A kind of biomass green substitute wood board

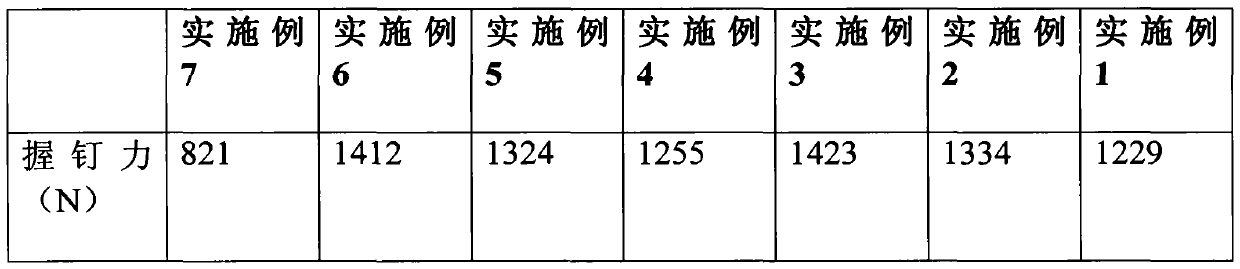

A biomass and board technology, applied in the field of biomass green wood substitute boards, can solve the problems of poor nail holding force, affect effective application, poor flexibility, etc., and achieve the effects of dimensional stability, long life and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material weighing: polymer resin polyethylene (low-density polyethylene, high-density polyethylene, which can be recycled materials) 25 kg, rubber powder 2 kg, natural plant fiber 60 kg by mass, maleic anhydride modified The mass fraction of vinyl resin is 2 kg, the mass fraction of compound auxiliary agent is 2 kg of natural electric-rich mineral powder, the mass fraction of toughening agent EVA is 2 kg, the mass fraction of zinc stearate is 2 kg, The anti-ultraviolet agent is 0.5 kg by mass of UV9, 1 kg by mass of antioxidant 1010, 2 kg by mass of silane coupling agent as the modifier, and 2 kg by mass of iron oxide red as the coloring agent .

[0033] Manufacturing method of rubber powder

[0034] First batching, formula is that the mass fraction of natural rubber NR3# is 100 kilograms, the mass fraction of accelerator M is 2 kilograms, the mass fraction of accelerator DM is 1 kilogram, the mass fraction of zinc oxide is 3 kilograms, hard The mass fraction of f...

Embodiment 2

[0037] Weighing of raw materials: polymer resin polyethylene (low-density polyethylene, high-density polyethylene, which can be recycled materials) 25 kg, rubber powder 4 kg, natural plant fiber 60 kg by mass, ethylene-vinyl acetate copolymer The mass fraction of the substance is 2 kg, the compound auxiliary agent is 2 kg of natural electric-rich mineral powder, the mass fraction of toughening agent EVA is 2 kg, one or two of calcium stearate and polyethylene wax A combination of 2 kg in parts by mass, 0.5 kg in parts by mass of UV9 as an anti-ultraviolet agent, 1 kg in parts by mass of antioxidant 1010, 2 kg in parts by mass of a silane coupling agent as a modifier, and 2 kg in parts by mass of a coloring agent The mass fraction of iron oxide red is 2 kilograms.

[0038]First add 60 kg of natural plant fiber into the channel-type continuous drying equipment, control the temperature of the channel-type continuous drying equipment at 100-105°C for 10-12 minutes, and test that t...

Embodiment 3

[0040] Weighing of raw materials: polymer resin polyethylene (low-density polyethylene, high-density polyethylene, can be recycled material) 25 kg, rubber powder 6 kg, natural plant fiber mass 60 kg, rosin modified resin mass The number of parts is 2 kg, the compound additive is 2 kg of natural electric-rich mineral powder, the weight part of toughening agent EVA is 2 kg, the weight part of zinc stearate is 2 kg, and the anti-ultraviolet agent is UV9 The mass part is 0.5 kg, the antioxidant 1010 is 1 kg, the modifier is 2 kg of silane coupling agent, and the colorant is 2 kg of iron oxide red.

[0041] First add 60 kg of natural plant fiber into the channel-type continuous drying equipment, control the temperature of the channel-type continuous drying equipment at 100-105°C for 10-12 minutes, and test that the raw materials are dried until the moisture is less than 1%, and then use The high-speed mixer mixes all raw materials including rubber powder evenly, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com