Lost foam multi-station digital gluing system and its gluing method

A multi-station, lost foam technology, applied in the direction of material gluing, coating, devices for coating liquid on the surface, etc., can solve the problems of increased maintenance difficulty, influence on the quality of glue, low degree of automation, etc., to simplify the equipment structure The effect of the installation process, reducing the equipment footprint, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

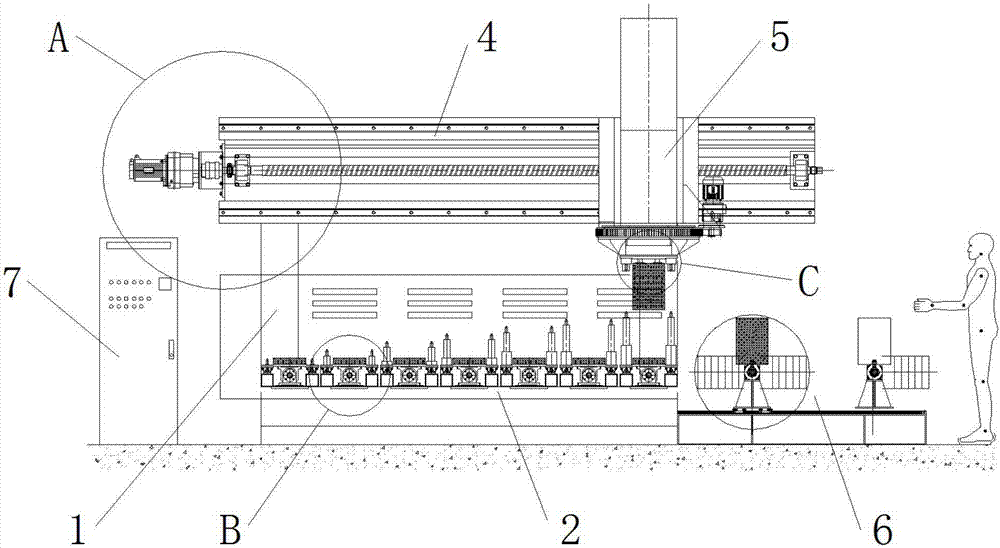

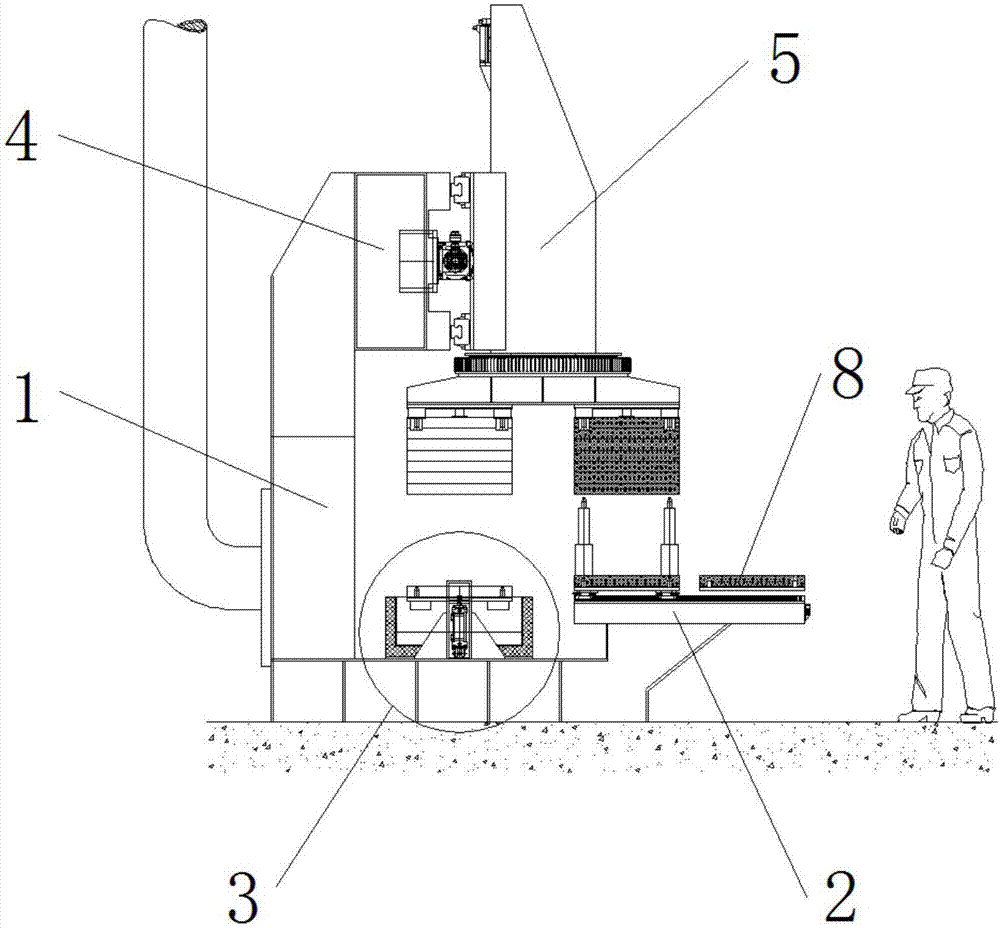

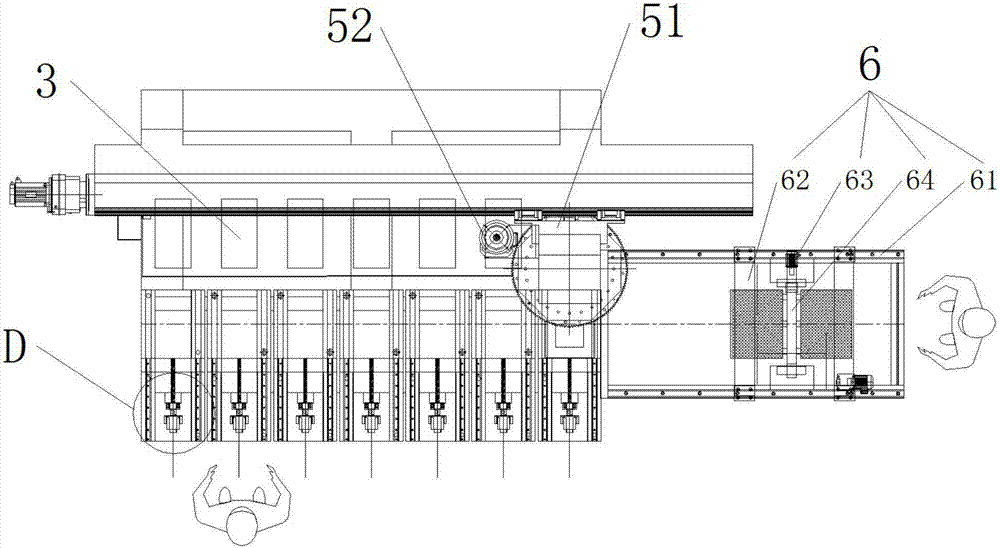

[0045]As shown in the figure, the lost foam multi-station digital viscose system in the present invention includes a main frame 1, a numerical control slide device 2, a viscose system 3, a lateral movement drive system 4, a lifting rotary table 5, and a main sprue Paste the displacement device 6 and the electrical system 7 connected to each part; the numerical control sliding table device 2 and the glue system 3 are arranged at the lower end of the main frame 1, and the traverse drive system 4 is arranged at the upper end of the main frame 1 , the lifting rotary table 5 is located above the CNC sliding table device 2 and the glue system 3 and is set on the traversing drive system 4, and the main sprue sticking and displacing device 6 is set along the axial direction of the traversing drive system 4 At one end of the CNC sliding table device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com