Disassembling and assembling tool for mixed flow horizontal water turbine

A water turbine and horizontal technology, which is applied in the field of disassembly and assembly tools for mixed-flow horizontal water turbine runners, can solve the problems of low safety, easy to produce shaking, etc., and achieve the effects of high connection strength, good positioning, and high bending resistance and deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

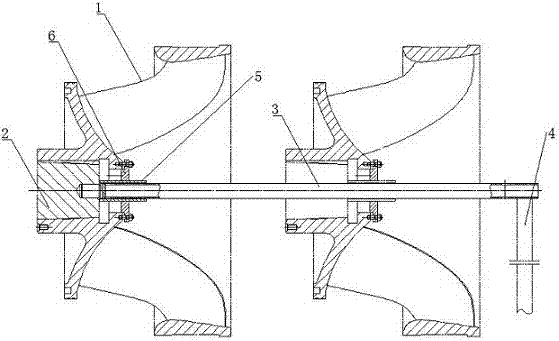

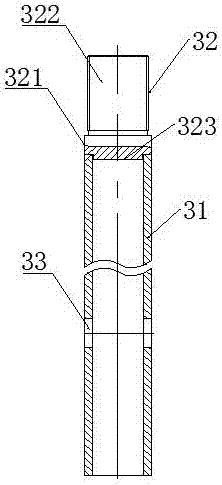

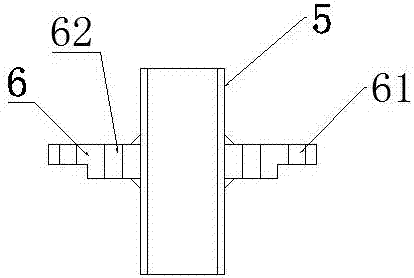

[0020] The reference signs in the drawings of the description include: runner 1, main shaft 2, tie rod 3, rod body 31, joint 32, installation section 321, connection section 322, positioning platform 323, through hole 33, buttress 4, bushing 5, Flange 6, connecting hole 61, jacking hole 62.

[0021] The embodiment is basically as attached figure 1 Shown: The dismantling tool for the mixed flow horizontal turbine runner, including the main shaft 2, the runner 1 and the tie rod 3, the end of the main shaft 2 is provided with a central hole, the inner wall of the central hole is provided with an internal thread, and the end of the main shaft 2 is tapered shape setting; the middle part of the runner 1 is provided with a mounting hole. Such as figure 2 As shown, the pull rod 3 includes a rod body 31 made of a seamless steel pipe and a joint 32 made of a round steel. The jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com