Processing device for smart phone

A processing device and smart phone technology, applied in positioning devices, clamping devices, metal processing, etc., can solve problems affecting processing quality, long production cycle, high labor cost, etc., to ensure accuracy and product quality, and avoid offset , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

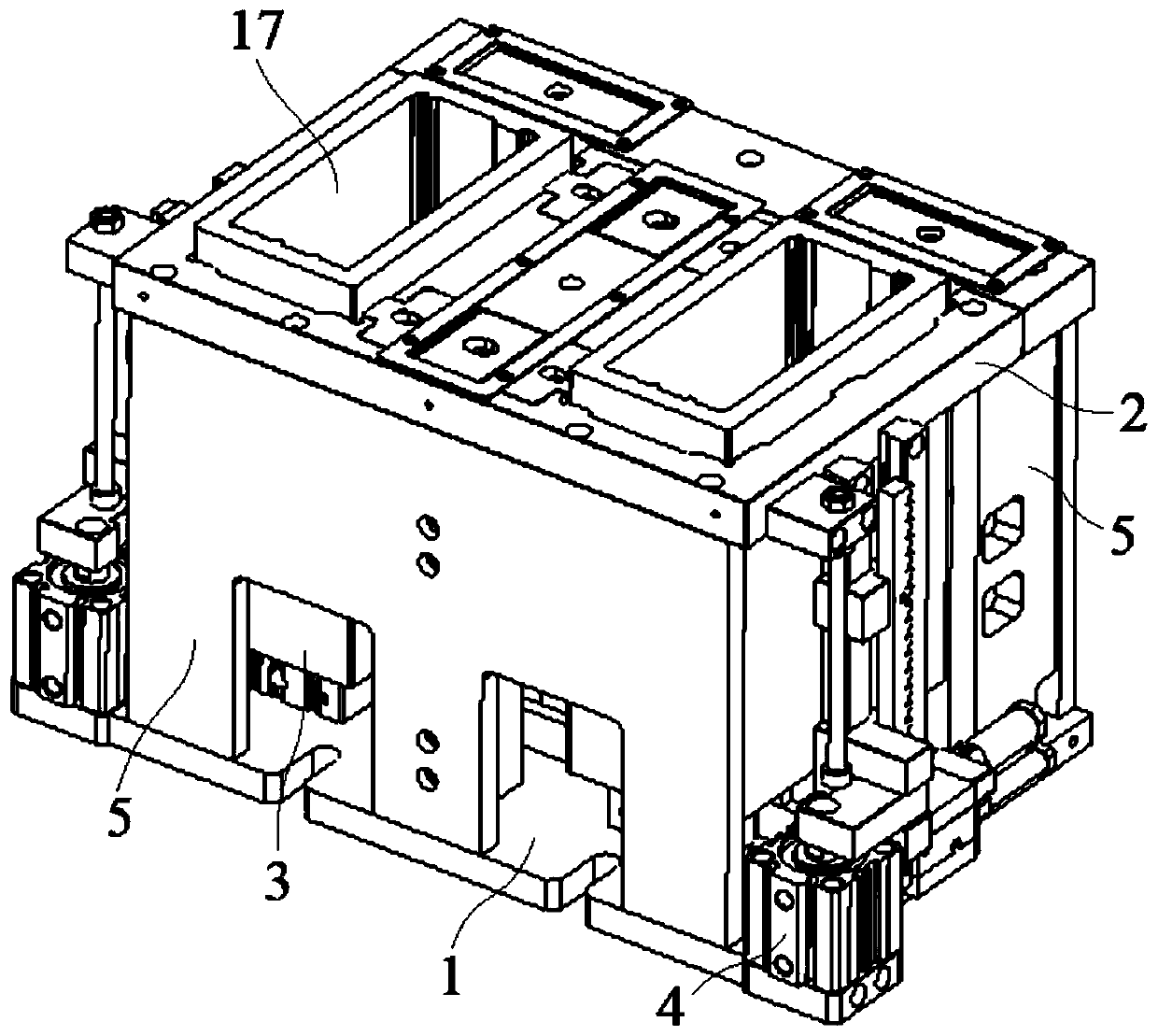

[0032]Embodiment 1: A processing device for smart phones, including a bottom plate 1, a top plate 2, a material seat 3 movably arranged between the bottom plate 1 and the top plate 2, and at least one pushing mechanism 4, the bottom plate 1 and the top plate 2 They are connected by several support plates 5, the ejector mechanism 4 is located on the side of the bottom plate 1, and the material seat 3 is provided with a material to be processed 17;

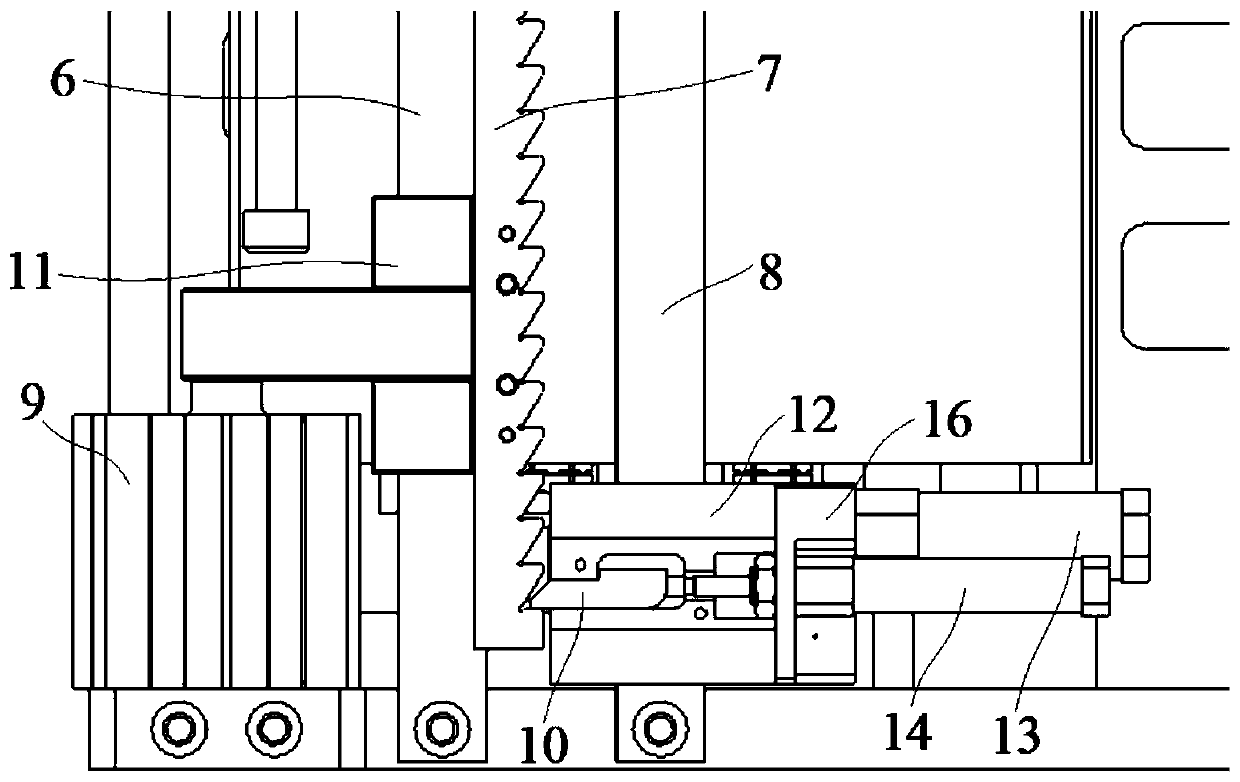

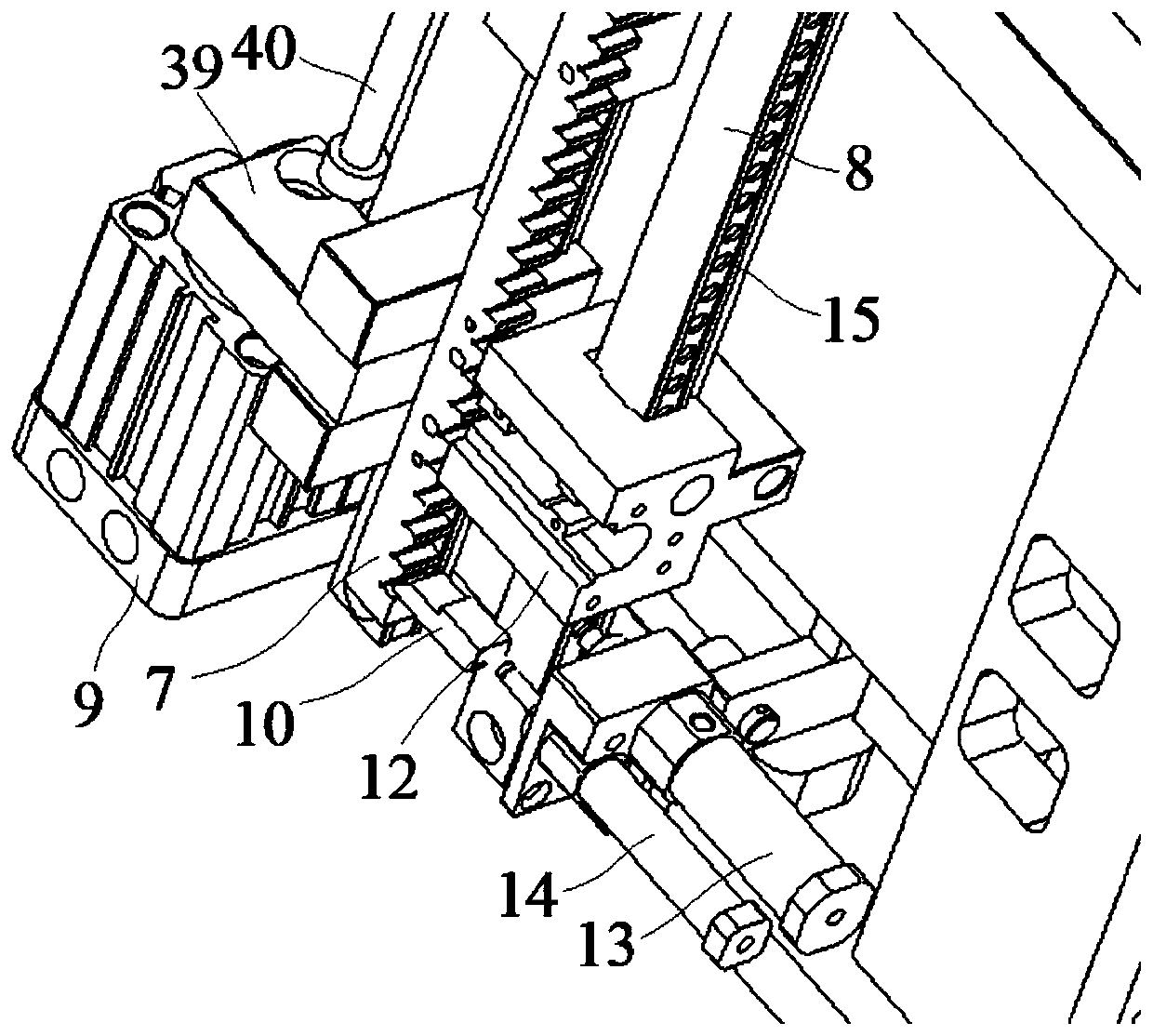

[0033] The ejector mechanism 4 further includes a guide post 6, a rack 7 movably mounted on the guide post 6, a positioning post 8, an ejector cylinder 9 and a snap-in tongue 10 for being embedded in the rack 7, the guide post 6 and the upper and lower ends of the positioning column 8 are respectively connected with the top plate 2 and the bottom plate 1, the rack 7 is movably connected with the guide column 6 through at least one slider 11, and the piston rod of the pushing cylinder 9 is connected with the slider 11 , for driving t...

Embodiment 2

[0039] Embodiment 2: A processing device for smart phones, including a bottom plate 1, a top plate 2, a material seat 3 movably arranged between the bottom plate 1 and the top plate 2, and at least one ejector mechanism 4, the bottom plate 1 and the top plate 2 They are connected by several support plates 5, the ejector mechanism 4 is located on the side of the bottom plate 1, and the material seat 3 is provided with a material to be processed 17;

[0040] The ejector mechanism 4 further includes a guide post 6, a rack 7 movably mounted on the guide post 6, a positioning post 8, an ejector cylinder 9 and a snap-in tongue 10 for being embedded in the rack 7, the guide post 6 and the upper and lower ends of the positioning column 8 are respectively connected with the top plate 2 and the bottom plate 1, the rack 7 is movably connected with the guide column 6 through at least one slider 11, and the piston rod of the pushing cylinder 9 is connected with the slider 11 , for driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com