Catalyst for preparing aromatic hydrocarbons through directed conversion of CO2 and preparation method of catalyst

A directional conversion, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, carbon compound catalysts, etc., can solve the problems of stability and repeatability of industrial application of catalyst systems, without quantitative control of the distance between components, Aromatization efficiency is reduced and other problems, to achieve the effect of high repeatability, uniform properties, and high CO2 conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

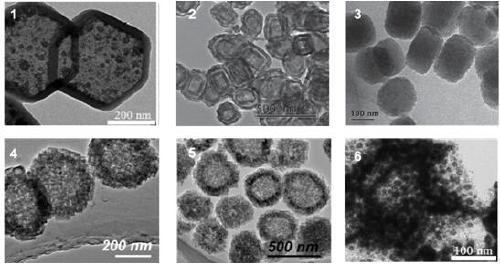

[0024] a CO 2 A catalyst for the directional conversion of aromatics, a core-shell structure Zn@ZSM-5 catalyst with ZnO as the core and ZSM-5 molecular sieve as the shell.

[0025] a CO 2 A method for preparing a Zn@ZSM-5 catalyst for preparing aromatics through directional conversion: comprising the following steps:

[0026] 1) Mix zinc nitrate hexahydrate and terephthalic acid at a molar ratio of 3:1, weigh 50g of the mixture and disperse it in 500mL of N,N-dimethylformamide, stir and mix evenly, and place in a hydrothermal kettle Hydrothermal treatment at 150°C for 12 hours, suction filtration and drying to obtain metal skeleton compound A1;

[0027] 2) Disperse A1 in 500mL of silica sol (silica content 15% (w%)), then add 10g of aluminum nitrate and 0.5g of tetrapropylammonium hydroxide, adjust the pH to 9, place in a hydrothermal kettle at Treat at 180°C for 36 hours, suction filter, and dry to obtain solid powder B1; put solid powder B1 into a muffle furnace and calci...

Embodiment 2

[0029] a CO 2 Catalysts for directional transformation of aromatics to ZrO 2 As the core, the core-shell structure Zr@MCM-41@ZSM-5 catalyst with MCM-41 and ZSM-5 molecular sieve as the shell.

[0030] a CO 2 The preparation method of the Zr@MCM-41@ZSM-5 catalyst for the directional conversion of aromatics: comprising the following steps:

[0031] 1) Mix zirconium chloride and trimesic acid at a molar ratio of 5:1, weigh 40g and dissolve in 300mL N,N-dimethylformamide / formic acid (volume ratio 1:1) mixed solution, stir After uniformity, place in a hydrothermal kettle at 120°C for hydrothermal reaction for 18 hours, filter and dry to obtain metal skeleton compound A2;

[0032]2) Disperse the solid powder A2 in 300mL of silica sol (silica content 15% (w%)), add 0.2g of cetyltrimethylammonium bromide, adjust the pH to 10, and then hydrothermally treat at 180°C for 36h , filtered and dried to obtain solid powder B2; disperse the solid powder B2 in an aqueous aluminum nitrate so...

Embodiment 3

[0034] a CO 2 The catalyst for the directional conversion of aromatics is a core-shell structure ZnCo@ZSM-5 catalyst with ZnO and CoO as the core and ZSM-5 molecular sieve as the shell.

[0035] a CO 2 A method for preparing a ZnCo@ZSM-5 catalyst for preparing aromatics through directional conversion: comprising the following steps:

[0036] 1) Mix zinc nitrate hexahydrate and terephthalic acid at a molar ratio of 3:1, weigh 50g of the mixture and disperse it in 500mL of N,N-dimethylformamide, stir and mix evenly, and place in a hydrothermal kettle Hydrothermal treatment at 150°C for 12 hours, suction filtration, and drying to obtain metal-organic framework compound A3; mix cobalt nitrate hexahydrate and 2-methylimidazole at a molar ratio of 4:1, weigh 50 g of the mixture and disperse it in 300 mL of methanol, After mixing evenly, place in a hydrothermal kettle for 12 hours at 100°C, filter and dry to obtain metal organic framework compound A4;

[0037] 2) Mix the solid pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com