Method for recycling hexanediamine key intermediate reaction residues and co-producing carboxylic acid

A technology for the parallel co-production of carboxylic acid and intermediates, which is applied in the field of recycling and co-production of carboxylic acid from the key intermediate reaction residue of hexamethylenediamine, which can solve problems such as serious environment, production efficiency and product quality impact, residue solid waste, etc. Achieve the effects of reducing pollution, less side reactions, and reducing the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

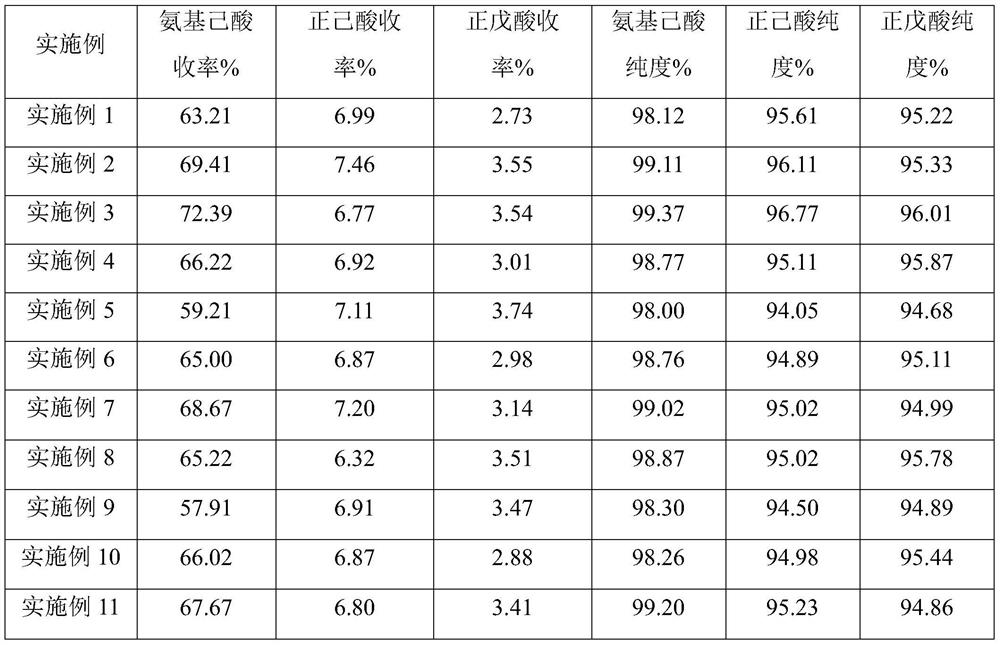

Examples

Embodiment 1

[0031] A kind of hexamethylenediamine key intermediate reaction residue of the present invention recycles and utilizes the method for co-producing carboxylic acid, comprises the steps:

[0032] (1) Continuously pump the residue and water into the first fixed-bed reactor simultaneously with a high-pressure pump to carry out the depolymerization reaction; wherein, the mass ratio of the residue to water is 0.1; the first fixed-bed reactor The inner diameter is 10mm and the length is 1000mm; in the first fixed bed reactor, the reaction temperature is 150°C, the reaction pressure is normal pressure, and 50g of BF 3 / Al 2 o 3 Solid catalyst, the total raw material space velocity is 20h -1 The residue and water are all imported from the lower end of the first fixed bed reactor, and the depolymerization reaction liquid material obtained after the depolymerization reaction is output from the upper end of the first fixed bed reactor; the first fixed bed reaction The feed and discharg...

Embodiment 2

[0038] A kind of hexamethylenediamine key intermediate reaction residue of the present invention recycles and utilizes the method for co-producing carboxylic acid, comprises the steps:

[0039] (1) Continuously pump the residue and water into the first fixed-bed reactor simultaneously with a high-pressure pump to carry out the depolymerization reaction; wherein, the mass ratio of the residue to water is 0.5; the first fixed-bed reactor The inner diameter is 10mm and the length is 1000mm; in the first fixed bed reactor, the reaction temperature is 200°C, the reaction pressure is 1MPa, and 50g of SiO 2 Solid catalyst, the total raw material space velocity is 5h -1 The residue and water are all imported from the lower end of the first fixed bed reactor, and the depolymerization reaction liquid material obtained after the depolymerization reaction is output from the upper end of the first fixed bed reactor; the first fixed bed reaction The feed and discharge of the device are kep...

Embodiment 3

[0045] A kind of hexamethylenediamine key intermediate reaction residue of the present invention recycles and utilizes the method for co-producing carboxylic acid, comprises the steps:

[0046] (1) Continuously pump the residue and water into the first fixed-bed reactor simultaneously with a high-pressure pump to carry out the depolymerization reaction; wherein, the mass ratio of the residue to water is 0.25; the first fixed-bed reactor The inner diameter is 10mm and the length is 1000mm; in the first fixed bed reactor, the reaction temperature is 250°C, the reaction pressure is 6MPa, and 50g of SiO 2 -Al 2 o 3 Solid catalyst, the total raw material space velocity is 10h -1 The residue and water are all imported from the lower end of the first fixed bed reactor, and the depolymerization reaction liquid material obtained after the depolymerization reaction is output from the upper end of the first fixed bed reactor; the first fixed bed reaction The feed and discharge of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com