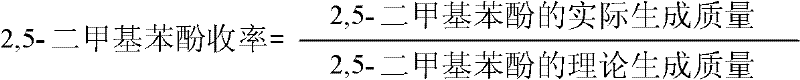

Patents

Literature

142results about How to "Less discharge of three wastes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

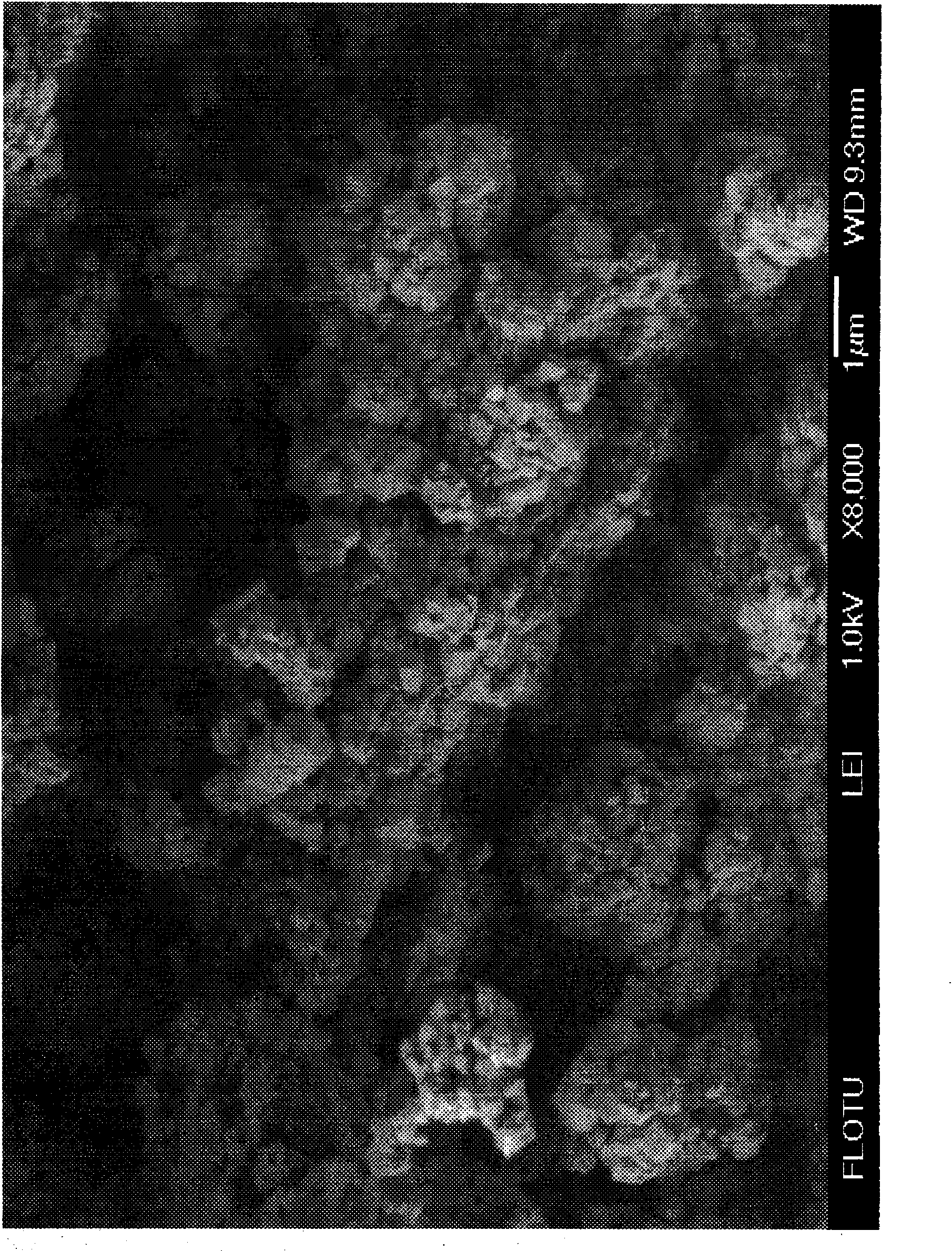

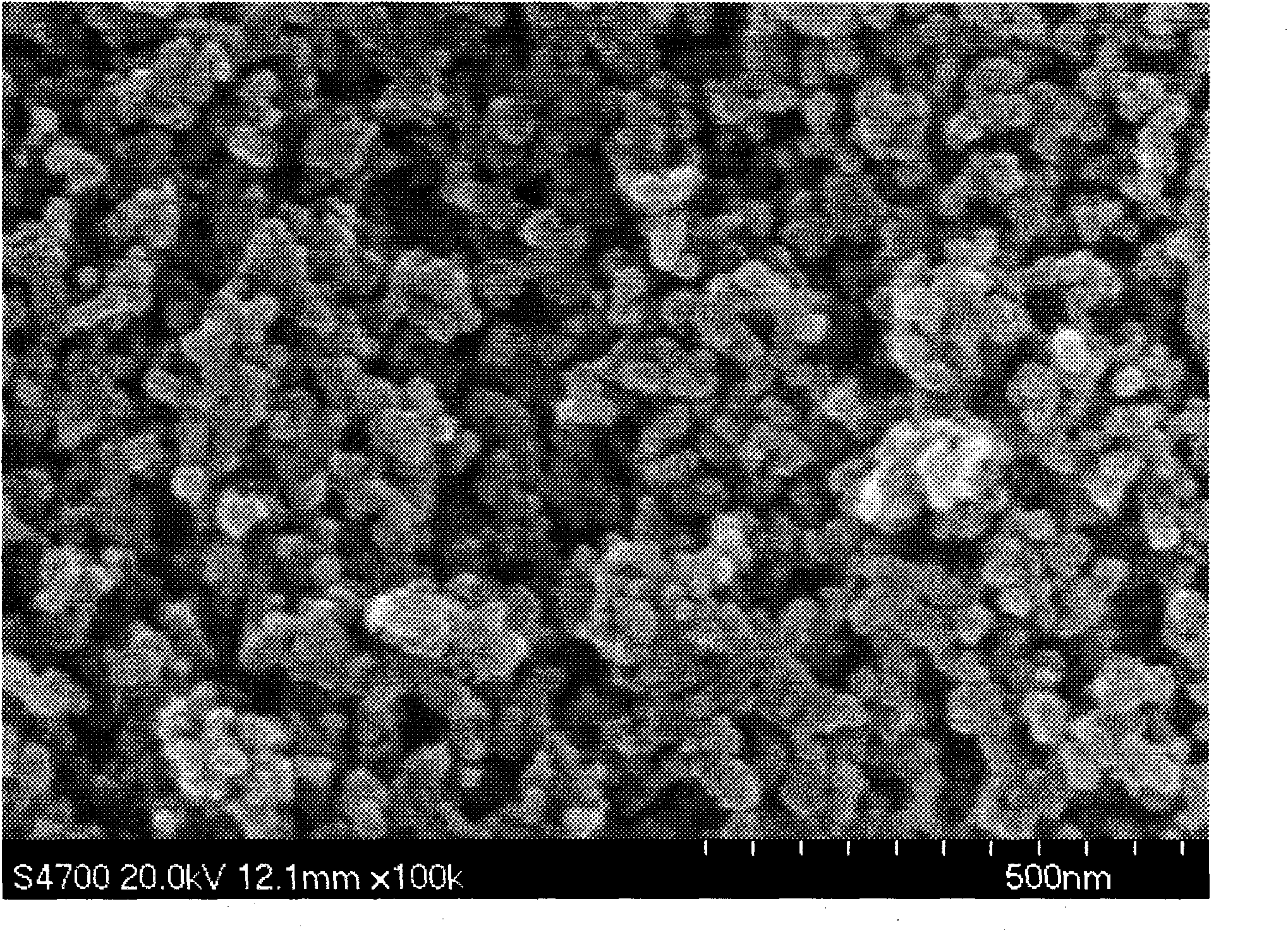

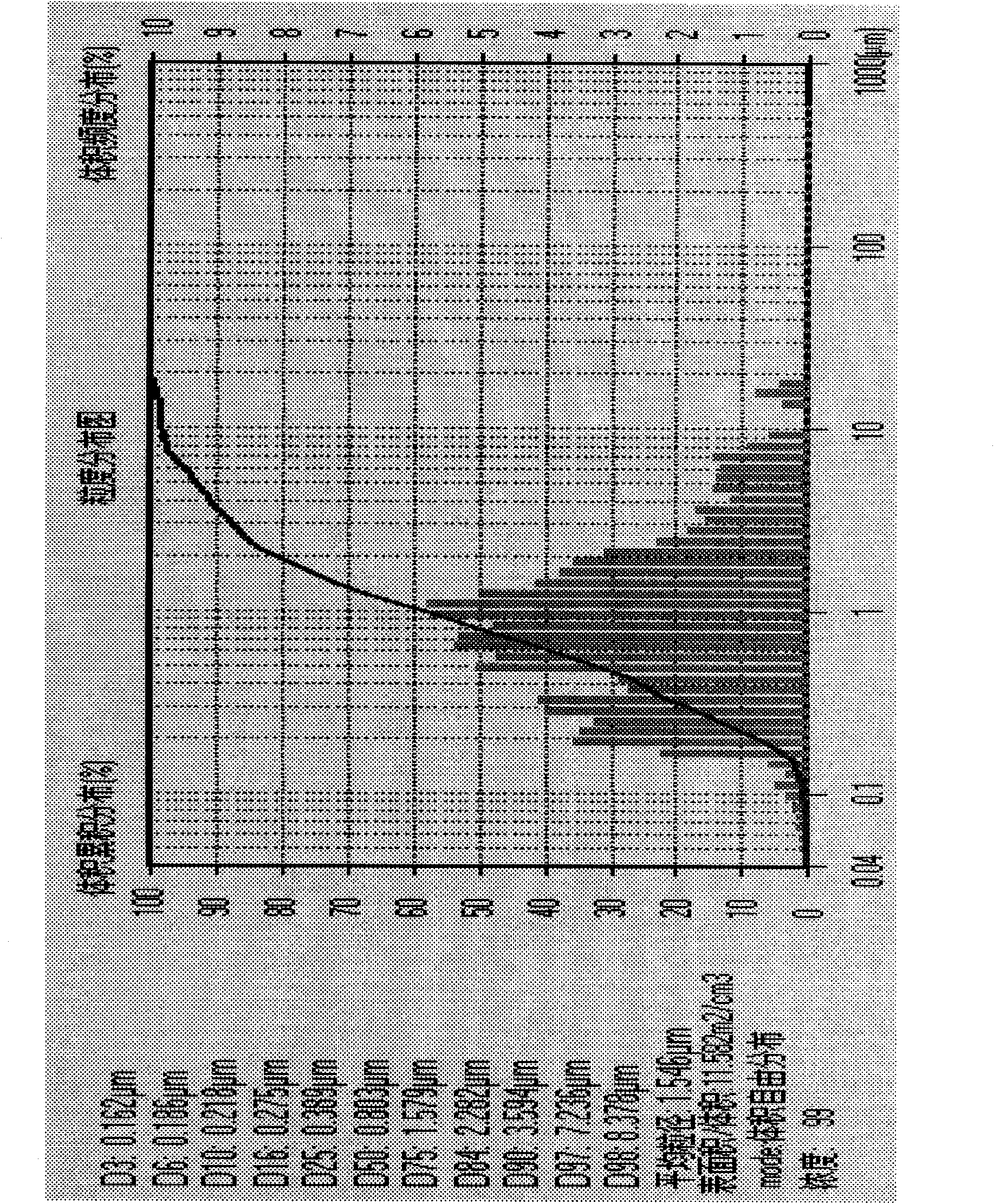

New process for co-producing ultra-fine white carbon black and calcium carbonate

InactiveCN101898776AAddress effectivenessImprove qualityCalcium/strontium/barium carbonatesSilicaPhysical chemistryCarbide

The invention provides a method for co-producing white carbon black and calcium carbonate. Carbide slag or lime and quartz sand are used as main raw materials. The method comprises the following steps of: introducing sodium silicate solution into carbon dioxide to obtain a mixture of white carbon black and sodium carbonate or sodium bicarbonate, filtering the solution, adding lime or carbide slag into the solution, preparing caustic soda and ultra-fine calcium carbonate by causticizing reaction, adding the quartz sand into the filtered dilute alkali liquor, and reacting the mixture under a heating band pressure to obtain sodium silicate solution so as to realize circulation and co-production.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

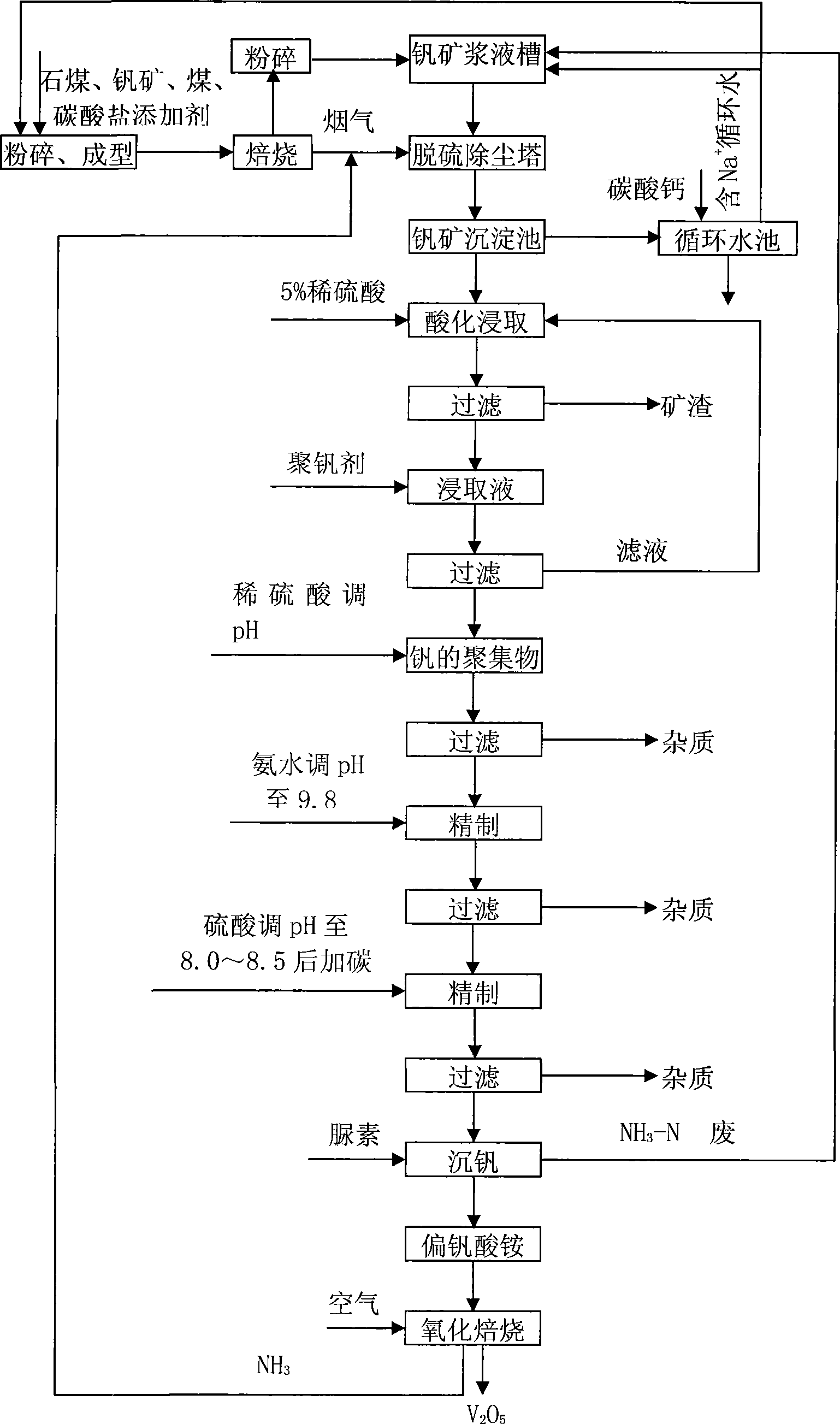

Desulphurization and vanadium extraction technique for calcinated vanadium ore

InactiveCN101503762ANo pollution in the processEliminate pollutionProcess efficiency improvementResource utilizationSodium salt

The invention provides a process for primary desulfurization and secondary vanadium purification of roasted vanadium ores. The process takes sodium salts which do not contain chlorine ions as a roasting additive of vanadium ores and molds the vanadium ores; and the roasted sodium-containing vanadium ores are used for reclaiming SO2 gas generated in the roasting process at first, and diluted acid is used for immersion and vanadium purification. The maximum characteristic of the process is that the sodium-containing vanadium ores are taken as alkaline desulfurized substances and circulated into a desulfurizing tower; Na ions in the vanadium ores are recycled in the form of intermediate carriers; when the concentration of the Na ions in a circulating absorption liquid reaches a certain value, the recovery rate of the SO2 gas generated in the roasting process can be improved and the amount of sulfuric acid in the procedure of immersion in the diluted acid and vanadium purification can be reduced; and sodium salt wastewater can be taken as the roasting additive of the vanadium ores instead of the sodium salts which do not contain the chlorine ions, so that the problem of severe environmental pollution of a large quantity of sodium salt wastewater and the SO2 gas produced in the conventional technological line is solved, and the process is a novel environment-friendly stone-like coal vanadium purification process having the advantages of utilization of waste materials to produce waste materials, high resource utilization rate, low production cost, small environmental pollution and even non pollution.

Owner:HUNAN UNIV

Stone-like coal gas phase vanadium extracting method

A method to extract vanadium with stone coal gas phase, the technology steps are as following: the stone coal or the stone material prepared with the ore containing alum will be broke, and milled to produce the powder, the size of which is 60-80 eyes, the powder will be delivered into the furnace in fluid bed to degrade at high temperature and be aerified by burning. They will be burned for 8-30 seconds at 900-1250deg.C, and at the same time, will be oxygen aerified by inputting air containing 30-50% oxygen, the vanadic oxide in the material will become burner gas. The burner gas enters the deposition room, and it will be cooled to 500deg.C by heat exchanger, and will be flushed of f by two-stage whirlwind according to dry method. The burner gas after deslagging will enter the electrostatic dust catcher from the deposition room to enrich. The enriched material will be dipped by alkali solution and dipping solution containing alum can be gained. The remained burned gas will enter the two-stage apray tower to make the vanadic oxide in gas phase become spray solution containing vanadic. Vitriol will be added into the two solution containing alum, the raw vanadic oxide will be deposit out by neutralized with acid. This patent can widely take advantage of the stone coal resource with low caloric value and low grade, the reclaim rate is high, and it can save energy, it does not need flux and the cost of it is low, the exhaust of the three wastes, and it is helpful to protect environment.

Owner:黎吉星

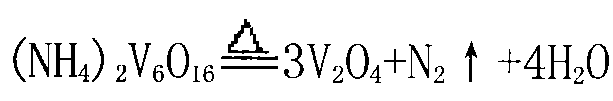

Method of producing xylose and xylitol and co-producing L-arabinose by bagasse

InactiveCN104046705AIncrease profitIncrease added valueSugar derivativesOrganic compound preparationRare sugarAlcohol sugars

The invention relates to a method of producing xylose and xylitol and co-producing L-arabinose by bagasse. The method comprises the following steps: first, treating the bagasse; then, producing xylose by the bagasse; and respectively producing xylitol and arabinose by the product xylose and a xylose mother liquid. By using the bagasse as a raw material, the method provided by the invention obtains crystallized xylose and further products of xylitol and L-arabinose which are high in additional value and are widely applied to the fields of foods and medicines through a whole set of process line. The method provided by the invention is simple to operate, novel in technology, low in cost, diversified in product and high in economic value, is a process method which is initiated at home for co-producing functional sugar alcohols and rare sugar products by bagasse, and has an extremely wide application value.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

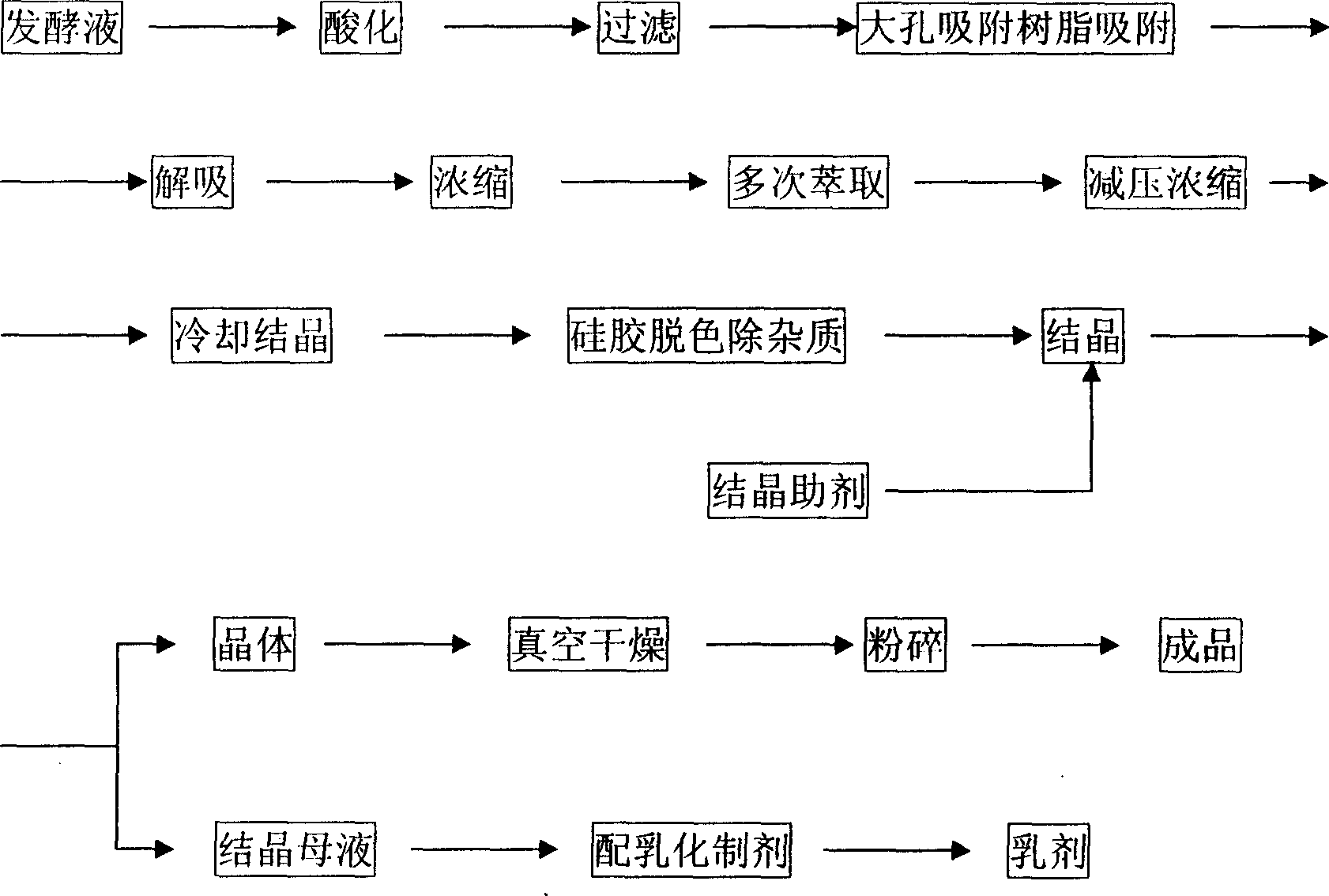

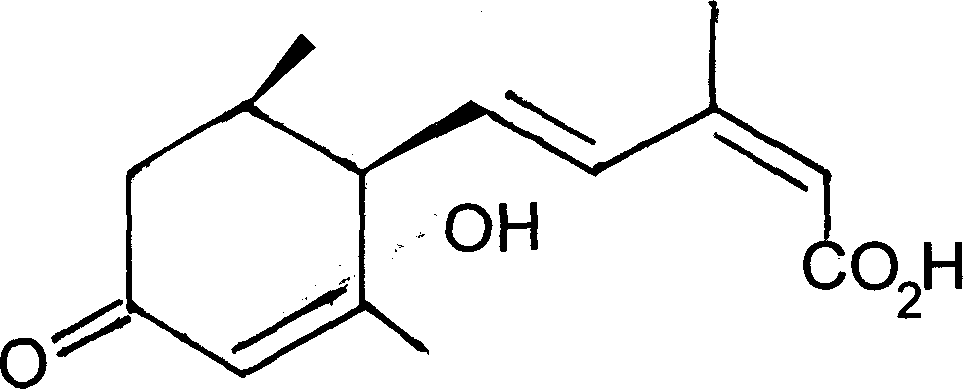

Method for extracting natural abscisic acid

ActiveCN1749401ASimple processing methodProcess method is feasibleFermentationBio engineeringSilica gel

The present invention belongs to the field of biological engineering, and discloses natural abscisic acid extracting method. Through acidifying fermented liquid, filtering, adsorption with macroporous adsorption resin, elution, concentrating and extracting the eluted liquid, concentrating the extracted liquid to obtain coarse crystallized product, dissolving the coarse crystallized product, adsorbing impurity with silicon gel, adding hexane, benzene, petroleum ether or carbon tetrachloride as crystallization assistant, decompression concentration, cooling to crystallize, washing, and vacuum drying, crystalline natural abscisic acid of purity over 95 % is produced. The method has high extracting rate, high abscisic acid product purity and other advantages.

Owner:江西新瑞丰生化股份有限公司

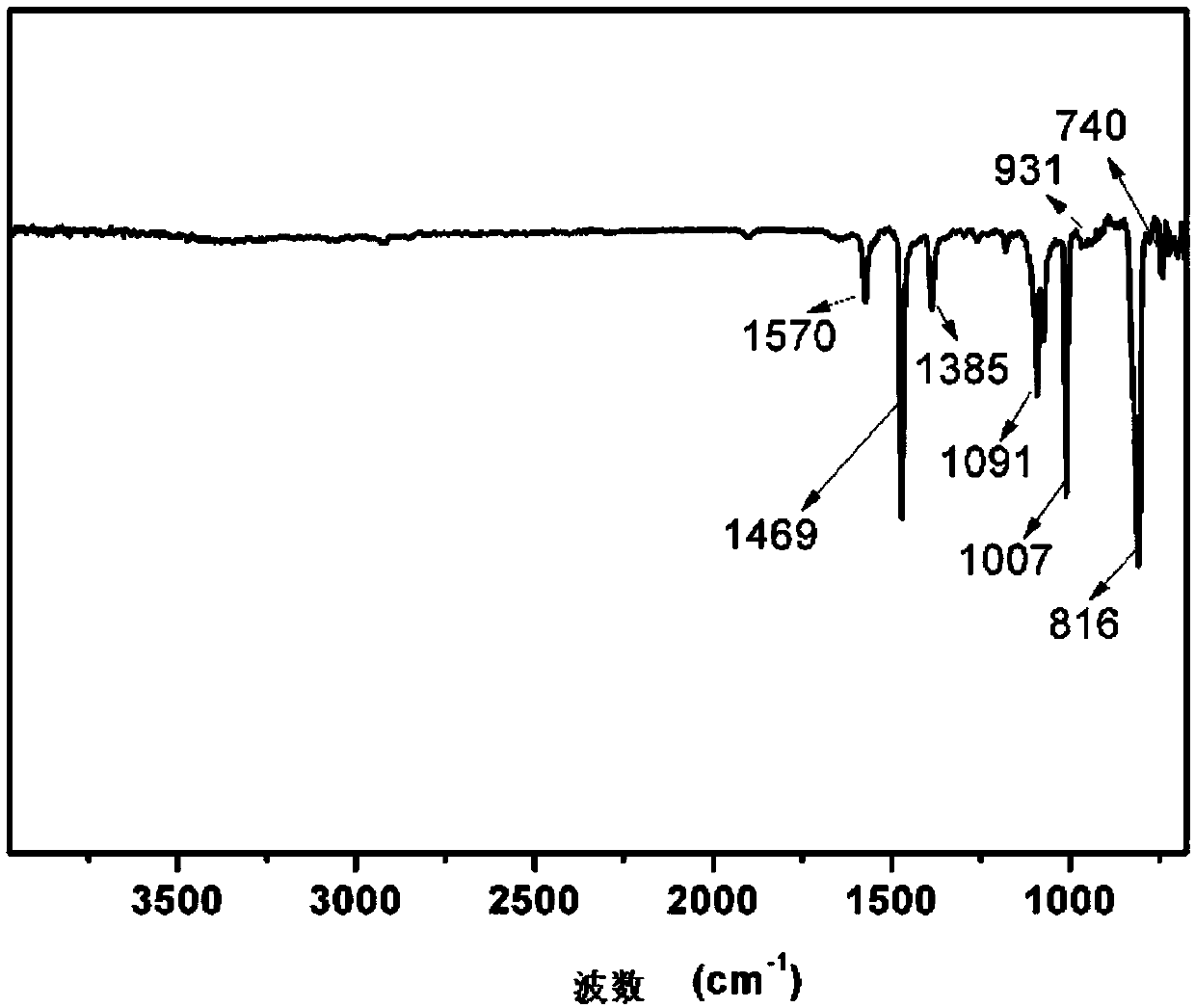

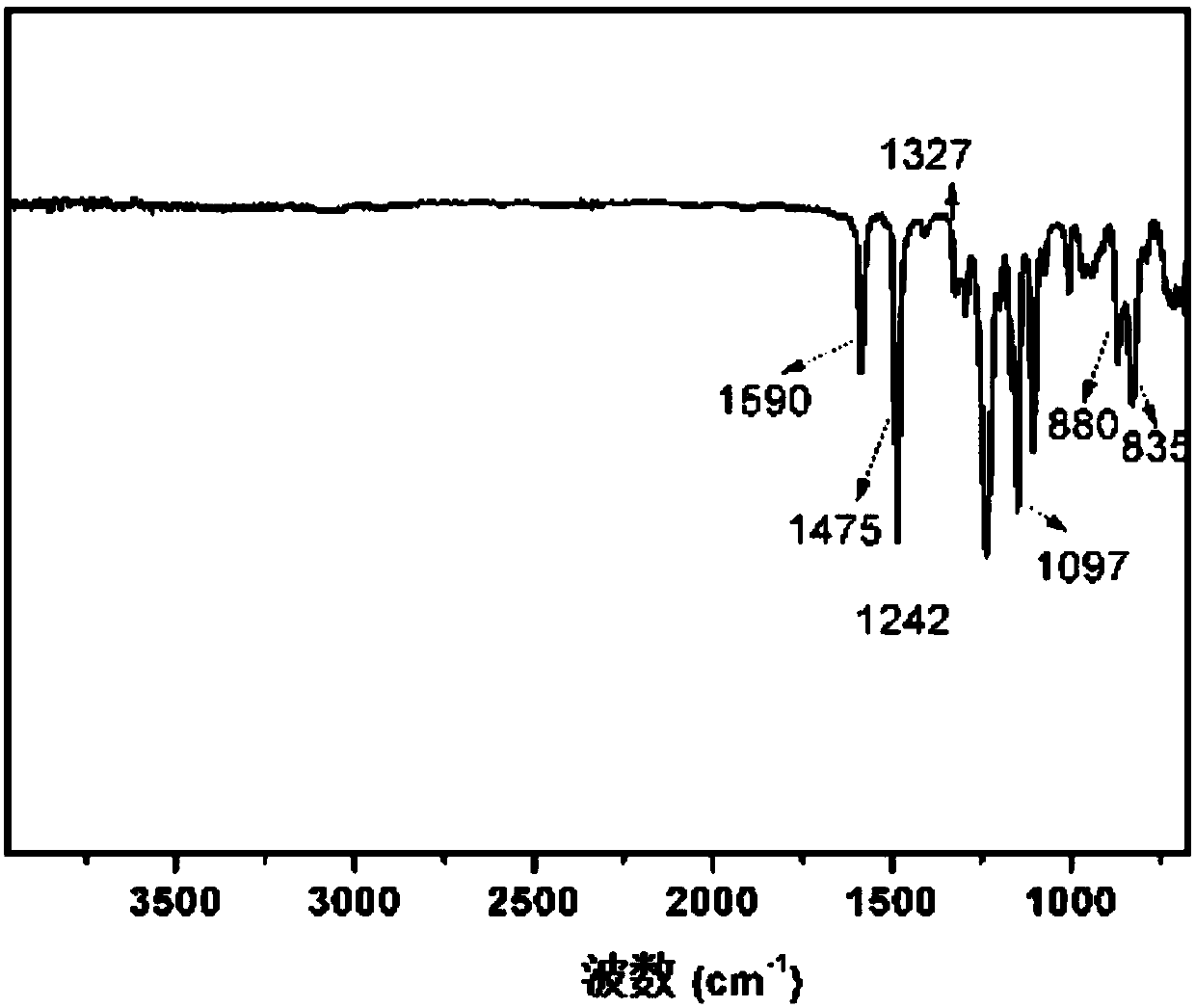

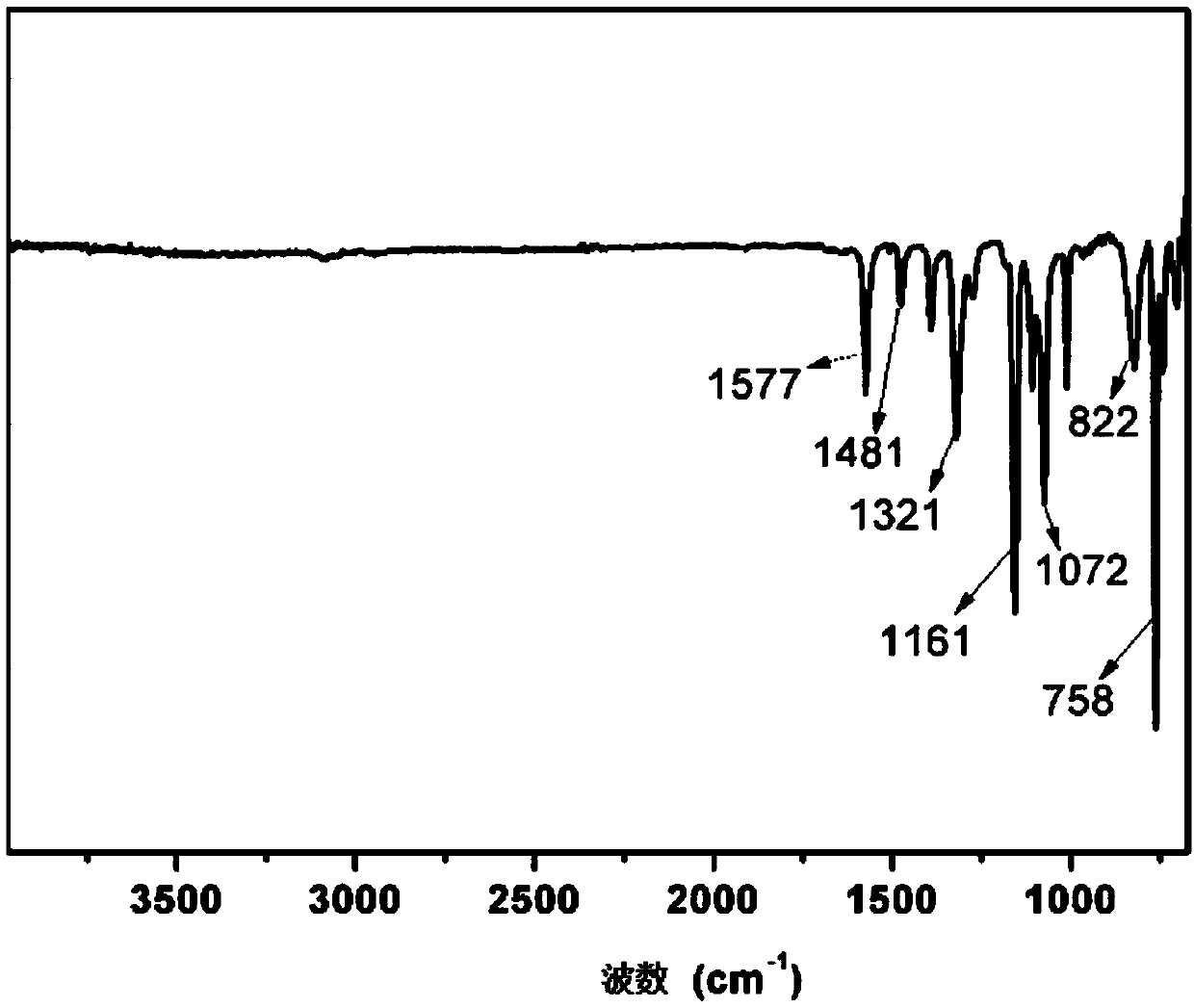

Green high-purity polyarylether and preparation method thereof

The invention relates to a green high-purity polyarylether and a preparation method thereof, and belongs to the field of polymer synthesis. A initial raw material of the green high-purity polyarylether is composed of the following components in parts by weight: 56 to 324 parts of a diphenol compound or a sulfide, 114 to 577 parts of a dihalogenated aromatic compound, 400 to 5000 parts of a solvent, 0.1 to 300 parts of an auxiliary agent, 500 to 5000 parts of a supercritical extraction agent and 300 to 3000 parts of an auxiliary agent leaching agent; the green high-purity polyarylether is prepared by the following preparation method: 1) carrying out dehydration reaction; 2) recovering the solvent for the first time through high-temperature filtration or high-temperature closed flash evaporation; 3) carrying out supercritical extraction to recovery the solvent; and 4) carrying out auxiliary agent recovery and separation. The purity of the obtained polyarylether is more than or equal to 99.9%, the whiteness is more than or equal to 75, the impurity content is less than or equal to 20 ppm, the complete recycling of the solvent and the auxiliary agent is achieved in the whole preparation process, and the method is green and environmentally friendly.

Owner:成都锦颜科技有限公司

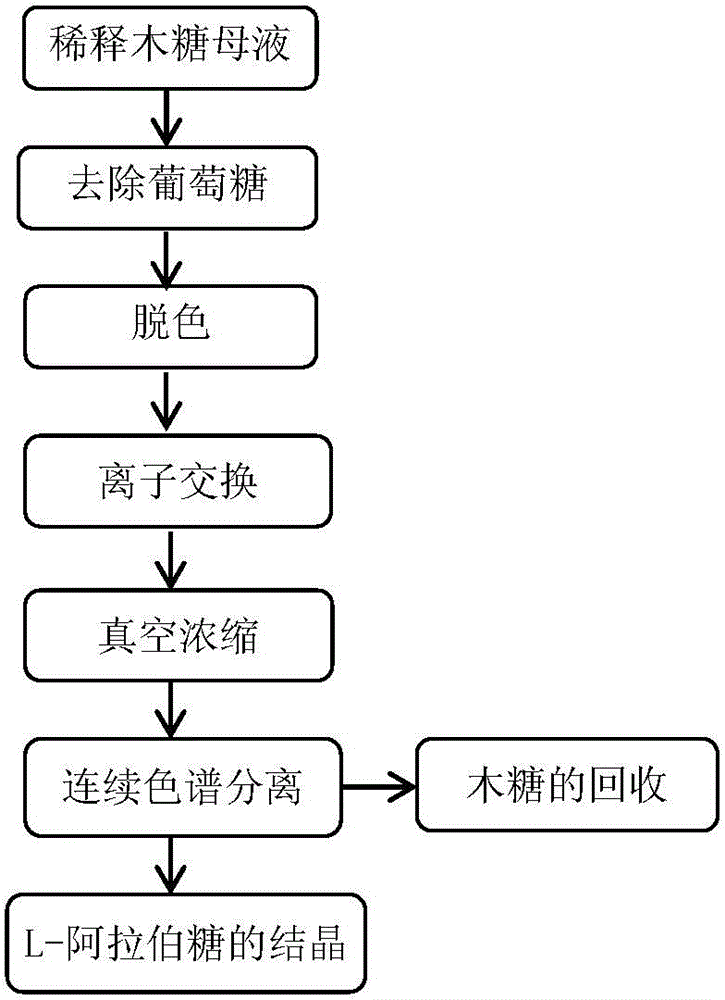

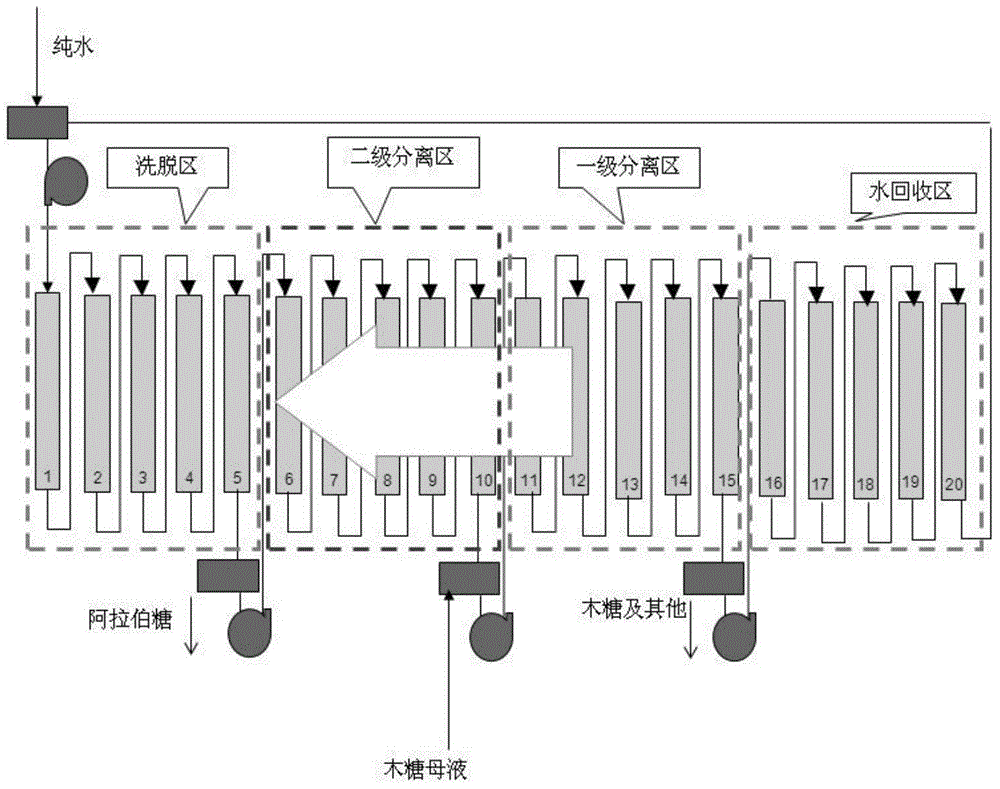

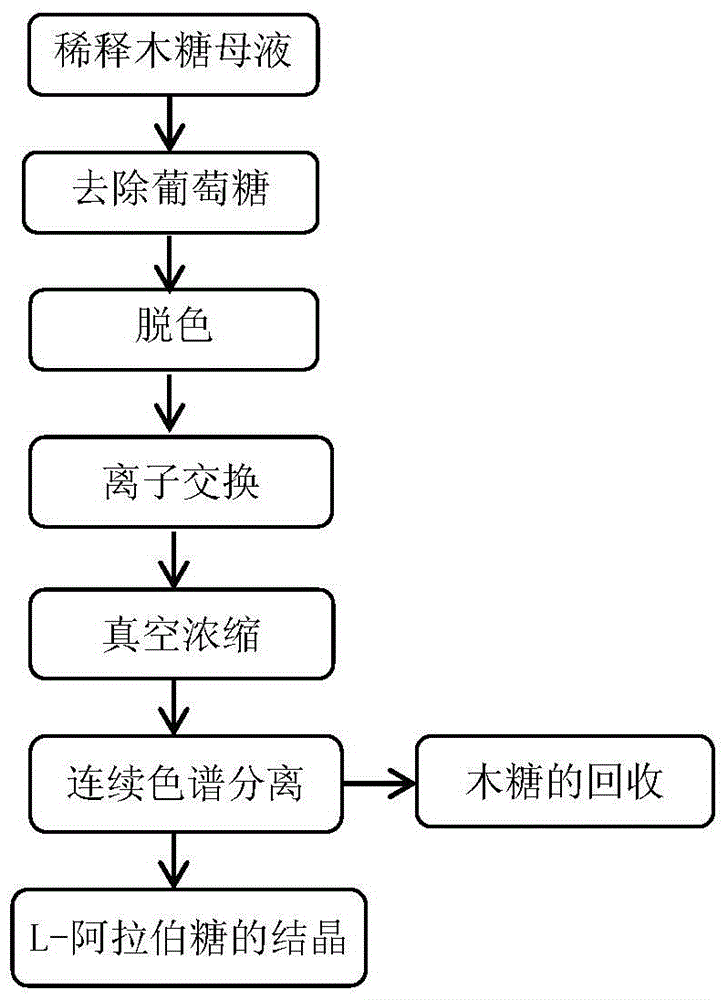

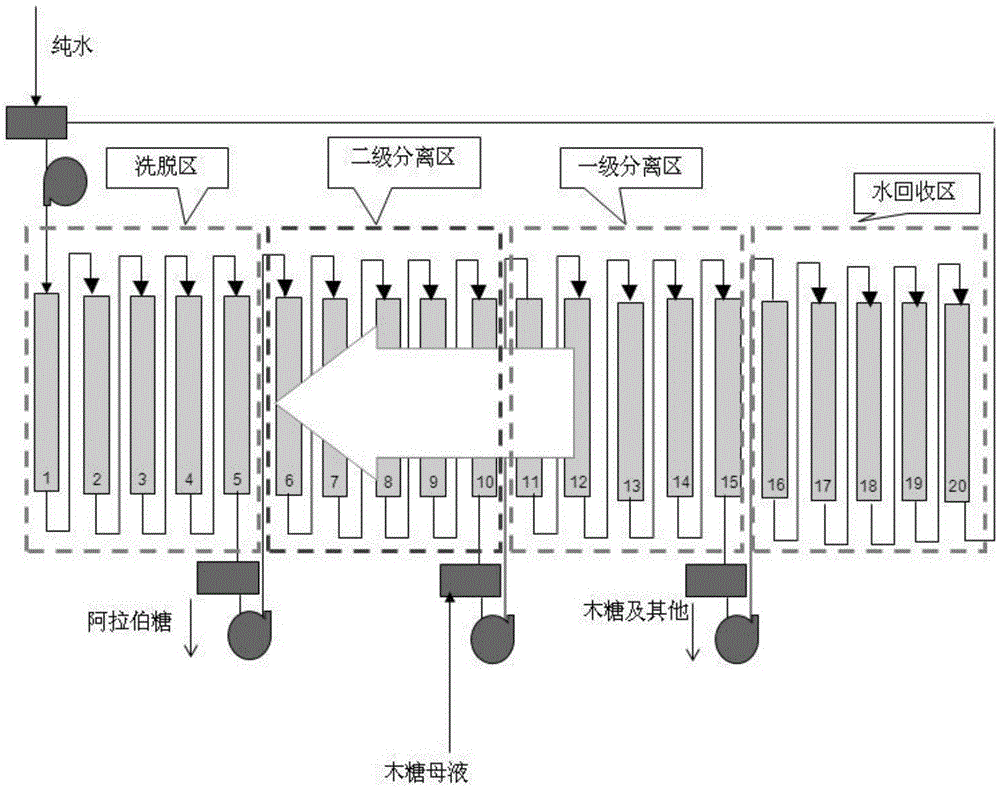

Method of producing L-arabinose by xylose mother liquid

InactiveCN104086607ASimple processLow input costSugar derivativesSugar derivatives preparationChromatographic separationEvaporation

The invention provides a method of producing L-arabinose by a xylose mother liquid. The method comprises the following steps: first, diluting the xylose mother liquid; then, removing glucose by active dry yeast powder; further refining the xylose mother liquid through decoloration, ion exchange and evaporation concentration; then obtaining an L-arabinose component solution and a xylose component solution through a continuous chromatographic mobile bed and respectively crystallizing to obtain an L-arabinose product and a xylose product. The method provided by the invention extracts L-arabinose through the continuous chromatographic mobile bed by using a byproduct xylose mother liquid in production of crystallized xylose by bagasse, is simple in operation, low in technical cost and good in separating effect, and has an extremely wide application valve. The obtained L-arabinose is high in purity and yield.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

Method for preparing 5-hydroxymethyl furfural

InactiveCN103204836AUnique Catalytic PropertiesImprove catalytic performanceOrganic chemistrySucroseReaction temperature

The invention discloses a method for preparing 5-hydroxymethyl furfural, namely a method for preparing 5-hydroxymethyl furfural by catalyzing biomass sugar with a double-acid catalyst. The method is characterized in that double-acid compound consisting of acid quaternary ammonium salt cations functionalized by alkyl sulfonic acid and Lewis acid inorganic anions is used as a catalyst, and the target of improving the yield of hydroxymethyl furfural (HMF) is reached on the basis of the adjustable features of acid intensity and the concerted catalysis effect of the acid quaternary ammonium salt cations functionalized by alkyl sulfonic acid and the Lewis acid inorganic anions, wherein the reaction conditions are that the volume ratio of water to an organic solvent is (1:5) to (1:20); the mass ratio of the catalyst to the biomass sugar (fructose, glucose and cane sugar) is (1:2) to (1:10); the reaction temperature is 160-220 DEG C; and the reaction time is 5-60 minutes, and preparing the HMF. Compared with the prior art, the method has the advantages that the catalyst has unique catalytic characteristic, is stable in catalytic performance, and easy to separate, and can be repeatedly used; the process is simple, and emission of the 'three wastes' is low; and the selection range of biomass sugars serving as raw materials is wide and the biomass sugar such as cheap cane sugar can be used as a reactant to produce high value-added products.

Owner:QINGDAO UNIV OF SCI & TECH

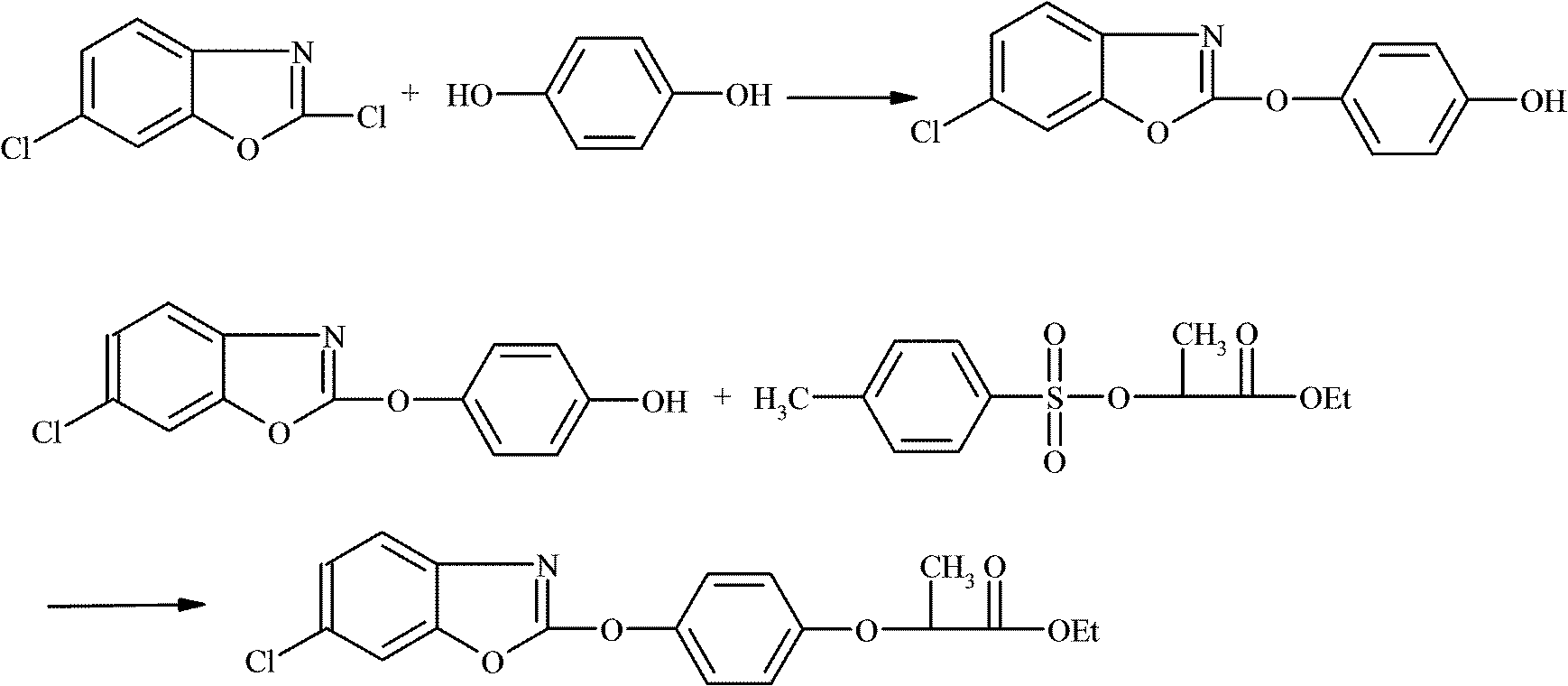

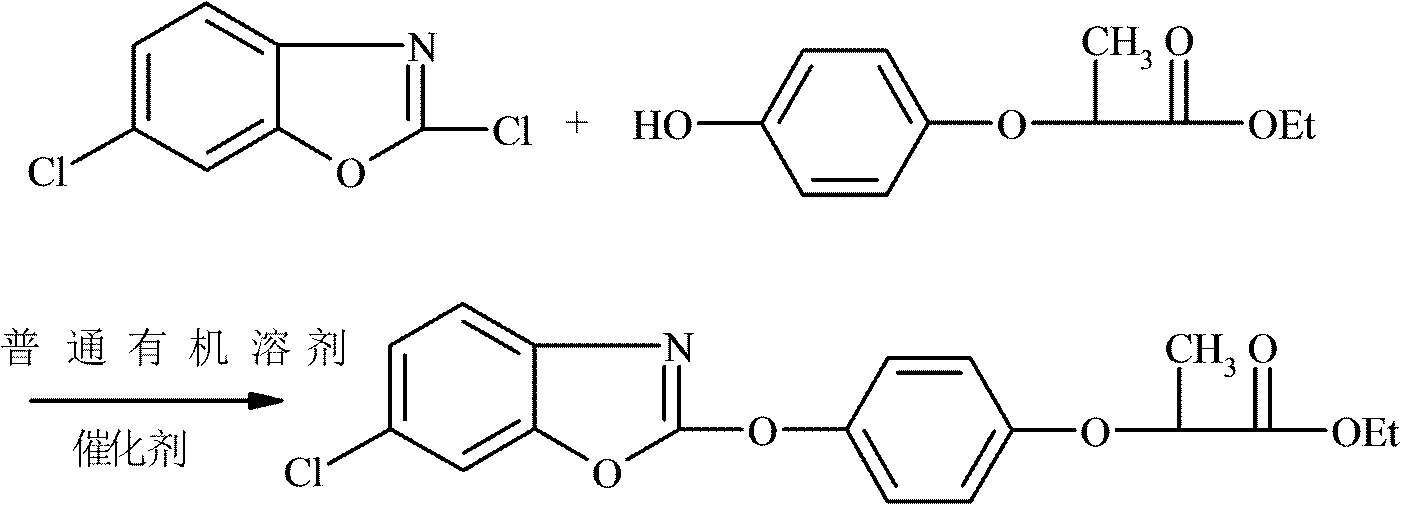

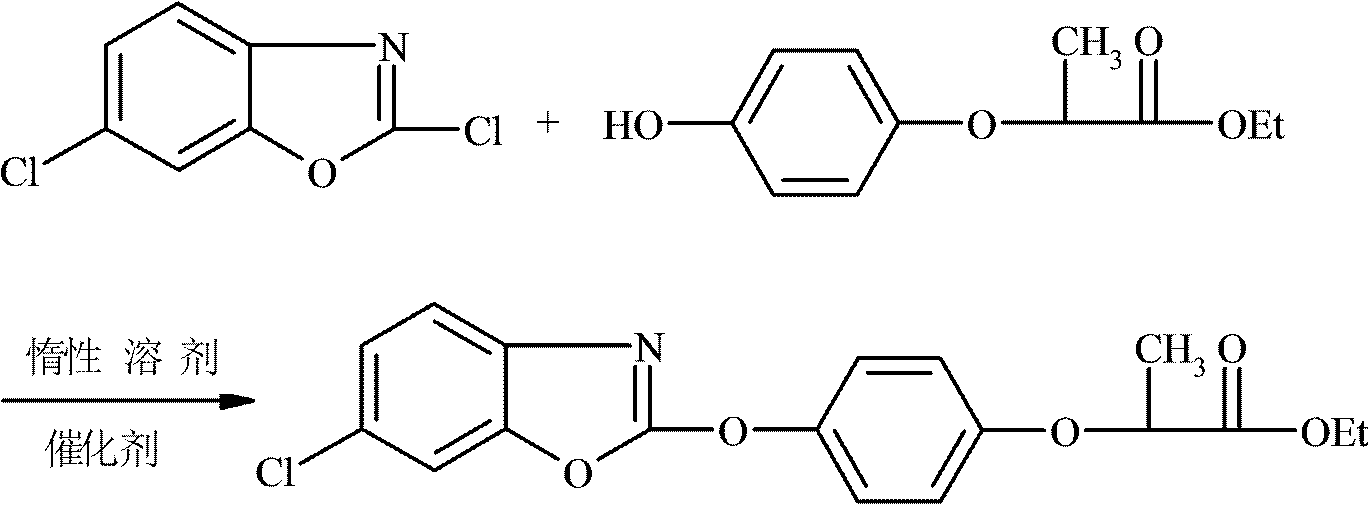

New method for synthesizing fenoxaprop-P-ethyl

The invention discloses a new method for synthesizing fenoxaprop-P-ethyl. The method comprises the following steps of: dissolving ethyl R-(+)-2-(4-hydroxyphenoxy)propionate in an inert organic solvent, adding an acid binding agent potassium carbonate and a catalyst polyethylene glycol, stirring and mixing at the temperature of between 20 and 55DEG C, heating, slowly adding 2,6-dichlorobenzoxazole, keeping the temperature for reaction, filtering, evaporating the inert organic solvent for direct recovery and mechanical application, separating out a crude product, and recrystallizing to obtain the fenoxaprop-P-ethyl, wherein the inert organic solvent is one or more of benzene, methylbenzene, chlorobenzene and dichloroethane. The synthesis method only requires one-step reaction, the synthesiscost is saved, the preparation product has the advantages of high yield, high purity, high rotary content and the like, the pollution is light, and the recovered solvent can be directly applied to production mechanically. The fenoxaprop-P-ethyl has high market competitiveness and can meet the requirements of high-end markets at home and abroad.

Owner:JIANGSU FLAG CHEM IND

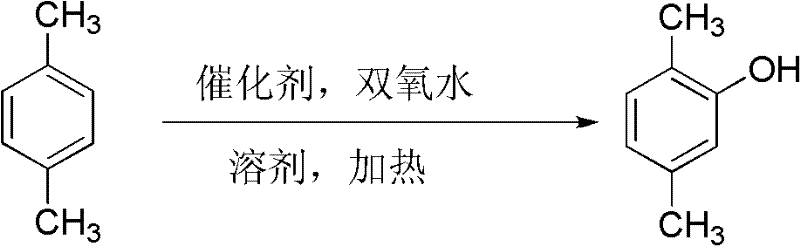

Method for preparing 2,5-dimethyl phenol through direct catalytic hydroxylation of p-xylene

InactiveCN102199072AEasy to getEasy to implementOrganic chemistryOrganic compound preparationReaction temperatureAcetonitrile

The invention provides a method for preparing 2,5-dimethyl phenol through the direct catalytic hydroxylation of p-xylene. In the method, acetonitrile is taken as a solvent, H2O2 is taken as a hydroxylation reagent, C.I. pigment green 8 is taken as a catalyst, the p-xylene is subjected to one-step catalytic hydroxylation at the temperature of between 40 and 70 DEG C for 4 to 7 hours to form the 2,5-dimethyl phenol, and the mass ratio of reaction materials, namely the H2O2 to the acetonitrile to the C.I. pigment green 8 to the p-xylene is (6-9):(15-30):(0.05-0.2):1. The catalyst is readily available, a few reaction steps are performed, the H2O2 can be fully utilized, the solvent can be recycled, and a few three wastes (waste water, waste gas and waste residues) are generated; and the catalytic hydroxylation operation process is easy to implement.

Owner:TIANJIN UNIV

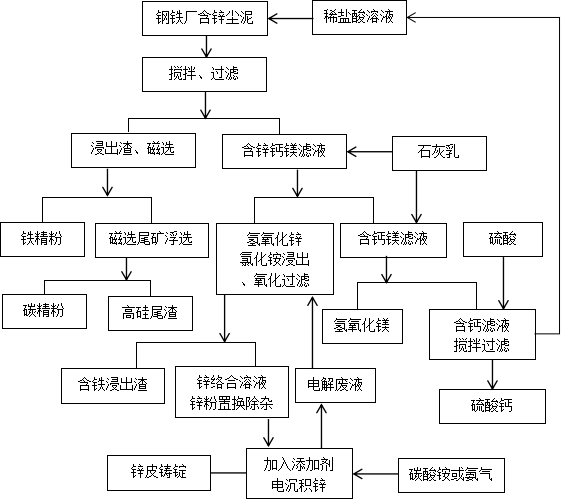

Comprehensive utilization method of zinc-containing dust mud of steel plant

PendingCN111647754AHigh feasibilityHigh economic valuePhotography auxillary processesSolid separationAmmonium chloride mixtureSulfuric acid

The invention relates to a comprehensive utilization method of zinc-containing dust mud of a steel plant. The method comprises the following steps that the zinc-containing dust mud and diluted hydrochloric acid are ground and leached at the same time and then stirred and leached, and solid-liquid separation is carried out to obtain leach residues and a solution; lime milk is added into the solution, the ph value is controlled to be 6-9, and solid-liquid separation is carried out to obtain zinc hydroxide and a solution; lime milk is added into the solution, the ph value is controlled to be 9-10, and solid-liquid separation is carried out to obtain magnesium hydroxide and a solution; sulfuric acid is added into the solution, after stirring is carried out, solid-liquid separation is carried out to obtain calcium sulfate and diluted hydrochloric acid, and the hydrochloric acid is leached again; magnetic separation and flotation combined treatment is carried out on leach residues to obtainiron powder, carbon powder and tailings; and zinc hydroxide is subjected to leaching with an ammonium chloride solution, impurity removal purification and zinc electrodeposition, ammonia water is added, the ph value is kept within the range of 3-8, and zinc skin is melted and cast into a zinc ingot. According to the method, iron, carbon, zinc, calcium, magnesium and silicon in the zinc-containingdust mud are separated, extracted and enriched through the process combination of hydrochloric acid leaching, beneficiation iron and carbon separation, ammonia process zinc electrodeposition and the like, and the problems of environmental protection, efficiency, operation cost and the like of treatment of the zinc-containing dust mud of the steel plant are solved.

Owner:吴坤

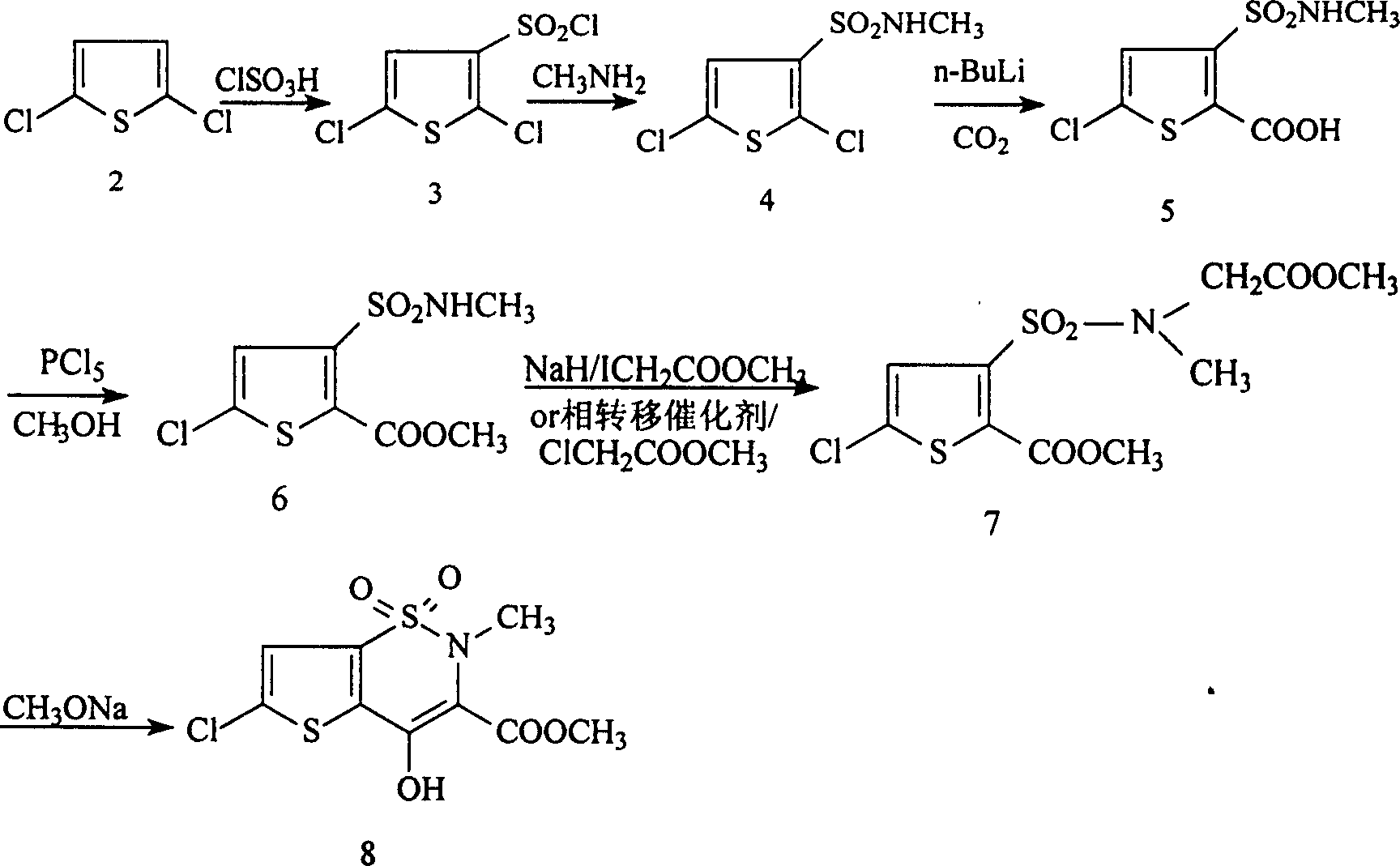

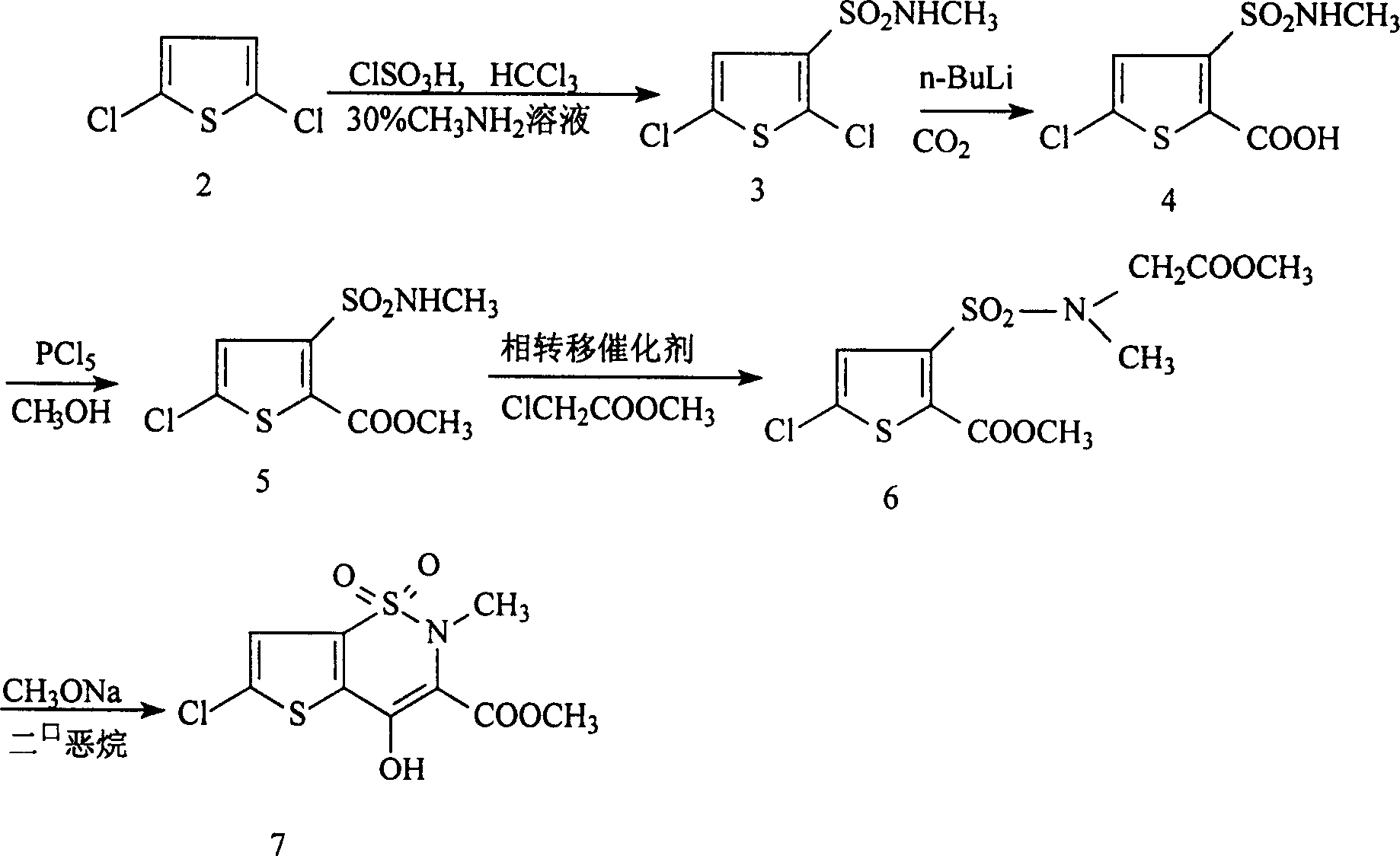

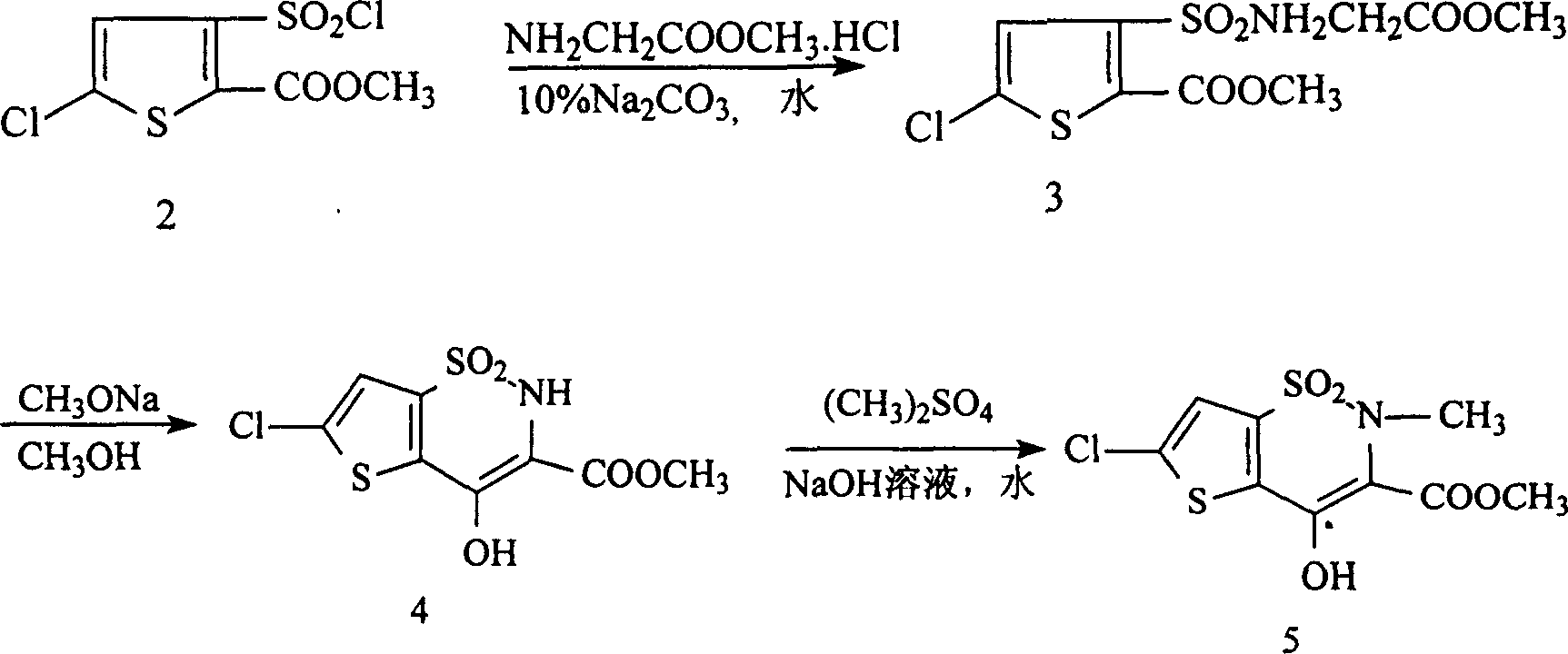

Process for synthesizing lornoxicam intermediate against inflammation and pain

Disclosed is a process for synthesizing lornoxicam intermediate against inflammation and pain, which comprises using 5-chloro-3-thiophene sulfonyl chloride-2-carboxylate as raw material, charging 2-10% of sodium carbonate aqueous solution and 5-30% of glycine methylester hydrochloride simultaneously into water and methanol phases, thermal insulating 6-26 hours at 10-60 deg. C, then filtering and drying to obtain 6-chloro-3-sulfamoyl amido methyl acetate thiophene-2 methyl formate, reacting it with 5-27% of sodium methylate methanol solution 1-15 hours at 30-75 deg. C, filtering to obtain 6-chloro-4-hydroxyl-2H-thione[2,3-e]-1 and 2-thiazine-3-methyl formate-1,1-dioxide, then reacting the filtered substance with dimethyl sulfate in 1-10% aqueous solution of sodium-hydroxide.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

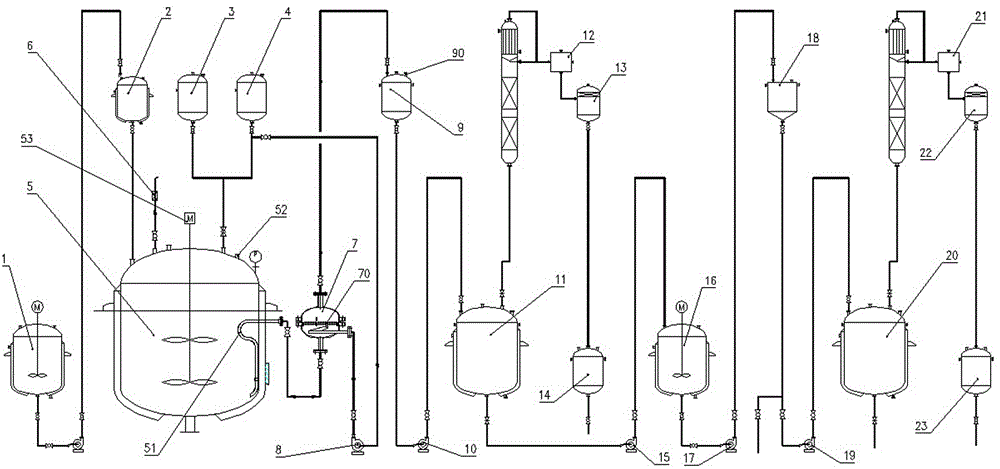

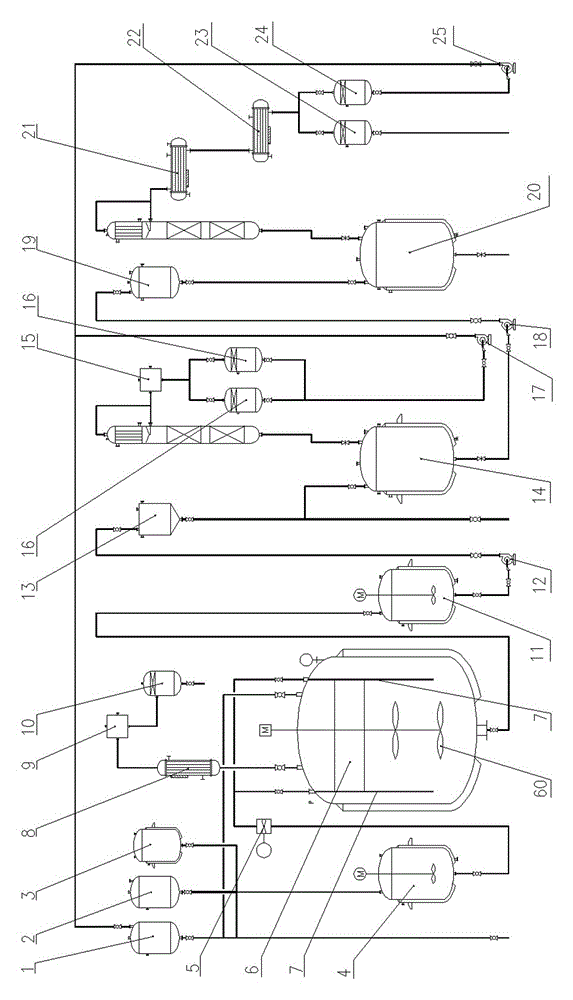

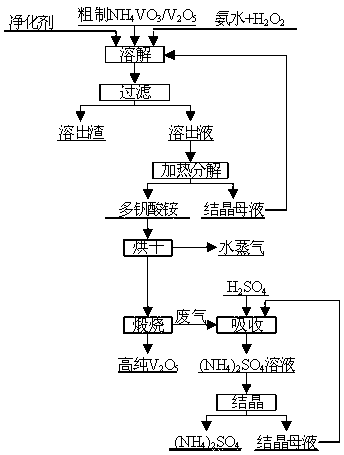

Constant-pressure production device for methyl decalactone synthesized spice and production method

The invention provides a constant-pressure production device for methyl decalactone synthesized spice. The constant-pressure production device comprises a DL-2-Octanol high-level tank, a di-tert-butyl peroxide high-level tank, and an acrylic or methyl acrylate high-level tank and further comprises a kettle type rectifying tower, wherein the DL-2-Octanol high-level tank, the di-tert-butyl peroxide high-level tank and the acrylic or methyl acrylate high-level tank are in pipeline connection with an ingredient pan; the ingredient pan is in pipeline connection with a dropwise adding pump, one or more dropwise adding pipes are arranged in a reaction kettle, and the dropwise adding pump is connected with the dropwise adding pipes; the bottom of the reaction kettle is in pipeline connection with a rinsing pan, the bottom of the rinsing pan is in pipeline connection with a standing high-level tank through a pump A, the standing high-level tank is in pipeline connection with a kettle type distillation tower, and the bottom of the kettle type distillation tower is in pipeline connection with a material high-level temporary storage groove through a pump C; the material high-level temporary storage groove is in pipeline connection with the kettle type rectifying tower, and the kettle type rectifying tower is connected with a product vacuum holding tank through a first-class condenser and a second-class condenser. According to the constant-pressure production device disclosed by the invention, the methyl decalactone synthesized spice can be synthesized in a constant-pressure manner, the product yield is high, the technological conditions are mild, the production cost is relatively low, and environmental pollution is avoided in a production process.

Owner:ANHUI HYEA AROMAS

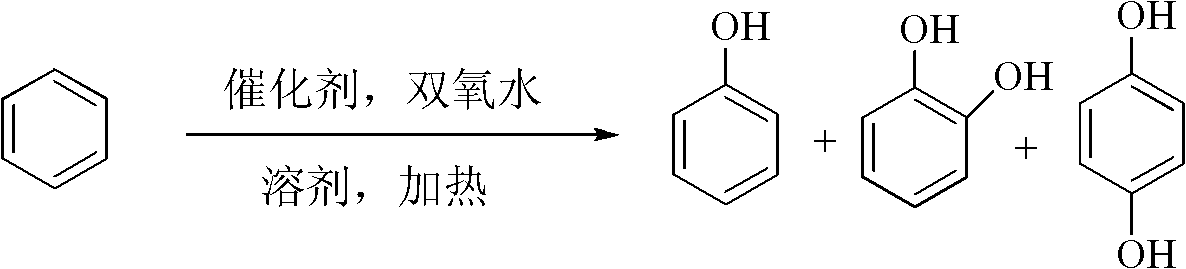

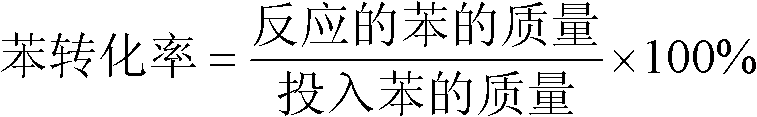

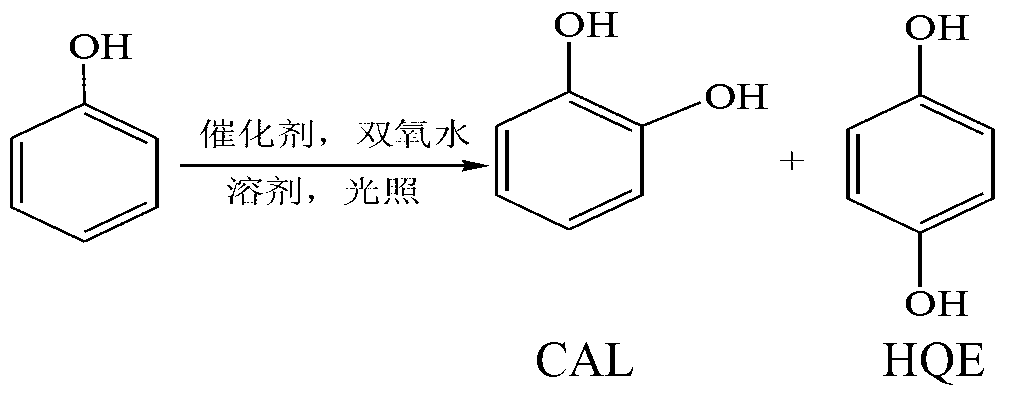

Method for preparing phenol and dihydroxybenzene by catalytic hydroxylation of benzene

InactiveCN102627530AHigh yieldTake advantage ofOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a method for preparing phenol and dihydroxybenzene by catalytic hydroxylation of benzene. The method comprises that benzene undergoes a one-step hydroxylation reaction in the presence of acetonitrile as a solvent, H2O2 as a hydroxylation reagent and pigment green B as a catalyst to be converted into phenol, o-dihydroxybenzene and p-dihydroxybenzene, wherein a mass ratio of H2O2 to benzene is (3 to 8): 1; a mass ratio of acetonitrile to benzene is (15 to 30): 1; a mass ratio of the catalyst to benzene is (0.05 to 0.1): 1; catalytic hydroxylation time is in a range of 4 to 7 hours; and a catalytic hydroxylation temperature is in a range of 40 to 70 DEG C. The method adopts the pigment green B as a catalyst and provides a novel catalysis system for synthesizing phenol, o-dihydroxybenzene and p-dihydroxybenzene by pigment green B catalysis of benzene. The method overcomes the defects that the traditional technology has a lot of reaction steps, produces serious pollution and has a low atom utilization rate. Catalytic hydroxylation is carried out under mild conditions so that discharge of three wastes is reduced; the catalyst can be separated out easily; and a phenol yield is high. Therefore, the method is an environmentally-friendly green synthesis technology of phenols.

Owner:TIANJIN UNIV

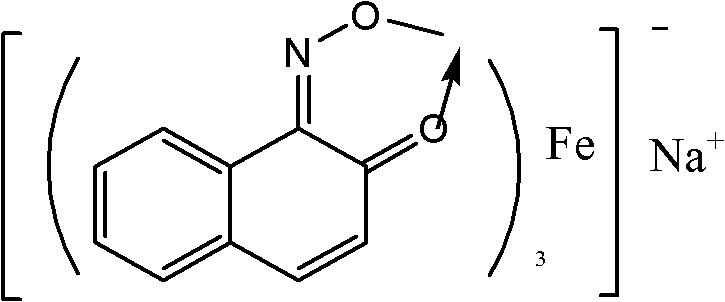

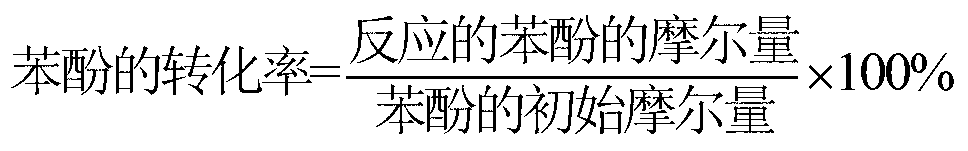

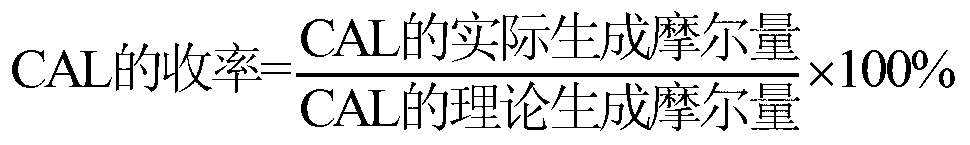

Photocatalyst for synthesizing o-(p-)benzenediol, and synthetic method for o-(p-)benzenediol

InactiveCN103240129AImprove conversion rateHigh selectivityPreparation by oxidation reactionsOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic reactionSurface-active agents

The invention discloses a photocatalyst for synthesizing o-(p-)benzenediol, and a synthetic method for o-(p-)benzenediol. The photocatalyst is prepared by the following steps of: dissolving C.I. pigment yellow 154 into dimethyl sulfoxide solvent, then, adding TiO2 powder into the solution, adding surface active agent Twain-80, and treating under 180-210 DEG C to get the photocatalyst. By photocatalytic reaction, phenol is used as hydroxylation reaction substrate, water and acetonitrile mixture are used as the solvent, H2O2 is used as a hydroxylation reaction reagent, and o-benzenediol and p-benzenediol are synthesized by single step reaction of photocatalytic hydroxylation. In the method disclosed by the invention, hydroxylation reaction is performed just under normal temperature, and high temperature and energy consumption are avoided; the exciting light can be the sunlight which is a clean and cheap reaction driving force, thus, energy is saved; H2O2 can be fully used, and emission of wastewater, waste gas and residue is reduced; phenol conversion rate (more than 62%), product selectivity (more than 86%) and total recovery of catechol and hydroquinone (more than 53) are higher; and the photocatalysis operation process is easier to implement.

Owner:TIANJIN UNIV

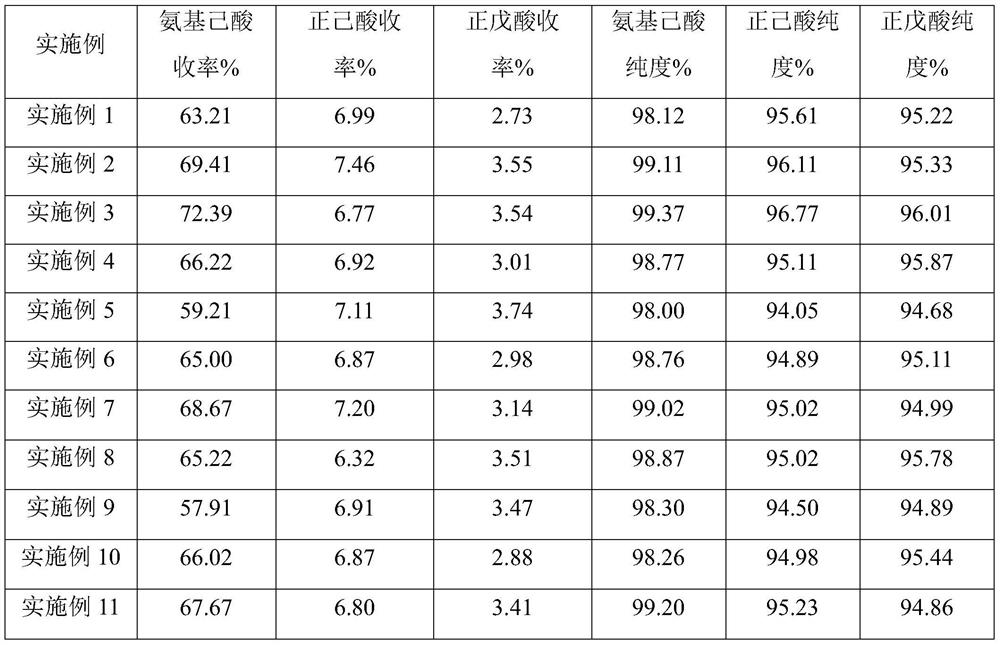

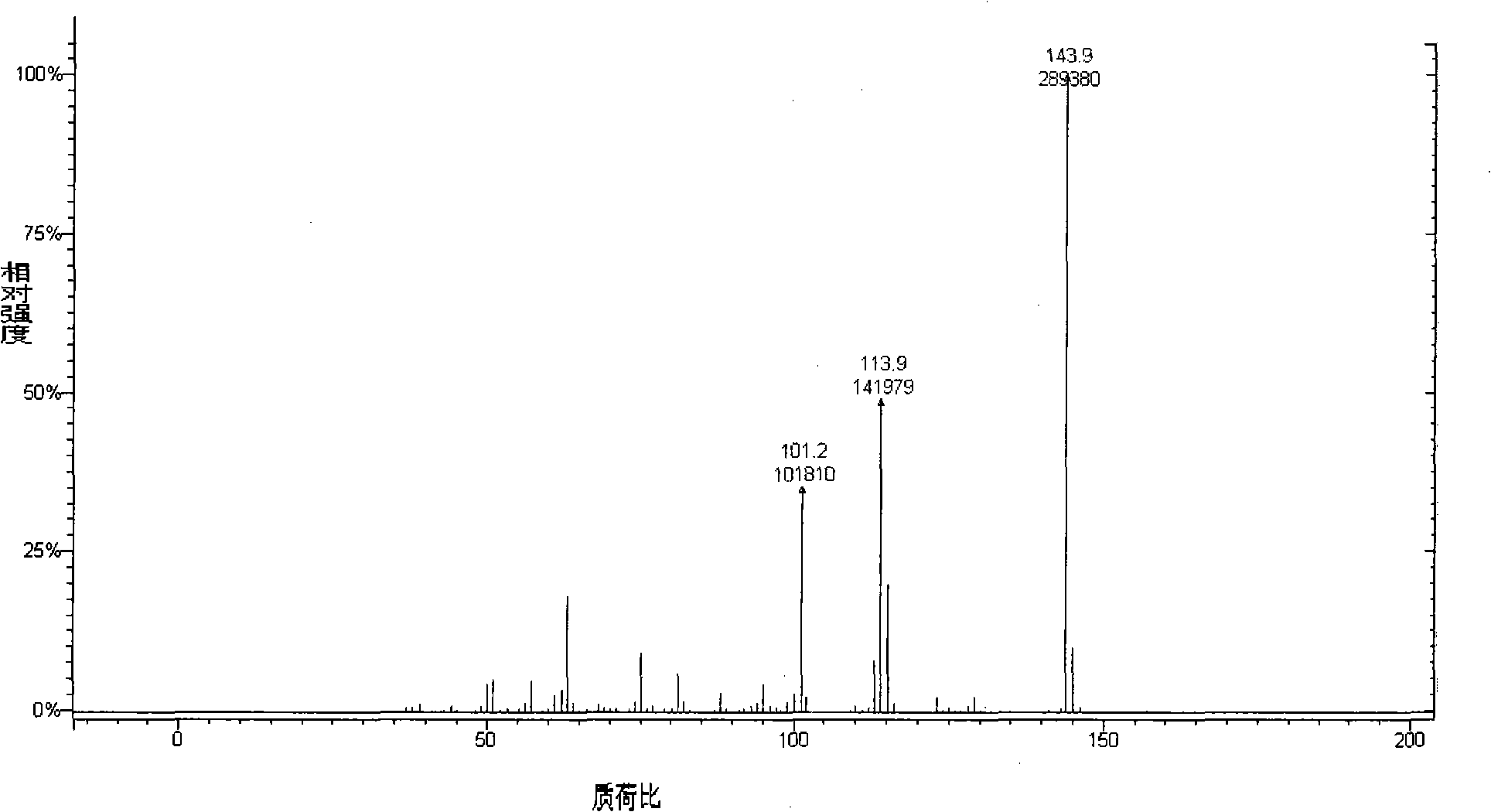

Method for recycling hexanediamine key intermediate reaction residues and co-producing carboxylic acid

ActiveCN111635330ASolve pollutionProcess design innovationOrganic compound preparationAmino-carboxyl compound preparationDepolymerizationHexamethylenediamine

The invention relates to a method for recycling hexanediamine key intermediate reaction residues and co-producing carboxylic acid. The method comprises the following steps: introducing residues and water into a first fixed bed reactor, and carrying out a depolymerization reaction; carrying out heat exchange on the obtained depolymerization reaction liquid, then introducing into a second fixed bedreactor, and carrying out a hydrolysis reaction; carrying out a hydrogenation reaction on the obtained hydrolysis reaction solution, carrying out negative pressure distillation on the obtained hydrogenation reaction solution after the reaction is finished, and removing water to obtain a concentrated solution; and carrying out negative pressure rectification on the obtained concentrated solution, and collecting fractions at different gas phase temperatures to obtain corresponding products of aminocaproic acid, n-valeric acid and n-caproic acid. According to the invention, the method effectivelysolves the problem of key intermediate reaction residue pollution generally existing in existing hexanediamine production, realizes recovery and resource utilization of the key intermediate reactionresidue of hexanediamine, obtains a high-added-value product, reduces the production cost, increases the economic benefit, reduces the emission of three wastes, substantially reduces the pollution tothe environment and provides a guarantee for green and safe production.

Owner:JIANGSU YANGNONG CHEM GROUP +3

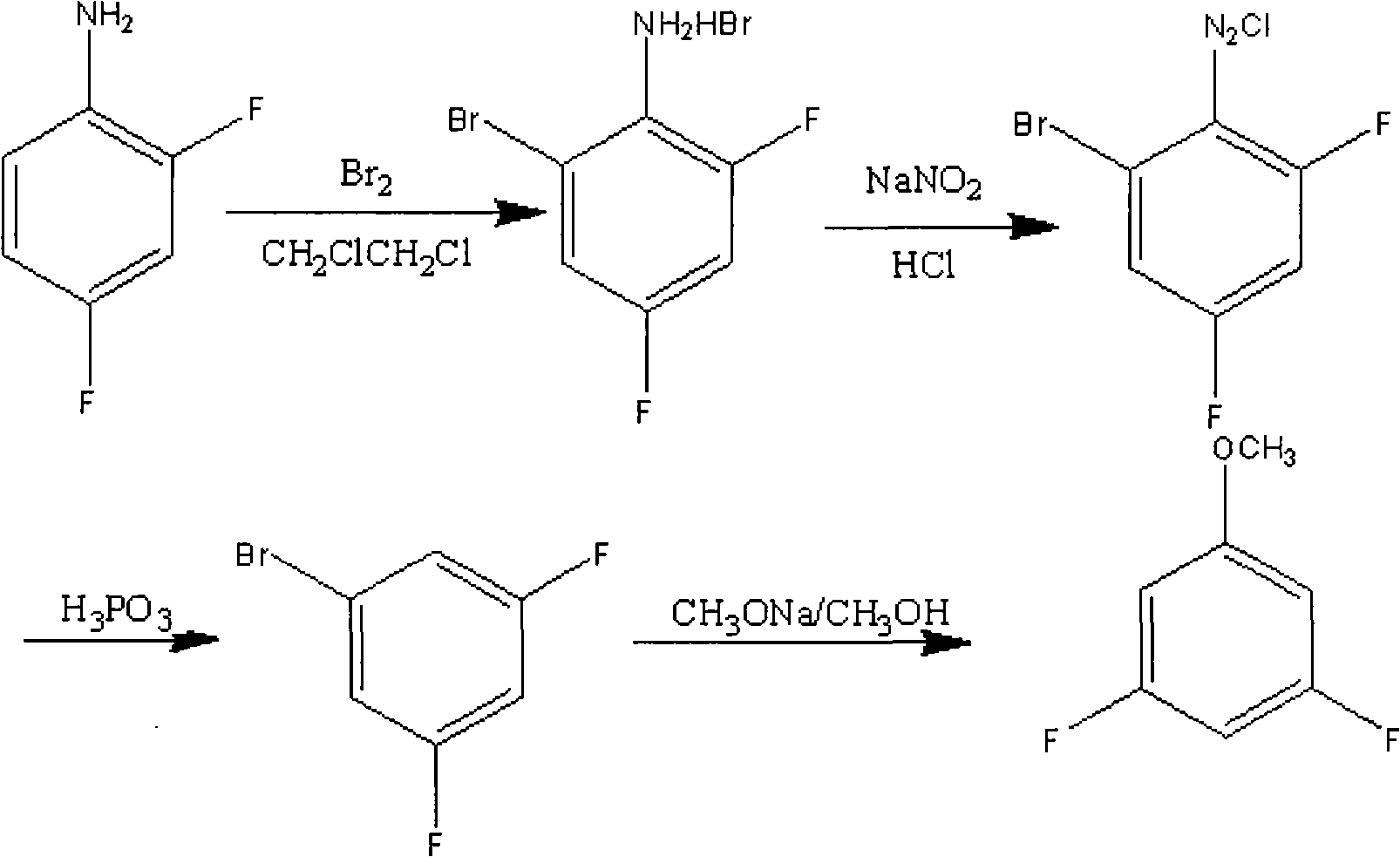

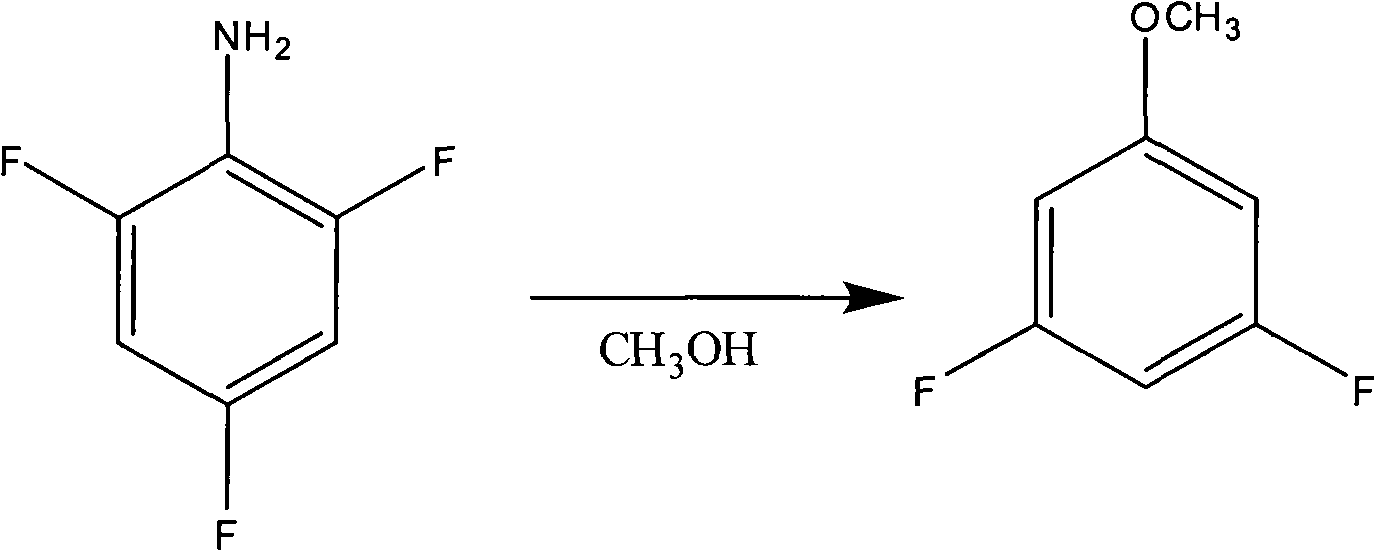

Preparation method of 3,5-difluoroanisole

The invention relates to preparation of an organic compound, particularly to a method for preparing 3, 5-difluoro anisole, which belongs to the field of organic compound preparation technology. With the preparation of the organic compound, reaction products are obtained through a reaction between 1, 3, 5-trifluoro-benzene and sodium methoxide solution with the presence of solvent; then a post treatment is carried out to the reaction products to get 3, 5-difluoro anisole; the prepared product 3, 5-difluoro anisole has high purity and high product yield coefficient; in addition, the reaction steps are few and the production cycle of the product is short.

Owner:HEBEI MAIERSTON ELECTRONICS MATERIAL

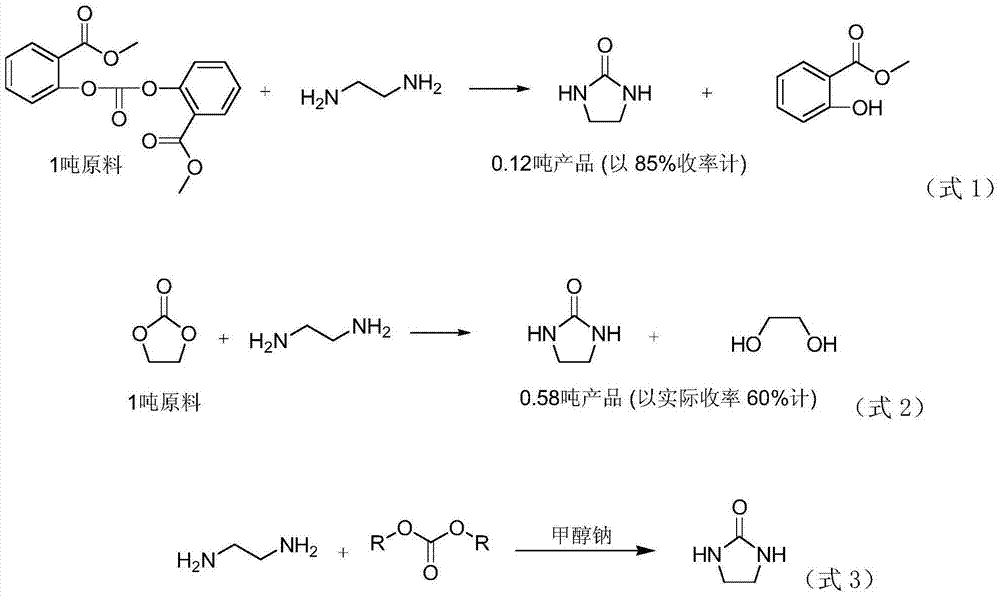

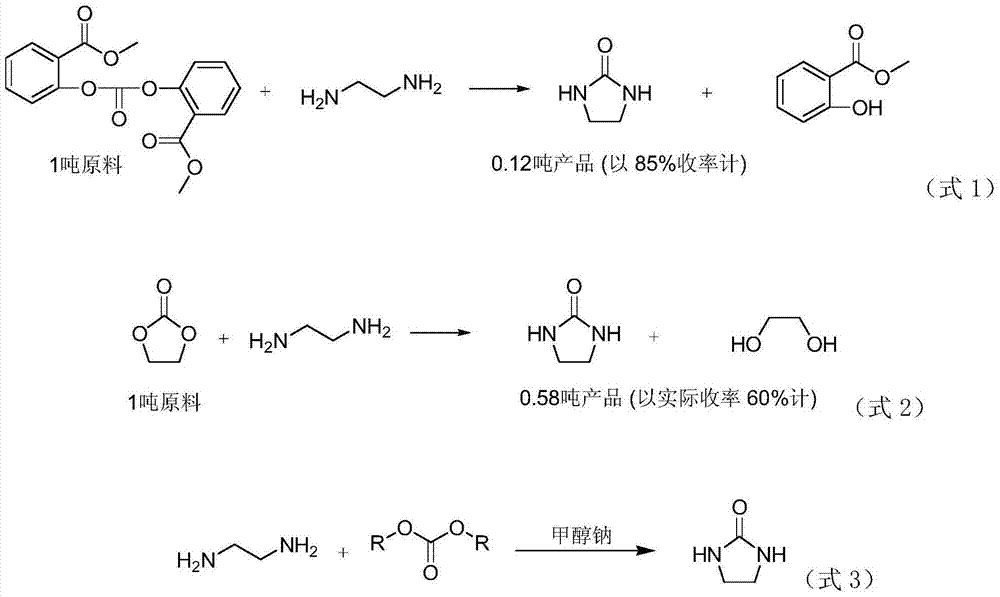

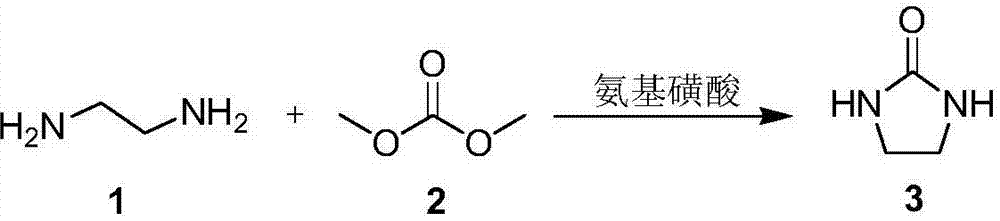

2-imidazolidone synthesis method

InactiveCN103497157ALow priceEasy to recycleOrganic chemistryChemical recyclingEthylenediamineAlcohol

The invention relates to 2-imidazolidone, and provides a 2-imidazolidone synthesis method simple in process and low in cost. The method includes: (1) sequentially adding a catalyst of sulfamic acid, a solvent of methyl alcohol, ethylenediamine and dimethyl carbonate into a heatable reactor for reacting at the temperature of 20-80 DEG C for 1-5 hours; (2) continuously raising the temperature to 120-180 DEG C, and reacting for 10-24 hours prior to generating a target product 2-imidazolidone; (3) after reaction is ended, filtering to remove the catalyst of sulfamic acid and remove the solvent of methyl alcohol so as to obtain a coarse product 2-imidazolidone; (4) refining the coarse product 2-imidazolidone obtained in the step (3) to obtain the product 2-imidazolidone. The defects that an existing synthesis process is carried out at high temperature under high pressure, high-corrosivity catalysts, toxic materials and high boiling solvent are used, atom utilization rate is low and the like are overcome.

Owner:XIAMEN UNIV +1

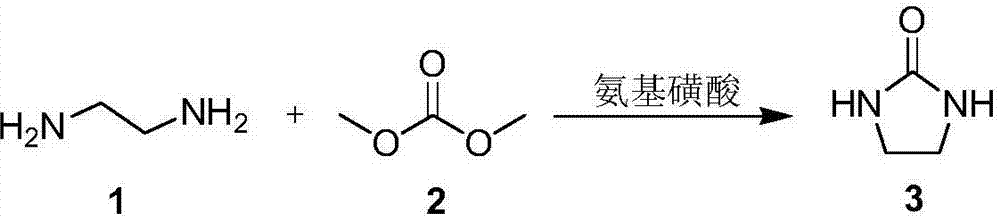

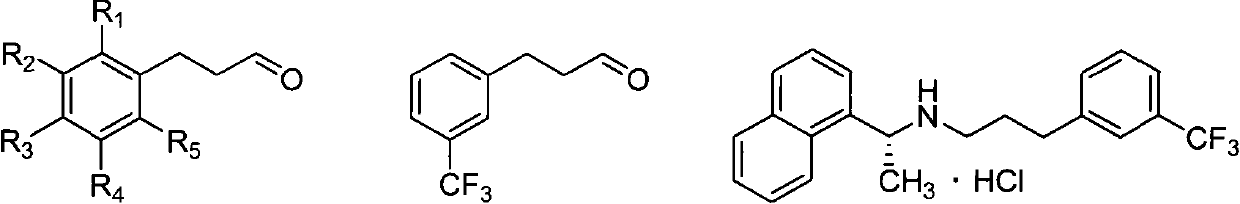

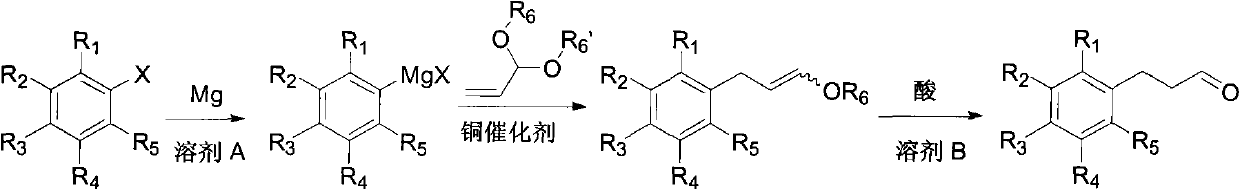

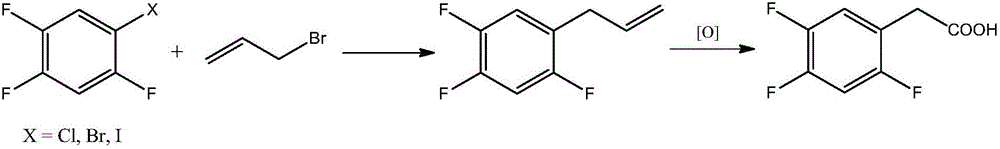

Method for preparing aryl propanal derivatives

InactiveCN102060679AExpensive to overcome source difficultiesHigh production equipment requirementsCarbonyl compound preparation by oxidationArylHydrogen

The invention relates to a method for preparing aryl propanal derivatives. The aryl propanal derivatives are prepared according to a route shown in the specifications, wherein R1, R2, R3, R4 and R5 independently represent hydrogen, C1 to C4 alkyl, C1 to C4 alkoxy, halogen, trihalogenated methyl or nitro respectively; R6 and R6' independently represent hydrogen, C1 to C4 alkyl, C1 to C4 trihalogenated alkyl, substituted benzyl or alkylacyl respectively, and are connected or not connected; and X represents fluorine, chlorine, bromine or iodine. For the method, raw materials are readily available and have low price, oxidation reaction and reduction reaction are not needed, the route is simple, reaction conditions are mild, the requirement on production equipment is low, the emission of three wastes is low, and industrial production is easy to implement, so the method can be widely applied to the synthesis of medicines, daily chemicals and the like.

Owner:中国中化股份有限公司 +1

Method of synthesizing tricyclodecenyl isobutyrate spice

InactiveCN104829454AOvercoming the disadvantages of inactivationHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationElectrophilic additionFine chemical

A method of synthesizing tricyclodecenyl isobutyrate spice relates to the technical filed of fine chemical engineering synthesis. In the invention, with dicyclopentadiene and isobutyric acid in approximate equimolar proportion as raw materials, with zeolite-carrying phosphotungstic acid as a catalyst and with isobutyric anhydride as a protective agent, the tricyclodecenyl isobutyrate is synthesized. An acetylation reaction is directly carried out to prepare a crude product of the tricyclodecenyl isobutyrate by one step through electrophilic addition under catalysis of a catalyst. Meanwhile, a less amount of the isobutyric anhydride is added for protecting the catalyst, and then the isobutyric acid is recycled and reused so that a finish product of the tricyclodecenyl isobutyrate is obtained through neutralization washing and rectification. The method can solve problems that the spice has a sour smell in fragrance and the quality of the spice is influenced since a method in the prior art pollutes environment, is complex in post-treatment process, causes equipment corrosion and is uncooperative in ratio of isomers. The method employs the raw materials being easy to get, is mild in conditions, is high in conversion rate, is convenient to carry out, is high in yield, is less in emission of waste gas, waste water and solid waste during production and belongs to a clean production process.

Owner:ANHUI HYEA AROMAS

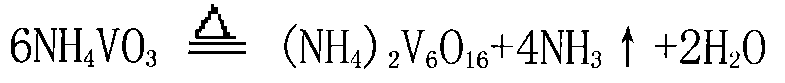

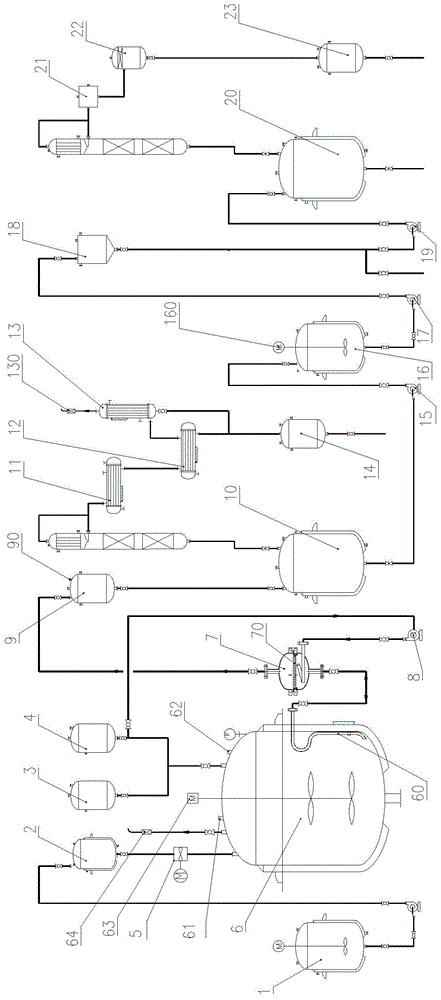

Method for clean production of high-purity vanadium pentoxide by using hydrogen peroxide and ammonia water

ActiveCN109336177AHigh purityLow impurity contentVanadium oxidesAmmonia compoundsAmmonium metavanadateAmmonia

The invention relates to the technical field of vanadium pentoxide production, in particular to a method for clean production of high-purity vanadium pentoxide by using hydrogen peroxide and ammonia water. The method comprises the following steps: (1) taking roughly prepared ammonium metavanadate of V2O5 of which the purity is 95% to 98% after calcined and roughly prepared vanadium pentoxide of which the purity is 95% to 98% as raw materials, adding ammonia water and hydrogen peroxide to be dissolved, slowly adding a purifying agent to remove impurities while dissolving and stirring; (2) filtering; (3) heating to decompose; (4) drying and calcining; (5) recovering exhaust gas. The method for the clean production of high-purity vanadium pentoxide by using hydrogen peroxide and ammonia waterdisclosed by the invention has the beneficial effects that compared with the prior art, vanadium pentoxide produced by the method provided by the invention is high in purity, low in impurity content,simple in process, low in consumption of chemical reagents, low in discharge of three wastes (waste water, waste gas and waste residues), low in investment and easy to industrialize.

Owner:联和能源投资控股有限公司

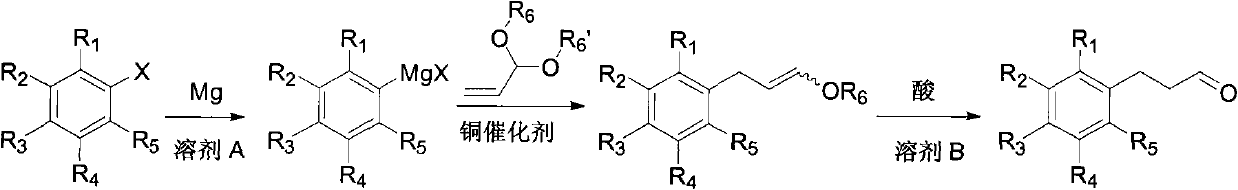

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951ARich sourcesReduce manufacturing costOrganic compound preparationAmino compound preparationSodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

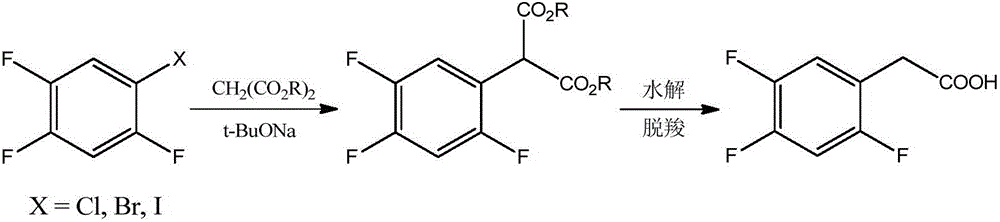

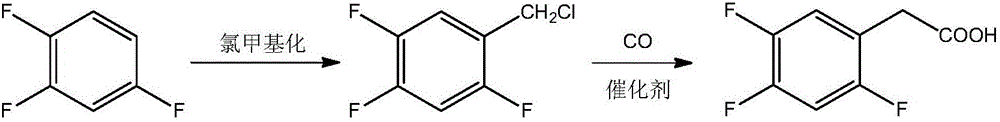

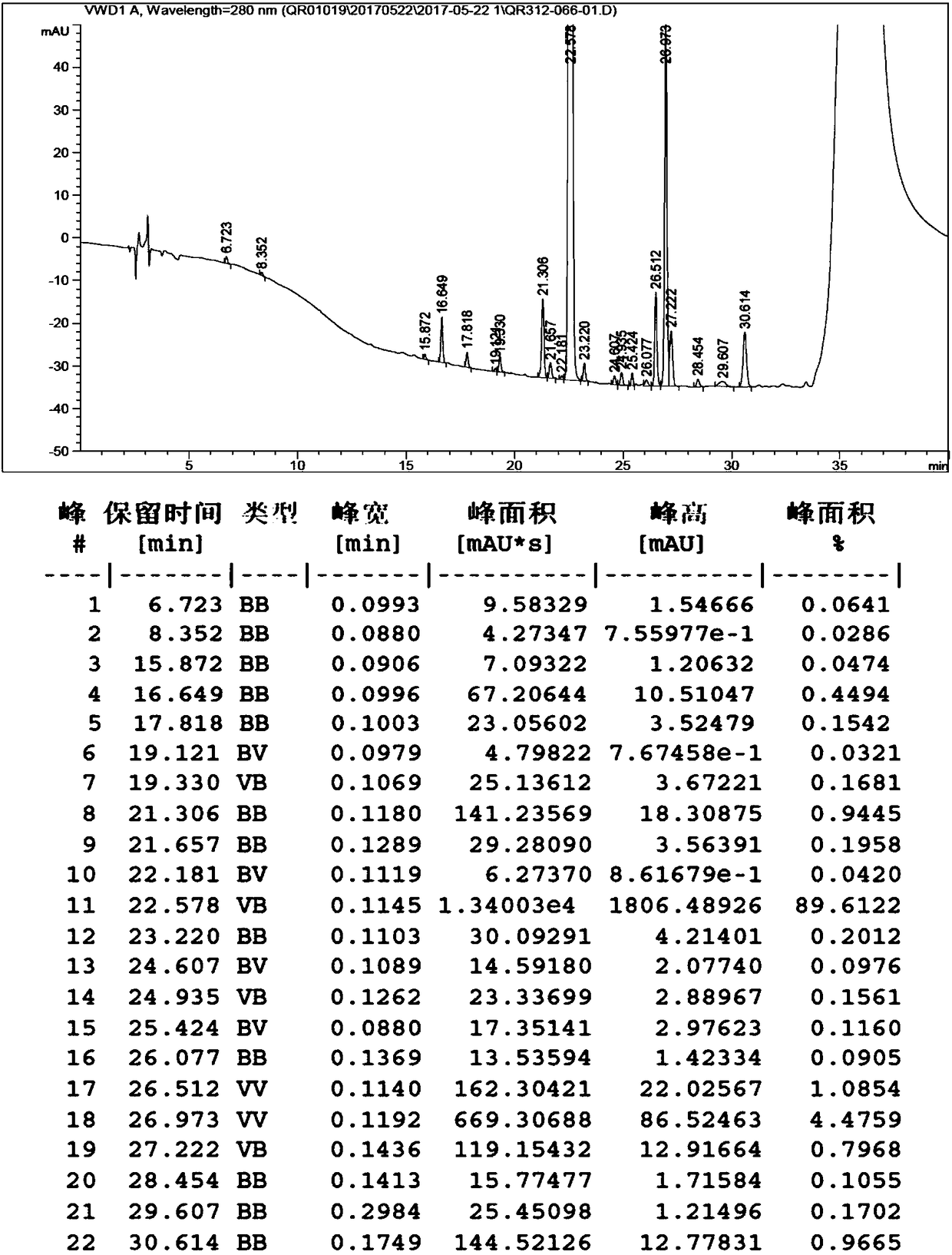

Novel method for preparing 2,4,5-trifluoro phenylacetic acid

ActiveCN106748716ARaw materials are easy to getMild reaction conditionsOrganic compound preparationHydroxy compound preparationAcetic acidAlkyl transfer

The invention provides a novel method for preparing 2,4,5-trifluoro-phenylacetic acid. The novel method specifically comprises the following steps: (1) dissolving 1,2,4-trifluoro benzene into 1,2-dihalogenated ethane, carrying out a Friedel-crafts alkylation reaction under catalysis of a lewis acid catalyst, thus preparing 2,4,5-trifluoro halogenated ethylbenzene; (2) hydrolyzing the 2,4,5-trifluoro halogenated ethylbenzene obtained in the step (1) in an alkaline system, thus obtaining 2,4,5-trifluoro phenethyl alcohol; (3) oxidizing the 2,4,5-trifluoro phenethyl alcohol obtained in the step (2), thus obtaining the 2,4,5-trifluoro phenylacetic acid. The novel method disclosed by the invention has the advantages that raw materials are easy to obtain, the reaction is mild, the operation is easy, the cost is low, environment friendliness is realized, no high-toxicity reagent exists, and the like.

Owner:JIANGSU HANKUO BIOLOGICAL

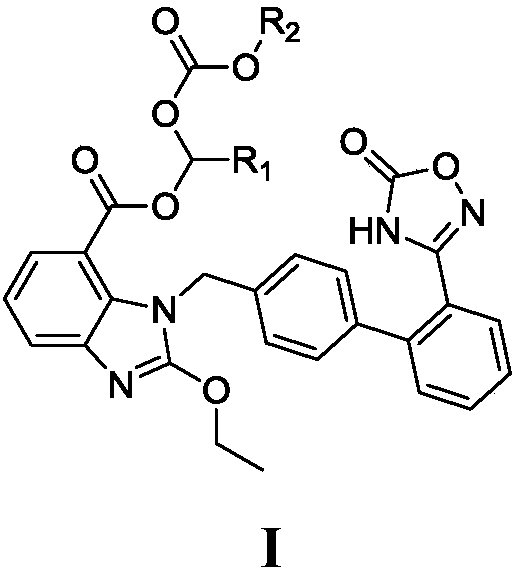

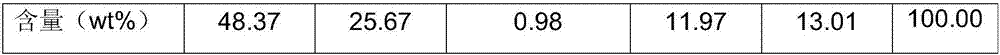

Preparation and analysis methods of benzimidazole derivative

The invention belongs to the field of preparation methods of drug compounds and particularly relates to preparation and analysis methods of a benzimidazole derivative. The preparation method comprisesthe steps of recrystallizing a mixture containing a compound represented by a formula I shown in the description with a solvent, carrying out pulping, carrying out filtering, and carrying out drying,thereby obtaining the product. According to the methods, the preparation process is simple in operation; compared with the prior art, the methods have the advantages that the operation cycle is short, the cost is low, the product yield is high, the discharge of waste gases, waste water and waste residues is low, the obtained compound is relatively high in purity, and the content of a rearrangement product is low. The purification process provided by the invention solves the technical problem of the existing column chromatography that amplified large-batch purification cannot be achieved and meets the requirements on industrial production.

Owner:WUHAN LL SCI & TECH DEV

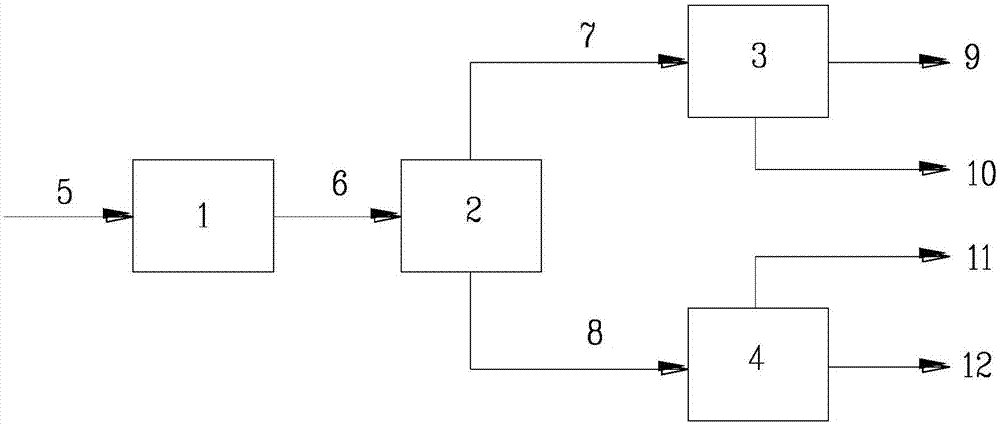

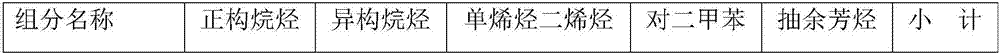

Method of comprehensively utilizing byproduct gasoline by methanol-to-propylene device

ActiveCN106947530AToxic reductionSimple processTreatment with hydrotreatment processesGasolineAromatic hydrocarbon

The invention relates to a method of comprehensively utilizing a byproduct gasoline by a methanol-to-propylene device and mainly solves the problem that in the prior art, MTP byproduct gasoline is low in comprehensive utilization ratio, the project investment is relatively high and the energy consumption is relatively high. By means of the method of comprehensively utilizing the byproduct gasoline by the methanol-to-propylene device, the MTP byproduct gasoline firstly passes through a gasoline hydrogenation unit to obtain hydrogenated gasoline, then the hydrogenated gasoline enters an aromatic hydrocarbon extraction unit, non-aromatic hydrocarbon raffinate oil enters a pressure swing adsorption unit to obtain n-alkanes and isoparaffin, and the aromatic hydrocarbon obtained by the aromatic hydrocarbon extraction unit enters a mobile bed adsorption separation unit to obtain raffinate aromatic hydrocarbon and paraxylene, so that the above problems are solved well, and the method can be used in the methanol-to-propylene device.

Owner:SINOPEC SHANGHAI ENG +1

A method for producing l-arabinose from xylose mother liquor

InactiveCN104086607BSimple processLow input costSugar derivativesSugar derivatives preparationYeastChromatographic separation

The invention provides a method of producing L-arabinose by a xylose mother liquid. The method comprises the following steps: first, diluting the xylose mother liquid; then, removing glucose by active dry yeast powder; further refining the xylose mother liquid through decoloration, ion exchange and evaporation concentration; then obtaining an L-arabinose component solution and a xylose component solution through a continuous chromatographic mobile bed and respectively crystallizing to obtain an L-arabinose product and a xylose product. The method provided by the invention extracts L-arabinose through the continuous chromatographic mobile bed by using a byproduct xylose mother liquid in production of crystallized xylose by bagasse, is simple in operation, low in technical cost and good in separating effect, and has an extremely wide application valve. The obtained L-arabinose is high in purity and yield.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

2-imidazolidone synthesis method

InactiveCN103497157BLow priceEasy to recycleOrganic chemistryChemical recyclingEthylenediamineAlcohol

The invention relates to 2-imidazolidone, and provides a 2-imidazolidone synthesis method simple in process and low in cost. The method includes: (1) sequentially adding a catalyst of sulfamic acid, a solvent of methyl alcohol, ethylenediamine and dimethyl carbonate into a heatable reactor for reacting at the temperature of 20-80 DEG C for 1-5 hours; (2) continuously raising the temperature to 120-180 DEG C, and reacting for 10-24 hours prior to generating a target product 2-imidazolidone; (3) after reaction is ended, filtering to remove the catalyst of sulfamic acid and remove the solvent of methyl alcohol so as to obtain a coarse product 2-imidazolidone; (4) refining the coarse product 2-imidazolidone obtained in the step (3) to obtain the product 2-imidazolidone. The defects that an existing synthesis process is carried out at high temperature under high pressure, high-corrosivity catalysts, toxic materials and high boiling solvent are used, atom utilization rate is low and the like are overcome.

Owner:XIAMEN UNIV +1

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951BRich sourcesReduce manufacturing costOrganic chemistrySodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

Process for photo catalytic reduction preparation of m-nitroaniline

InactiveCN1634863AStable in natureLow priceOrganic compound preparationAmino compound preparationPhotocatalytic reactionElectron donor

The invention discloses a method for reduction preparation of m-nitro aniline by photocatalysis. The lightcatalyzed reduction reaction can be carried out in photocatalysis reactor with temperature control apparatus, m-dinitrobenzene is solved by organic solvent with sacrificial electron donor with the mass ratio of m-dinitrobenzene to solvent between 1í†50 and 1í†500, said mixture and photocatalyst are added in the reactor with the concentration of photocatalyst in solvent between 0.2g / L and 8g / L, the solution is stirred to suspending liquid, then nitrogen is added for removing oxygen and the solution is irradiated for 2 hours to 12 hours by ultraviolet light at normal pressure to produce meta nitro aniline m-nitroaniline. The reduction reaction can be carried out at normal temperature without high temperature energy consumption device, and the initiation light can be natural sunlight.

Owner:TIANJIN UNIV

Method for synthesizing tricyclodecenyl propionate perfume by adopting loaded solid acid catalyst

ActiveCN104098470ARaw materials are easy to getMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationElectrophilic additionPropanoic acid

The invention discloses a synthesis method of a tricyclodecenyl propionate perfume. Petroleum coking byproducts dicyclopentadiene and propionic acid are used as the raw materials, under the catalysis of loaded solid acid, the raw materials directly have acetylation through electrophilic addition to prepare crude tricyclodecenyl propionate at one step, and meanwhile, a small amount of a propionic anhydride guard catalyst is added to prevent the crude tricyclodecenyl propionate from having hydrolysis reaction with a small amount of moisture in the material; then, propionic acid is recycled for applied mechanically, and the finished tricyclodecenyl propionate product is obtained through neutralizing, washing and rectification. According to the synthesis method, the petroleum coking byproducts used as the raw materials are easily available, the reaction condition is moderate, the reaction conversion rate is high, the technology is easier to implement, the discharge capacity of three wastes generated in the production process is low, the product yield is greatly increased, and the synthesis method belongs to technology of cleaner production. In addition, the content of tricyclo[5, 2, 1, 0<2.6>]-3-decene-9-yl acetate with delicate fragrance and fragrance and sweetness of anise is more than 92%, and the product green wood is pure, fine and mild in fragrance. The invention further provides a synthesis device special for the synthesis method of a tricyclodecenyl propionate perfume.

Owner:ANHUI HYEA AROMAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00031.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212d00061.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00011.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121D00031.PNG)