Method of comprehensively utilizing byproduct gasoline by methanol-to-propylene device

A methanol-to-propylene and by-product technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of high energy consumption, low comprehensive utilization rate of MTP by-product gasoline, high engineering investment, etc., and achieve separation efficiency High efficiency, low consumption of public works, low investment in equipment engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

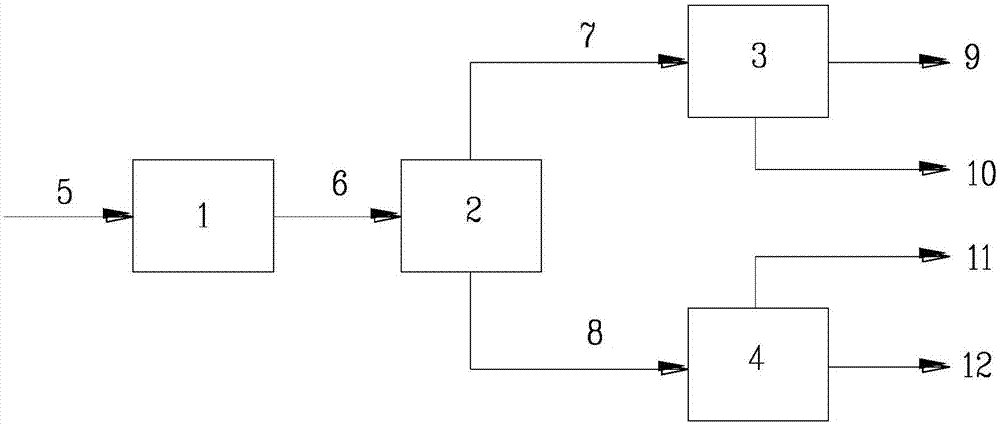

[0026] Process flow block diagram of the present invention is as figure 1 shown. MTP by-product gasoline is processed through gasoline hydrogenation (1), aromatics extraction (2), pressure swing adsorption separation (3) and moving bed adsorption separation (4) to obtain normal paraffins (9) and isoparaffins ( 10), raffinate aromatics (11), p-xylene (12) and other basic organic chemical raw materials.

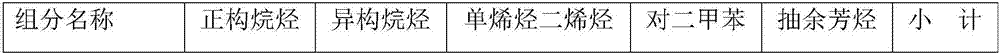

[0027] Taking the methanol-to-propylene MTP plant with a production capacity of 1.8 million tons / year as an example, the by-product is 159,500 tons / year of gasoline, and its composition ratio is as follows:

[0028] component name n-alkanes Isoparaffin monoolefin diene p-xylene Aromatics Subtotal Content (wt%) 44.52 29.72 0.75 14.98 10.03 100.00

[0029] 1) Firstly, gasoline hydrogenation technology is adopted, through the MTP by-product gasoline pretreatment system, one-stage hydrogenation system, two-stage hydrogenation system, and hydro...

Embodiment 2

[0037] According to the conditions and steps described in Example 1, but the production capacity is expanded to 3.6 million tons / year methanol-to-propylene MTP unit, the by-product is 319,000 tons / year gasoline, using gasoline hydrogenation, aromatics extraction, and pressure change of the present invention Adsorption separation and moving bed adsorption separation technical schemes are processed to obtain:

[0038] component name n-alkanes Isoparaffin p-xylene Aromatics total Output (10,000 tons / year) 14.34 9.58 4.78 3.20 31.90

[0039] The product yield is 99.3%, the product purity is 98.2%, the project investment is reduced by 10.4%, and the comprehensive energy consumption is reduced by 5.3%.

Embodiment 3

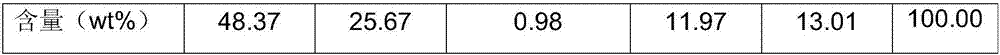

[0041] According to the conditions and steps described in Example 1, the production capacity is still 1.8 million tons / year of the methanol-to-propylene MTP plant as an example, and the by-product is 160,700 tons / year of gasoline, but the composition ratio changes as follows:

[0042] component name n-alkanes Isoparaffin monoolefin diene p-xylene Aromatics Subtotal Content (wt%) 40.64 32.23 0.51 17.87 8.75 100.00

[0043] Firstly, the gasoline hydrogenation technology is adopted, and the nickel-based hydrogenation catalyst containing 16% nickel oxide is used as the carrier. The reaction gauge pressure of the hydrogenation reactor is 2.2MPa, the inlet temperature is 60°C, and the liquid volume space velocity is 2.2h -1 , The volume ratio of hydrogen to oil is 150. Secondly, the aromatics extraction technology is adopted. The operating gauge pressure of the extractive distillation tower is 0.10MPa, the operating temperature of the tower top i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com