Method for synthesizing tricyclodecenyl propionate perfume by adopting loaded solid acid catalyst

A technology of tricyclodecenyl propionate and solid acid catalyst is applied in the field of preparation of organic synthetic fragrances, and can solve the problems of low content, insufficient isomer ratio to satisfy fragrance quality, product fragrance with sour taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

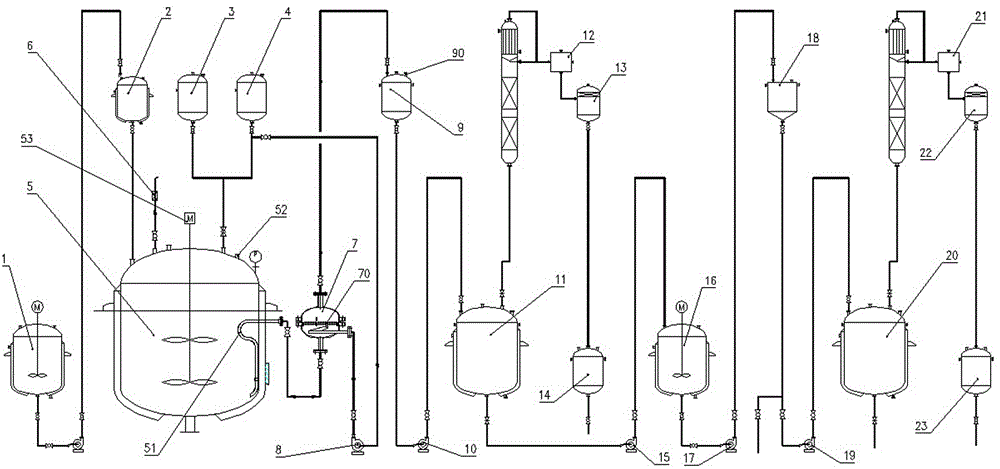

[0037] a) Pump the material in the dicyclopentadiene insulation tank 1 into the dicyclopentadiene high-level tank 2, and add dicyclopentadiene from the dicyclopentadiene high-level tank 2 to the 500 L esterification reactor 5 Pentadiene 260 kg, add propionic anhydride 2.5 kg from propionic anhydride header tank 3 to esterification reactor 5, after the feed finishes, add propionic acid 140 kg from propionic acid header tank 4, from esterification reactor 5 hand holes 52 Add 2 kg of catalyst zeolite loaded phosphotungstic acid, start the mixer 53 and mix evenly;

[0038] b) Open the steam valve, heat up the esterification reaction kettle 5, and control the reaction temperature to 95~98°C;

[0039] c) After 4 hours of reaction, take samples for gas chromatography detection, and then take samples for detection at intervals of 2 hours. When the dicyclopentadiene content is less than 2%, maintain the temperature and continue the reaction for 2 hours, then cool down to terminate the ...

Embodiment 2

[0049] a) Add 1300 kg of dicyclopentadiene and 13 kg of propionic anhydride to the 2500 L esterification reactor 5. After the feeding is completed, add 700 kg of propionic acid from the propionic acid head tank 4, and add 700 kg of propionic acid from the esterification reactor 5 Add catalyst zeolite-loaded phosphotungstic acid 8 kg into hole 52, start the mixer and mix evenly;

[0050] b) Open the steam valve, heat up the esterification reaction kettle 5, and control the reaction temperature to 95-100°C;

[0051] c) After 4 hours of reaction time, take samples for gas chromatography detection, and then take samples for detection at intervals of 2 hours. When the dicyclopentadiene content is less than 2%, maintain the temperature and continue the reaction for 2 hours, then cool down to terminate the reaction, and add 30 kg of clear water, continue to stir, and propionic anhydride is hydrolyzed into propionic acid;

[0052] d) The reaction solution in step c) is sent to the pr...

Embodiment 3

[0059] a) Add 260 kg of dicyclopentadiene and 3 kg of propionic anhydride to the esterification reactor 5. After the feed is completed, add 130 kg of propionic acid from the propionic acid head tank 4, and add it from the hand hole 52 of the esterification reactor 5 Catalyst zeolite loaded phosphotungstic acid 1.5 kg, turn on the mixer 53 and mix evenly;

[0060] b) Open the steam valve, heat up the esterification reaction kettle 5, and control the reaction temperature to 98~100°C;

[0061] c) After 4 hours of reaction time, take samples for gas chromatography detection, and then take samples for detection at intervals of 2 hours. When the dicyclopentadiene content is less than 2%, maintain the temperature and continue the reaction for 2 hours, then cool down to terminate the reaction, and add 6 kg of clear water, continue to stir, and propionic anhydride is hydrolyzed into propionic acid;

[0062] d) The reaction solution in step c) is sent to the precision filter 7 with nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com