Patents

Literature

52 results about "Green wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

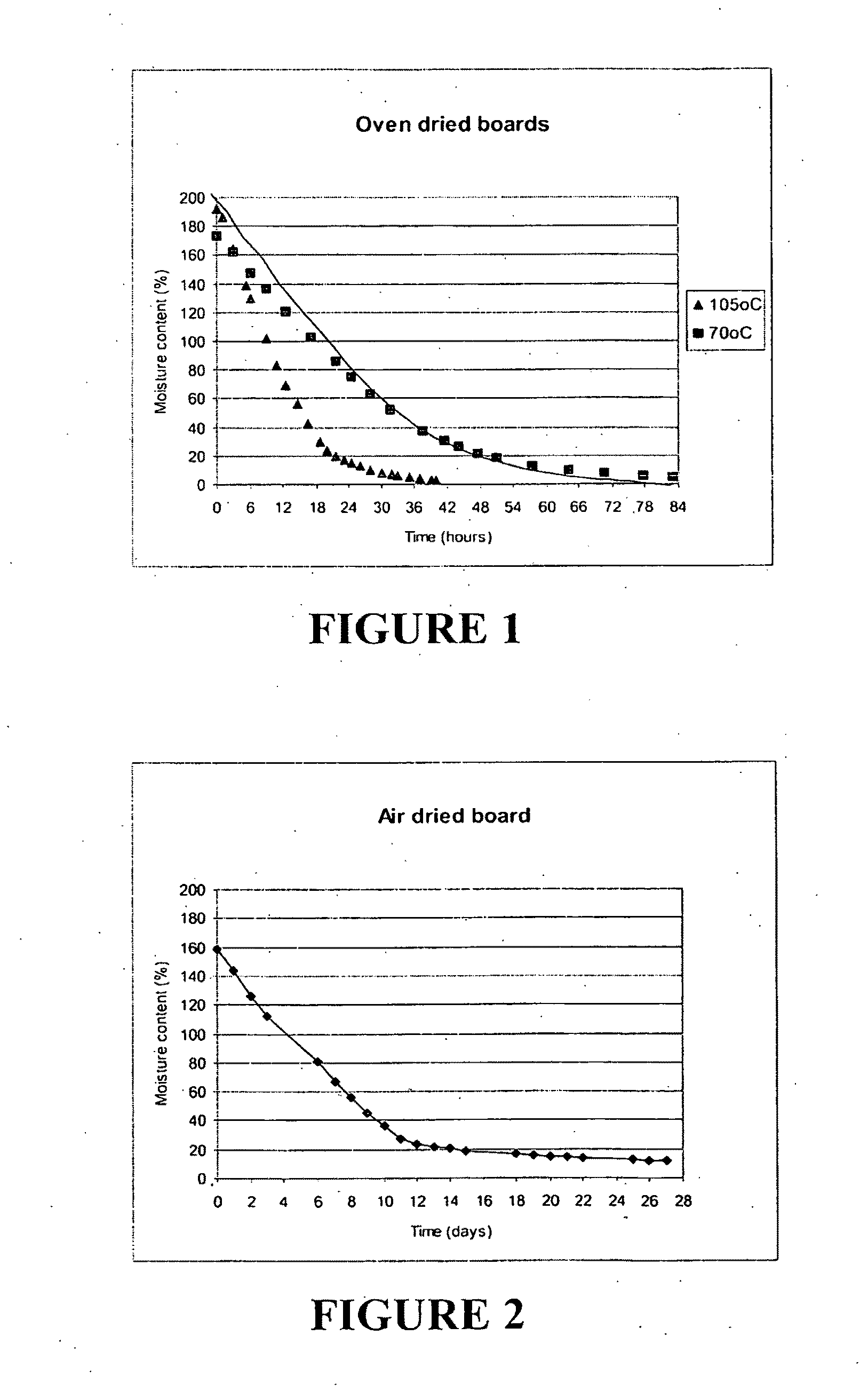

Green wood is wood that has been recently cut and therefore has not had an opportunity to season (dry) by evaporation of the internal moisture. Green wood contains more moisture than seasoned wood, which has been dried through passage of time or by forced drying in kilns. Green wood is considered to have 100% moisture content relative to air-dried or seasoned wood which is considered to be 20%. Energy density charts for wood fuels tend to use air-dried wood as their reference, thus oven-dried or 0% moisture content can reflect 103.4% energy content.

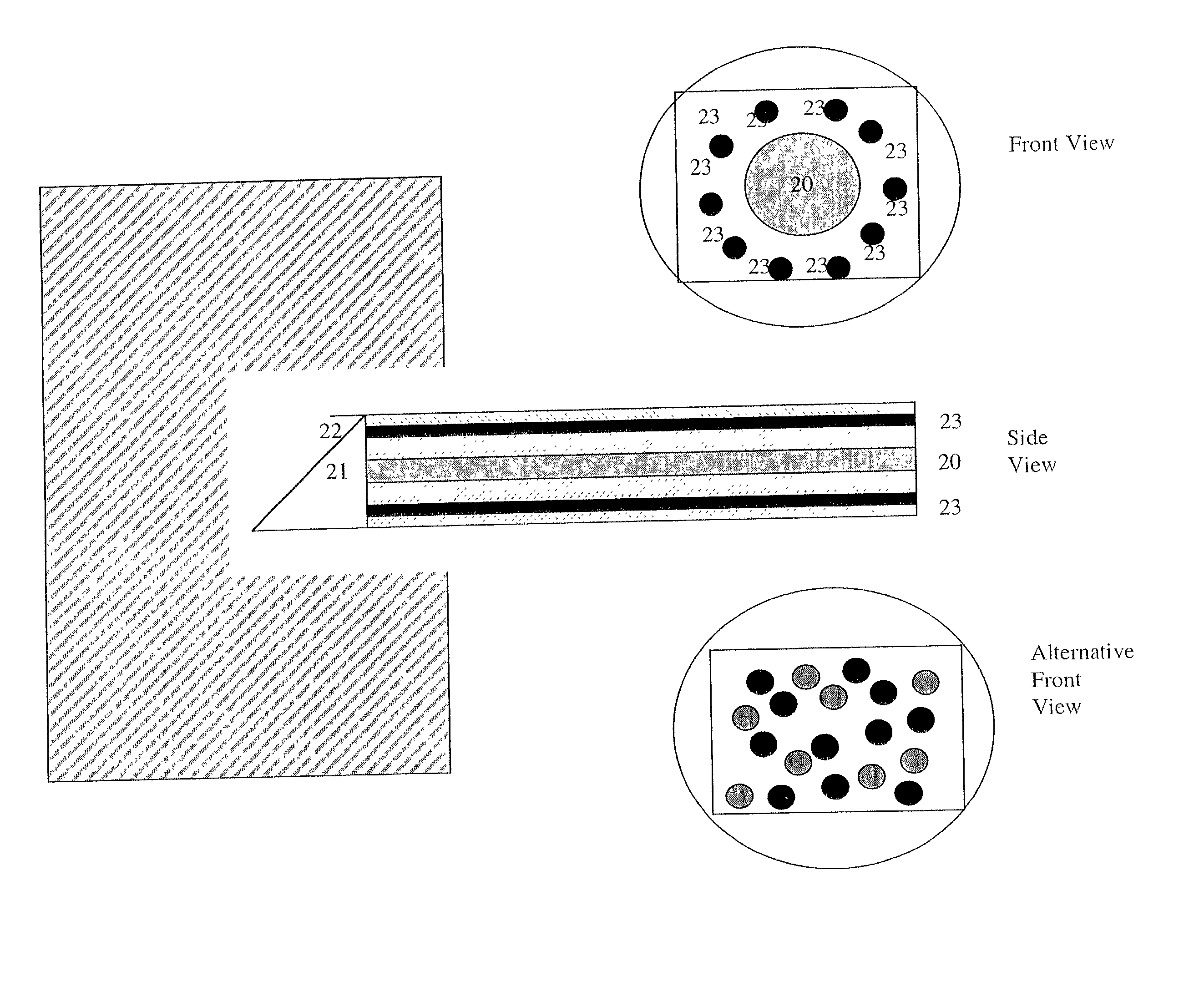

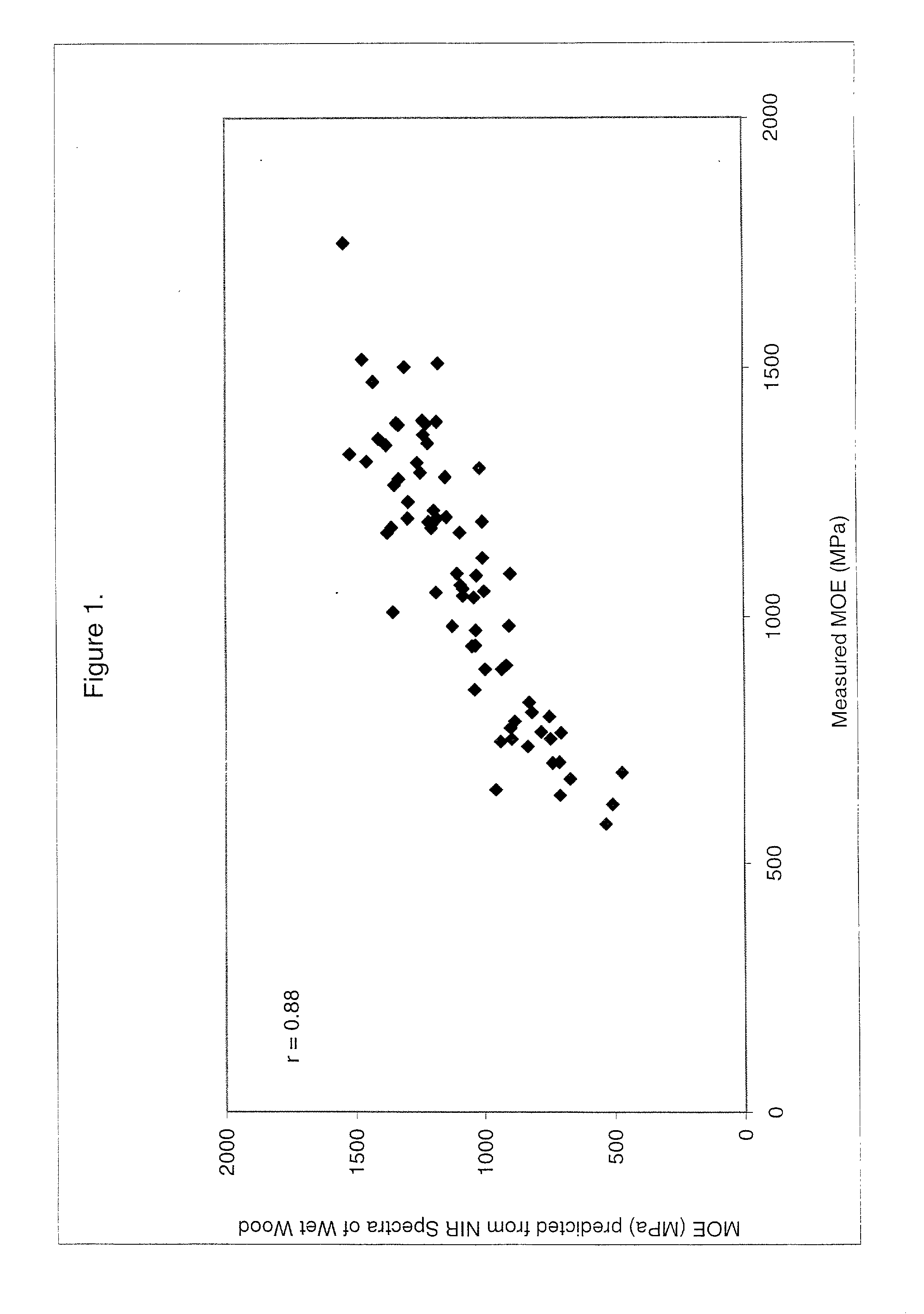

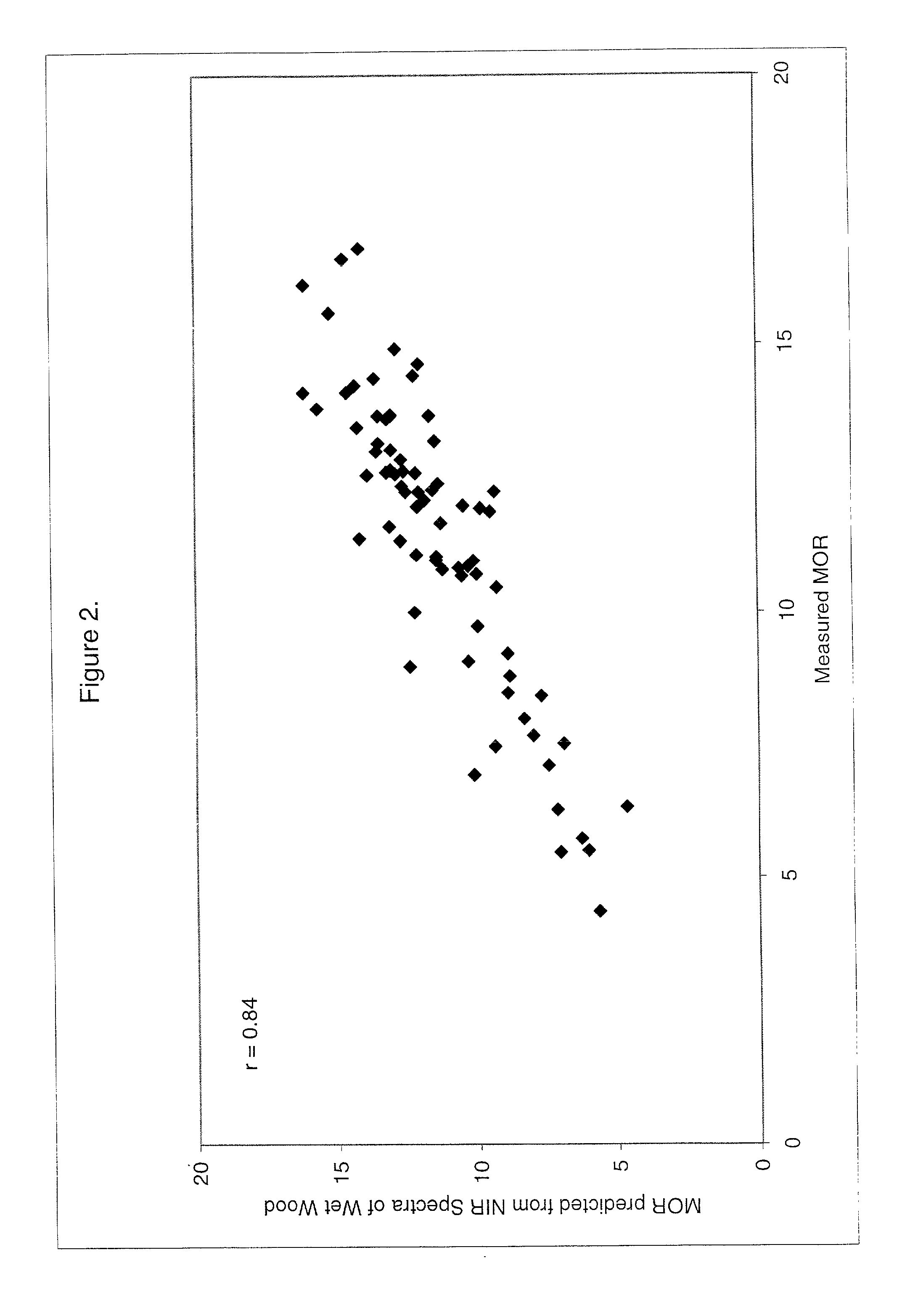

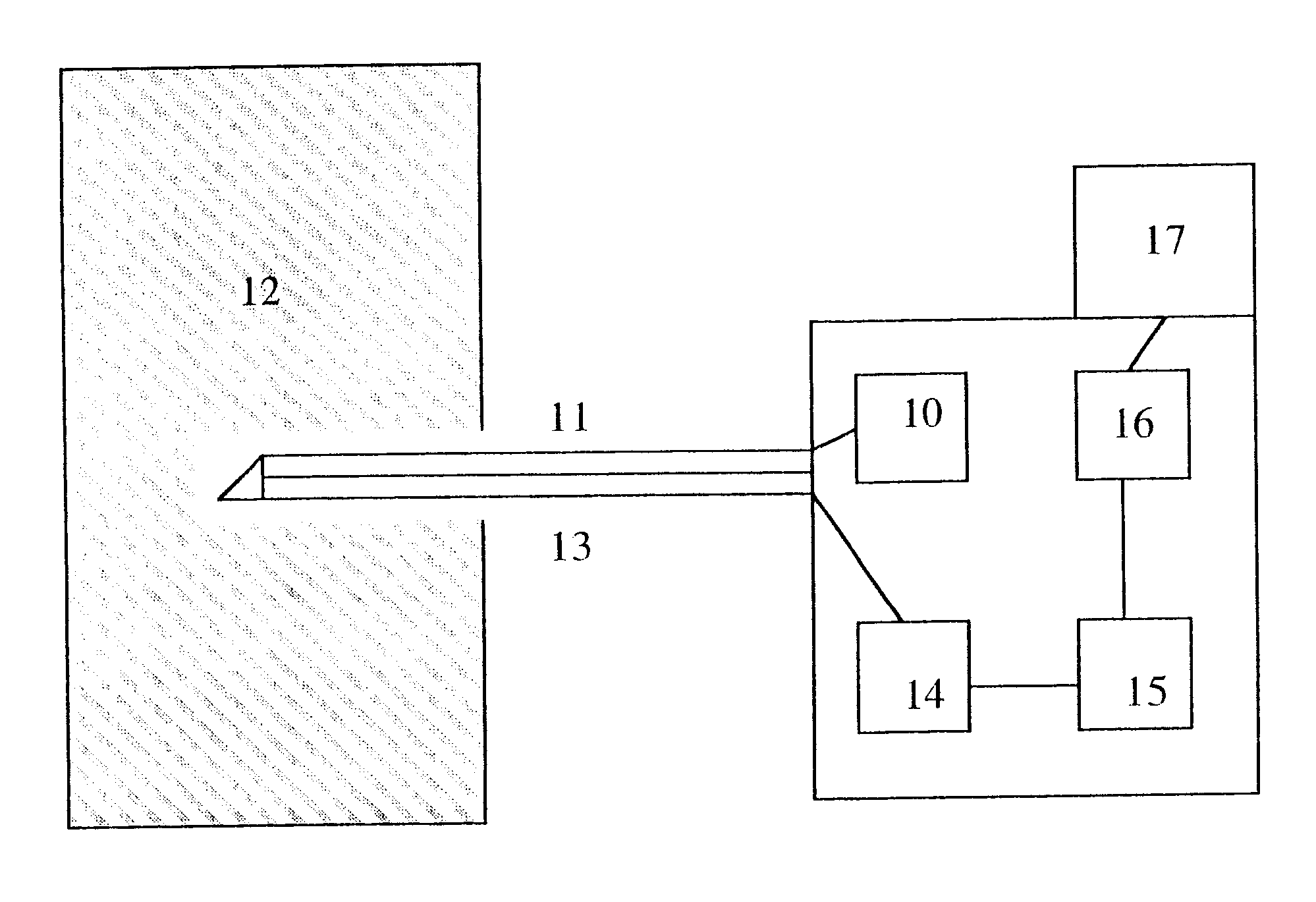

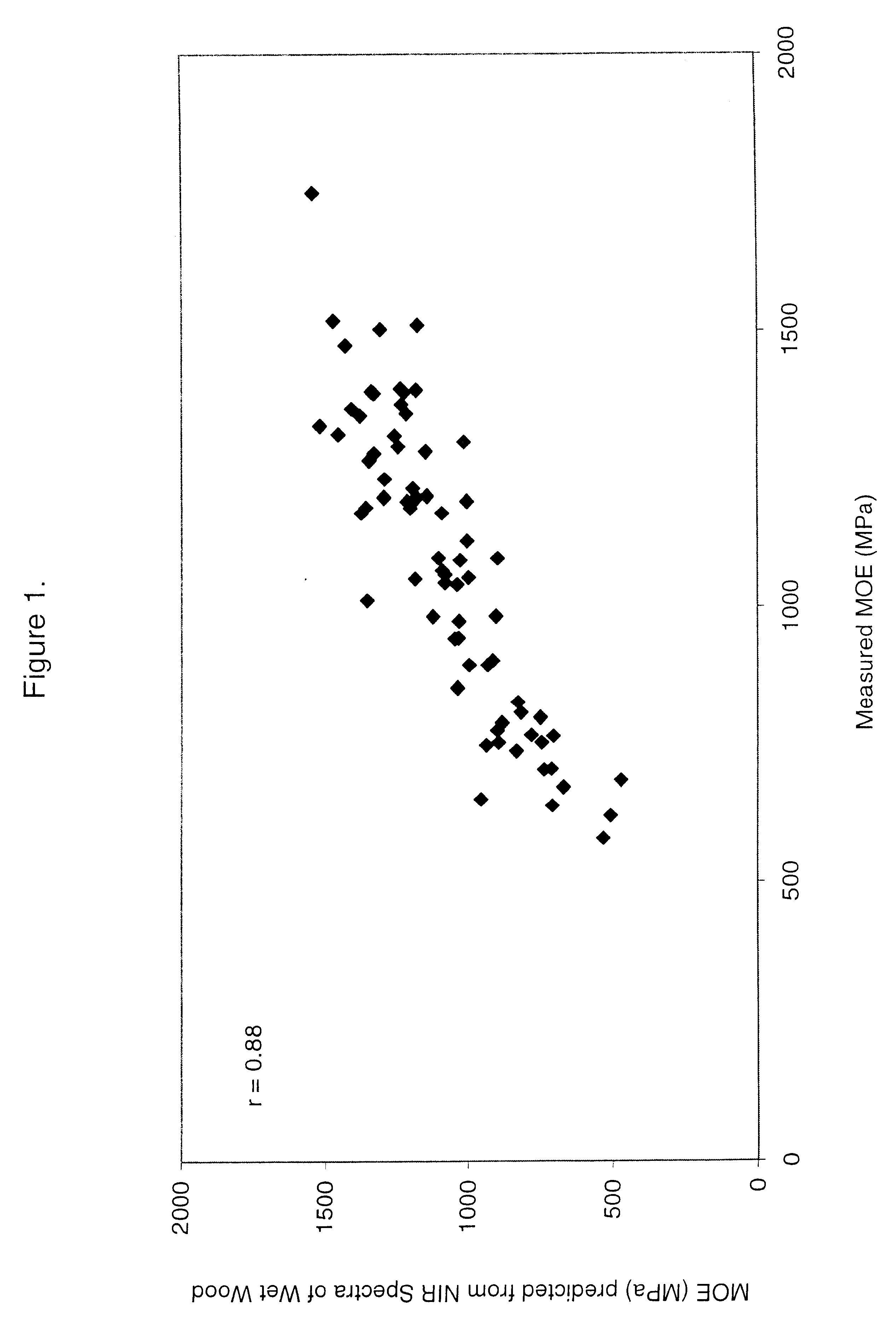

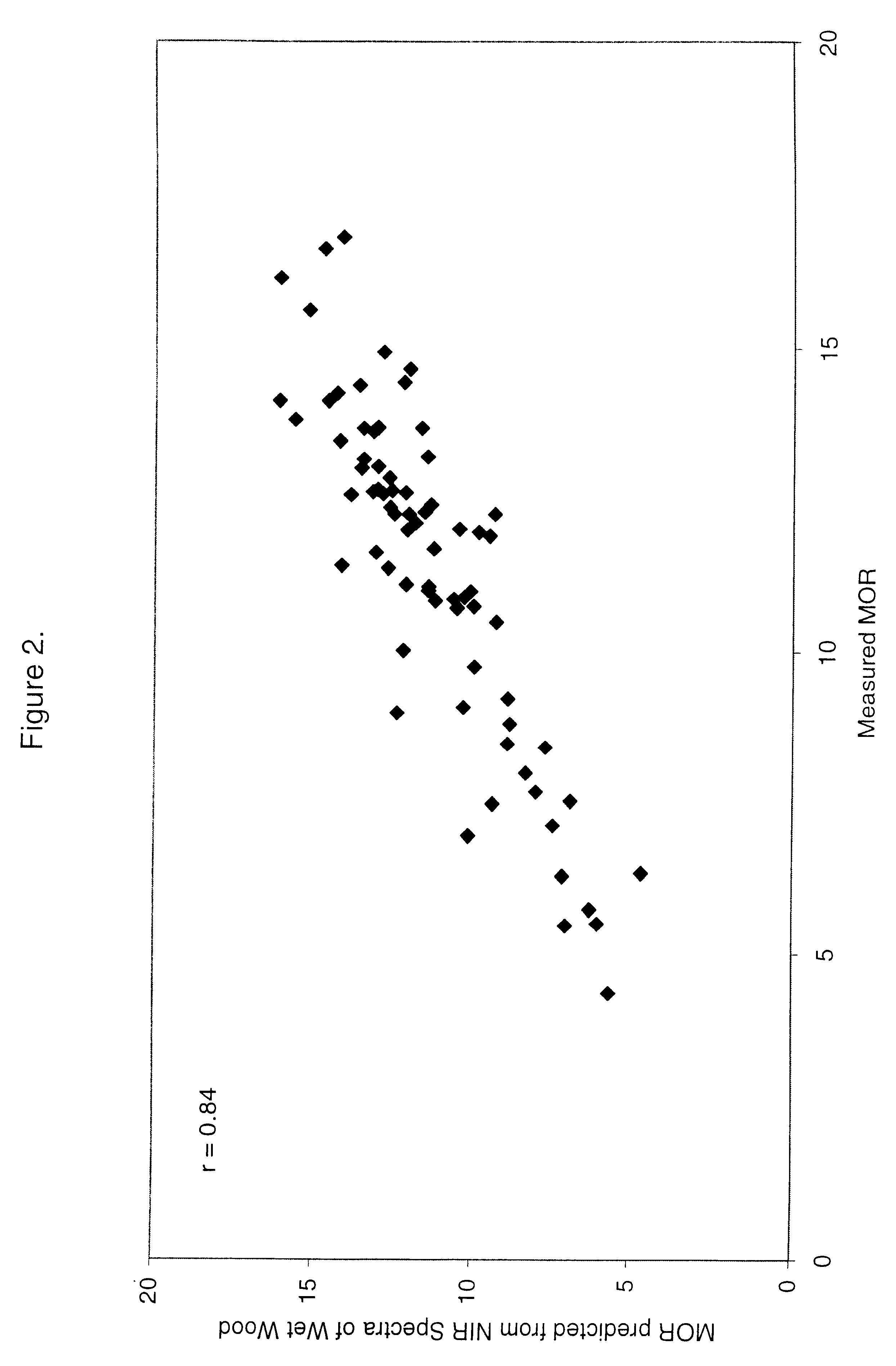

Use of a region of the visible and near infrared spectrum to predict mechanical properties of wet wood and standing trees

InactiveUS20020113212A1The process is fast and accurateEasy accessRadiation pyrometryColor/spectral properties measurementsGreen woodNir spectra

In a method for determining the dry mechanical strength for a green wood, the improvement comprising: (a) illuminating a surface of the wood to be determined with a reduced range of wavelengths in the VIS-NIR spectra 400 to 1150 nm, said wood having a green moisture content; (b) analyzing the surface of the wood using a spectrometric method, the method generating a first spectral data of a reduced range of wavelengths in VIS-NIR spectra; and (c) using a multivariate analysis technique to predict the mechanical strength of green wood when dry by comparing the first spectral data with a calibration model, the calibration model comprising a second spectrometric method of spectral data of a reduced range of wavelengths in VIS-NIR spectra obtained from a reference wood having a green moisture content, the second spectral being correlated with a known mechanical strength analytical result obtained from the reference wood when dried and a having a dry moisture content.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Use of a region of the visible and near infrared spectrum to predict mechanical properties of wet wood and standing trees

InactiveUS6525319B2The process is fast and accurateRadiation pyrometryColor/spectral properties measurementsMultivariate analysisMoisture

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

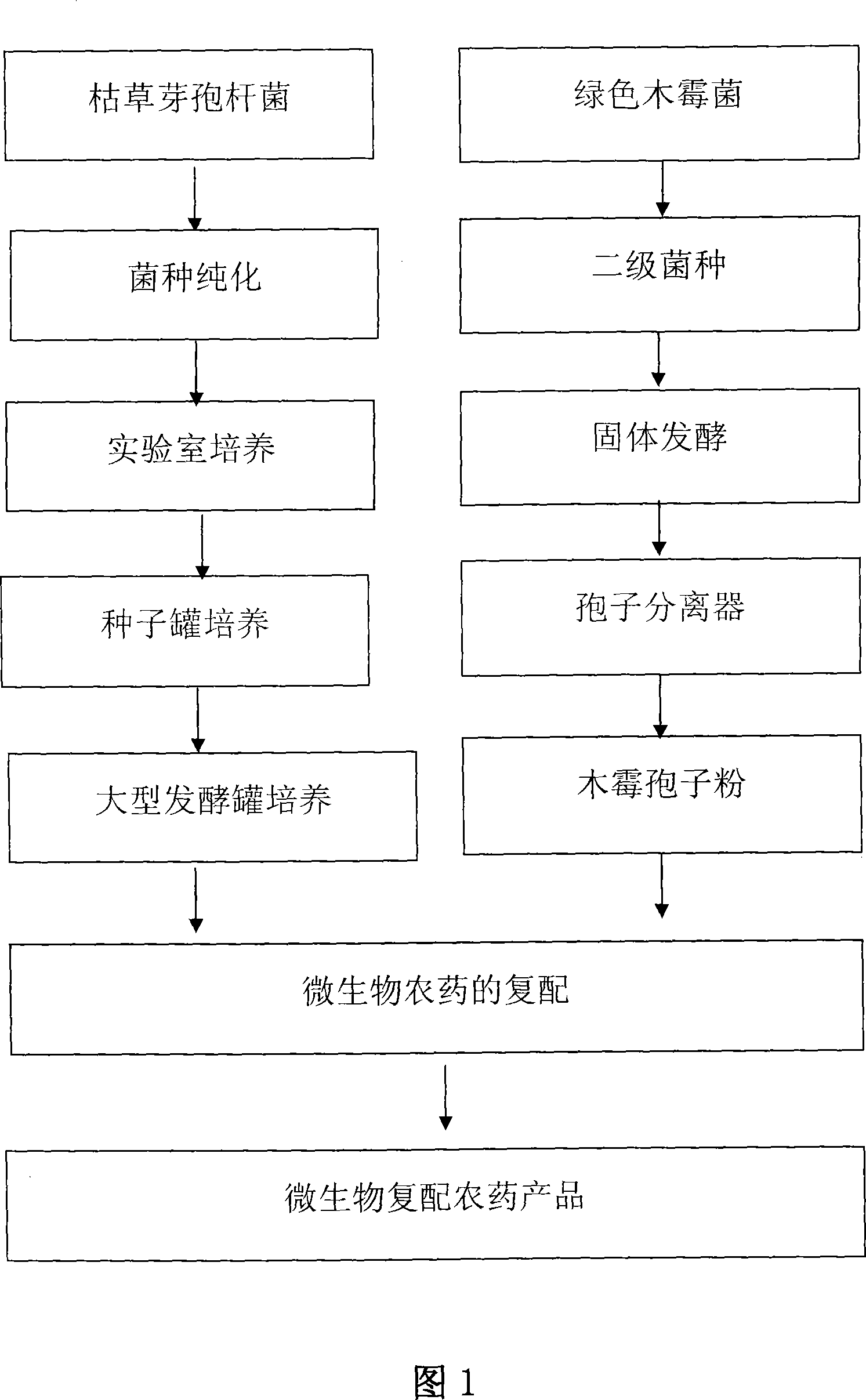

Biocontrol bacteria compound agent for preventing and controlling crop soil-infectious diseases and preparation method

The invention discloses a biological bacterium prevention compound agent used for preventing and curing a soil-borne disease of the crops, which is characterized in that the contents and weight ratios of all components are: 7 to 9 of dried grass fungus gemma bacillus fermentation broth, 7 to 9 of green wood mold sporule powder, 60 to 80 of diatomaceous earth or light calcium carbonate, 1 to 3 of potassium acid phosphate and 2 to 5 of sodium lignin sulfonate. Through the ferment cultivating to the dried grass fungus gemma bacillus, the fermentation broth is obtained, and the fermentation broth with certain bacterium content is compounded with the green wood mold sporule powder, a microorganism compound agricultural drug is made based on a carrier of diatomaceous earth and by adding suitable nourishing elements. The dried grass fungus gemma bacillus and the green wood mold sporule powder form an effect of mutual predominance compensation. The invention is used for preventing and curing soil-borne diseases, such as a damping off disease, a stand drying disease, a root corrosion disease and a blast which are caused by corrupting leaf mold and fusarium. The product is harmless and is steady and durable in drug effect.

Owner:SHENYANG AGRI UNIV

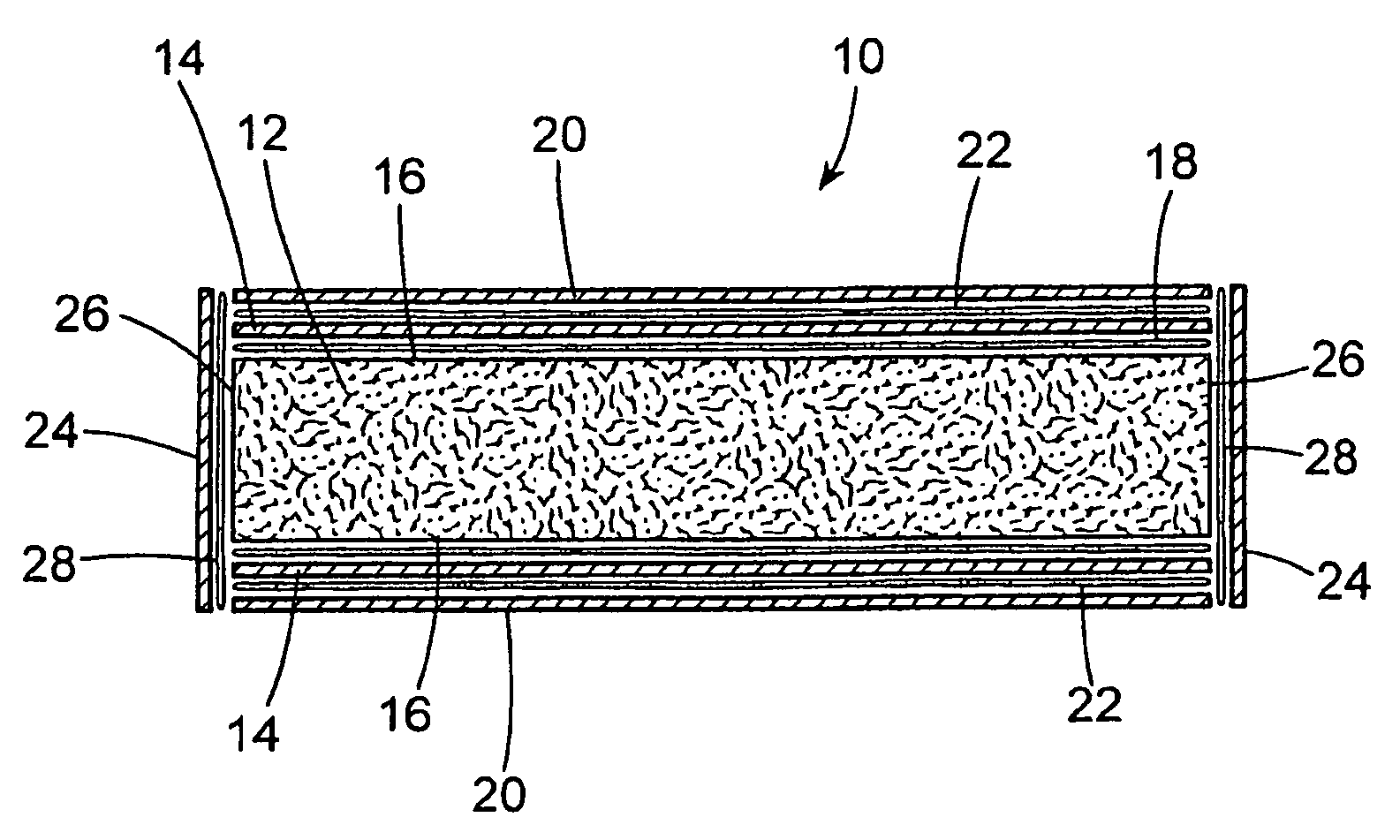

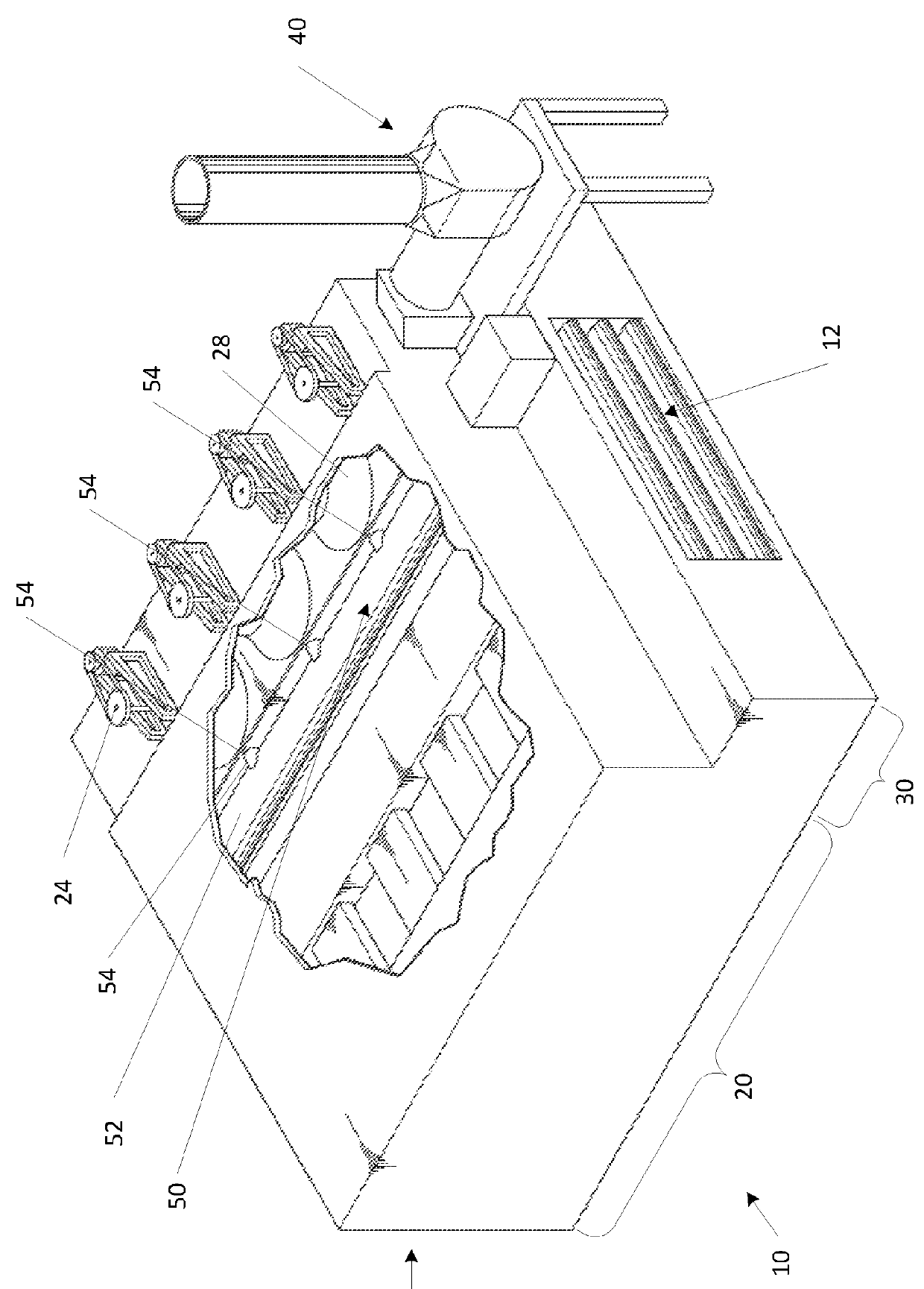

Laminate manufacturing system, method, and article of manufacture

InactiveUS20090291286A1Convenient and efficientLight weightOther plywood/veneer working apparatusFibreboardGreen woodManufacturing systems

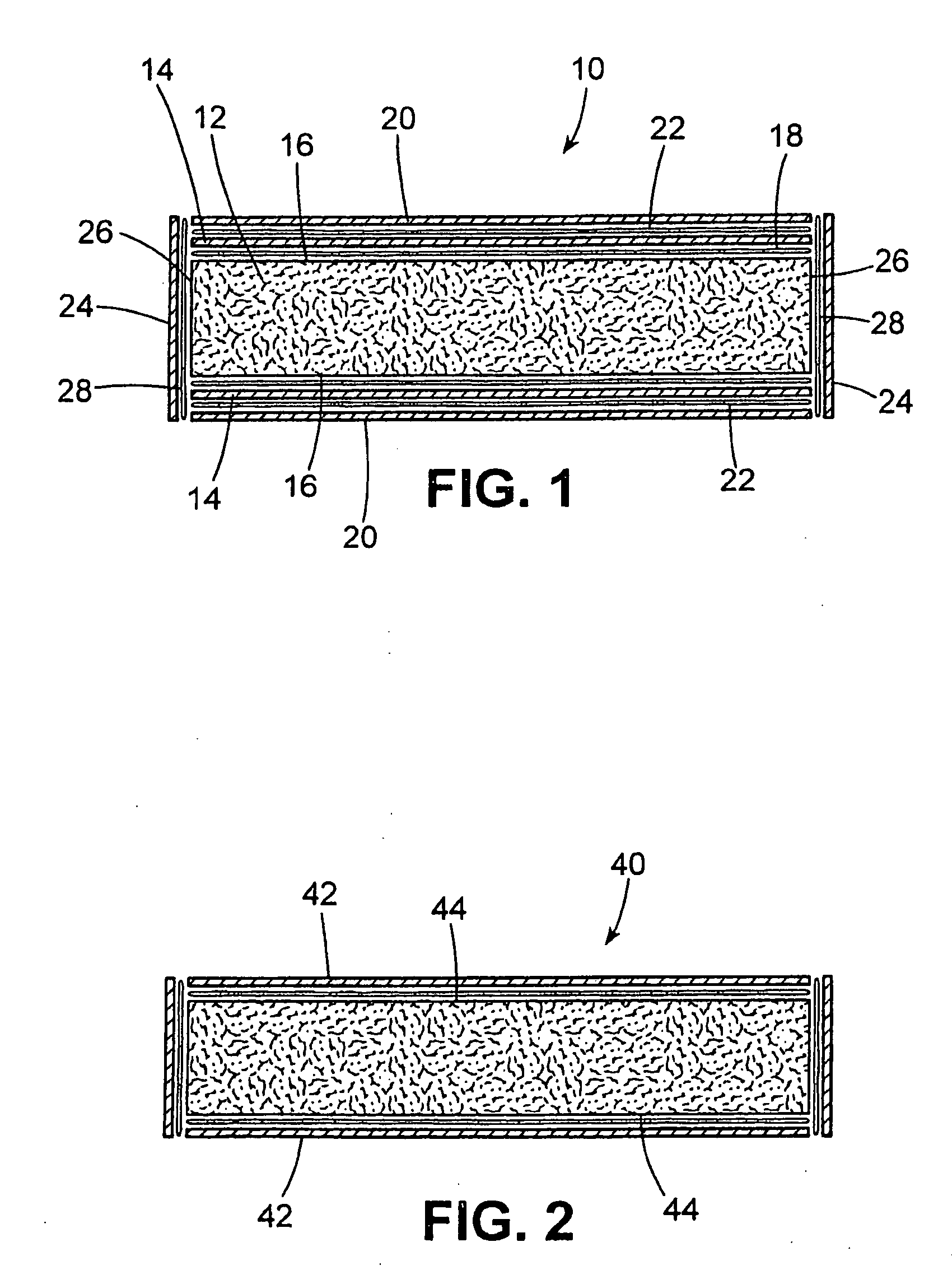

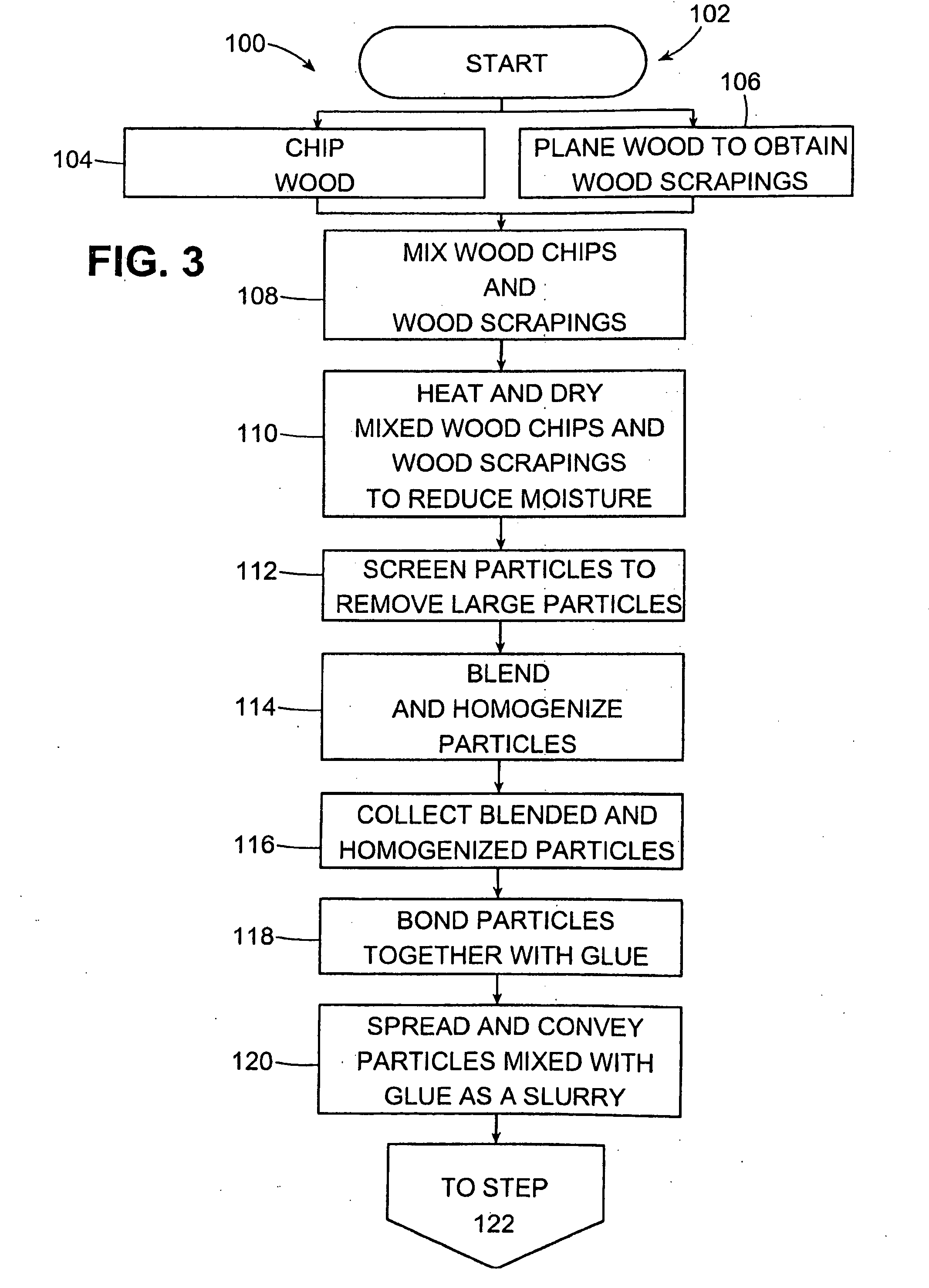

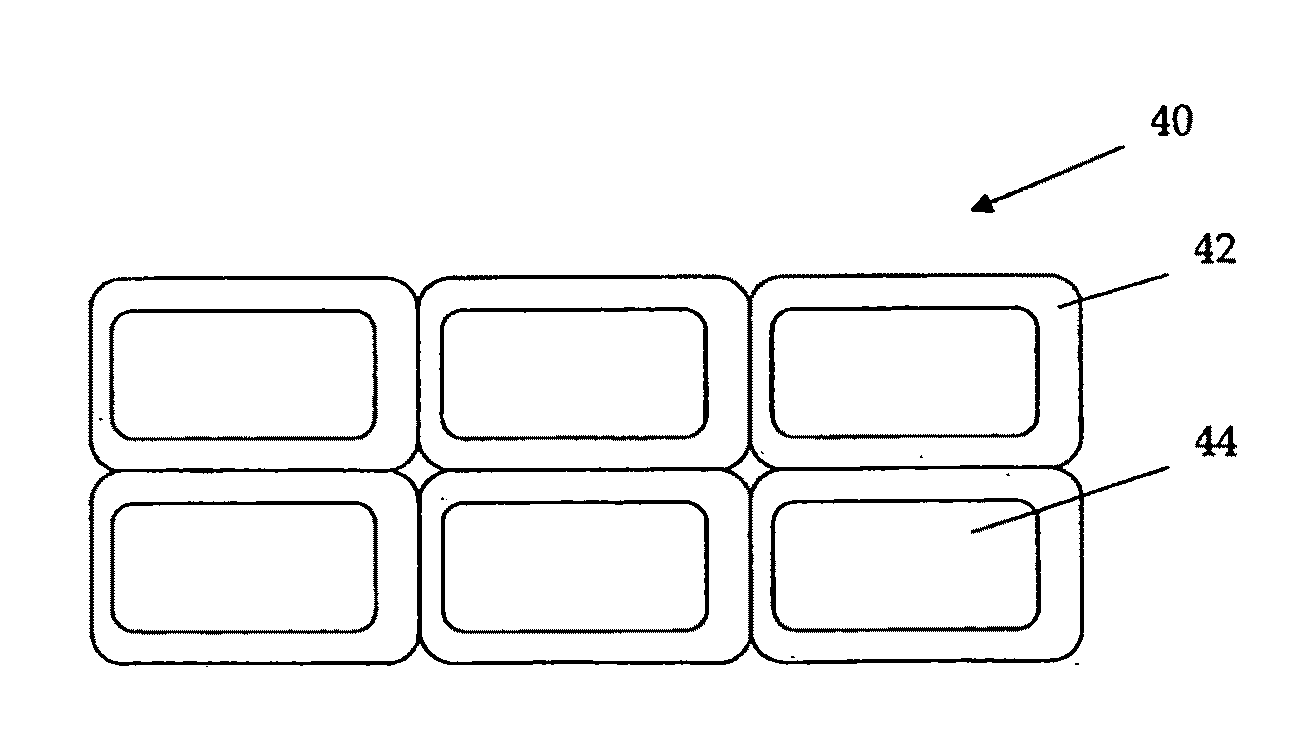

A laminate manufacturing system, method, and article of manufacture, the article of manufacture having a core of fresh or green wood and / or recycled wood products, processed down to a particle size of less than 5 mm, and preferably less than 3 mm, and bonded together with glue, opposing surface inner veneer bonded to opposing surfaces of the core with glue, opposing surface outer veneer bonded to opposing surface inner veneer with glue, opposing edge veneer bonded to opposing edges of the core with glue. Each of the veneers is preferably 0.5 mm thick, although suitable veneer thicknesses may range from 0.3 to 0.5 mm. The article of manufacture thus produced is a laminated wood product having a particle to glue ratios that provides a durable, lightweight, strong attractive product that gives the appearance of wood.

Owner:SHEN ZIMING

Wood drying

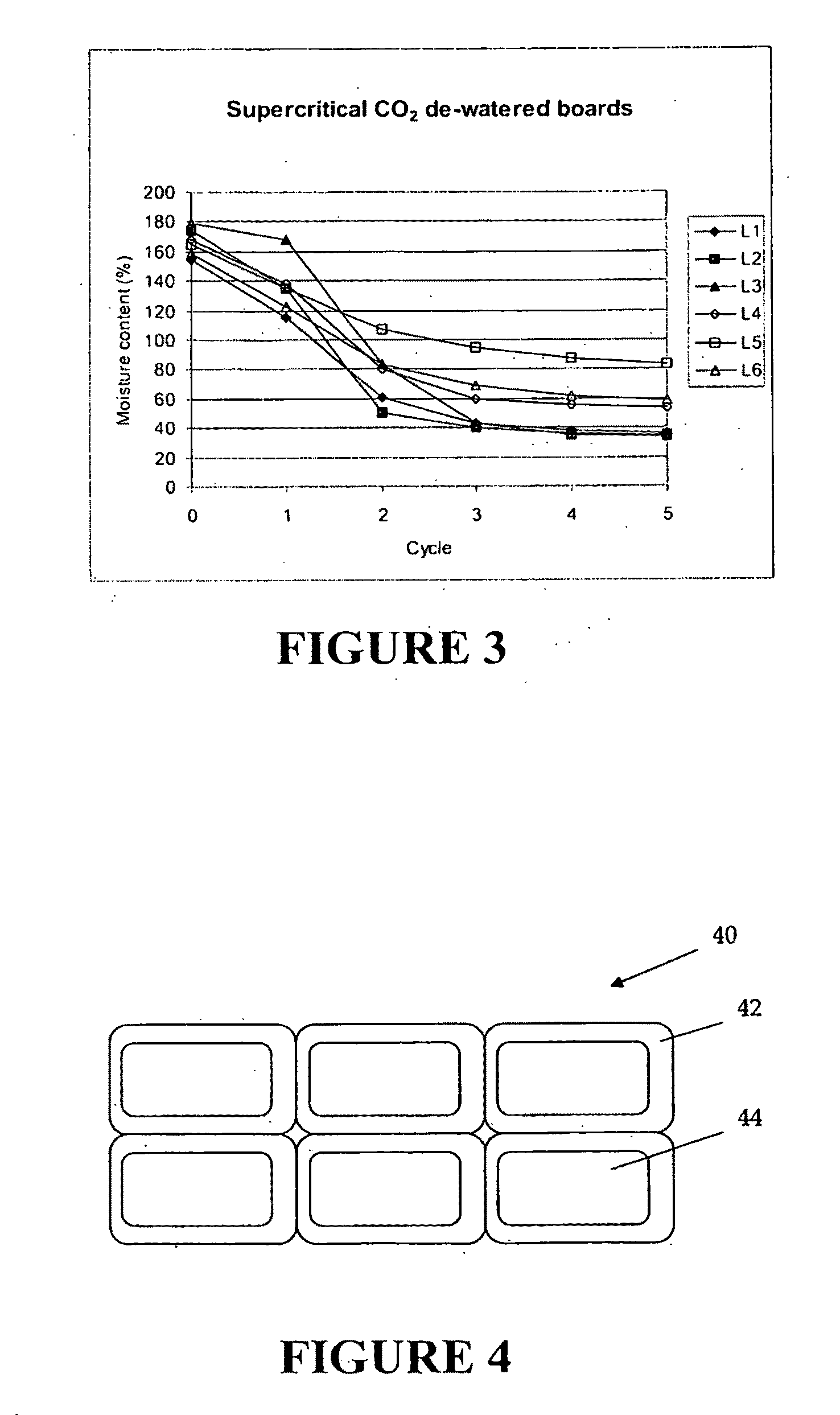

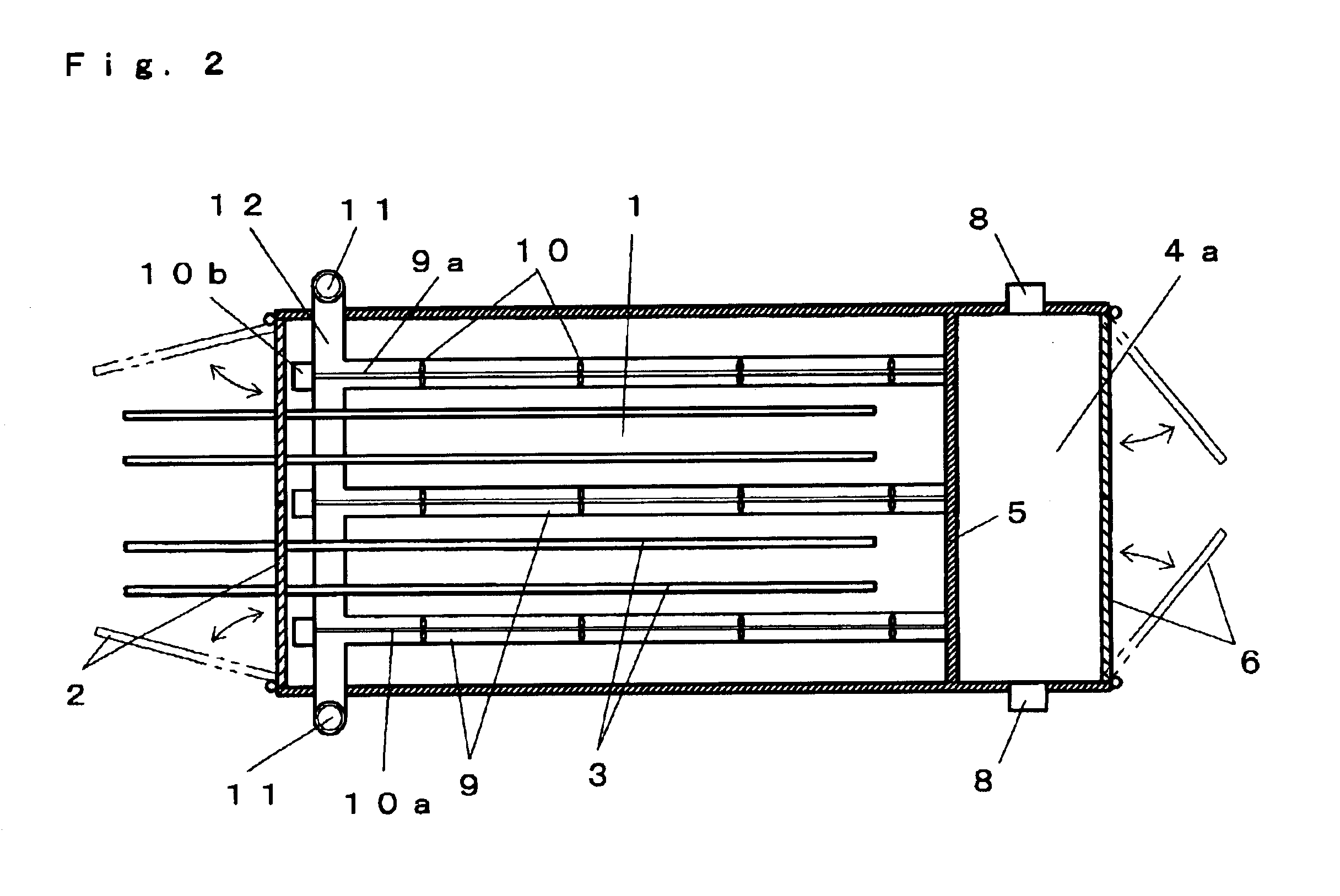

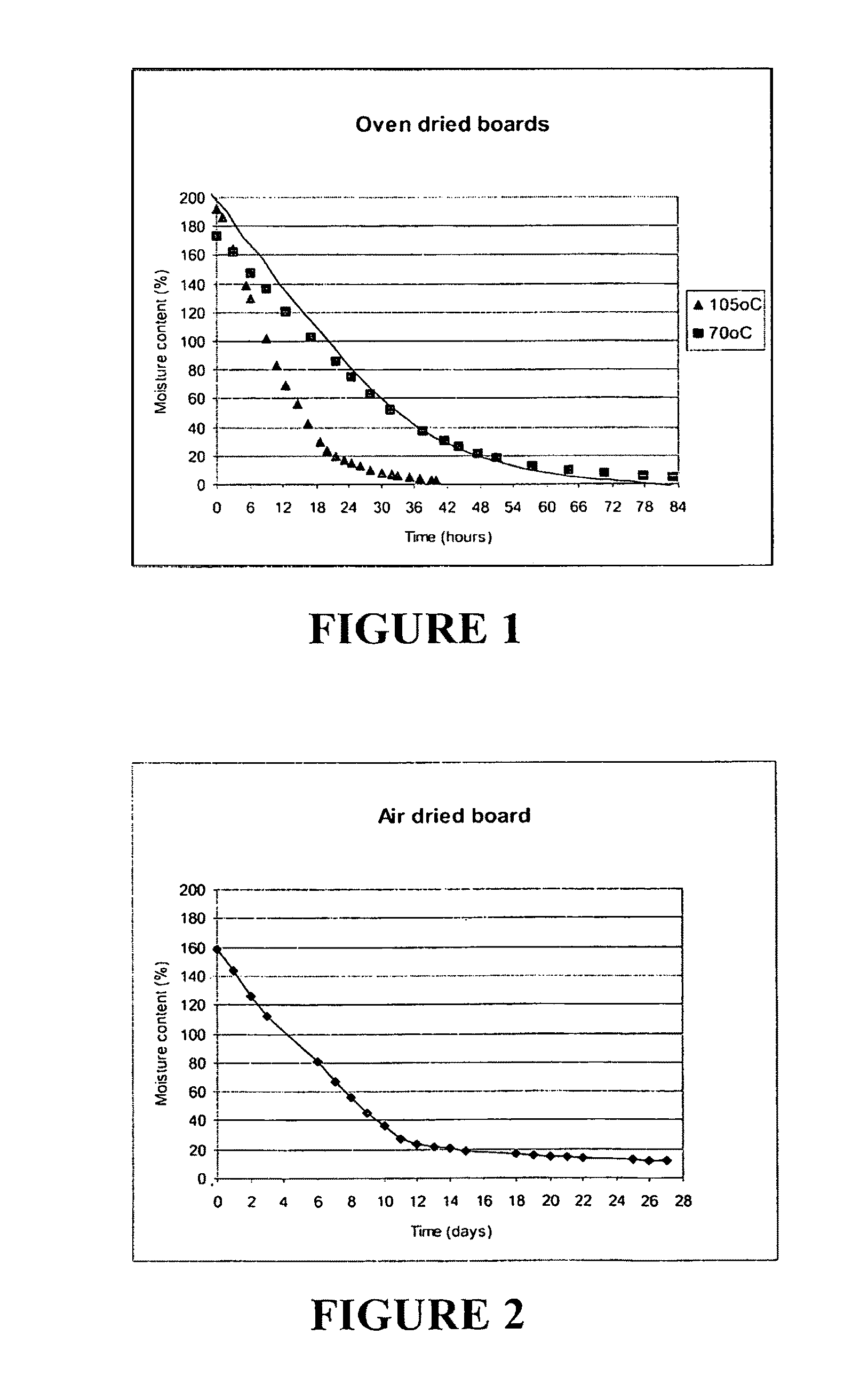

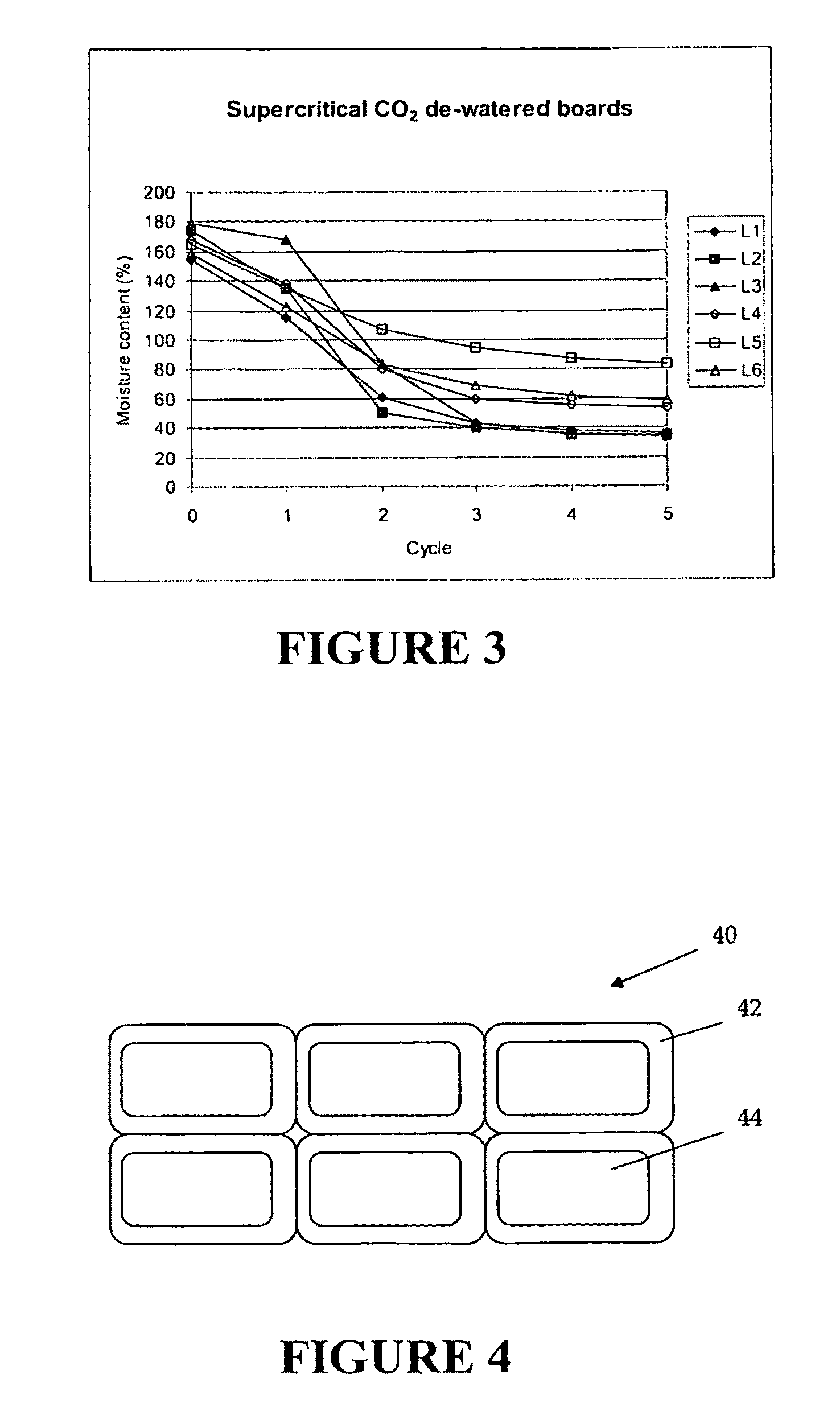

InactiveUS20100058607A1Increase biological durability durabilityExcellent physical durabilityDrying using combination processesPressure wood treatmentGreen woodCell wall

A process for removing water and solutes from the lumens of green wood, while leaving the cell walls throughout the wood uniformly fully swollen, comprises subjecting the green wood to supercritical carbon dioxide.

Owner:NEW ZEALAND FOREST RES INST

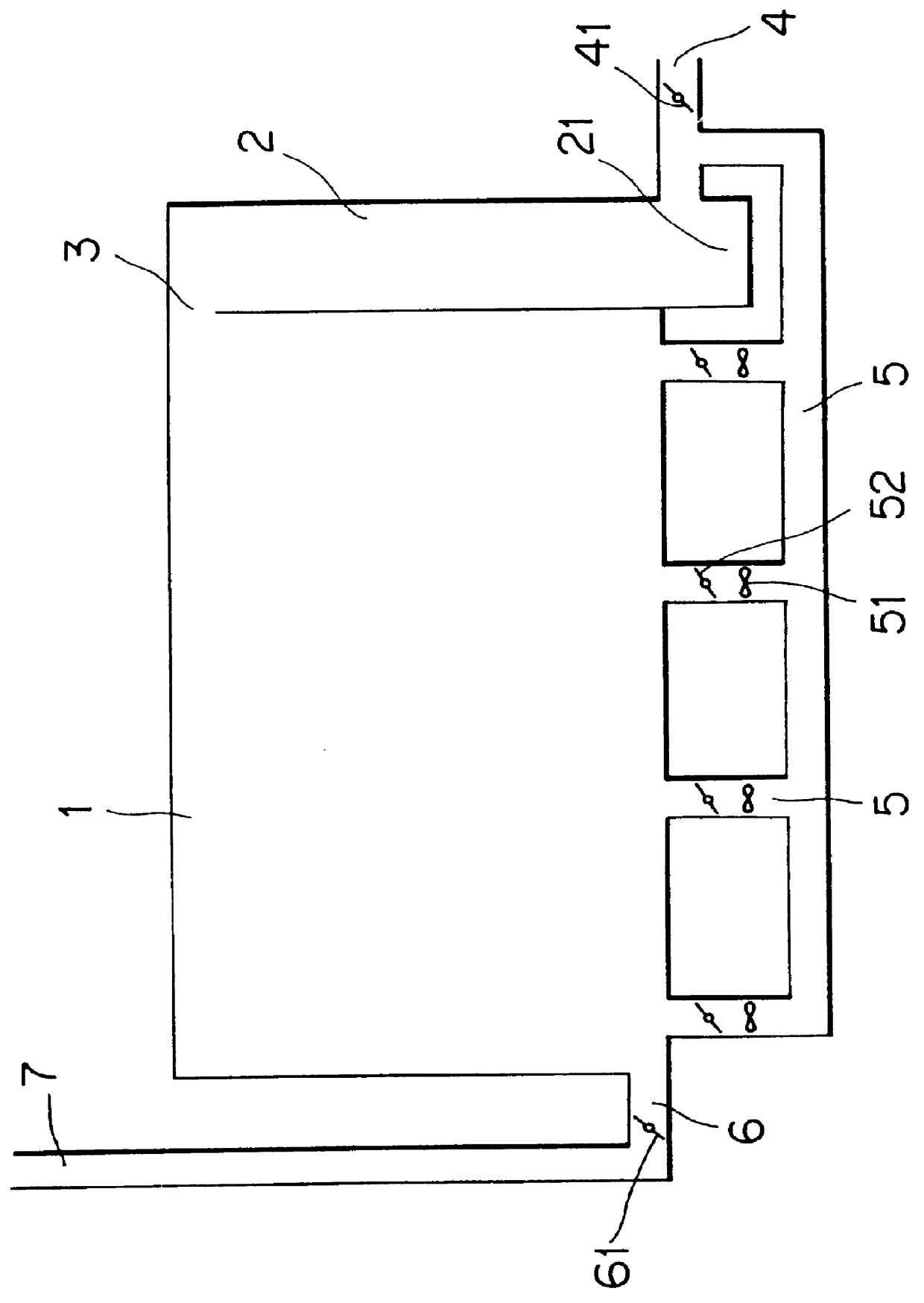

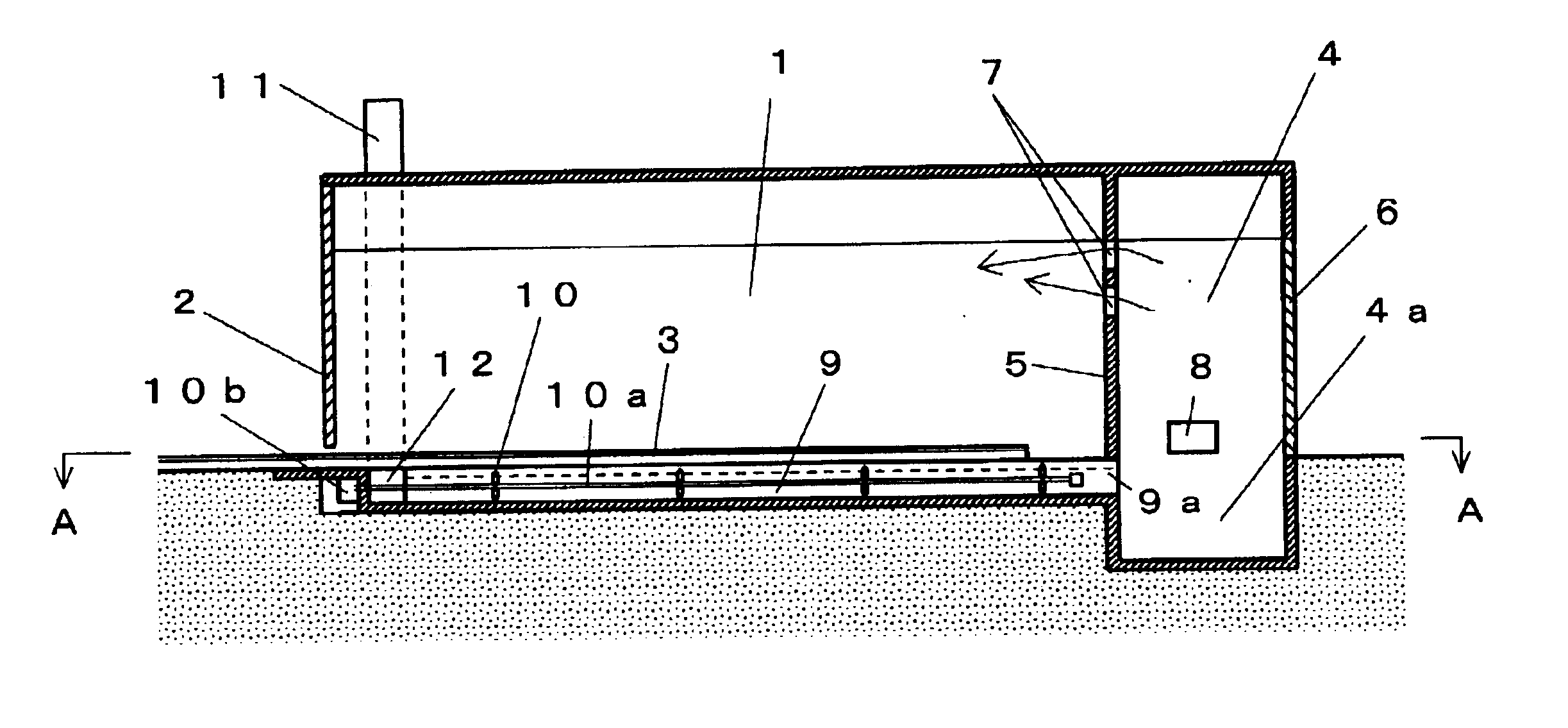

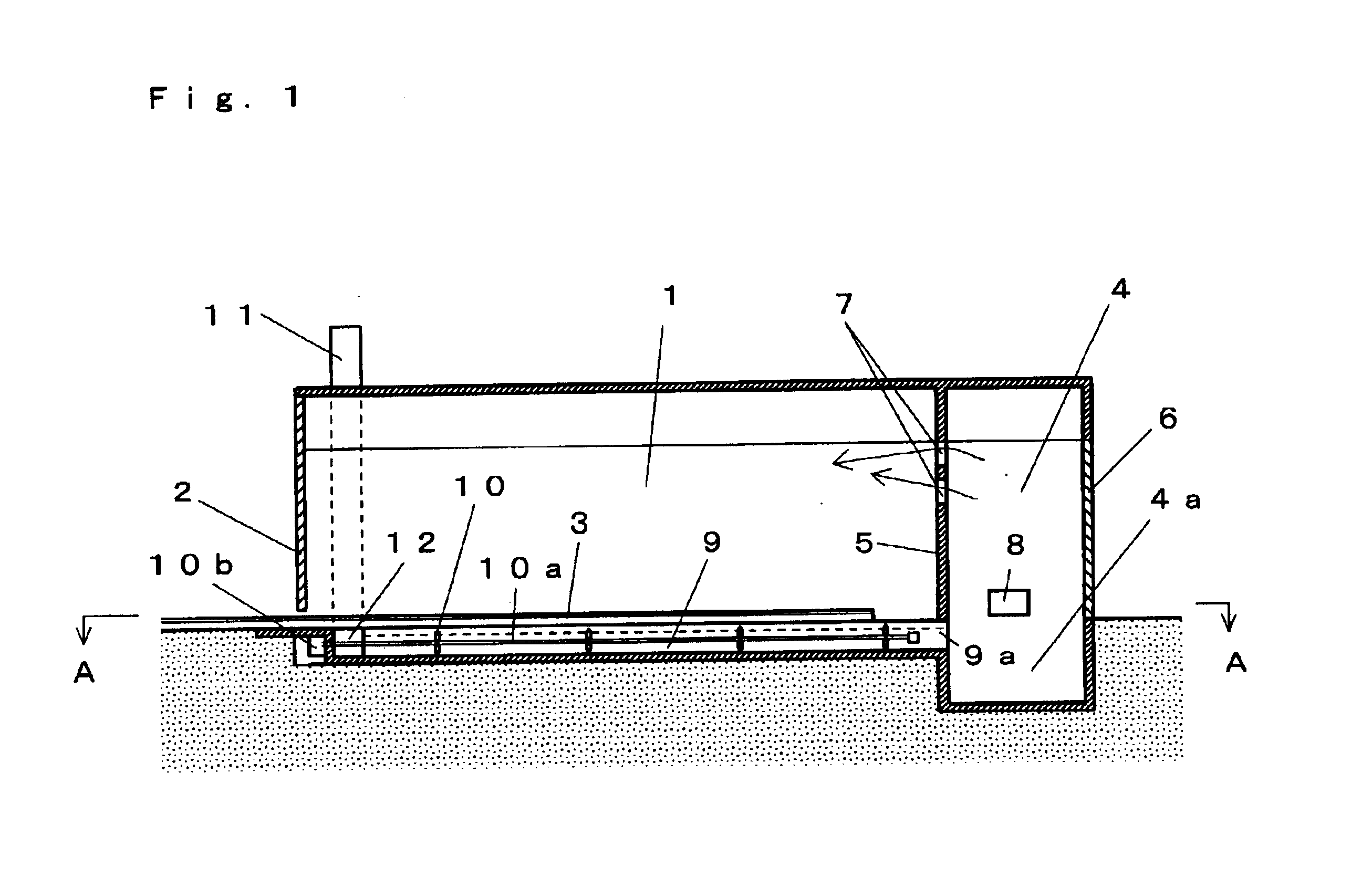

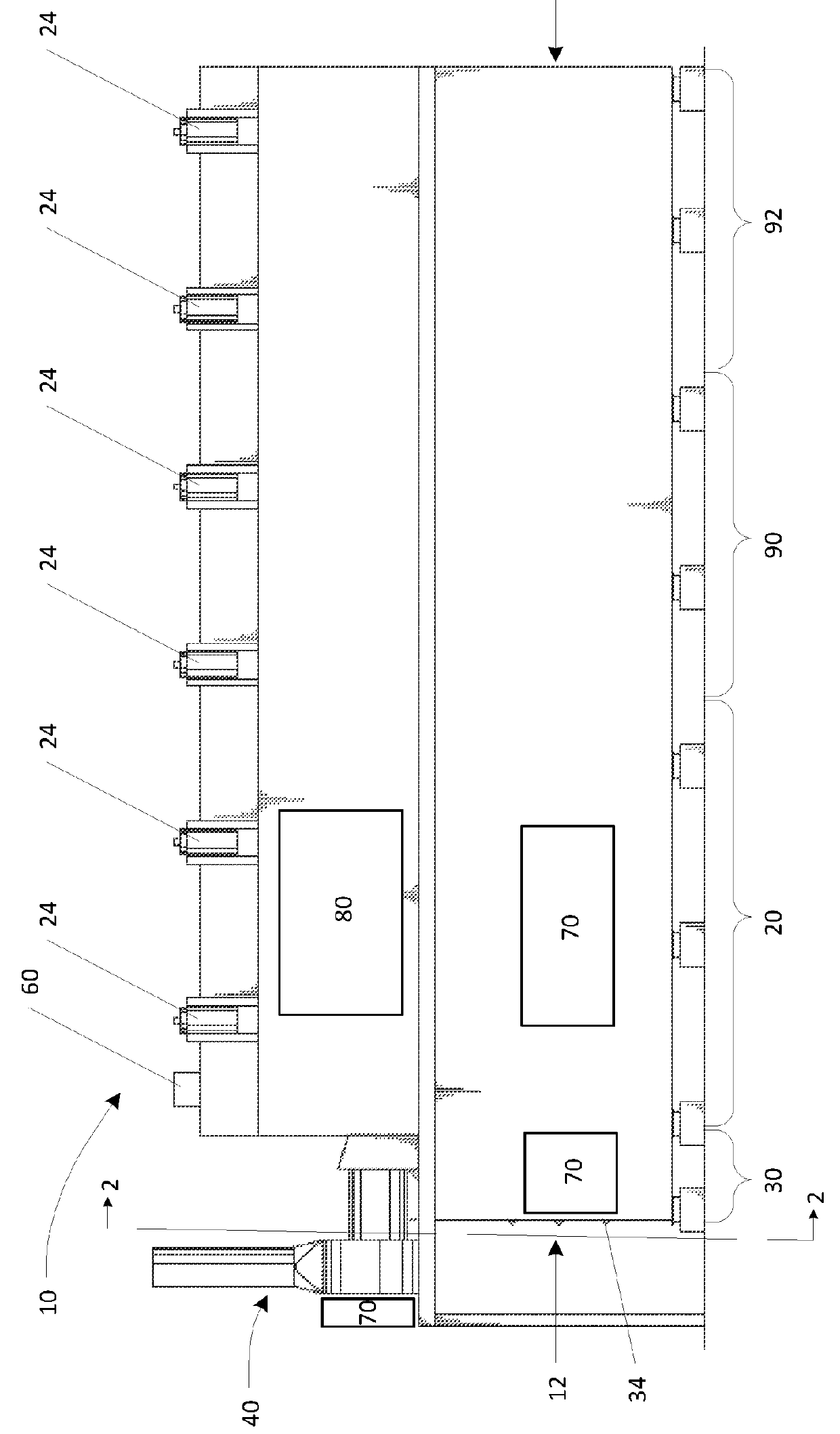

System and method for drying green woods

InactiveUSRE36728E1Low costDrying using combination processesDrying solid materials with heatCombustion chamberFresh air

A system for drying a large quantity of wood efficiently, which includes: a wood drying room capable of being sealed; a combustion-gas generator provided with an air-inlet conduit for introducing fresh air for combustion use into a combustion chamber provided in a lower area of the combustion-gas generator; a combustion-gas supplying passage extending from an upper area of the combustion-gas generator to an upper area of the wood drying room; an exhaust-gas discharging conduit extending from a bottom area of the wood drying room to a chimney; a combustion-gas recovery conduit extending from the bottom area of the wood drying room to the combustion-gas generator, and a gas flow-rate control unit provided in at least one of the exhaust-gas discharging conduit and the combustion-gas recovery conduit.

Owner:YG TECHN SYST KEEP

In-situ compaction and antibacteria preservative treatment technology of low mass-speed green wood

InactiveCN101829788AImprove flexural strengthIncrease elasticityWood treatment detailsWood impregnation detailsAcetic acidPreservative

The invention relates to the in-situ compaction and antibacteria preservative treatment technology of a low mass-speed green wood, belonging to the field of wood sciences. The technology comprises the following steps of: preparing an SiO2 / wood composite material doped with nanometer Ag by using a sol-gel method; preparing nano-silver with the size of 10-100nm by using a liquid-phase chemical method; dispersing and dissolving the nano-silver into the sol prepared by mixing tetraethoxysilane, ethanol and glacial acetic acid; adding PVP and a binding agent FWT to obtain the sol with different particle diameters and concentrations of the nano-silver subjected to in-situ compaction treatment; soaking the gel for 2h through a finishing process and drying the gel to form an antibacteria preservative in-situ compact material. The wood prepared by the treatment maintains better size temperature property, greatly improves the mechanical property, and has favorable antibacteria preservative property at the same time.

Owner:WUYI UNIV +1

Enzymatic composition and method for seasoning wood

InactiveUS6623953B1Improve impact on tasteMethod is fastProtein adhesivesWood treatment detailsFood industryGreen wood

The invention relates to an enzymatic composition and also to a method for seasoning wood, intended in particular for applications in the food industry. The method consists in immersing green wood in an aqueous solution comprising an enzymatic composition. The wood can subsequently be dried very rapidly in a drying facility. The invention makes it possible to improve the aromatic characteristics of the wood by eliminating certain substances judged to be undesirable due to their astringent nature or bitter nature, and transforming them into neutrally-tasting molecules.

Owner:ETAB ROBERT STIERNON

Rapid drying method for cottonwood thick plate

ActiveCN102435046AHelps to moveFast dryingDrying solid materials with heatHearth type furnacesThick plateEngineering

The invention relates to a rapid drying method for a cottonwood thick plate, and the method comprises the following steps of: at a preprocessing stage of a cottonwood, sawing the cottonwood to be plates with certain length and thickness according to operating requirements, stacking the plates and placing the plates into preprocessing equipment, then carrying out superheated steam preprocessing, and drying the preprocessed plates according to strengthening benchmark. In the rapid drying method, at the preprocessing stage of the cottonwood, constant-pressure superheated steam with temperatures of 110 DEG C-160 DEG C is used as a processing medium, therefore, not only can smooth and zero-defect of plate surfaces of the processed cottonwood be achieved, but also growth stress of the cottonwood can be released, a water passage inside a wood is opened, initial water ratio of the plates can be substantially reduced. A green wood is preprocessed, water ratio descending ratio is 40%-80%, descending mean value of the water ratio is above 60%,so that a drying stage time in a later period of the cottonwood can be greatly shortened. Compare with the conventional drying method, drying cycle is shortened above one half, energy sources are saved, drying cost is reduced, drying quality is favorable, and the rapid drying method is particularly applicable to cottonwood plates with thickness more than 5.0cm.

Owner:LANDBOND FURNITURE GROUP

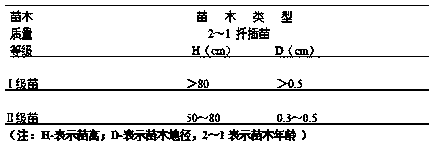

Rapid rooting method of tianshanica cerasus green wood cutting

The invention relates to a rapid method of tianshanica cerasus green wood cutting. The method aims at overcoming the defects that tianshanica cerasus green wood cutting is difficult to root or slow in rooting, and semi-lignification tianshanica cerasus annual new shoots are utilized. Cutting is conducted after the semi-lignification tianshanica cerasus annual new shoots are dipped through combined liquid of three kinds of plant rooting agents. The semi-lignification tianshanica cerasus annual new shoots are inserted in the matrix which is made of river sands. Humidity and temperature are maintained, and light are shaded through a sunshade net. Cutting survival rate is 92%. Average length of root systems is 7cm, average thickness of the f root systems is 0.2cm, survival rate of transplanting is 98%, and plantlets are strong in adaptability. The cutting is immediately conducted after the semi-lignification tianshanica cerasus annual new shoots are collected by utilizing the method, rooting is rapid, planet survival rate is high, quality is good, and time can be saved. The rapid method of the tianshanica cerasus green wood cutting is easy to operate, convenient to manage, and suitable for large-scale growing seedlings and private small-size growing seedlings.

Owner:XINJIANG AGRI UNIV

Method for grafting chestnut tree

The invention relates to a method for grafting chestnut trees, and belongs to the technical field of forest fruit tree grafting. The method for grafting Chinese chestnut trees uses a single bud green wood of Chinese chestnut as a scion, the scion and a stock are in side grafting. The shape of a side grafting notch on the stock is an inverted triangle, and the peak of the inverted triangle is provided with a lengthwise cutting extending downward. The single bud green wood with a xylem is used as the scion. In a grafting process, just a forming layer on a section is exposed in air, so brown stain area is greatly reduced, and survival rate after grafting is improved. The single bud green wood is easier to insert into the side grafting notch, so as to improved operation speed, shorten contact time of the forming layer and air, reduce brown stain degree, and improve survival rate. In addition, the cortex of the inverted triangle part of the notch is stripped, so that the cortex on two sides of the lengthwise cutting is easy to pick open, pick-open degree is large, and the scion is easier to insert, so as to improve inserting speed, shorten contact time of the forming layer and air, and improve survival rate.

Owner:SHANDONG INST OF POMOLOGY

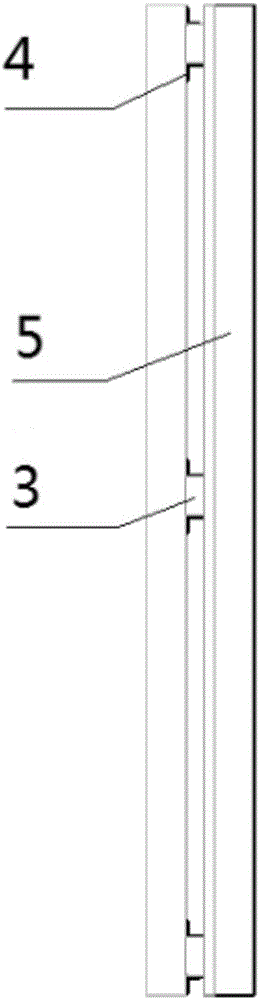

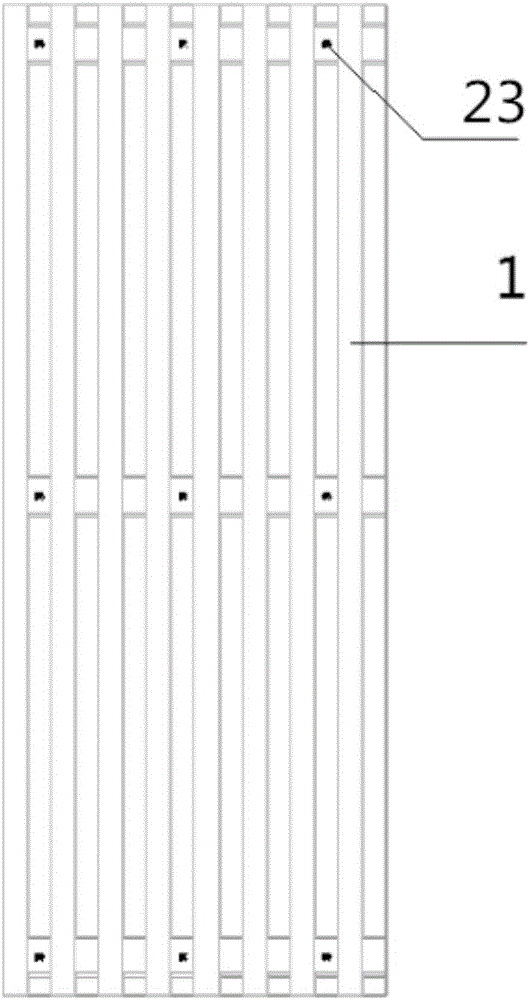

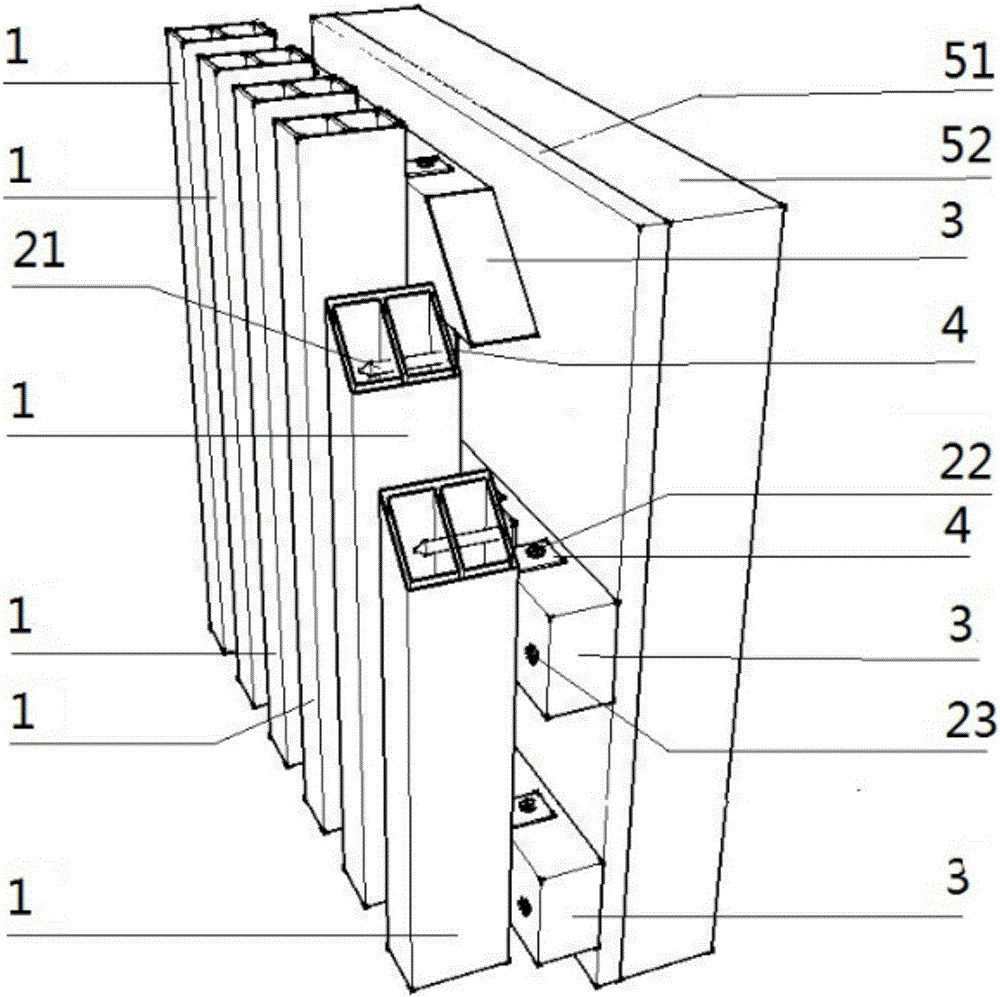

Building exterior wall double-layer heat insulation ventilation cuticle structure

The invention relates to a building exterior wall double-layer heat insulation ventilation cuticle structure. The structure comprises an exocuticle and an endocuticle which is fixedly connected with an outer wall. A predetermined distance is reserved between the exocuticle and the endocuticle, a plurality of wood joists are fixedly connected between the exocuticle and the endocuticle, the wood joists are connected with the exocuticle through L-shaped connecting pieces, and the exocuticle comprises a plurality of green woods arranged in parallel at intervals. According to the invention, the exocuticle and the endocuticle are mutually spaced to form intervals, interlayer ventilation between the cuticles can be promoted, at the same time, the exotucicle can shield most of vertical incident solar rays to a certain degree, the surface temperature of the endocuticle is reduced, heat penetrating into a room is reduced, and the refrigeration load of an air conditioner in summer is reduced.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Methods of incorporating treatment agents into wood based composite products

InactiveUS7371787B2Effective treatmentSave energyAntifouling/underwater paintsPaints with biocidesPreservativeBleach

A treated wood-based composite is formed by treating a green wood furnish with an amount of a treating agent effective to increase the value of the resulting wood-based composite. The treating agent can be, for example, a fire retardant, a wood preservative, a dye, a pigment, a stain, bleach, a water repellant, a drying oil, or a combination thereof. The treated green wood furnish is blended with a binder and then bound, as by pressing the furnish, to form a non-leaching fire-retardant wood based composite. Another aspect of the invention is the product formed according to the preceding process. The addition of the treating agent to green wood chips, without the need to dry them to low moisture content, is believed to be novel.

Owner:VIANCE

Wood drying method

InactiveUS6742283B2Drying solid materials with heatDrying solid materials without heatCombustion chamberPulp and paper industry

Method for drying wood in a short period of time by maintaining the concentration of a combustion gas contained in a drying room atmosphere for use in drying the wood to a high value and by maintaining the pressure of the drying room atmosphere to a high value. Wood fuels such as waste wood are put into a combustion chamber ins lower area of a combustion gas generating furnace and then the wood fuels are burned, followed by introducing the high-temperature combustion gas generated by the burning of the wood fuels into an upper area of a drying room housing the green wood to thereby dry the wood. Thermal drying of the wood is carried out by maintaining the concentration of the combustion gas present in the drying room atmosphere at a the high value and by maintaining the pressure of the drying room atmosphere at a high value.

Owner:TECHN SYST KEEP

Wood drying

InactiveUS8578625B2Reduce moisture contentDrying using combination processesPressure wood treatmentGreen woodCell wall

A process for removing water and solutes from the lumens of green wood, while leaving the cell walls throughout the wood uniformly fully swollen, comprises subjecting the green wood to supercritical carbon dioxide.

Owner:NEW ZEALAND FOREST RES INST

Novel biological fuel oil and formulating method thereof

InactiveCN101319146AAchieve sustainable developmentReproducibleLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionBiodieselEcological environment

The present invention relates to a novel biological fuel oil, in particular to a biological oil using citrus oil as a material and a preparation method thereof. The materials used by the technology are the offal and rejects of fruits, making a break through in the prior production mode of biological diesel oil at home and abroad, which is the biggest contribution made by the technology. The citrus oil is regenerative energy, and can substitute petrifaction fuel. Citrus fruit is evergreen xylophyta which is beneficial to ecological environment improvement. The method for preparing the biological fuel oil by using the citrus oil as the material comprises the following steps that: that raw oil extracted from the materials which are pericarps, stones, roots, branches and leaves, etc. of rutaceae citrus plants such as lemon, pomelo, orange, king orange, mandarin, etc. is subjected to water filtrating, impurity filtering and substance such as pigment, etc. extraction so as to obtain the oil; the oil mainly contains limonene of 95 percent, which is terpene with a molecular formula C10H16 and can be directly used as fuel oil to ignite and burn. The biological oil also can be prepared from the citrus oil of between 50 and 80 percent and methanol (ethanol) of between 20 and 50 percent, by weight percentage.

Owner:李泰春

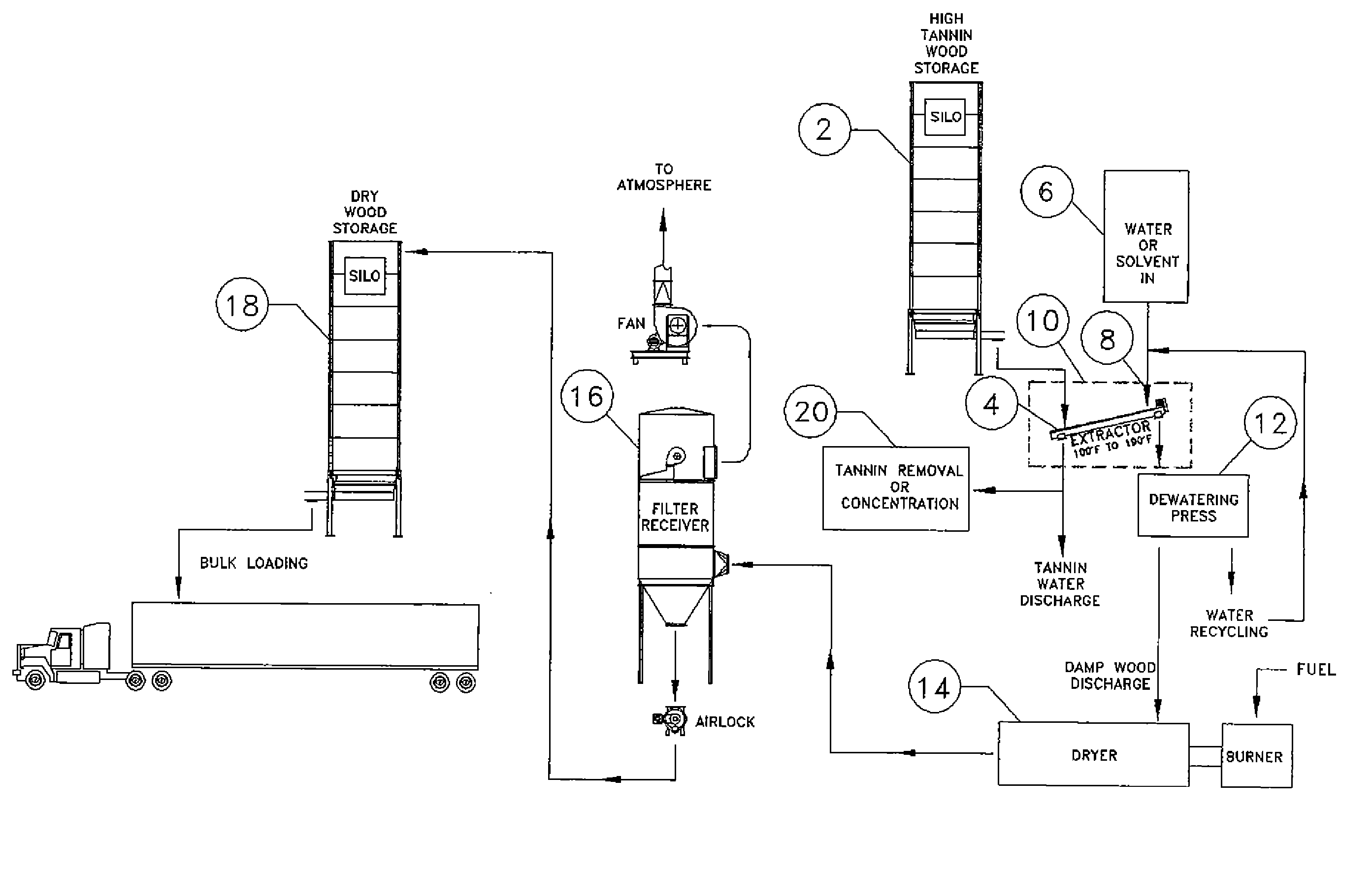

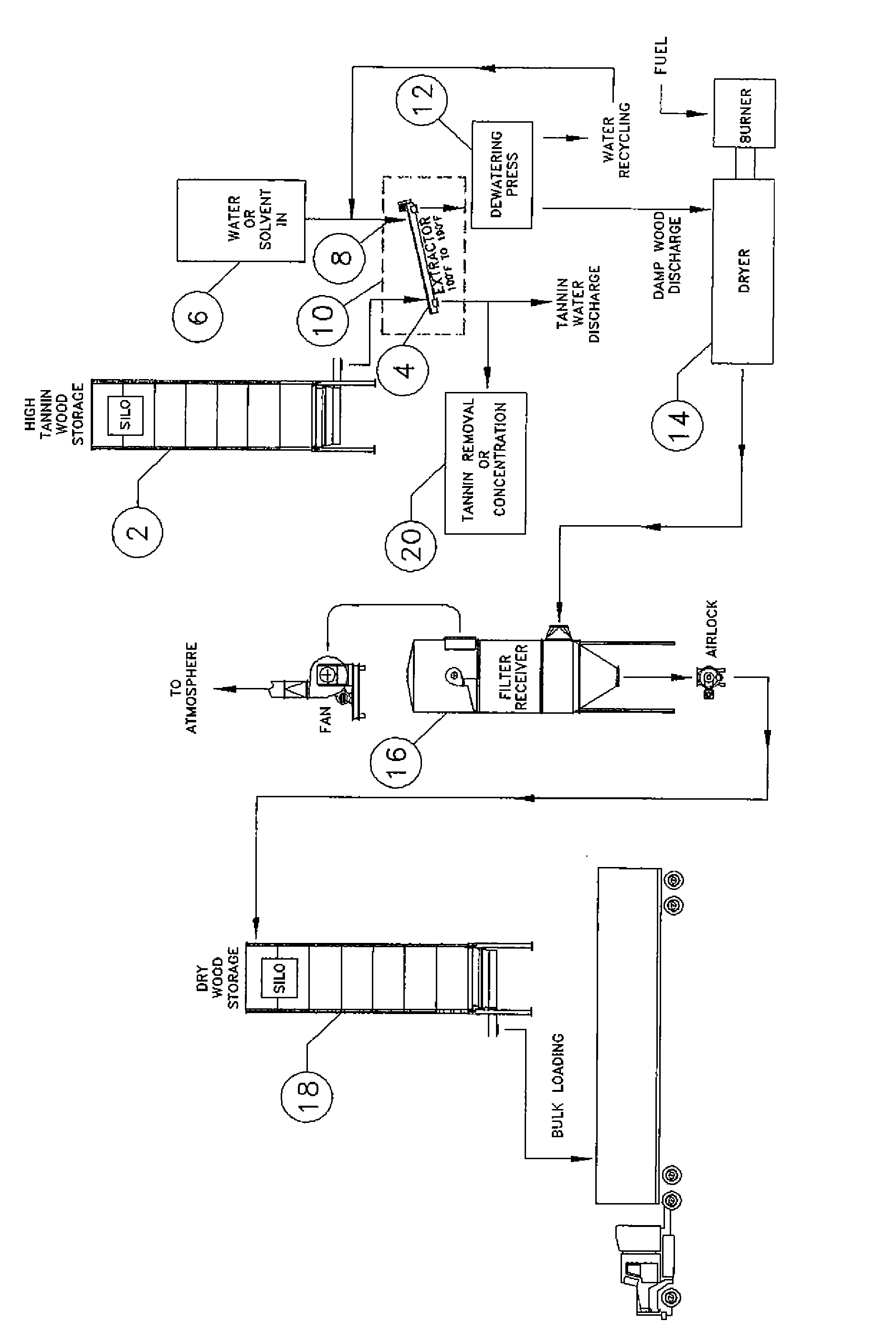

Reducing tannin staining in wood plastic composite materials

InactiveUS20090095694A1Lower Level RequirementsImprove the finishWater/sewage treatment by centrifugal separationSolvent extractionCycloneSolvent

A process for reducing or eliminating tannins in wood flour so to reduce the level of tannins in wood / plastic composites made with the wood flour, and improve the finish provided by these products when in use. The process involves taking a precursor comprised of wood flour, dry wood waste or green wood waste, all of which contain high levels of tannin, rinsing the precursor with a solvent such as acetone, water or a base solution including Sodium Hydroxide (NaOH) or other salts, and heating the resultant mixture to a predetermined elevated temperature. The tannins in the mixture are rinsed out of the mixture with the solution out, with the remaining material which containing only a very slight amount of tannins. The remaining material is next dried, and then separated from the drying air stream through a cyclone or filter receiver. The material is then stored in bulk for delivery to a manufacturer of wood / plastic composites, an animal fur processor, or processed further into a finer wood flour.

Owner:OWENS EDWARD F

Reactive oil/copper preservative systems for wood products

InactiveUS20050003190A1Low water absorptionReduce thickness swellLiquid surface applicatorsSynthetic resin layered productsSolid woodDecomposition

The specification describes preserved solid wood or wood composites including a copper ammonium acetate complex wood preservative and a drying oil. The wood preservative is present in the wood in an amount effective to improve the resistance of the treated wood to at least one type of decomposition, such as decay or insect attack. The drying oil is present in the wood in an effective amount to accomplish at least one useful end, such as reducing the water absorption or thickness swell of the treated wood or increasing its mechanical strength, even in a wood composite made using less binding resin than usual. Yet another aspect of the invention is a method of making the treated wood from green wood in solid or flaked form. A copper ammonium acetate complex wood preservative and optionally a drying oil are added to the green wood.

Owner:ARCHER DANIELS MIDLAND CO +1

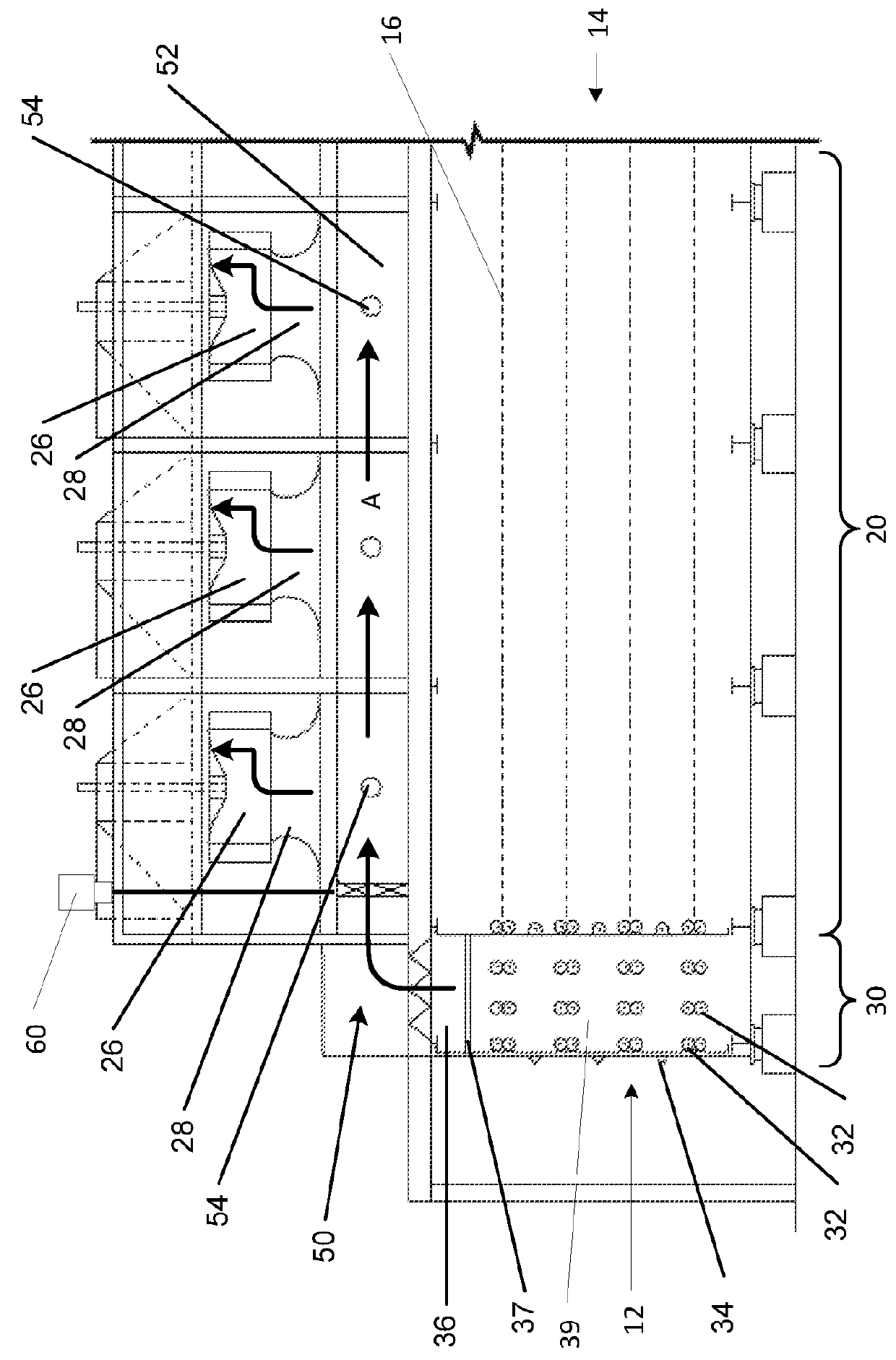

Recirculating system for use with green wood veneer dryers and method for drying green wood veneer

ActiveUS10006712B2Drying solid materials without heatDrying gas arrangementsGreen woodPulp and paper industry

A recirculating system for use with a green wood veneer dryer is provided. The recirculating system includes a duct connecting an input end seal chamber at an input end of a drying chamber to at least one fan disposed within the drying chamber. The at least one fan generates a negative pressure differential within the duct to redirect gases from the input end seal chamber to the drying chamber to maintain the pressure within the input end seal chamber within an accurate range of pressure external the veneer dryer. A method of drying green wood veneer is provided including recirculating gases from the input end seal chamber to the drying chamber and maintaining the pressure within the input end seal chamber within an accurate range of the pressure external the dryer.

Owner:WESTMILL INDS

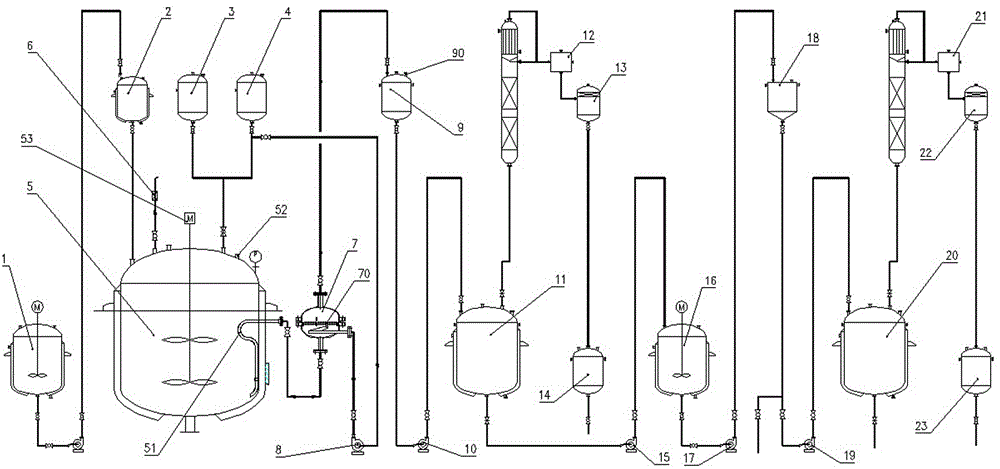

Method for synthesizing tricyclodecenyl propionate perfume by adopting loaded solid acid catalyst

ActiveCN104098470ARaw materials are easy to getMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationElectrophilic additionPropanoic acid

The invention discloses a synthesis method of a tricyclodecenyl propionate perfume. Petroleum coking byproducts dicyclopentadiene and propionic acid are used as the raw materials, under the catalysis of loaded solid acid, the raw materials directly have acetylation through electrophilic addition to prepare crude tricyclodecenyl propionate at one step, and meanwhile, a small amount of a propionic anhydride guard catalyst is added to prevent the crude tricyclodecenyl propionate from having hydrolysis reaction with a small amount of moisture in the material; then, propionic acid is recycled for applied mechanically, and the finished tricyclodecenyl propionate product is obtained through neutralizing, washing and rectification. According to the synthesis method, the petroleum coking byproducts used as the raw materials are easily available, the reaction condition is moderate, the reaction conversion rate is high, the technology is easier to implement, the discharge capacity of three wastes generated in the production process is low, the product yield is greatly increased, and the synthesis method belongs to technology of cleaner production. In addition, the content of tricyclo[5, 2, 1, 0<2.6>]-3-decene-9-yl acetate with delicate fragrance and fragrance and sweetness of anise is more than 92%, and the product green wood is pure, fine and mild in fragrance. The invention further provides a synthesis device special for the synthesis method of a tricyclodecenyl propionate perfume.

Owner:ANHUI HYEA AROMAS

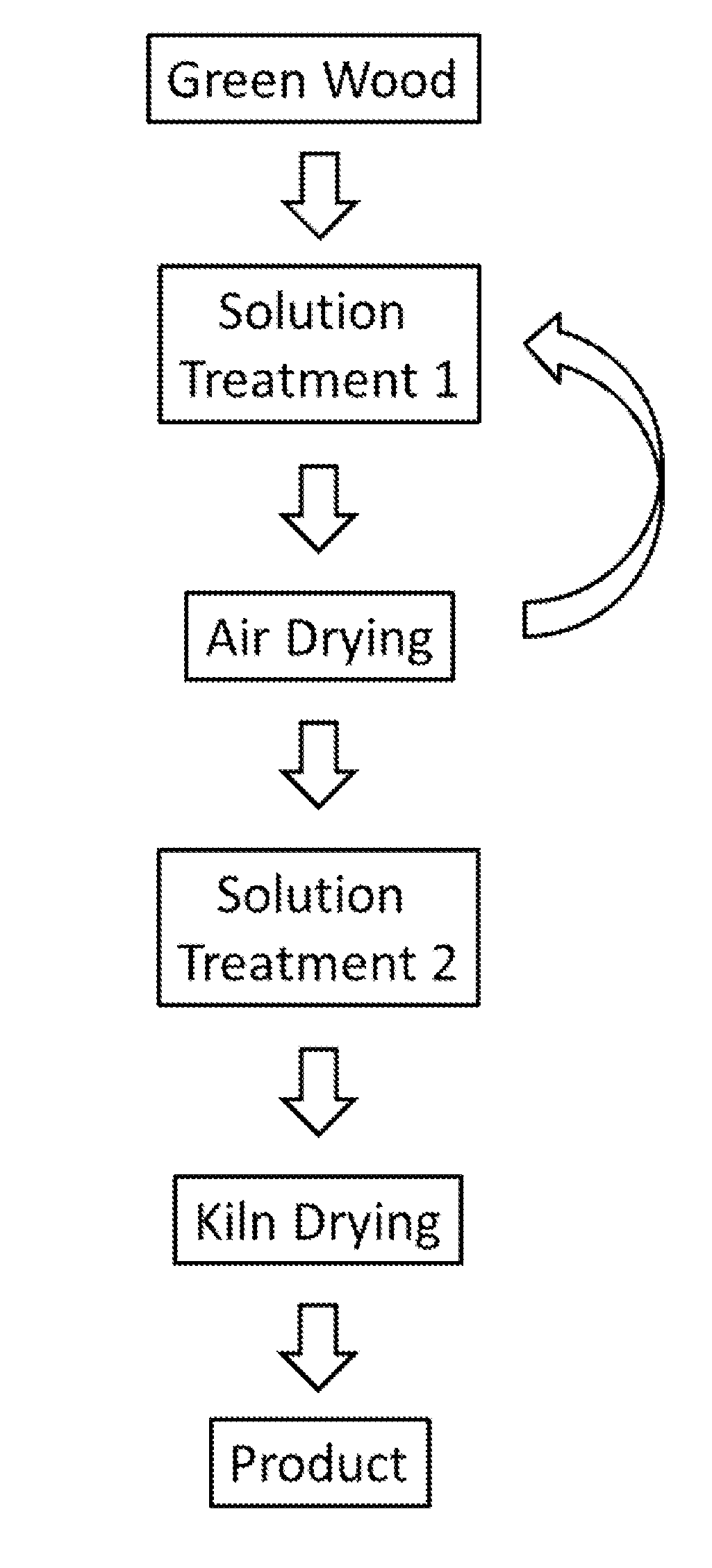

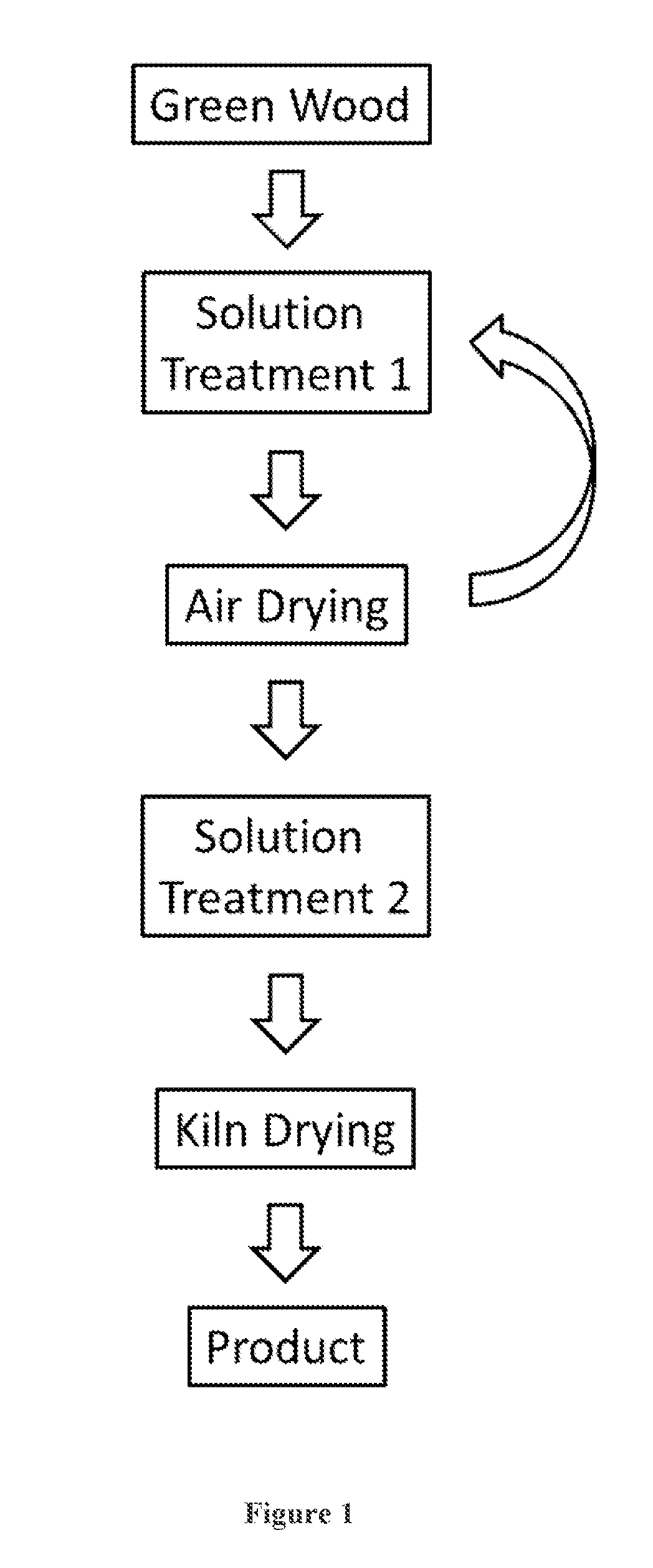

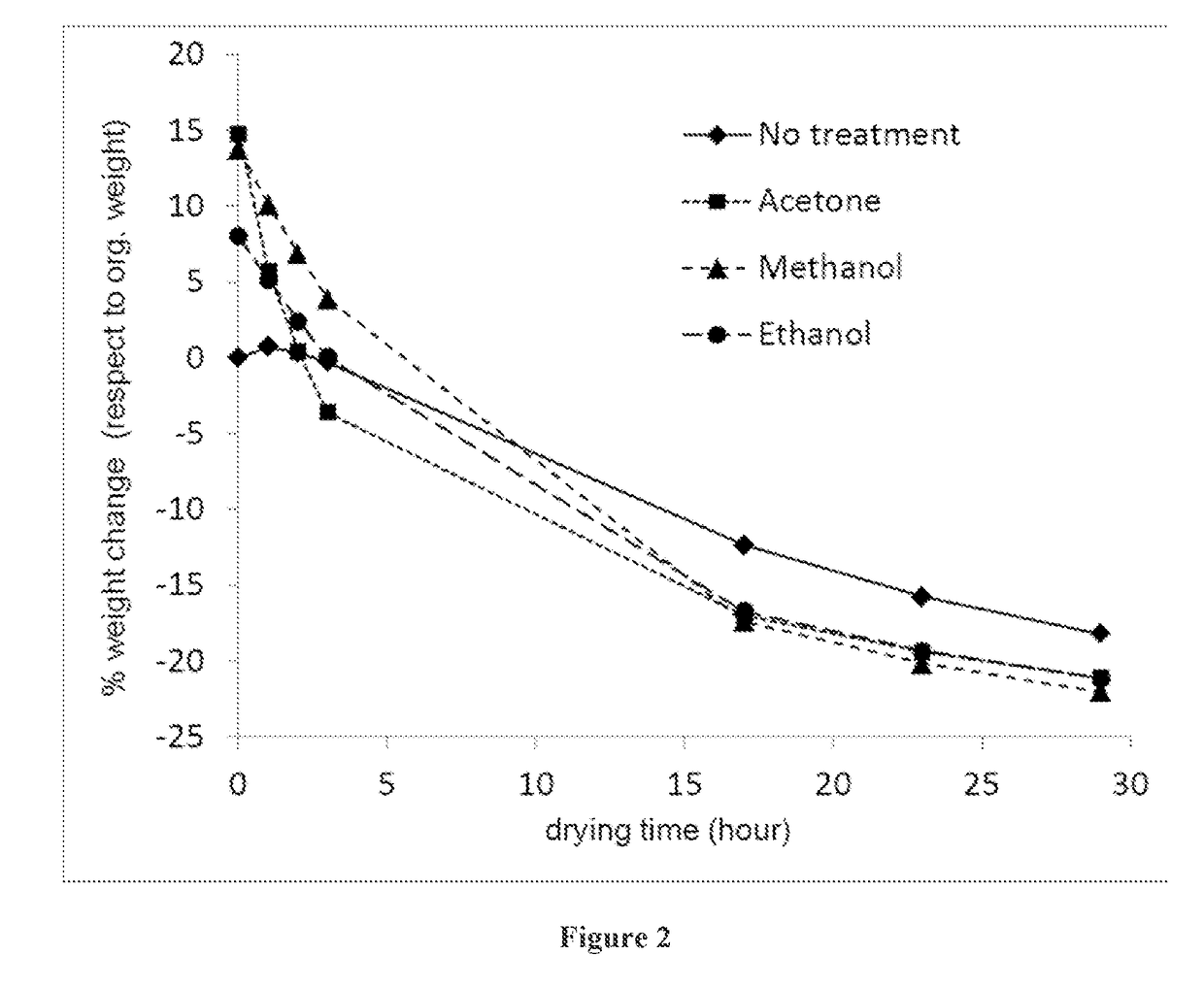

Wood drying and preservation methods

InactiveUS20180071944A1Avoid leachingAvoid damageDrying solid materials with heatWood treatment detailsAnti fungalUltraviolet

The new methods for treating green wood discuss herein speed up air drying of common green wood, including both softwood and hardwood. This method involves treating and altering the green wood with a base solution, and subjecting the wood to an air drying process. The new methods require less time to dry the green wood to a desired water content. In addition, other additives may be included in the base solution such as miscibility solvent(s), preservative(s), solubilizer(s) / stabilizer(s), chelating agent(s), bonding agent(s), pigment(s), UV protective, anti-oxidant, anti-fungal, anti-microbial and / or anti-insect chemical(s). The base solution solution may also slow down the wood deterioration caused by physical, chemical and biological sources under ambient conditions.

Owner:UNIV HOUSTON SYST

Green wood cutting method for cultivating seedlings of Triadica sebifera

InactiveCN108617298AHigh rooting rateImprove qualityCultivating equipmentsVegetative propogationEconomic benefitsGreen wood

The invention discloses a green wood cutting method for cultivating seedlings of Triadica sebifera. A green wood cutting technology is adopted, and by adopting seedling raising facilities, constructing a special cutting bed, preparing the cutting bed before cutting is conducted, selecting cuttings of Triadica sebifera, performing preparation and processing, performing seedling management after cutting is conducted, performing temperature and humidity control and treating ends of the cuttings with different hormones of different concentrations, the rooting rate of the cuttings is promoted, andthe quality and resistance of the green wood cutting seedlings of Triadica sebifera are improved. In addition, through the fine management at the seedling stage, not only can a uniform growth trend ofthe cutting seedlings, reduction of the incidence of the seedlings and cultivation of the high-quality strong seedlings of Triadica sebifera be achieved, but also improvement of the economic value ofthe seedlings and the survival rate of transplanted seedlings can be achieved, so that economic benefits are improved; maintaining of the excellent characteristics of a female parent is facilitated,flowering and fruiting are conducted in advance, and the obtained fruit is large and has high quality; and the rooting rate of the cutting seedlings cultivated by using the method is high, grown rootsare long and abundant, the cutting survival rate is high, and the transplanting survival rate is high.

Owner:徐华龙

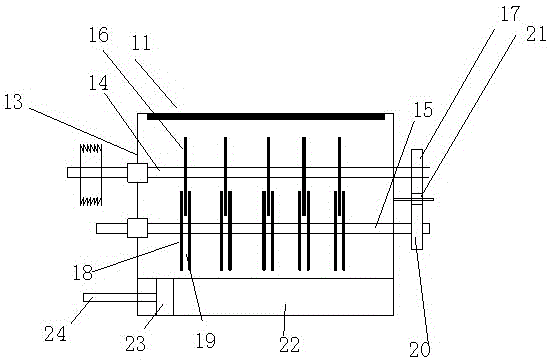

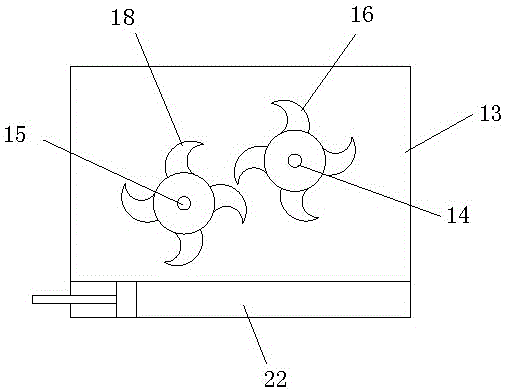

Double-shaft cutting machine for solid green wood

The invention discloses a double-shaft cutting machine for solid green wood. The machine comprises a second casing (13), wherein a feeding port (11) is formed in the upper part of the second casing (13), a second rotary shaft (14) and a third rotary shaft (15) are arranged in the second casing (13) , multiple forward cutter blades (16) are arranged on the second rotary shaft (14), a driving gear (17) is arranged at one end of the secondary rotary shaft (14), multiple double-cutter-blade sets (19) are arranged on the third rotary shaft (15), each double-cutter-blade set (19) is correspondingly formed by two reverse cutter blades (18), and the forward cutter blades (16) on the secondary rotary shaft (14) are clamped in the double-cutter-blade sets (19); a driven gear (20) is arranged at one end of the third rotary shaft (15) and is reversely meshed with the driving gear (17) through a transitional gear; a bottom groove (22) is formed in the lower part of the second casing (13). Wood sections processed by the machine are thin and small, the uniformity is high, and further processing is facilitated.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Cultivation method of mushrooms

InactiveCN107593274AFull of nutritionStrong growthCultivating equipmentsHeatAnimal scienceShiitake mushrooms

The invention discloses a cultivation method of mushrooms. The cultivation method includes: preparing a cultivation medium of the mushrooms and weighing, by weight, 55-80% of dried green wood and fruit, 5-22% of wheat bran, 5-15% of saw dust, 0.8-3% of sugar, 0.8-3% of plaster and 2-4% of straw rotting fungus; performing uniform mixing and fermentation; adding traditional Chinese medicine sterilizing liquid in the well-fermented cultivation medium prior to packaging, wherein the weight proportion of the cultivation medium to the traditional Chinese medicine sterilizing liquid is 10-12:1; subjecting the packaged cultivation medium to sterilization; performing inoculation on the cultivation medium and regulating temperature and humidity; performing daily management till harvest. The mushrooms cultivated are high in resistance to disease, high in yield, high in nutrition content, good in taste and less in investment of labor force.

Owner:贵州省印江自治县梵净山生态菌业有限公司

Cutting and stirring equipment for green wood feed processing

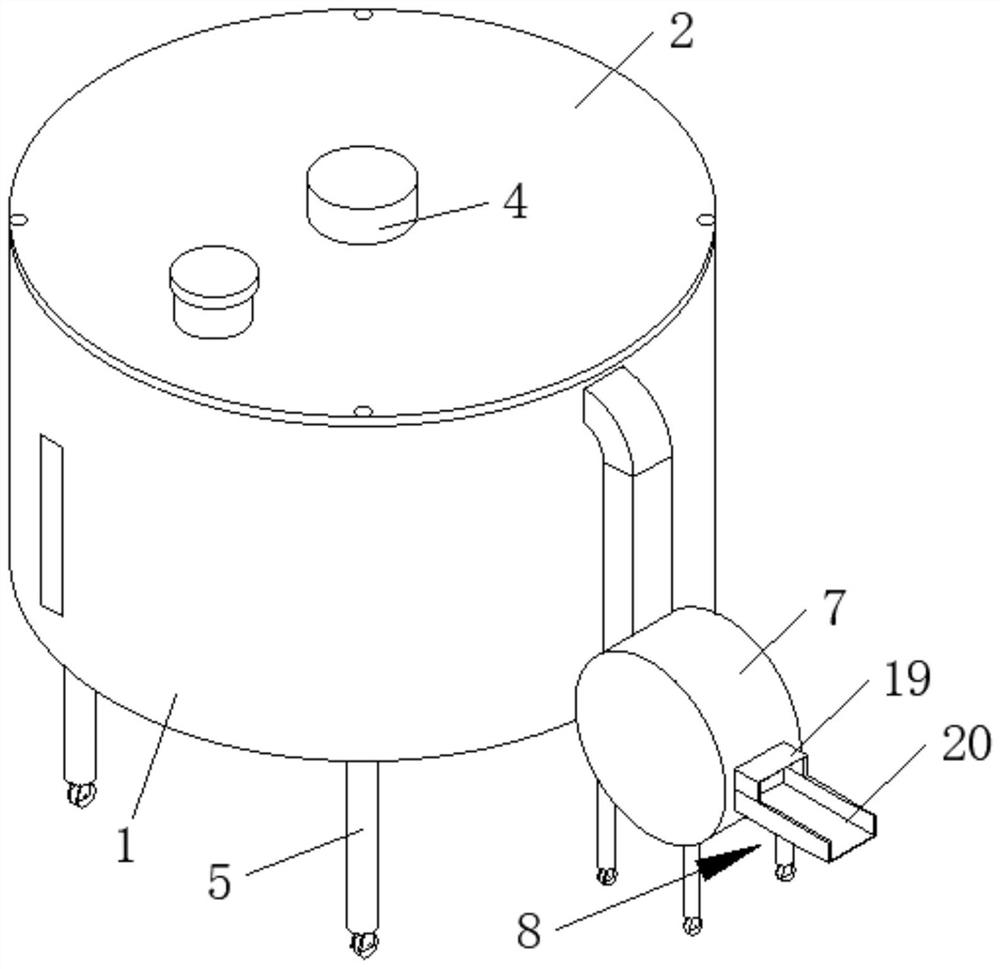

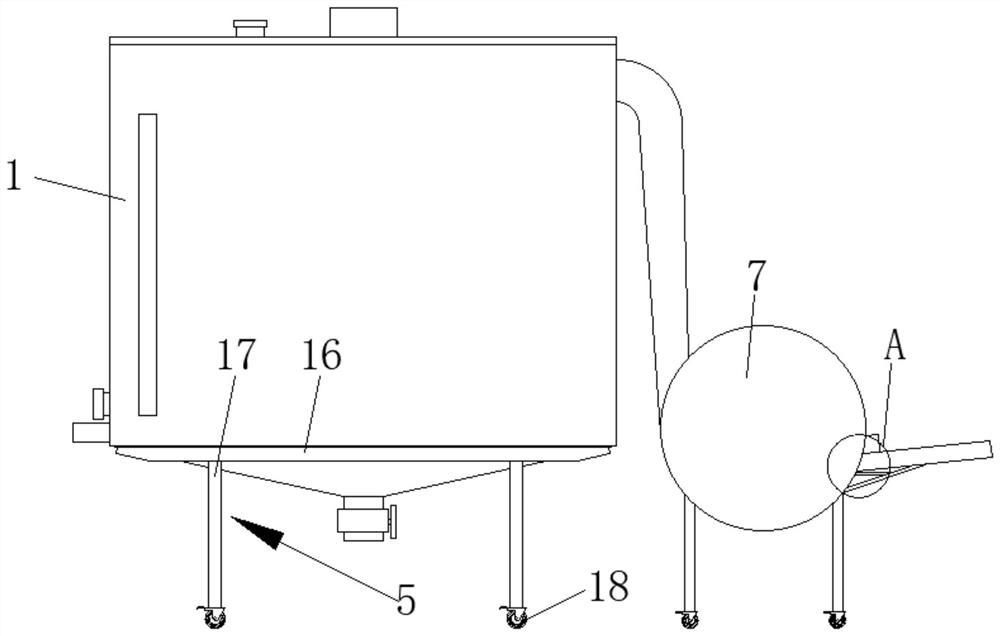

InactiveCN111889011AGuaranteed stabilityConvenient centrifugal flipTransportation and packagingMixer accessoriesElectric machineEngineering

The invention discloses cutting and stirring equipment for green wood feed processing, wherein the cutting and stirring equipment comprises a stirring barrel, a barrel cover arranged at top end of thestirring barrel, an air exhaust mechanism and a turnover mechanism; the air exhaust mechanism and the turnover mechanism are connected with the top end of the barrel cover, the lower half part of thestirring barrel is funnel-shaped, the bottom end of the stirring barrel is communicated with a discharge pipe with an electromagnetic valve, the bottom end of the stirring barrel is connected with asupporting mechanism, and the inner wall of the stirring barrel is connected with a plurality of groups of heating mechanisms; a cutting machine for cutting green fodder is arranged on one side of thestirring barrel, a discharging opening of the cutting machine is formed in a feeding channel of the barrel cover, and a shell of the cutting machine is connected with a feeding mechanism in a communicating mode; the turnover mechanism comprises a rotating motor, a stirring shaft, an upper processing plate and a turnover plate, the rotating motor is connected to the top end of the barrel cover through a plurality of sets of screws, and the rotating motor is connected with the stirring shaft through a coupler. The cutting and stirring equipment for green wood feed processing can be used for cutting and stirring, is good in stirring effect, and can also be used for exhausting air and treating air.

Owner:敖文娟

Stalk feed processing method

InactiveCN106720927ABig spaceReduce manufacturing costFood processingAnimal feeding stuffFermentationRotating drum

The invention relates to a stalk feed processing method, which is characterized in that corn flour, wheat bran, ferrous sulfate, water and trichoderma virens are uniformly mixed according to a ratio of 10:10:0.1:7:4; aerobic fermentation is performed for 48 hours at 20 to 28 DEG C; trichoderma virens raw material powder is prepared; the stalks are subjected to short chopping, cutting-up, kneading and pulping processing; then, base materials are obtained; the trichoderma virens raw material powder and the base materials are uniformly stirred by a stirring machine according to a proportion of 1:1000; the water content is regulated to be 70 percent; the materials are fed into a rotating drum type aerobic fermentation device for aerobic fermentation for at least 24 hours; the materials are taken out and are dried by a drying machine until the water content is less than or equal to 14 percent; the stalk feed finished product is obtained; bag charging and warehouse entering are performed. Various stalks are sufficiently utilized for preparing livestock, poultry and aquatic product feed; the production cost is effectively reduced; the economic benefits are improved; meanwhile, various kinds of stalks are sufficiently utilized, and the practical significance is realized on environment protection.

Owner:贾仲光

Straw feed

InactiveCN106689680ABig spaceReduce manufacturing costFood processingAnimal feeding stuffSulfateEconomic benefits

The invention relates to a straw feed. The preparation method of the straw feed includes: mixing corn flour, wheat bran, ferrous sulfate, water and Trichoderma virens evenly according to a ratio of 10:10:0.1:7:4, and conducting aerobic fermentation at 28DEG C for 48h to obtain Trichoderma virens raw material powder; cutting straw short, and carrying out shredding, rubbing and pumping to obtain a base material; mixing the Trichoderma virens raw material powder and the base material evenly with a stirrer in a ratio of 1:1000, regulating the water content to 70%, sending the mixture into an aerobic fermentation device to conduct aerobic fermentation for not less than 24h, then taking the product out, and performing drying with a dryer to a water content of not less than 14%, thus obtaining the straw feed. The invention makes full use of various straws to make livestock and aquatic feed, effectively reduces the production cost and improves economic benefits, and also makes full use of various straws, therefore the straw feed provided by the invention has practical significance in environmental protection.

Owner:贾仲光

Rapid drying method for cottonwood thick plate

ActiveCN102435046BHelps to moveFast dryingDrying solid materials with heatHearth type furnacesThick plateEngineering

Owner:LANDBOND FURNITURE GROUP

Quick-dry eco-friendly wooden product adhesive

InactiveCN107779125ARaw materials are easy to getSimple methodNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesEnvironmental resistanceEpoxy

The invention discloses a quick-drying environmental-friendly wood product adhesive, which belongs to the field of adhesives. A quick-drying environmental-friendly wood product adhesive, comprising the following components in parts by weight: 10-15 parts of linear polyvinyl ether, 100-120 parts of neoprene, 50-70 parts of epoxy resin, and 5 parts of zinc oxide -10 parts, 3-7 parts of magnesium oxide, 0.5-2 parts of accelerator TMTD, 8-12 parts of m-phenylenediamine. The quick-drying environmental-friendly wood product adhesive of the present invention has easy-to-obtain raw materials, simple preparation method, low cost, convenient operation during use, has the advantages of non-toxic, harmless, strong cohesive force, good quick-drying and leakage, and is environmentally friendly and pollution-free. Strong practicality.

Owner:NANJING YIHE CULTURE CREATIVE CO LTD

A kind of biomass green substitute wood board

Owner:李和平 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com