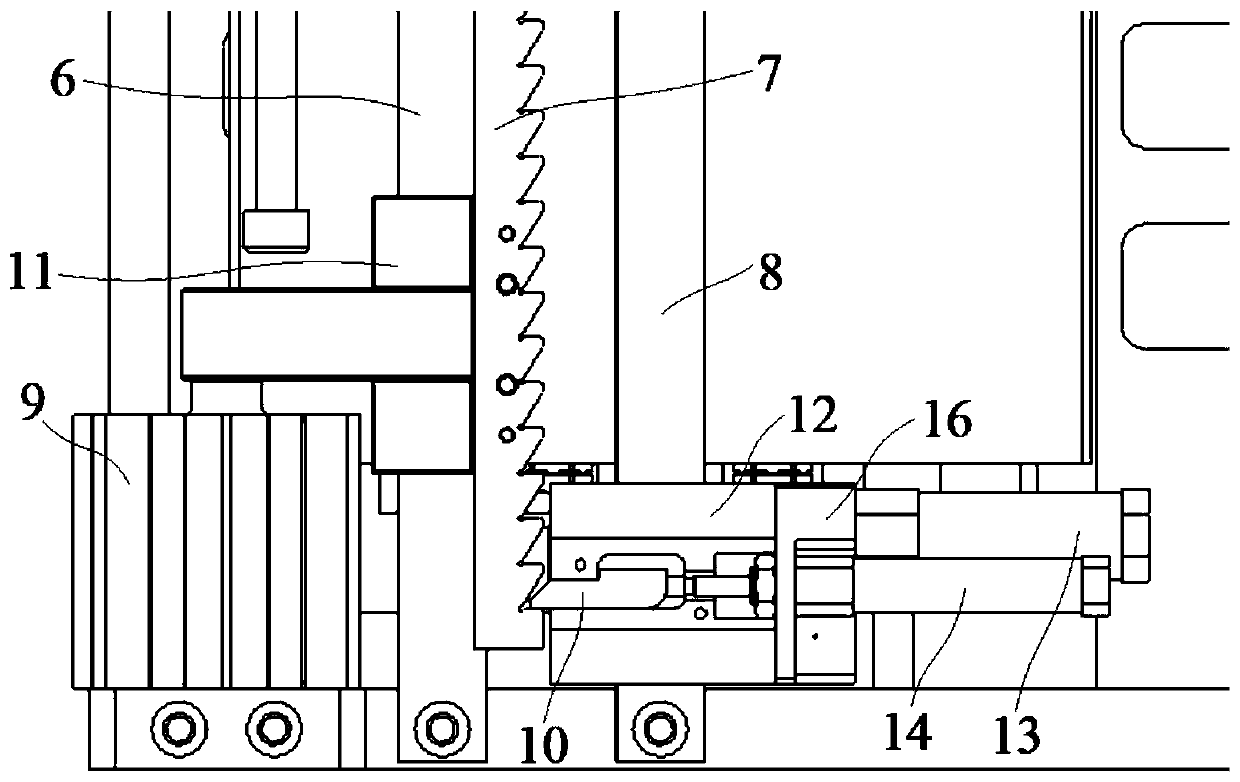

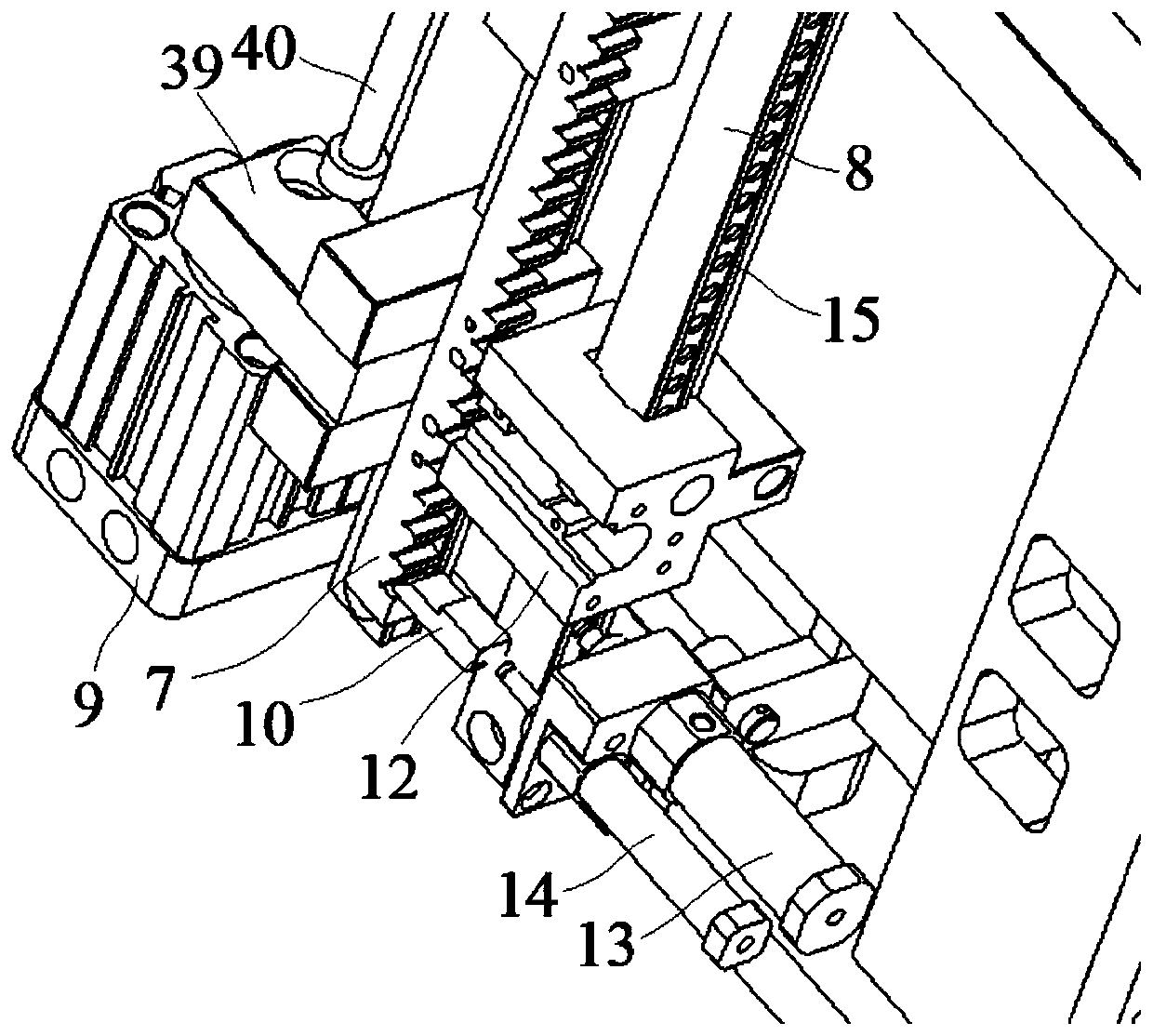

Processing device for smart phone

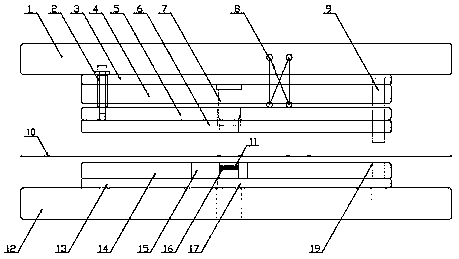

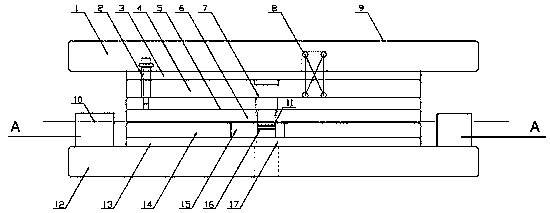

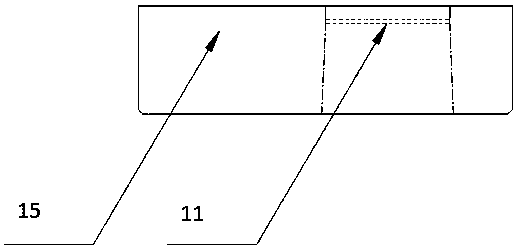

ActiveCN110961972ALoad accuratelyGuaranteed accuracyWork clamping meansPositioning apparatusStructural engineeringBackplane

The invention discloses a processing device for a smart phone. The processing device comprises a bottom plate, a top plate, a material seat movably arranged between the bottom plate and the top plate,and at least one pushing mechanism; the bottom plate and the top plate are connected through a plurality of supporting plates; the pushing mechanism is located on the side edge of the bottom plate; ato-be-processed material is arranged on the material seat; the pushing mechanism comprises a guide column, a rack movably installed on the guide column, a positioning column, an ejection air cylinderand a clamping tongue which is embedded into the rack; the upper ends and lower ends of the guide column and positioning column are connected with the top plate and the bottom plate respectively, therack is movably connected with the guide column through at least one sliding block; and the piston rod of the ejection air cylinder is connected with the sliding block. According to the processing device, the to-be-machined material placed on the material seat can be automatically fed; and therefore, manpower is replaced, processing efficiency is improved, errors of manual feeding can be avoided,processing precision is guaranteed, accidental injuries to workers can be avoided, and the automation level of equipment is improved.

Owner:江苏金科森电子科技有限公司

A data processing method for linear displacement measurement of injection molding machine clamping thrust seat

InactiveCN103902823BImprove precision qualityMeasurement devicesSpecial data processing applicationsData seriesThrust bearing

The invention discloses an injection molding machine die assembly thrust seat linear displacement measuring data processing method. The method includes: acquiring measured linear displacement data series and corresponding time data series, determining the total length of the data series, taking one section of effective data, allocating a serial number to each datum, using the time data series as horizontal axis value and the linear displacement data series as longitudinal axis value, displaying a displacement-time curve, and calculating the average value of all effective displacement data; traversing the displacement data series, segmenting circulation by using the displacement location closest to the average value as the starting point and in the displacement ascending direction, and recording the displacement vale, time value and data serial number information of the location; traversing the displacement data series, counting circulation number and datum number in each circulation according to the circulation segmenting point, searching for the maximum displacement valve and die assembly displacement value of each circulation, and calculating stroke value. The method has the advantages that relations among data are found according to measured discrete data series, and the motion features of the thrust seat can be analyzed.

Owner:ZHEJIANG UNIV

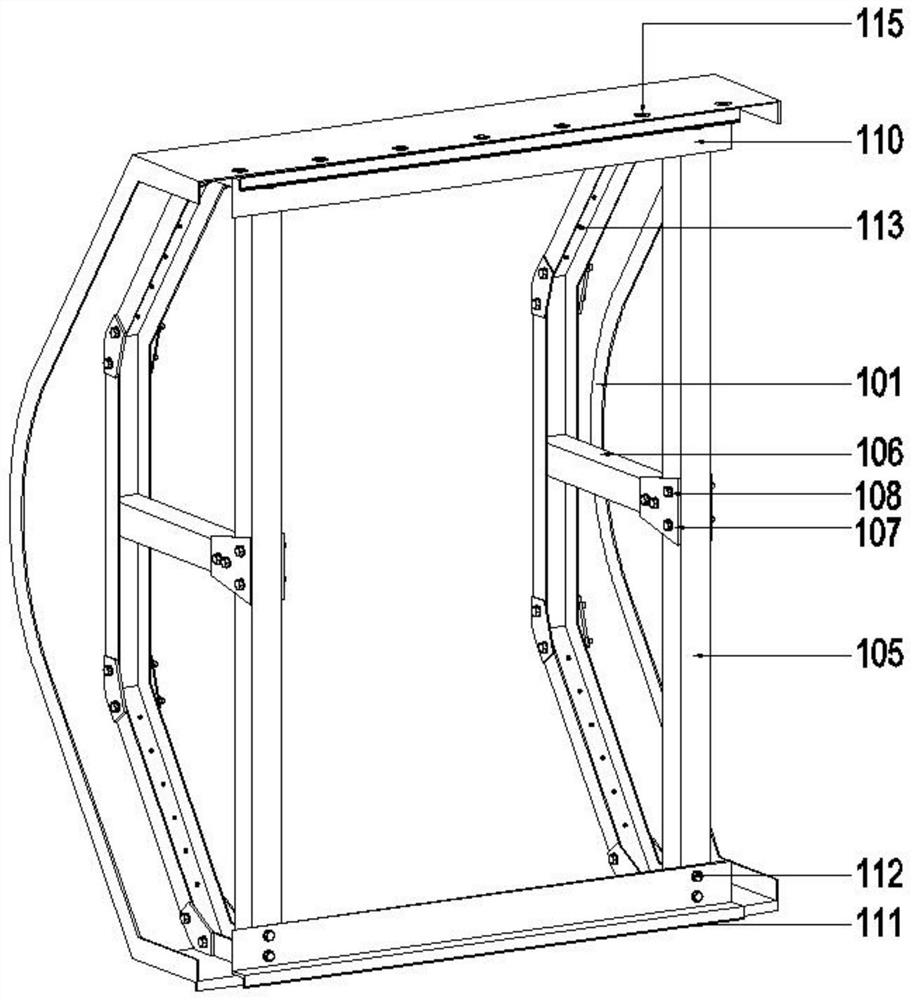

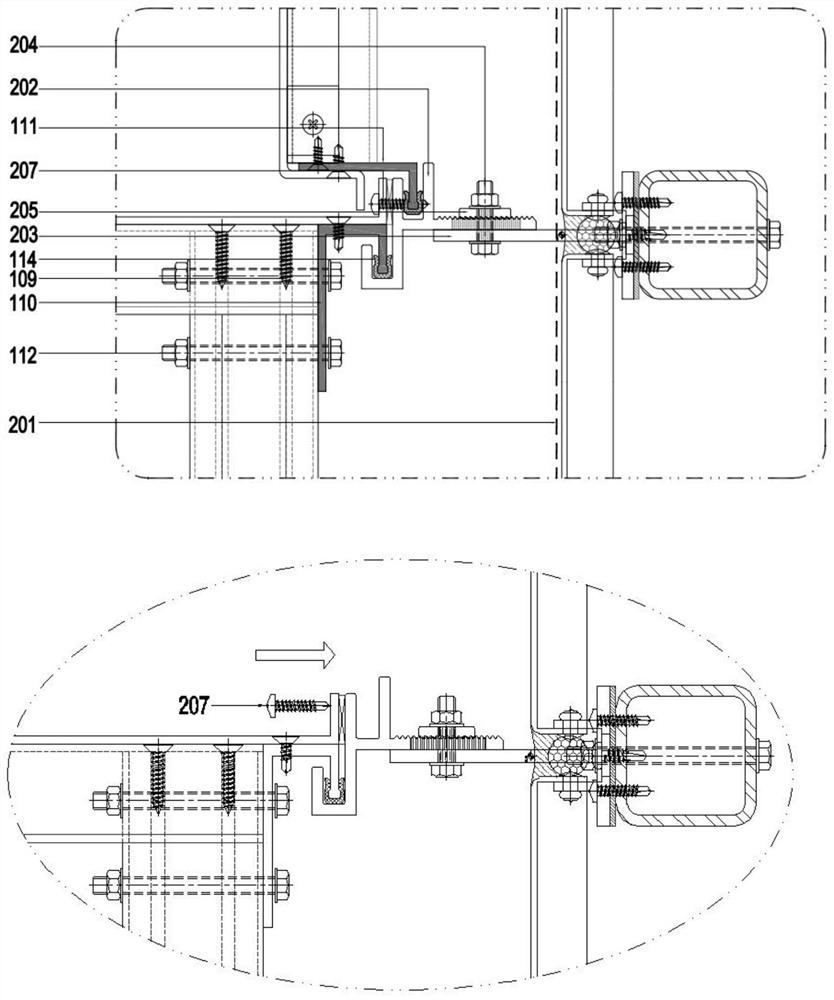

Slotting type special-shaped aluminum plate curtain wall assembly type installation system

PendingCN113914519AGuaranteed flatnessAvoid water leakage hazardsWallsBuilding insulationsMachiningIndustrial engineering

The invention discloses a slotting type special-shaped aluminum plate curtain wall assembly type installation system, and relates to the technical field of building curtain walls. The slotting type special-shaped aluminum plate curtain wall assembly type installation system comprises a component frame, a special-shaped aluminum plate and a prefabricated frame, the component frame comprises an auxiliary frame, the two ends of the auxiliary frame are fixedly connected to a vertical main frame, and the vertical main frame is provided with an upper transverse frame and a lower transverse frame which are parallel to each other; the special-shaped aluminum plate is fixedly connected to the auxiliary frame through a fixing piece the prefabricated frame comprises a base, grooves used for installing the upper transverse frame and the lower transverse frame are formed in the base, and the base is fixedly connected to a prefabricated part in a to-be-installed plane. By means of the arrangement, the slotting type special-shaped aluminum plate curtain wall assembly type installation system is provided, a unit type installation system is adopted, factory machining and assembly are achieved, and machining and installation precision is guaranteed.

Owner:BEIJING GANGYUAN CURTAIN WALL CO LTD +1

Lost foam multi-station digital gluing system and its gluing method

ActiveCN105909639BSimplify the installation processSimple structureLiquid surface applicatorsMaterial gluingNumerical controlEngineering

The invention discloses a multi-station digital pasting system for a lost foam and a pasting method of the multi-station digital pasting system. The multi-station digital pasting system mainly comprises a main rack, numerical control sliding table devices, a pasting system, a transverse movement driving system, a lifting rotating table, a main pouring gate pasting position changing device and an electric system connected with all the parts; by using the system, continuous pasting of a plurality of stations and automatic pouring gate pasting can be realized at one time, and corresponding moulds can be automatically switched according to the combination demand of templates to mount different templates; and compared with the prior art, the pasting system and method are high in automation degree and are used for reducing the cost while reducing the labor intensity of workers, and not only improving the pasting quality of the templates of the lost foam, but also remarkably increasing the pasting efficiency of the templates so as to have a considerable promotional value in the current trend of enterprise technological innovation transformation.

Owner:CMCU ENG

A treatment method suitable for roll taper defects of four-high rolling mill

InactiveCN104525579BAchieving Quantitative CompensationReduce or even eliminate the impactMetal rolling stand detailsMetal rolling arrangementsBending forceIndustrial engineering

A roller taper defect treatment method for a four-high rolling mill mainly includes the following steps executed by a computer of 1 collecting basic device parameters; 2 collecting basic rolling process parameters of products of typical specifications; 3 defining an optimal roller inclining calculation process variable, a roller inclining amount, a roller inclining optimal step size, an objective function, an initial value of the objective function, a working roller channeling amount, a working roller bending force and an optimal roller inclining amount; 4 calculating the working roller channeling amount, the working roller bending force, the roller inclining amount and lateral distribution values of front tension of strips at an outlet of the rolling mill; 5 calculating the objective function; 6 completing the calculation after obtaining the roller inclining amount. The roller taper defect treatment method for the four-high rolling mill can achieve quantitative compensation for roller taper defects, minimizes or even eliminates the impact of the roller taper defects on the shape of the strips, solves the problem that the treatment of strip shape defects caused by roller taper is almost entirely dependent on experience of field operators and improves the accuracy quality of rolled strips.

Owner:山东冠洲股份有限公司

Anti-high frequency interference servo motor

InactiveCN105305728AImprove shielding effectImprove precision qualitySupports/enclosures/casingsSuppressing electromagnetic interferenceMetal rubberEngineering

The invention discloses an anti-high frequency interference servo motor which comprises a servo driver, a screw rod driven by the servo driver and an anti-high frequency interference box covering the servo driver, wherein a through hole is disposed in the box wall of the anti-high frequency interference box, the screw rod passes through the through hole in order to be extended out from the anti-high frequency interference box, and the servo driver is installed on the bottom inside the anti-high frequency interference box by an anti-seismic suspension assembly; the anti-seismic suspension assembly comprises a connecting screw rod, the rod body of the connecting screw rod is successively equipped with an installation part, a raised shoulder and a sleeving part, and a floating rotary ball is connected to the tail end of the connecting screw rod; and the installation part is connected to the bottom part of the servo driver, the sleeving part is successively sleeved by a cover plate, a metal rubber spring, an installation base and an installation plate, and the cover plate and the metal rubber spring are successively clamped and pressed between the raised shoulder and the installation base. The anti-high frequency interference servo motor provided by the invention can still be used normally under a high frequency (high harmonic wave) or an electromagnetic wave, has high shielding performance and high precision, and is low is cost, efficient and energy-saving.

Owner:SUZHOU KUNK & SAM LIGHTING TECH CO LTD

A Method of Improving the Shape Precision of Hot-rolled Strip

ActiveCN111451294BImprove precision qualityReduce the chance of rolling offProfile control deviceStrip steelLoad distribution

The invention relates to a method for improving the shape accuracy of a hot-rolled strip steel plate. The method comprises the following steps of: (1) calculating the stiffness correction coefficientK; and (2) when the roll diameter of a finishing mill changes, feeding a rack for stiffness measurement, calculating the stiffness measurement value of the rack, and simultaneously judging the stiffness deviation value before and after the roll diameter changes; when the size of a backing plate under a support roll of the finishing mill changes, feeding the rack for stiffness measurement, calculating the stiffness measurement value of the rack, and simultaneously judging the stiffness deviation value before and after the backing plate changes. The method has the advantages that calculation andjudgment of the stiffness adjustment correction coefficient are introduced when calculating the roll gap value and the rolling force load distribution of the strip steel, which improves the shape accuracy and quality of the hot-rolled strip steel plate, and reduces steel clogging in a finishing zone and rolling breakage of the finishing tail due to poor shape of the plate, prevents influences onthe roll shape of the coiling head and tail, and improves the quality.

Owner:ANGANG STEEL CO LTD

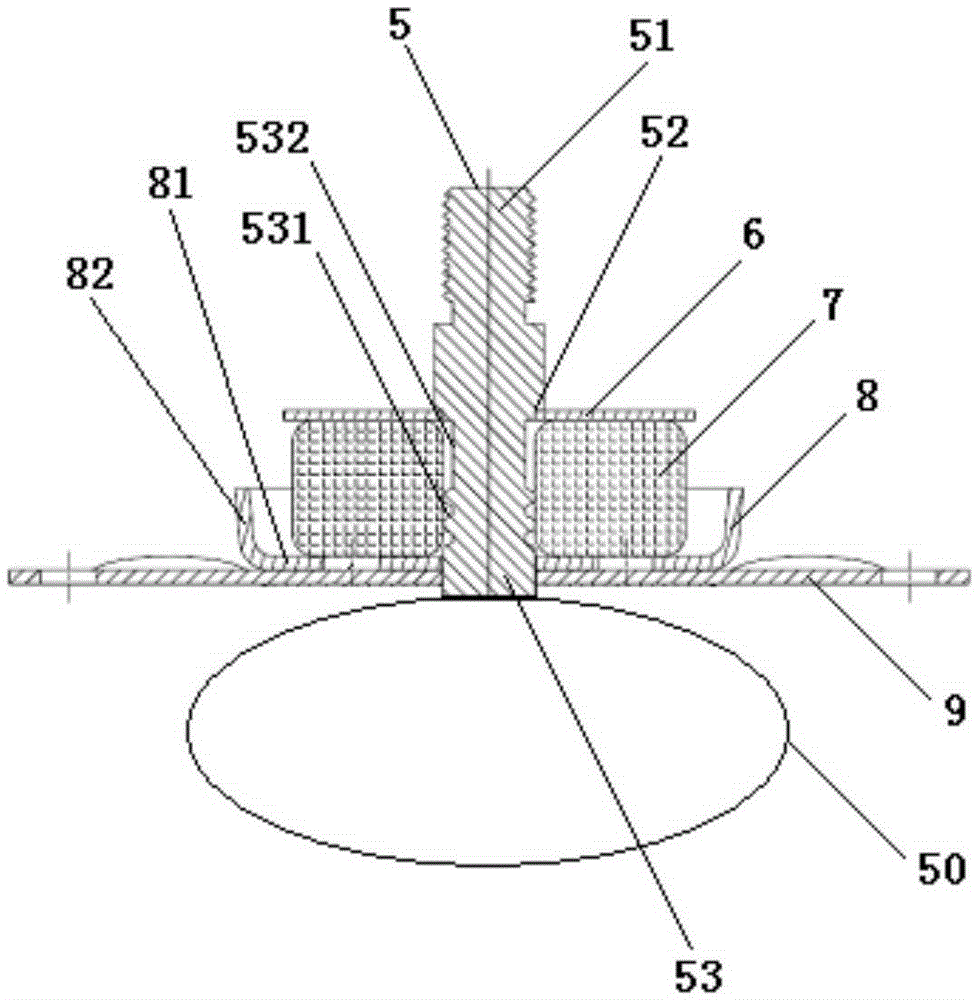

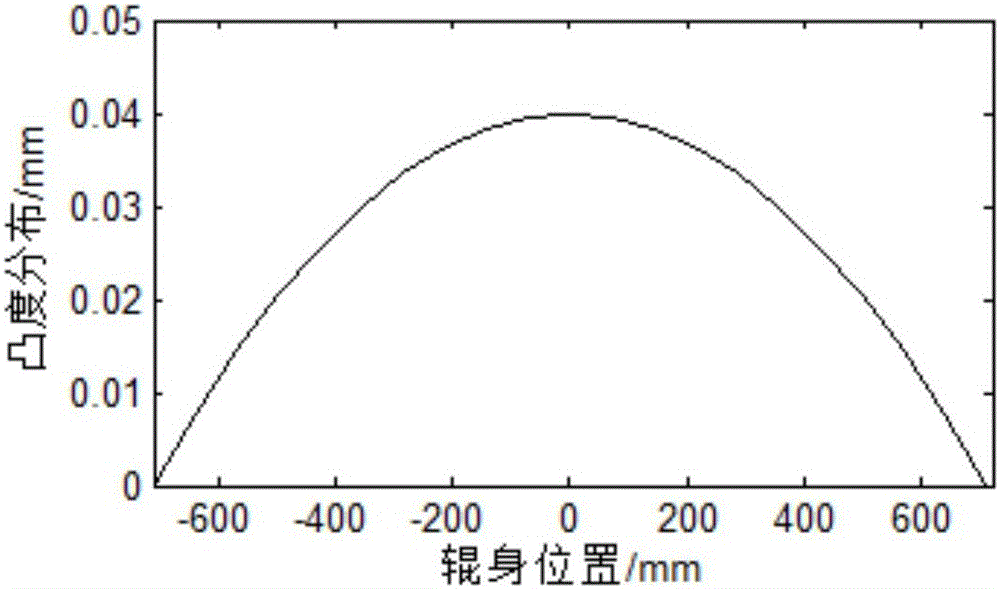

Method for calculating convexity conversion relationship between work roll and support roll of four-high mill

InactiveCN105975771AEnsure consistencyImprove precision qualitySpecial data processing applicationsInformaticsEngineeringObject function

The invention discloses a method for calculating convexity conversion relationship between a work roll and a support roll of a four-high mill. The method mainly comprises the following calculation steps: 1, collecting basic parameters of rolls; 2, defining a maximum convexity coefficient, a maximum opening degree coefficient, an optimum convexity coefficient and an optimum opening degree coefficient of the support roll; 3, defining a target function and initializing the target function; 4, calculating export plate shape value distribution under specific conditions of convexity and opening degree coefficients of the work roll; 5, calculating export plate shape value distribution when the work roll is a flat roll and the support roll is in a corresponding roll shape; 6, calculating the target function; and 7, obtaining the optimum convexity coefficient and the optimum opening degree coefficient of the support roll. According to the method disclosed in the invention, the convexity conversion between the work roll and the support roll can be calculated, so that the consistency of the strip outlet plate shapes is ensured to the greatest extent, the problem that the work rolls with convexity alternates to generate complicated roll cleaning so as to make the plate shape worse under certain specific conditions is solved, and the precision and quality of plate rolling under certain specific conditions are improved.

Owner:TANGSHAN DELONG STEEL CO LTD

Processing equipment for smartphones

ActiveCN110961972BGuaranteed stabilityAvoid accidental injuryWork clamping meansPositioning apparatusBlocked ConnectionEngineering

The invention discloses a processing device for a smart phone, comprising a bottom plate, a top plate, a material seat movably arranged between the bottom plate and the top plate, and at least one pushing mechanism. The bottom plate and the top plate are connected by a plurality of supporting plates, so The ejecting mechanism is located on the side of the bottom plate, and the material to be processed is arranged on the material holder. The upper and lower ends of the guide column and the positioning column are connected to the top plate and the bottom plate respectively, the rack is movably connected to the guide column through at least one slider, and the piston rod of the ejecting cylinder is connected to the slider. block connection. The invention realizes the automatic feeding of the material to be processed placed on the material base, which not only replaces the manual work, improves the processing efficiency, but also avoids the error of manual feeding, ensures the processing accuracy, and also avoids the need for personnel. Accidental injury improves the automation level of the equipment.

Owner:江苏金科森电子科技有限公司

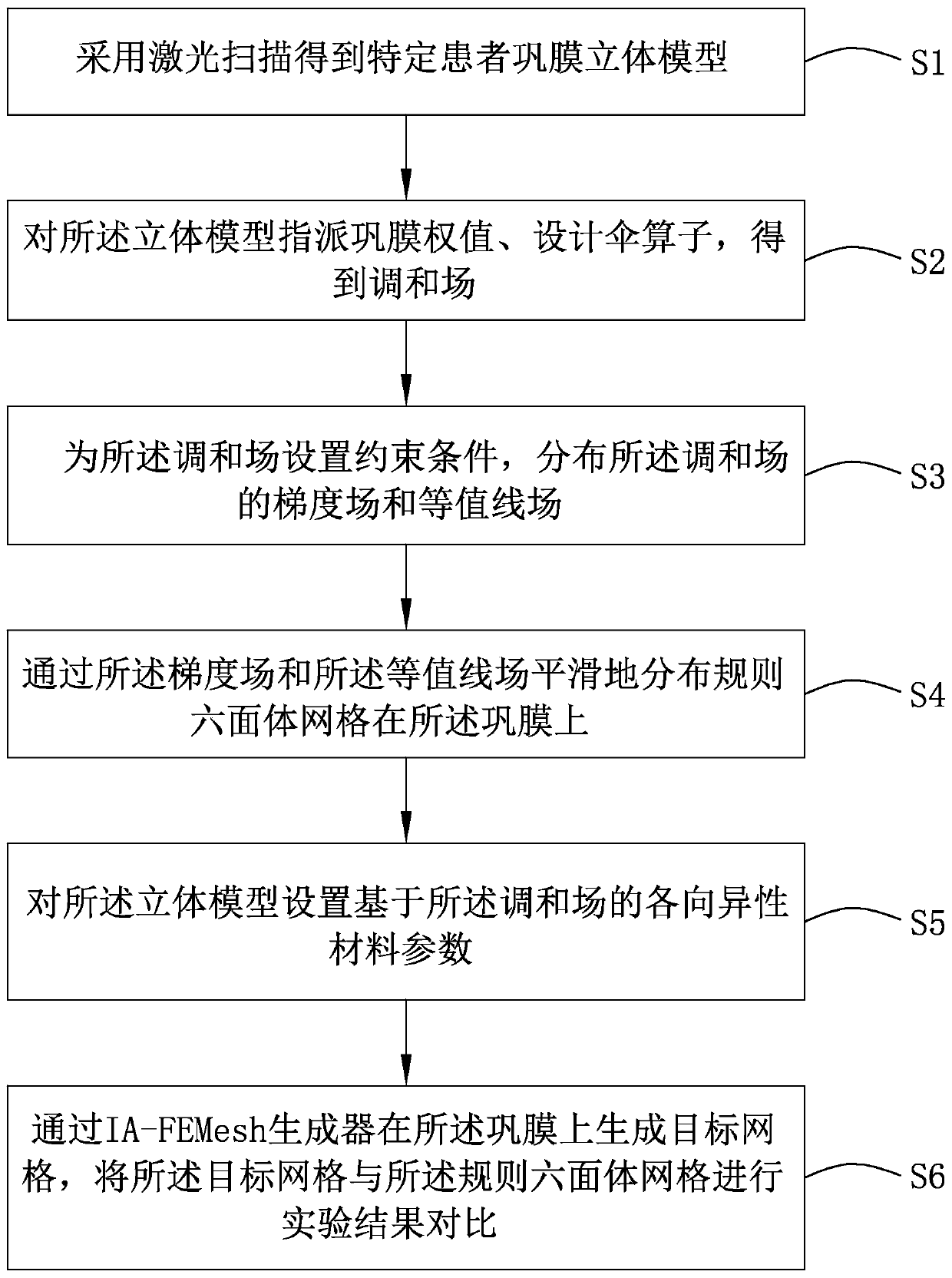

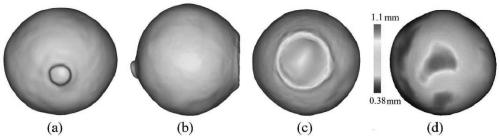

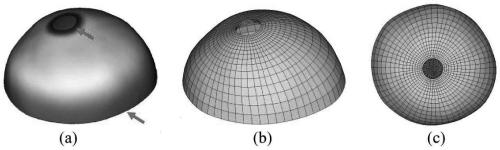

Finite element modeling method of anisotropic patient-specific sclera based on harmonic field

ActiveCN106909724BEffective modelingImprove precision qualityMedical simulation3D modellingLaser scanningEngineering

The invention discloses an anisotropic finite element modeling method based on harmonic field for patient-specific sclera, which comprises the following steps that high precision laser scanning is applied to attain a stereoscopic model of a patient-specific sclera; the stereoscopic model is designated with a sclera weight and provided with a umbrella operator to attain the harmonic field; the harmonic field is provided with constrained conditions, the gradient field and the contour field of the harmonic field are distributed; through the gradient field and the contour field, a regular hexahedral mesh is distributed smoothly on an irregular sclera; the stereoscopic model is provided with anisotropic material parameters based on the harmonic field; the experiment result is compared. The anisotropic finite element modeling method based on harmonic field for patient-specific sclera can provide effective modeling for patient-specific sclera. Anisotropic material orientation field are added, thereby high accuracy and quality of the modeling being guaranteed, and irregular hemisphere sclera being provided with individual parameters.

Owner:CENT SOUTH UNIV

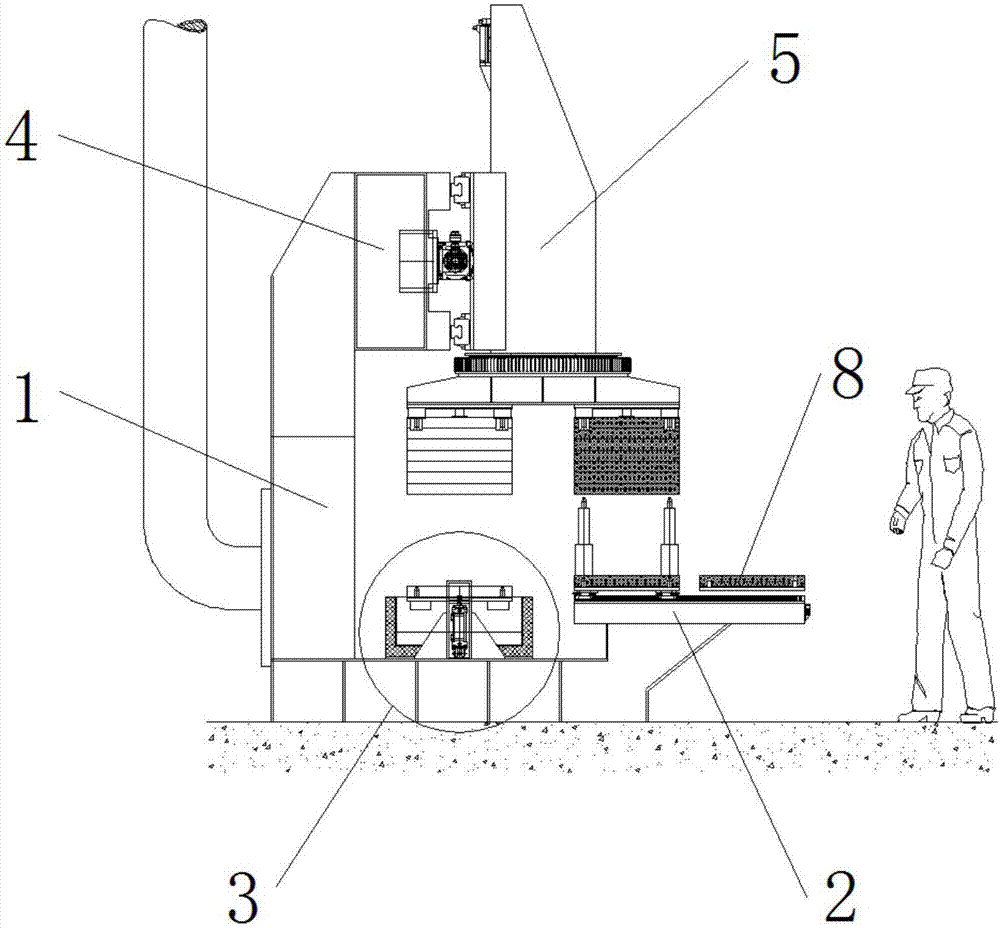

Pattern automatic bonding device

ActiveCN105945223BSimple structureSimplify the installation processLiquid surface applicatorsFoundry moulding apparatusControl systemUltimate tensile strength

The invention discloses a mold sample automatic bonding device. The automatic bonding device is mainly composed of a mold sample shuttling and conveying device, a mucilage glue device, a grabbing and transferring device, a shuttling position changing machine and a control system connected with all components; according to the device, continuous bonding and automatic sprue bonding of a plurality of stations can be achieved at one time, according to mold sample combined needs, corresponding jigs are automatically switched to be used for mounting of different mold samples, and compared with the prior art, the automatic bonding device is high in automatic degree, the cost is further saved while the labor intensity of workers is reduced, the bonding quality of lost foam mold samples is improved, and the bonding efficiency of the mold samples is more obviously improved; and under the tendency of the current enterprise technical innovation transformation, the device has the considerable popularization value.

Owner:CMCU ENG

A high-precision anti-jump waste stamping die

InactiveCN104259298BEasy to limitEasy to fixMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to a high-precision stamping die capable of preventing waste materials from jumping. A punching tool edge is provided with a punching section in an inverted frustum shape. The high-precision stamping die is characterized in that an inlet and an outlet of the stamping die capable of preventing the waste materials from jumping are each provided with a stamped part pressing and limiting mechanism (A) which acts on a stamped part (10). Due to the fact that the inlet and the outlet of the stamping die capable of preventing the waste materials from jumping are each provided with the stamped part pressing and limiting mechanism, the stamped part pressing and limiting mechanisms can act on the stamped part in the horizontal direction and the perpendicular direction, the stamped part is well limited and fixed, and thus the obtained stamped product is higher in precision and quality.

Owner:广州市富工精密制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com