Green high-purity polyarylether and preparation method thereof

A high-purity polyarylether technology, applied in the production of bulk chemicals, can solve problems such as dark color, impure resin, and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

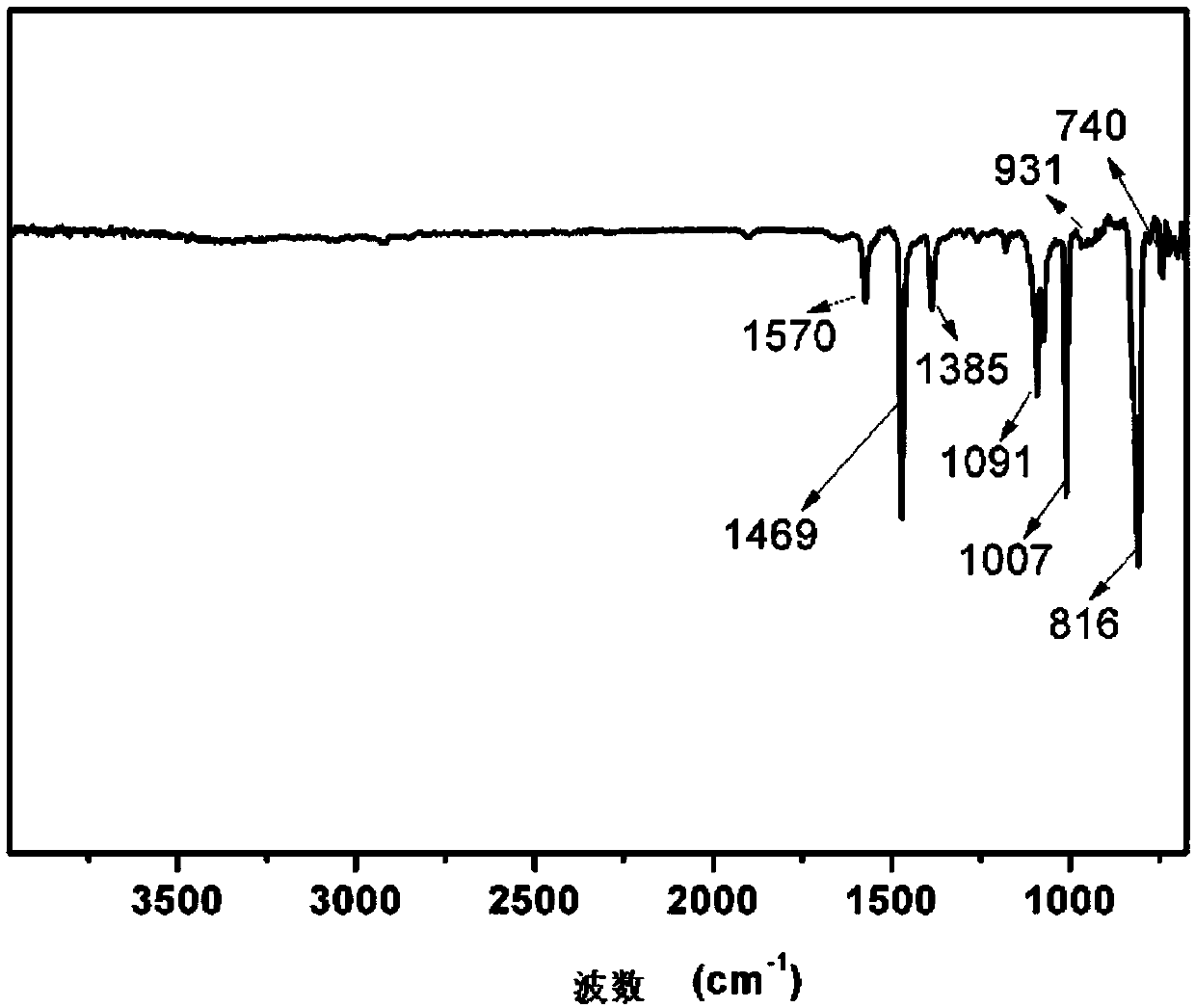

[0057] 10kg lithium hydroxide, 20kg potassium acetate, 500kg 1,3-dimethyl-2-imidazolinone and 178kg hydrous sodium sulfide were dehydrated at 220°C for 0.5h under the protection of nitrogen to obtain a dehydrated reaction solution , when the temperature of the above solution drops to 180°C, add 114kg of p-difluorobenzene, react at a temperature of 230°C for 1h, then keep at a temperature of 280°C for 10h, cool down to 200°C, perform a high-temperature filtration, and recover the part in the reaction slurry solvent, and transported to the solvent recovery tank; continue to cool the reactor to 160 ° C, close all inlet and outlet valves in the reactor, open the supercritical extraction agent feed valve, switch the reactor mode to the extraction tank mode, and feed the extraction tank respectively Add 500kg of supercritical extractant trifluoromethane three times each time, extract the remaining reaction solvent at a temperature of 30°C and a pressure of 5MPa, and then send the ext...

Embodiment 2

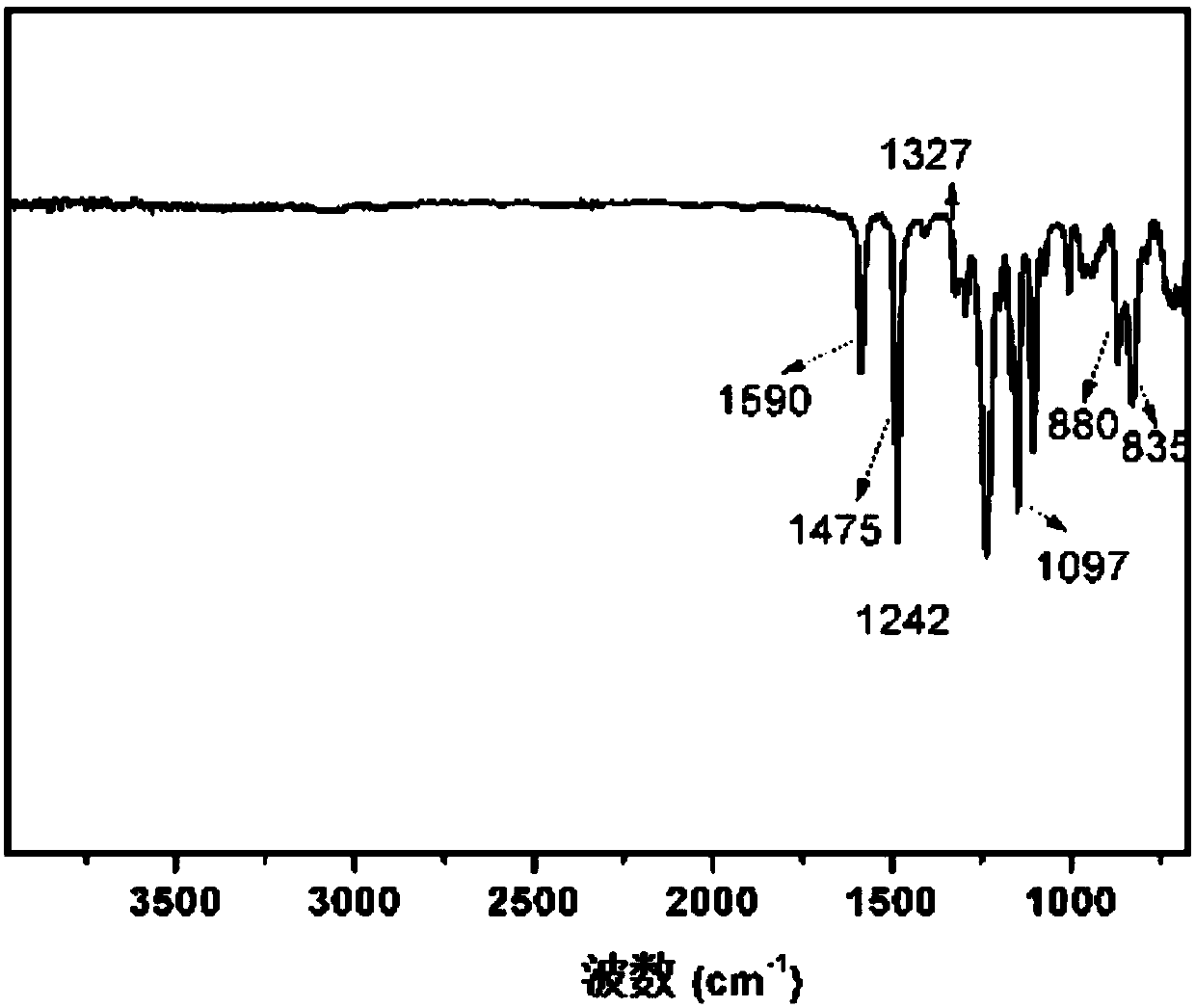

[0060] 100kg of sodium carbonate, 120kg of sodium alginate, 1000kg of hexamethylphosphoric triamide and 186kg of biphenyldiphenol were dehydrated at a temperature of 210°C for 1 hour under the protection of nitrogen to obtain a dehydrated reaction solution. When the temperature reaches 120°C, add 254kg of 4,4'-difluorodiphenyl sulfone, react at 240°C for 1 hour, then keep at 270°C for 8 hours, cool down to 220°C, perform a high-temperature closed flash evaporation, and recover the part in the reaction slurry solvent, and transported to the solvent recovery tank; continue to cool the reactor to 130 ° C, close all inlet and outlet valves in the reactor, open the supercritical extraction agent feed valve, switch the reactor mode to the extraction tank mode, and feed the Add 800kg of supercritical extractant sulfur hexafluoride in 5 times each time, extract the remaining reaction solvent at a temperature of 50°C and a pressure of 4MPa, and then send the extracted mixed supercritica...

Embodiment 3

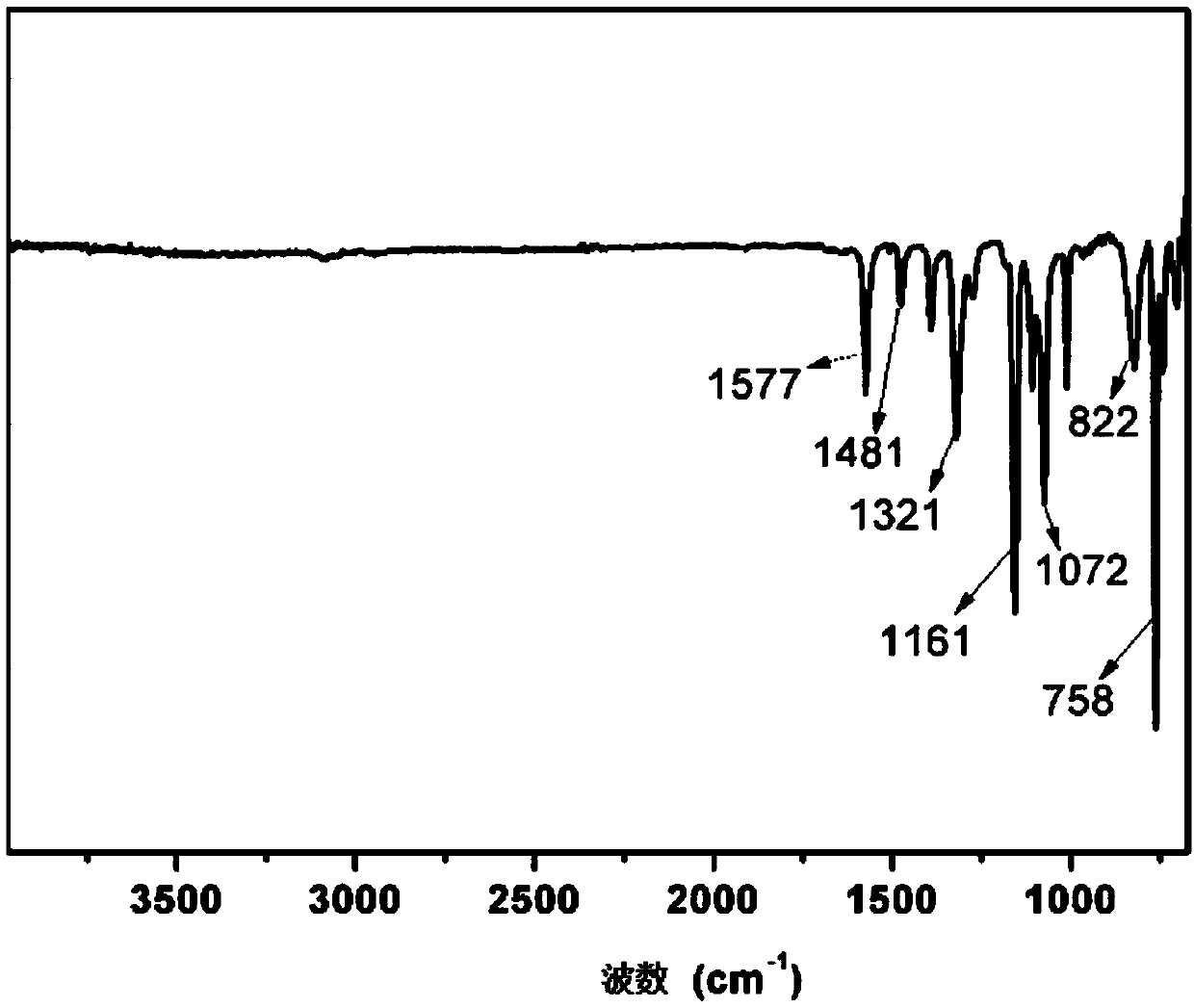

[0063] 200kg of potassium bicarbonate, 80kg of sodium adipate, 2000kg of N-cyclohexylpyrrolidone and 127kg of aqueous sodium hydrosulfide were dehydrated at a temperature of 180°C for 3 hours under the protection of nitrogen to obtain a dehydrated reaction solution. When the temperature reaches 160°C, add 287kg of 4,4'-dichlorodiphenylsulfone, react at a temperature of 190°C for 6 hours, then keep at a temperature of 230°C for 6 hours, cool down to 210°C, perform a high-temperature closed flash evaporation, and recover the reaction slurry part of the solvent, and sent to the solvent recovery tank; continue to cool the reactor to 30 ° C, close all the inlet and outlet valves in the reactor, open the supercritical extraction agent feed valve, switch the reactor mode to the extraction tank mode, respectively The kettle is divided into 6 times, each time adding 500kg of supercritical extractant carbon dioxide, and the remaining reaction solvent is extracted at a temperature of 32°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com