Support sheet mechanism of numerical control servo high-speed puncher

A technology of punching machine and sheet holder, applied in the field of sheet holder mechanism, can solve the problems of uneven spacing, unsatisfactory product accuracy, radial sheet fling, etc., so as to reduce rotational friction, improve precision and quality, prevent flick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

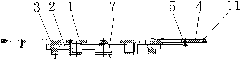

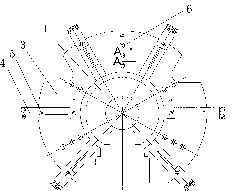

[0016] Example 1, such as Figures 1 to 3 As shown, a supporting plate mechanism of a CNC servo high-speed notching machine includes a supporting plate 1, and an actuating cylinder 7 is provided at the lower part of the supporting plate 1. Also be provided with the limiting mechanism that prevents the sheet from being thrown away concentrically with the carrier plate 1, the described limiting mechanism includes a bracket 2, a positioning disc 3 arranged on the bracket 2, and the positioning disc 3 is provided with A group of circumferentially distributed radially movable positioning blocks 4; the ends of the positioning blocks 4 are provided with rollers. The idler wheel is preferably a single row radial ball bearing. The bracket 2 is a fork bracket with an opening, and the cylinder 7 is a thin cylinder.

[0017] In order to adapt to the processing of various sizes of blanks, a group of circumferentially distributed radially adjustable positioning blocks 4 are arranged on th...

Embodiment 2

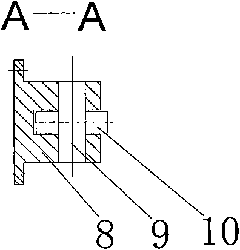

[0018] Embodiment 2 In order to reduce friction, a group of rolling devices are provided on the positioning plate to make the material rotate smoothly. Specifically, the rolling device is a group of bearings 10 or balls that are radially arranged and circumferentially distributed on the positioning disc. All the other are with embodiment 1.

Embodiment 3

[0019] Embodiment 3, the positioning block 4 is concentrically and uniformly arranged on the positioning plate 3, and there are 6 symmetrical circles, and a group of rollers 11 are arranged at one end of the positioning block 4, and the T set on the positioning block Type bolt 5 adapts to the groove on the positioning disc, and the spacing between the positioning disc and the positioning block is adapted to the size specification of the blank according to the specification adjustment bolt of different blanks. The rolling device is a group of balls that are uniformly distributed on the surface of the positioning plate in the radial direction, thereby reducing friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com