Method for clean production of high-purity vanadium pentoxide by using hydrogen peroxide and ammonia water

A vanadium pentoxide, clean production technology, applied in the direction of vanadium oxide, chemical instruments and methods, ammonia compounds, etc., can solve the problems of vanadium loss and consumption, and achieve the effect of low impurity content, high purity and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

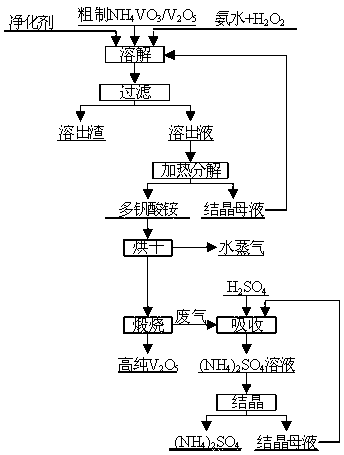

Image

Examples

Embodiment 1

[0023] A method for clean production of high-purity vanadium pentoxide with hydrogen peroxide and ammonia, comprising the steps:

[0024] (1) 100g of V with a purity of 97% can be obtained after calcination 2 o 5 The crude ammonium metavanadate or the crude vanadium pentoxide with a purity of 96% are raw materials, adding mass fractions of ammonia and hydrogen peroxide to dissolve, slowly adding 4g of purifying agent to remove impurities while dissolving, and stirring;

[0025] (2) Filtration: quickly filter the above-mentioned dissolved solution, and separate the dissolution residue and dissolution liquid;

[0026] (3) Thermal decomposition: heat and stir the filtered filtrate obtained in step (2) to decompose peroxovanadate ions, and vanadium is precipitated in the form of ammonium polyvanadate, and the crystallized mother liquor is returned to step (1) for dissolution until polyvanadate is dissolved. Ammonium is completely precipitated, and ammonium polyvanadate is obtain...

Embodiment 2

[0033] A method for clean production of high-purity vanadium pentoxide with hydrogen peroxide and ammonia, comprising the steps:

[0034] (1) Take 50g of crude vanadium pentoxide with a purity of 97.5% as raw material, add 7% ammonia water and 0.8% hydrogen peroxide by mass fraction to dissolve, slowly add 3g of purifying agent to remove impurities while dissolving, and stir;

[0035] (2) Filtration: quickly filter the above-mentioned dissolved solution, and separate the dissolution residue and dissolution liquid;

[0036] (3) Thermal decomposition: heat and stir the filtered filtrate obtained in step (2) to decompose peroxovanadate ions, and vanadium is precipitated in the form of ammonium polyvanadate, and the crystallized mother liquor is returned to step (1) for dissolution until polyvanadate is dissolved. Ammonium is completely precipitated, and ammonium polyvanadate is obtained by filtration;

[0037] (4) Drying and calcination: The ammonium polyvanadate obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com