Comprehensive utilization method of zinc-containing dust mud of steel plant

A technology of iron and steel plant and dust sludge, which is applied in the field of comprehensive utilization of zinc-containing dust and sludge in iron and steel plants, to achieve high economic value, high feasibility, and high value realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

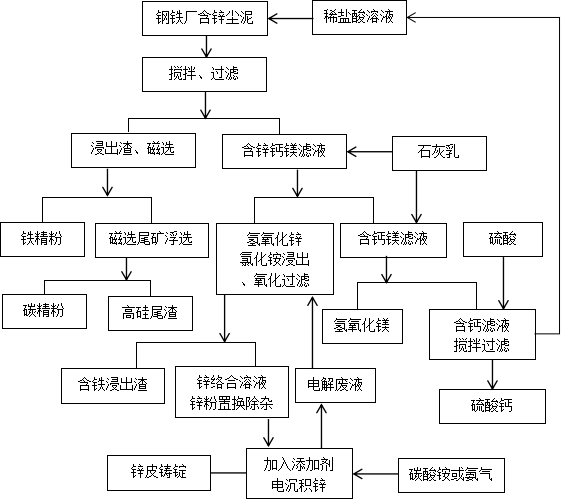

Image

Examples

Embodiment 1

[0038]Take a sample of 50kg of zinc-containing dust removal ash from No. 1 blast furnace of a steel plant. First carry out dilute hydrochloric acid solution leaching, add zinc-containing dedusting ash and dilute hydrochloric acid solution to the anti-corrosion ball mill for grinding and leaching, pump it to the stirring leaching tank to continue leaching, the leaching end point is pH2.4, and after the leaching is completed, the solid-liquid separation, Obtain leaching slag and zinc-containing calcium-magnesium solution; add lime milk to the zinc-calcium-magnesium solution and stir, control the end point pH to 7, and separate solid and liquid to obtain zinc hydroxide and calcium-magnesium-containing solution; add calcium-magnesium-containing solution into lime milk to control pH Range 9.5 After stirring, solid-liquid separation is obtained to obtain magnesium hydroxide and calcium-containing solution; after the calcium-containing solution detects its calcium chloride molar conce...

Embodiment 2

[0046] Take a 50kg sample of the wet dust filter mud of a steelmaking converter in a steel plant. Firstly carry out leaching with dilute hydrochloric acid solution, add the dedusting filter mud and dilute hydrochloric acid solution into anti-corrosion ball mill for grinding and leaching while pumping to the stirring leaching tank to continue leaching, the leaching end point is pH2. Leach slag and zinc-containing calcium-magnesium solution; add lime milk to the zinc-calcium-magnesium solution and stir, control the end point pH to 7.5, and separate solid and liquid to obtain zinc hydroxide and calcium-magnesium-containing solution; add calcium-magnesium-containing solution to lime milk to control the pH range 10 After stirring, solid-liquid separation is obtained to obtain magnesium hydroxide and calcium-containing solution; after the calcium-containing solution detects its calcium chloride molar concentration, add concentrated sulfuric acid at a ratio of 1:1, stir for 1 hour, an...

Embodiment 3

[0054] Take 50kg of dust samples from a steelmaking electric furnace in a steel mill. First carry out leaching with dilute hydrochloric acid solution, add the dedusting ash and dilute hydrochloric acid solution to the anti-corrosion ball mill for side-grinding and leaching, pump it to the stirring leaching tank to continue leaching, the leaching end point is pH2.8, and after the leaching is completed, the solid-liquid separation is obtained. Slag and zinc-containing calcium-magnesium solution; after the zinc-containing calcium-magnesium solution is added into milk of lime and stirred, the control endpoint ph is 7.2, and solid-liquid separation is obtained to obtain zinc hydroxide and calcium-magnesium-containing solution; the calcium-magnesium-containing solution is added into lime milk to control the pH range of 10 After stirring, solid-liquid separation is obtained to obtain magnesium hydroxide and a calcium-containing solution; after the calcium-containing solution detects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com