Pattern automatic bonding device

An automatic bonding and driving device technology, which is applied to the surface coating liquid device, casting molding equipment, coating, etc., can solve the problems that are not suitable for the lost foam casting production of precision castings, a large number of tooling workers, and low bonding quality. Problems, to achieve the effect of flexible production needs, uniform glue coating, and good precision retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

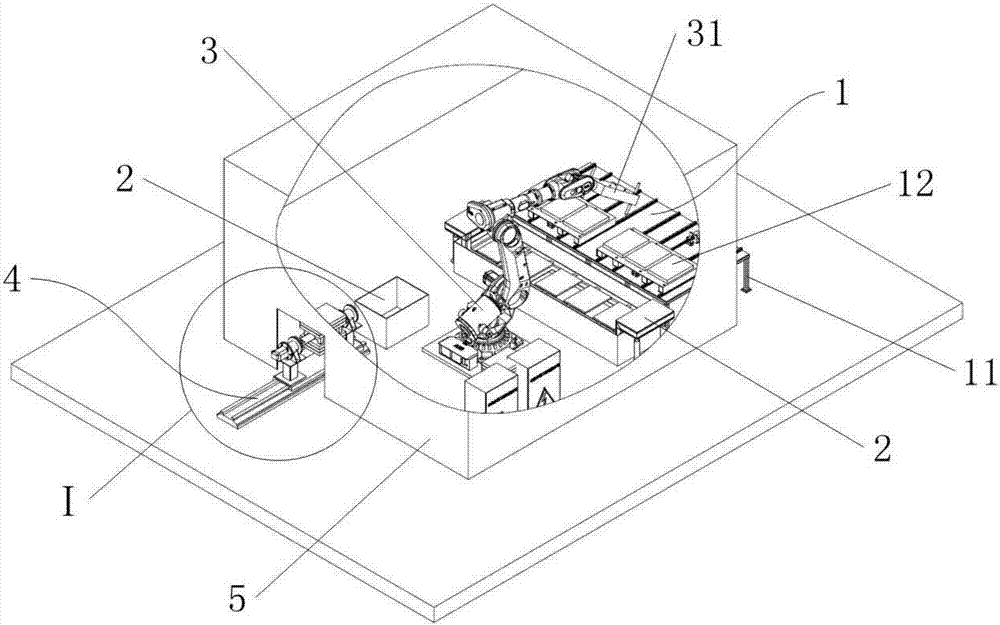

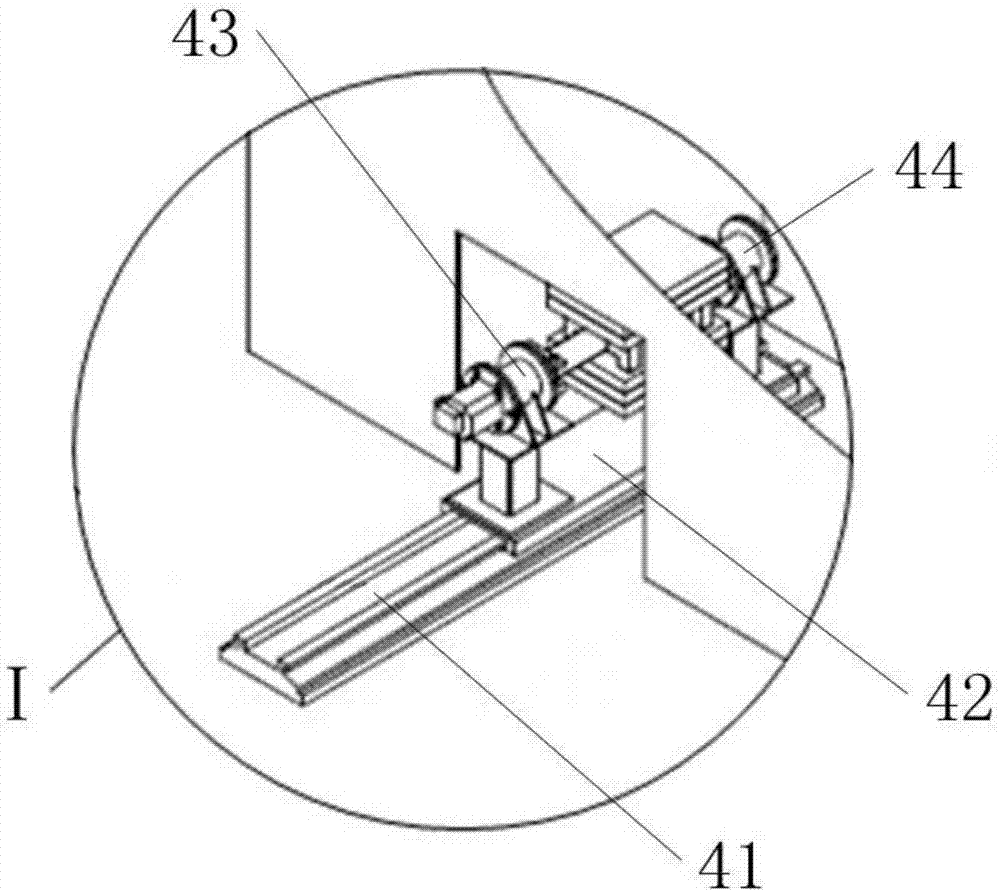

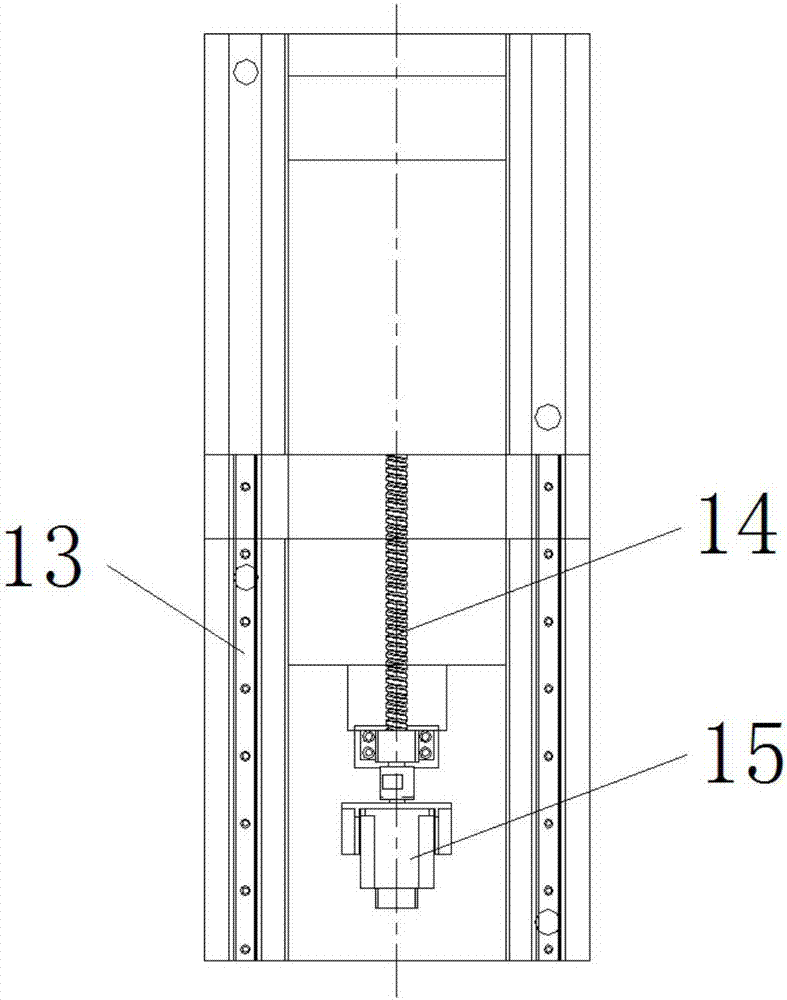

[0027] As shown in the figure, the pattern automatic bonding device in the present invention includes a pattern shuttle conveying device 1, a gluing device 2, a grabbing transfer device 3, a shuttle positioner 4 and a control system connected to each part; the pattern The shuttle conveying device 1 is arranged parallel to the gluing device 2 on one side of the grabbing and transferring device 3 . The bonding system transports the pattern to the pasting station through the pattern shuttle conveying device 1, and then uses the grasping and transferring device 3 to drive the pattern to be glued at the gluing device 2. The whole device is controlled by the control system, and the degree of automation is high. High precision not only reduces the labor intensity of workers, but also improves the precision and quality of pasting patterns. By sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com