Scrap-jumping prevention stamping die stamping method

A technology for stamping dies and scraps, applied in the stamping field of anti-jump scrap stamping dies, can solve problems such as errors, affecting stamping accuracy, and displacement of stamping parts, so as to shorten the unloading time, improve stamping efficiency, and prevent scraps from jumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

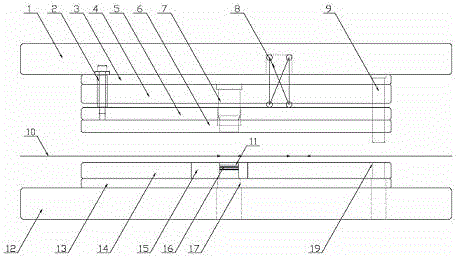

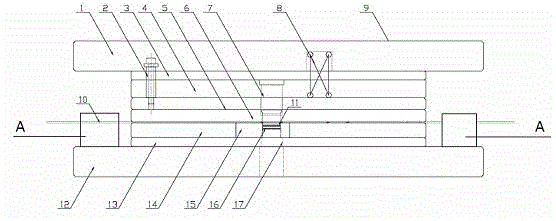

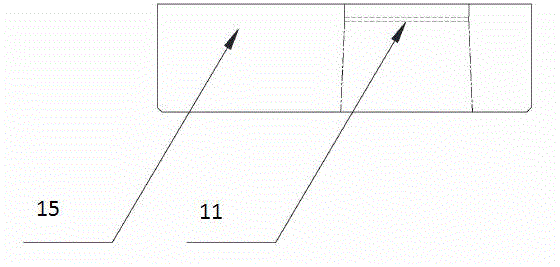

[0037] Combine below Figure 2 to Figure 6 , the present invention is further described:

[0038] like figure 2 As shown, the present invention provides a stamping die for anti-jump waste, which includes an upper die and a lower die that can move up and down relative to each other.

[0039] The upper mold includes an upper mold base 1, a stripper assembly, an elastic element 8, a mounting plate and a punch 7. The upper mold base 1 and the stripping assembly are connected through a connecting element 2, and the upper mold base 1 and the stripping assembly can move up and down relative to each other. The stripping assembly includes a stripping plate 6 and a sub-baffle 5, and the stripping plate 6 is fixedly connected under the sub-baffle 5 for pressing materials. The connecting element 2 is a bolt, one end of which is connected with the upper mold base 1, and the other end passes through the mounting plate and is connected with the sub-baffle 5.

[0040] The mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com