Coulter grinding correction device

A technology of correcting device and coulter, which is applied in the direction of grinding drive device, grinding frame, grinding bed, etc., can solve the problems of low efficiency and high labor intensity, so as to improve the accuracy, quality, work efficiency and reduce The effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

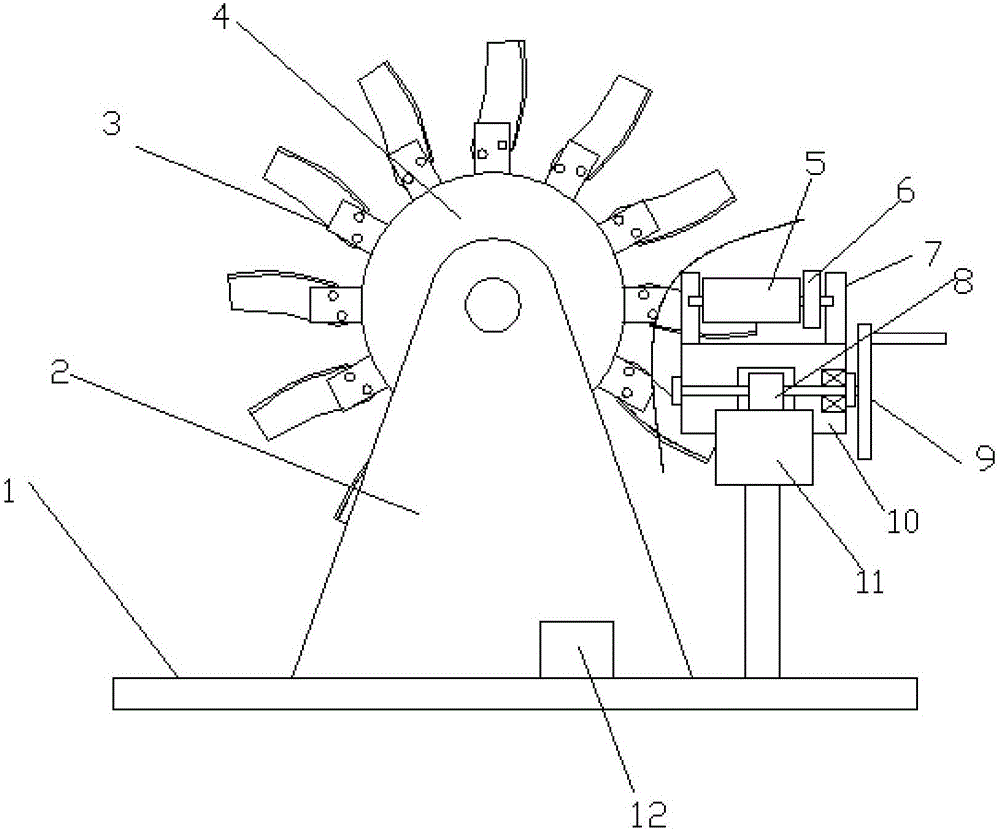

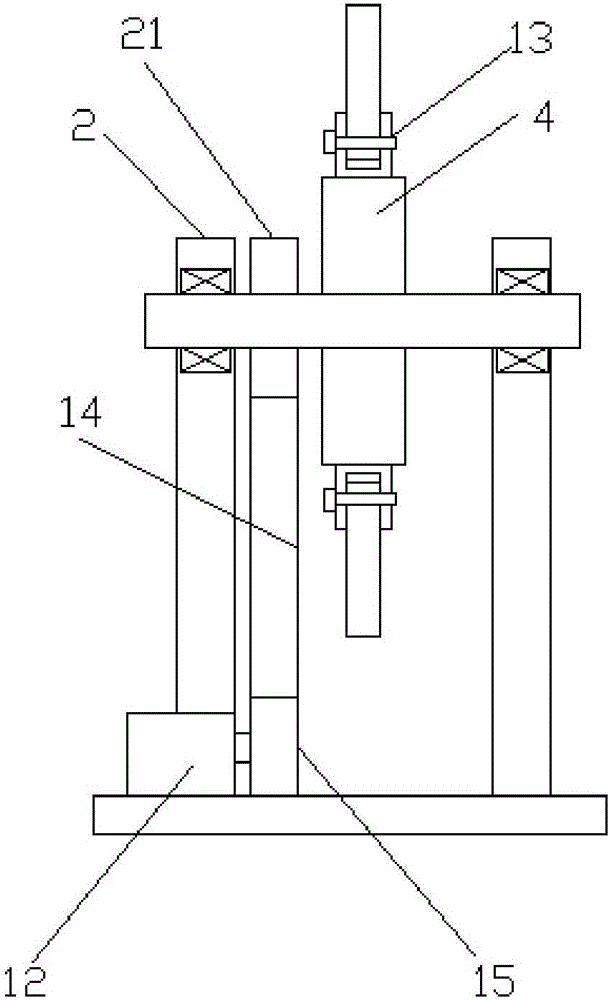

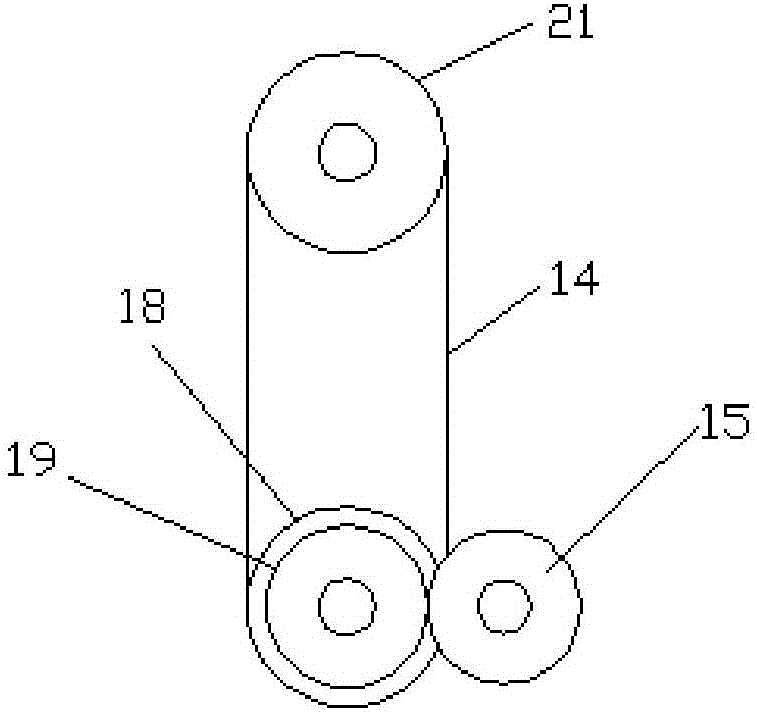

[0023] Implementation mode: the coulter is fixed on the cage 3 through the bolt 13, the rotating motor 12 drives the chuck 4 to rotate slowly to complete the simultaneous grinding and correction of multiple coulters, the grinding motor 17 drives the grinding wheel 5 to rotate and grind, and the hand wheel 9 drives the translation gear 8 rotates so that the grinder support 7 translates, which is used to adjust the distance between the grinding wheel 5 and the coulter so as to better complete the grinding work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com