Improved FX2 embossing roller for packaging machine

A machine embossing roller, an improved technology, used in packaging, packaging cigarettes, etc., can solve the problems of short service life of A roller and B roller, unstable pattern of aluminum foil paper or environmental protection paper, etc., to achieve clear and consistent patterns, Improve the service life and the effect of accurate connection positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

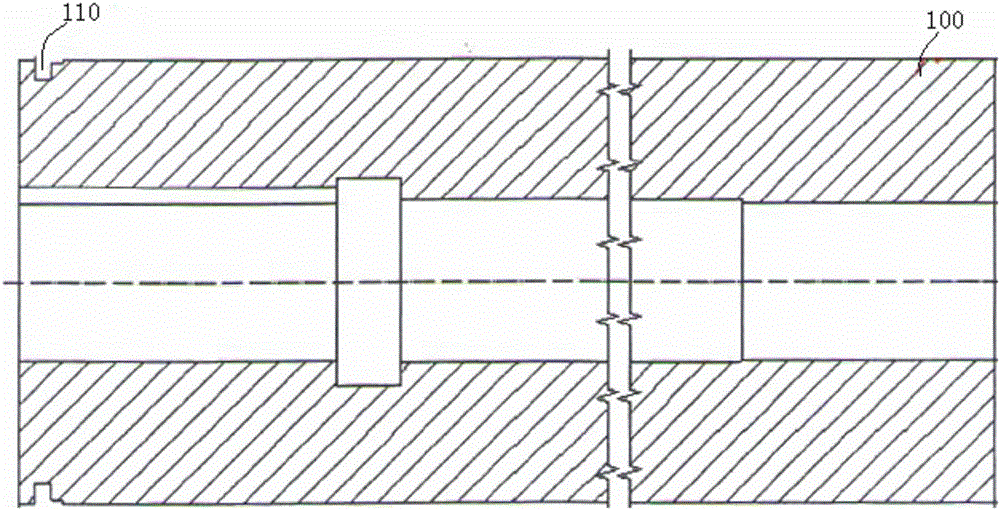

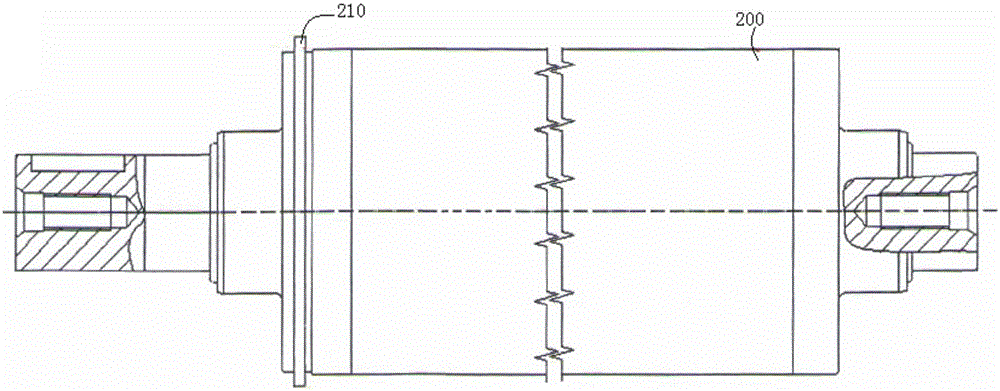

[0009] see figure 1 and figure 2 , an improved embossing roller of the FX2 packaging machine shown in the figure, including A roller 100 and B roller 200, the two are connected and driven by a gear pair, and one end of the roller of A roller 100 is processed with a concave positioning Flower 110, one end of the cylinder of B roller 200 is processed with convex positioning flower 210, the concave positioning flower 110 on the A roller 100 and the convex positioning flower 210 on the B roller 200 are mutually fitted, and the A roller 100 and the B Roller 200 performs axial positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com