Double-shaft cutting machine for solid green wood

A kind of solid wood and mechanical technology, applied in the direction of wood processing equipment, thin wood chip manufacturing, manufacturing tools, etc., can solve the problems of unfavorable processing, thick wood segments, unsatisfactory structure, etc., and achieve the effect of improving the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

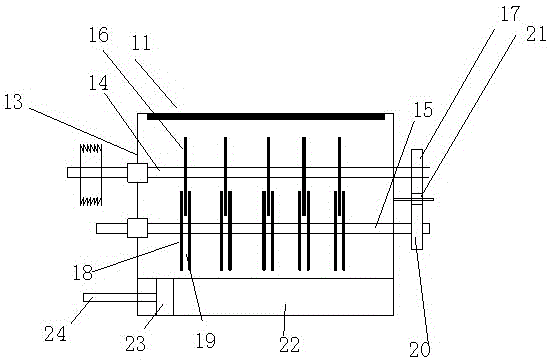

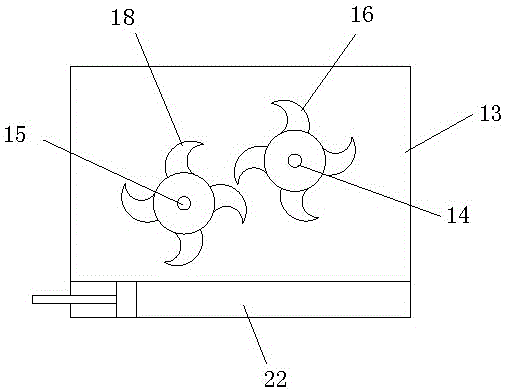

[0011] Embodiment: a kind of solid wood raw wood biaxial cutting machine, constitutes as Figure 1-2 As shown, the second housing 13 is included, the top of the second housing 13 is provided with a feed inlet 11, the second housing 13 is provided with a second rotating shaft 14 and a third rotating shaft 15, and the second rotating shaft 14 is provided with There are a plurality of forward blades 16, and the end of the second rotating shaft 14 is provided with a driving gear 17; the third rotating shaft 15 is provided with a plurality of double blade groups 19 that are correspondingly provided with by two reverse blades 18, and the second The forward blade 16 on the rotating shaft 14 is clamped in the double blade group 19; the end of the third rotating shaft 15 is provided with a driven gear 20, and the driven gear 20 is opposite to the driving gear 17 through the transition gear 21 engagement; the lower part of the second housing 13 is provided with a bottom groove 22 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com