High-precision lower drive type roller driving mechanism

A technology of roller mechanism and driving mechanism, which is applied in the direction of mechanical thickness measurement, instruments, manufacturing tools, etc., and can solve the problems of shaft workpieces that cannot meet the requirements of high-precision straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

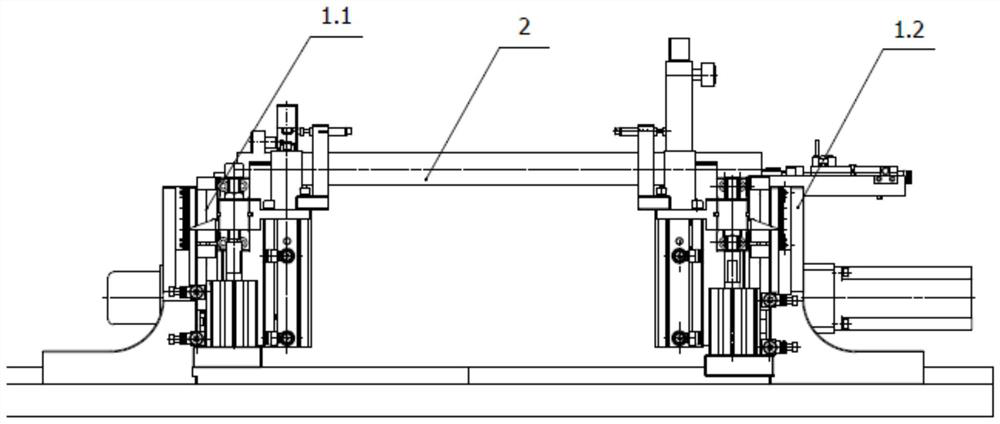

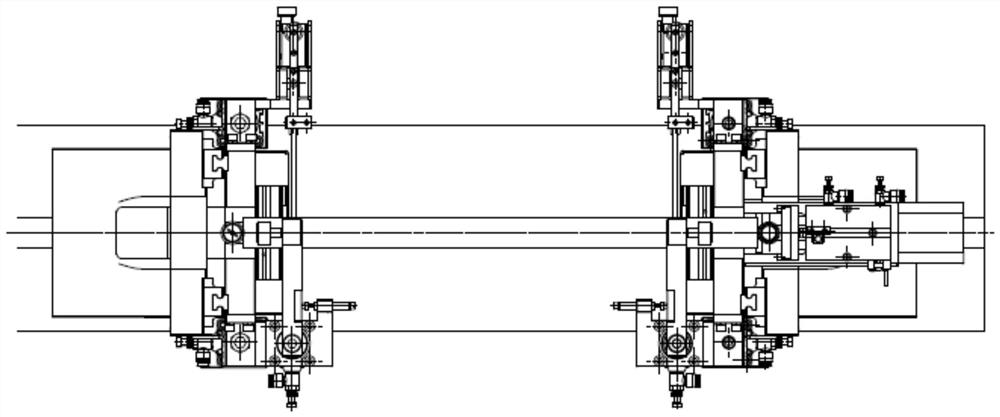

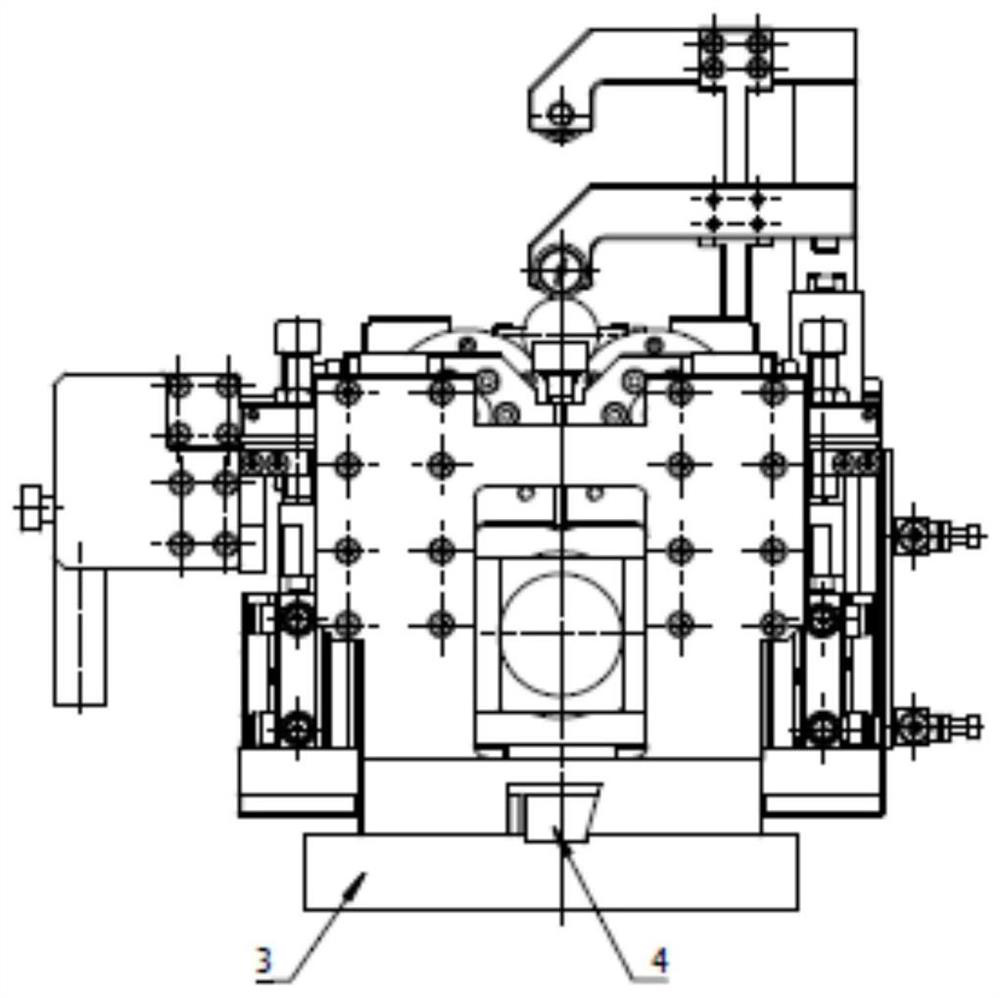

[0043] It includes two parts, the driven end 1.1 of the high-precision roller lower drive mechanism and the active end 1.2 of the high-precision roller lower drive mechanism. It cooperates with the upper surface of the workbench 3 and can slide on the surface of the workbench. The center of the upper surface of the workbench 3 is installed with a center guide rail 4. The cross section of the center guide rail 4 is in the shape of a single dovetail. The driven end of the high-precision roller drive mechanism is 1.1 And the fixed bracket 1.2.6-3 of the active end 1.2 of the high-precision roller lower drive mechanism has a single dovetail groove structure, which matches the dovetail slope of the center guide rail 4, and can adjust its installation position on the center guide rail 4, and can Lock the locking screw 1.2.6-2 on the inclined surface of the center guide rail 4, the driving end 1.2 of the high-precision roller lower driving mechanism and the driven end 1.1 of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com