Slotting type special-shaped aluminum plate curtain wall assembly type installation system

An installation system and prefabricated technology, applied in the direction of walls, building components, building insulation materials, etc., can solve the problem of restricting the promotion and use of large-area aluminum panel curtain walls, high quality requirements for glue sealing effect, and difficulty in ensuring the effect of aluminum panel flatness. requirements and other issues, to achieve the effect of increasing the service life, beautiful effect, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

[0024] In the description of the present invention, it is to be understood that the terms "upper", "lower", "front", "post", "left", "right", "top", "bottom", "inside", " The orientation or position of the instructions such as "is based on the orientation or positional relationship shown in the drawings, which is merely intended to describe the present invention and simplified description, rather than indicating or implying that the device or component must have a specific orientation. Specific orientation configurations and operations are not to be understood as limiting the invention.

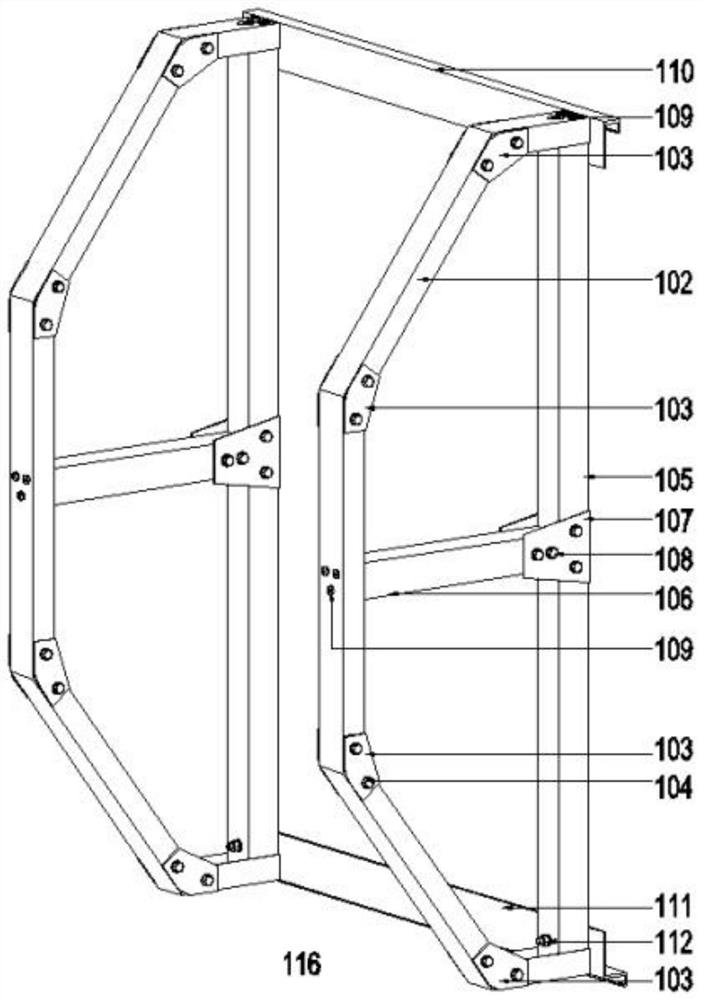

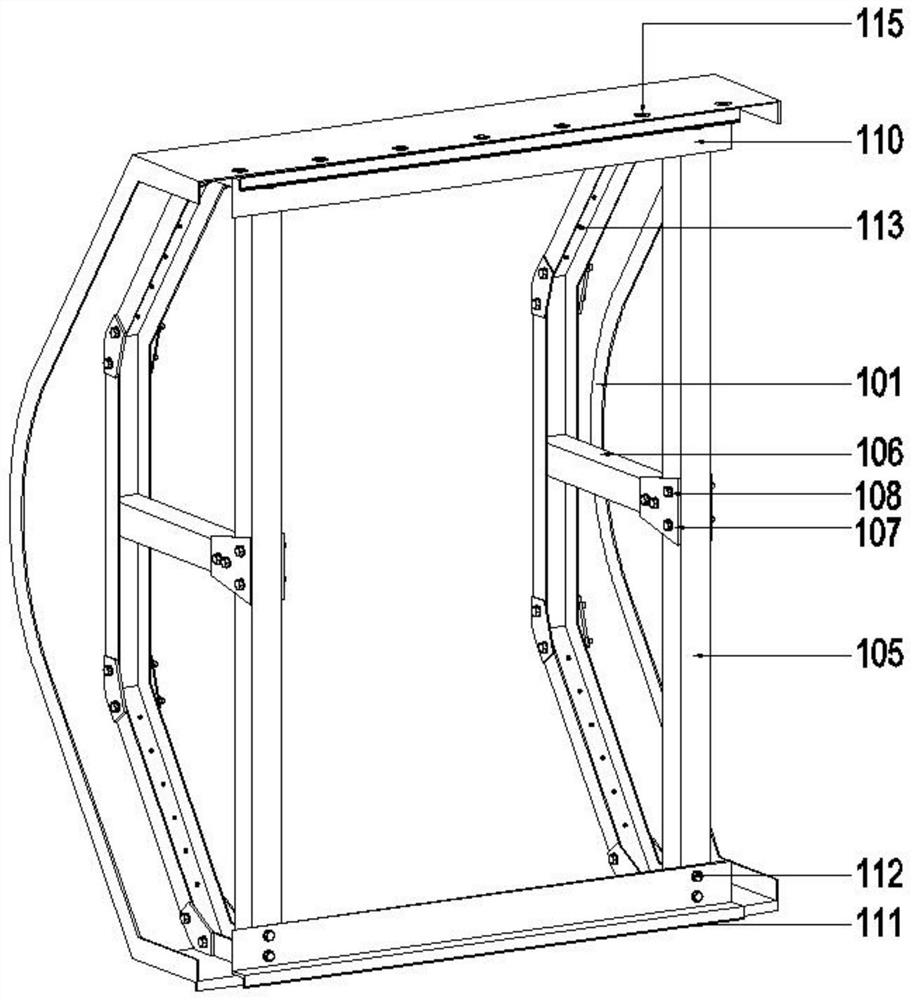

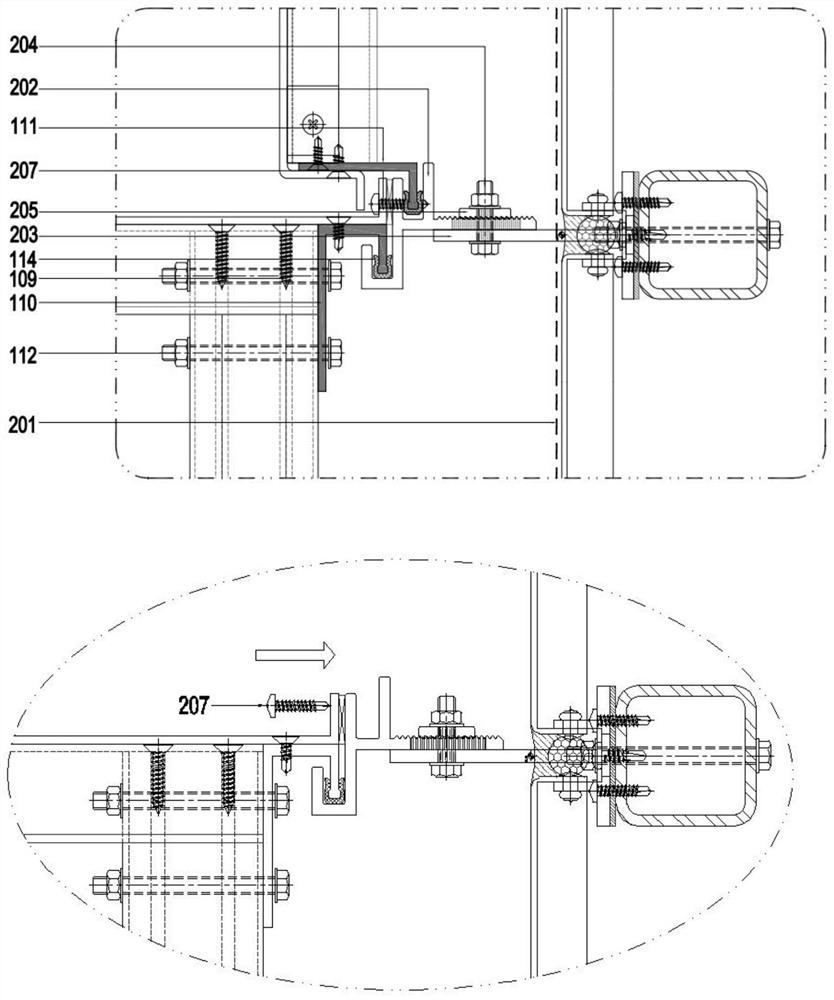

[0025] Refer Figure 1 - Figure 3 A seamless shaped aluminum curtain wall mounting system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com