Laser impact tensioning device and method for circular saw web

A technology of laser shock and circular saw blades, which is applied in the direction of heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of unsatisfactory tensioning effect, low efficiency of tensioning process, low degree of automation, etc., and achieve easy automatic control, impact area and pressure can be precisely regulated and used efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined arbitrarily with each other.

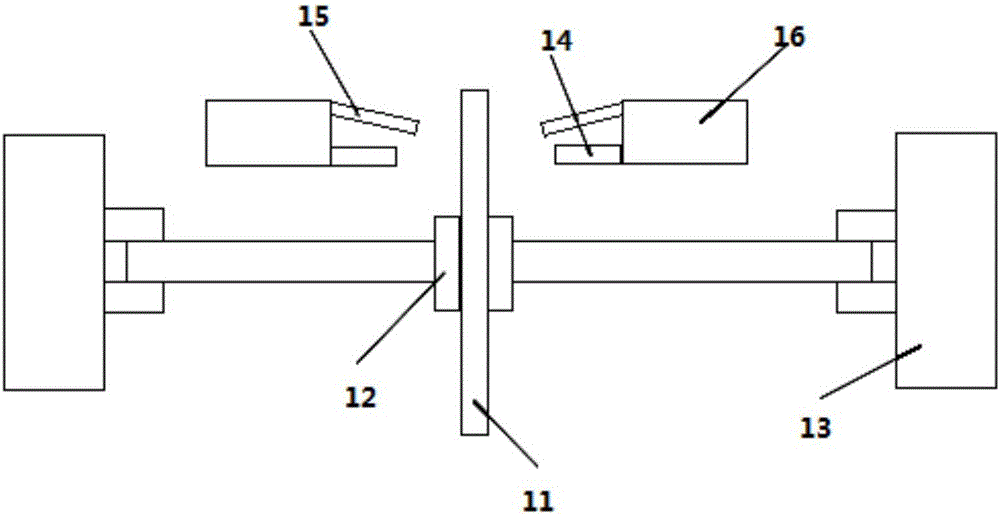

[0037] figure 1 Shown is a specific embodiment of the circular saw blade laser shock tensioning device of the present invention. Wherein, 11 is an ultra-thin circular saw blade, 12 is a fixture, 13 is a rotatable three-jaw chuck, 14 is a laser, 15 is a water delivery device, and 16 is an industrial manipulator.

[0038] The clamp 12 includes two symmetrical parts, each of which includes a chuck and a central axis extending outward from the chuck, and the two parts are used to clamp the ultra-thin circular saw blade 11 from two end faces. After the installation on the clamp 12 is completed, the center line of the ultra-thin circular saw blade 11 coincides with the axis of the cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com