Preparation method of 3,5-difluoroanisole

A technology of difluoroanisole and trifluorobenzene, which is applied in the field of preparation of organic compounds, can solve the problems of long reaction time, low yield, and only 68% yield, and achieve the effect of high product yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

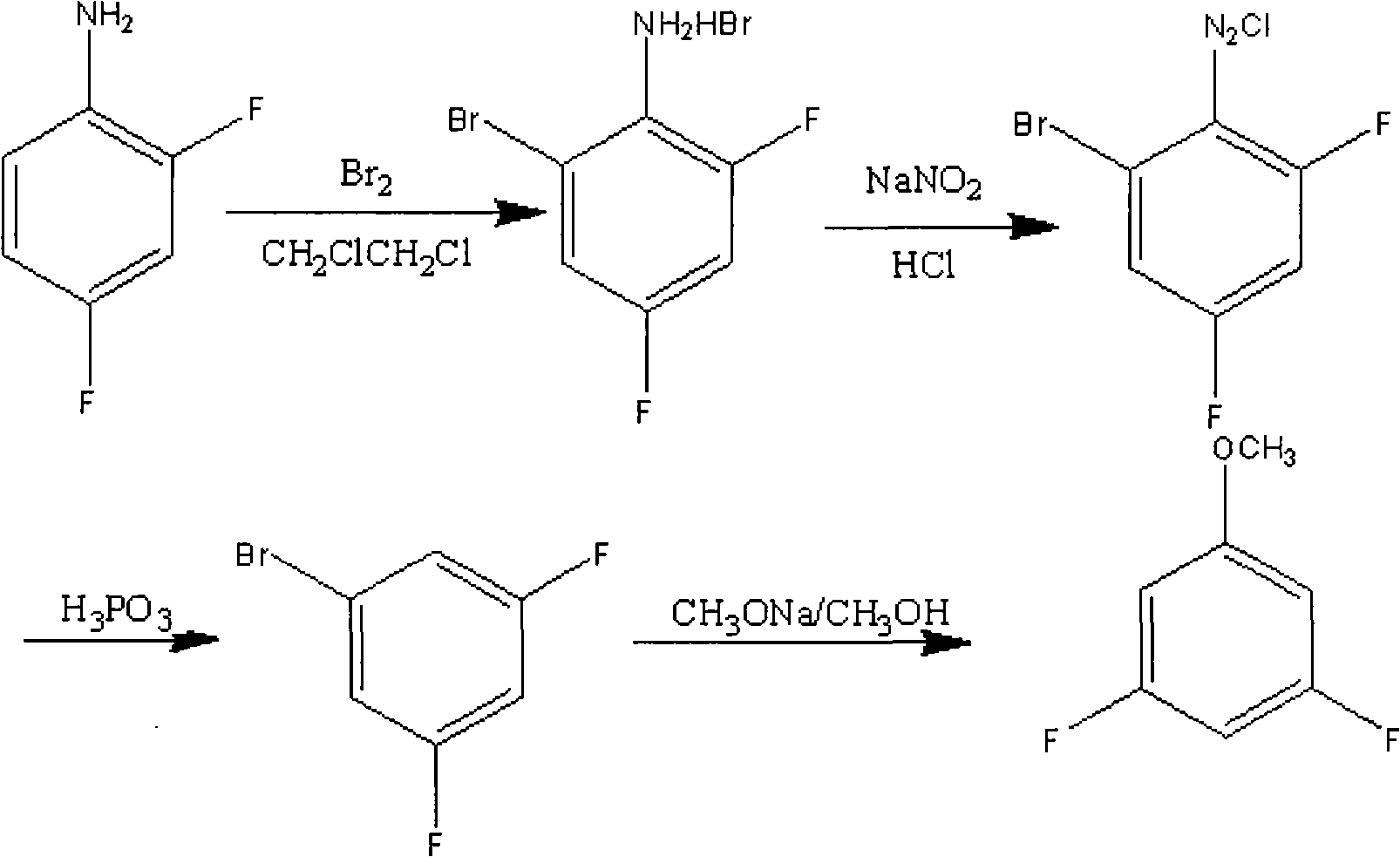

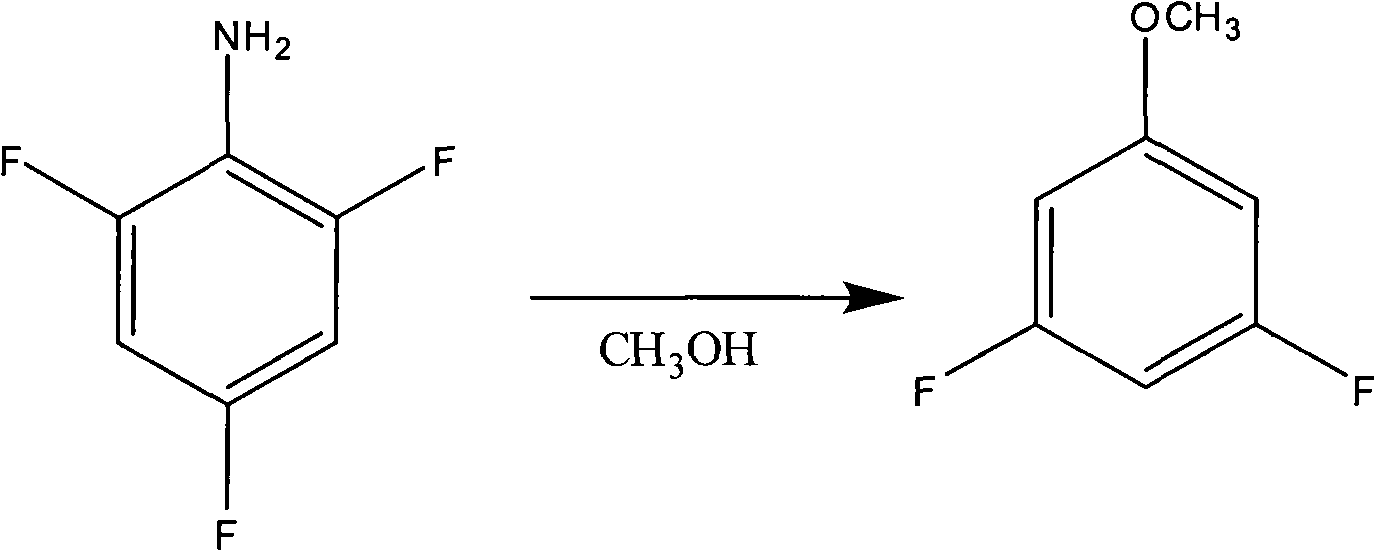

Method used

Image

Examples

Embodiment 1

[0055] In a 5L three-necked flask equipped with a thermometer, a spherical condenser and a mechanical stirrer, add a solution containing 10.72mol (578.8g) of sodium methoxide at room temperature, the concentration of the sodium methoxide solution is 20% in terms of methanol, and then 938mL of solvent Methanol was slowly added into the three-necked flask, and stirred evenly at a slow speed.

[0056] Under the condition of stirring, 5.36mol (708g) of 1,3,5-trifluorobenzene was added dropwise into the reaction flask, and heated to raise the temperature, so that the reaction was carried out at 70-80°C. After the reaction was carried out for 5 hours, Heating was stopped, and the reaction product was allowed to cool naturally.

[0057] The cooled reaction product is carried out aftertreatment, and described aftertreatment comprises

[0058] 1) The reaction product is subjected to suction filtration to obtain a solid and a filtrate, and the solid is washed twice with methanol; after...

Embodiment 2

[0063] In a 5L three-necked flask equipped with a thermometer, a spherical condenser and a mechanical stirrer, add a solution containing 5.36mol (289.44g) of sodium methoxide at room temperature. The concentration of the sodium methoxide solution is 30% in terms of methanol, and then 1000mL of solvent Slowly add toluene into the three-necked flask, and stir evenly at a slow speed.

[0064] Under the condition of stirring, 5.36mol (708g) of 1,3,5-trifluorobenzene was added dropwise into the reaction flask, and heated to raise the temperature, so that the reaction was carried out at 60-80°C. After the reaction was carried out for 10 hours, Heating was stopped, and the reaction product was allowed to cool naturally.

[0065] The cooled reaction product is carried out aftertreatment, and described aftertreatment comprises

[0066] 1) The reaction product is subjected to suction filtration to obtain a solid and a filtrate, and the solid is washed twice with methanol; after the fil...

Embodiment 3

[0071] In a 5L three-neck flask equipped with a thermometer, a spherical condenser and a mechanical stirrer, add a solution containing 8.04mol (434.16g) of sodium methoxide at room temperature. The concentration of the sodium methoxide solution is 40% in terms of methanol, and then 950mL of solvent Dimethylformamide was slowly added into the three-necked flask, and stirred evenly at a slow speed.

[0072] Under the condition of stirring, 5.36mol (708g) of 1,3,5-trifluorobenzene was added dropwise into the reaction flask, and heated to raise the temperature, so that the reaction was carried out at 60-100°C. After the reaction was carried out for 18 hours, Heating was stopped, and the reaction product was allowed to cool naturally.

[0073] The cooled reaction product is carried out aftertreatment, and described aftertreatment comprises

[0074] 1) The reaction product is subjected to suction filtration to obtain a solid and a filtrate, and the solid is washed twice with methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com