Method for calculating convexity conversion relationship between work roll and support roll of four-high mill

A calculation method and a technology for converting relationships, applied in the field of metallurgy, can solve problems such as complex wave shape, plate shape deterioration, and inability to improve plate shape, so as to achieve the effect of ensuring consistency and improving accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

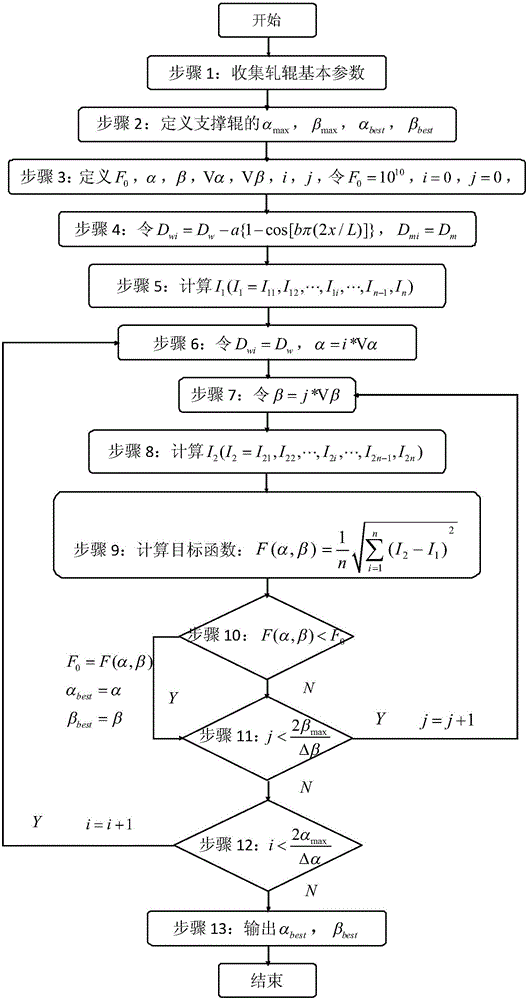

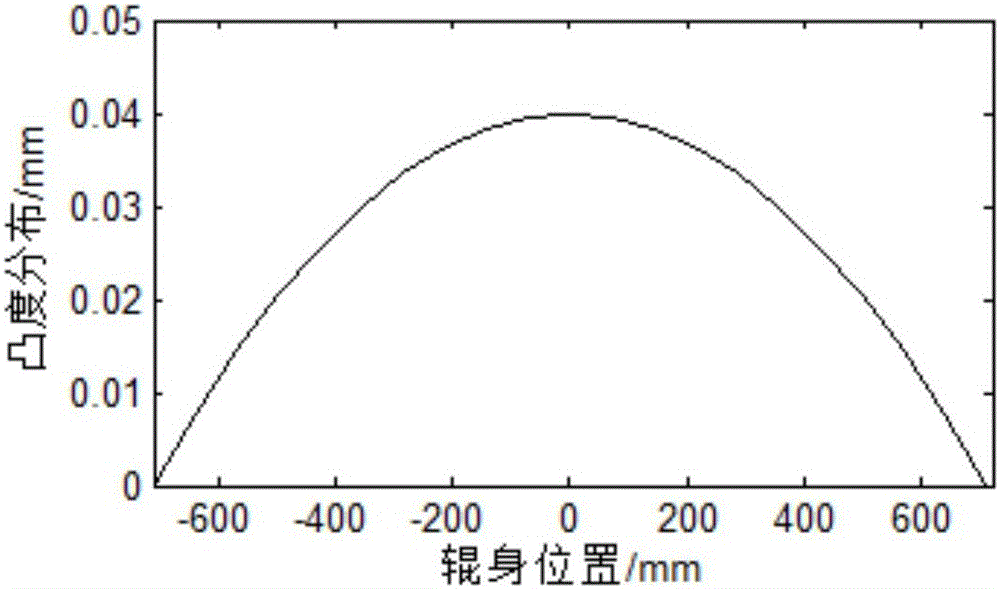

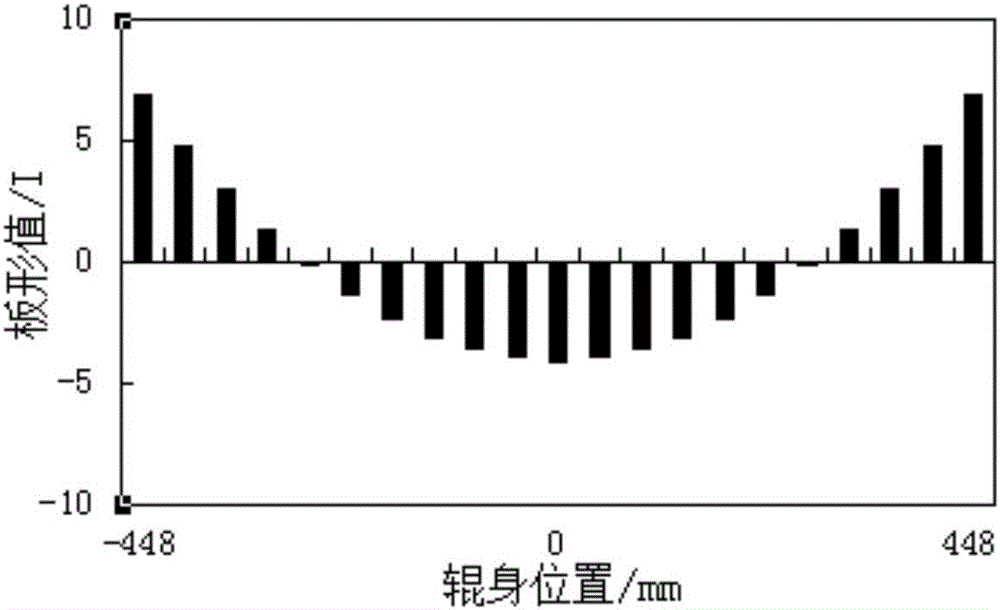

[0027] Taking a four-high rolling mill as an example, the calculation method of the crown conversion relationship between the work roll and the backup roll of the four-high rolling mill is further explained. The calculation process is as follows figure 1 Shown:

[0028] First, in step (a), the basic parameters of the rolls are collected: mainly including the body length L of the work rolls w =1420mm, length L of the roller body of the support roller b =1380mm, the nominal roll diameter D of the work roll w =449.5mm, the nominal roll diameter D of the support roll b =1099.8mm;

[0029] Subsequently, in step (b), the maximum crown coefficient α of the support roller is defined and given max =4、Maximum opening degree coefficient β max =0.5, define the optimal crown coefficient α of the support roller best , Optimum opening coefficient β best ;

[0030] Subsequently, in step (c), the objective function F is defined 0 , support roller crown coefficient α, opening degree co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com