Sheet mass measuring unit

a mass measurement and paper sheet technology, applied in the direction of instruments, electrographic processes, transportation and packaging, etc., can solve the problems of inability to accurately measure the mass of paper sheets, inability to reduce throughput, drive shafts, etc., and achieve the effect of high accuracy and enhanced throughpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]An embodiment of the invention will be described in detail with reference to the accompanying drawings.

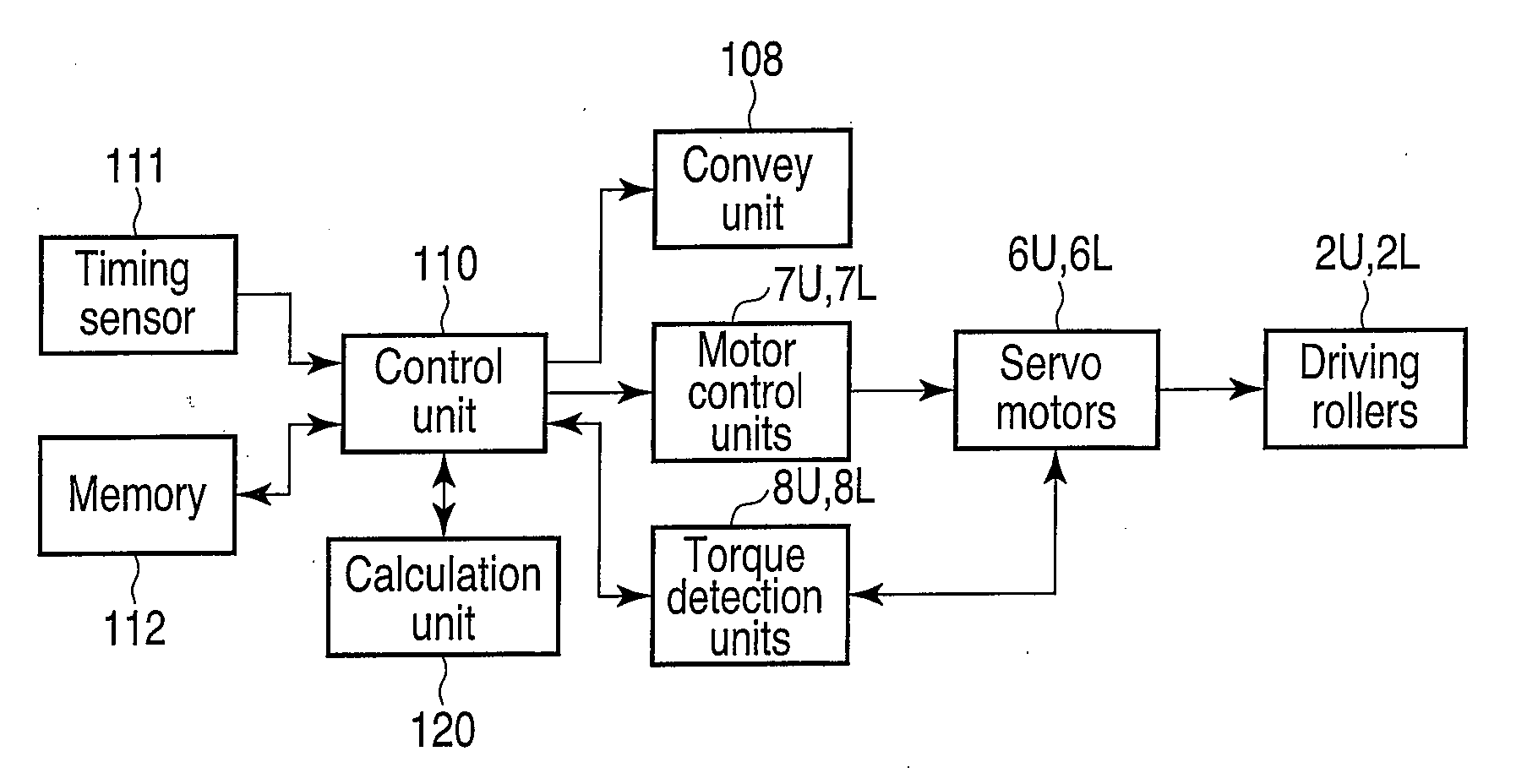

[0025]FIG. 1 is a schematic block diagram illustrating a mail matter selection / pickup / stamping apparatus 100 (hereinafter referred to simply as “the apparatus 100”) that incorporates a mass measuring unit according to the embodiment of the invention.

[0026]The apparatus 100 comprises a supply unit 101, a mechanical detection unit 102, an OCR scanner unit 103, a twisting / reversing unit 104, a switchback unit 105, a stamp unit 106 and a delivery / stacker unit 107. The apparatus 100 also comprises a convey unit 108 for conveying mail matters M through the above-mentioned units. The apparatus 100 also comprises an operation panel (not shown) for instructing the apparatus to perform various operations, to switch the operation mode and to display abnormality.

[0027]The supply unit 101 simultaneously receives a plurality of mail matters M of standard sizes, mass and widths (perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com