Cup feeding mechanism of cup printing machine

A cup printing machine and cup feeding technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of inaccurate printing alignment, lower printing quality, and complicated cup mold structure, so as to achieve stable conveying process and improve printing quality. quality, avoiding off-axis effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

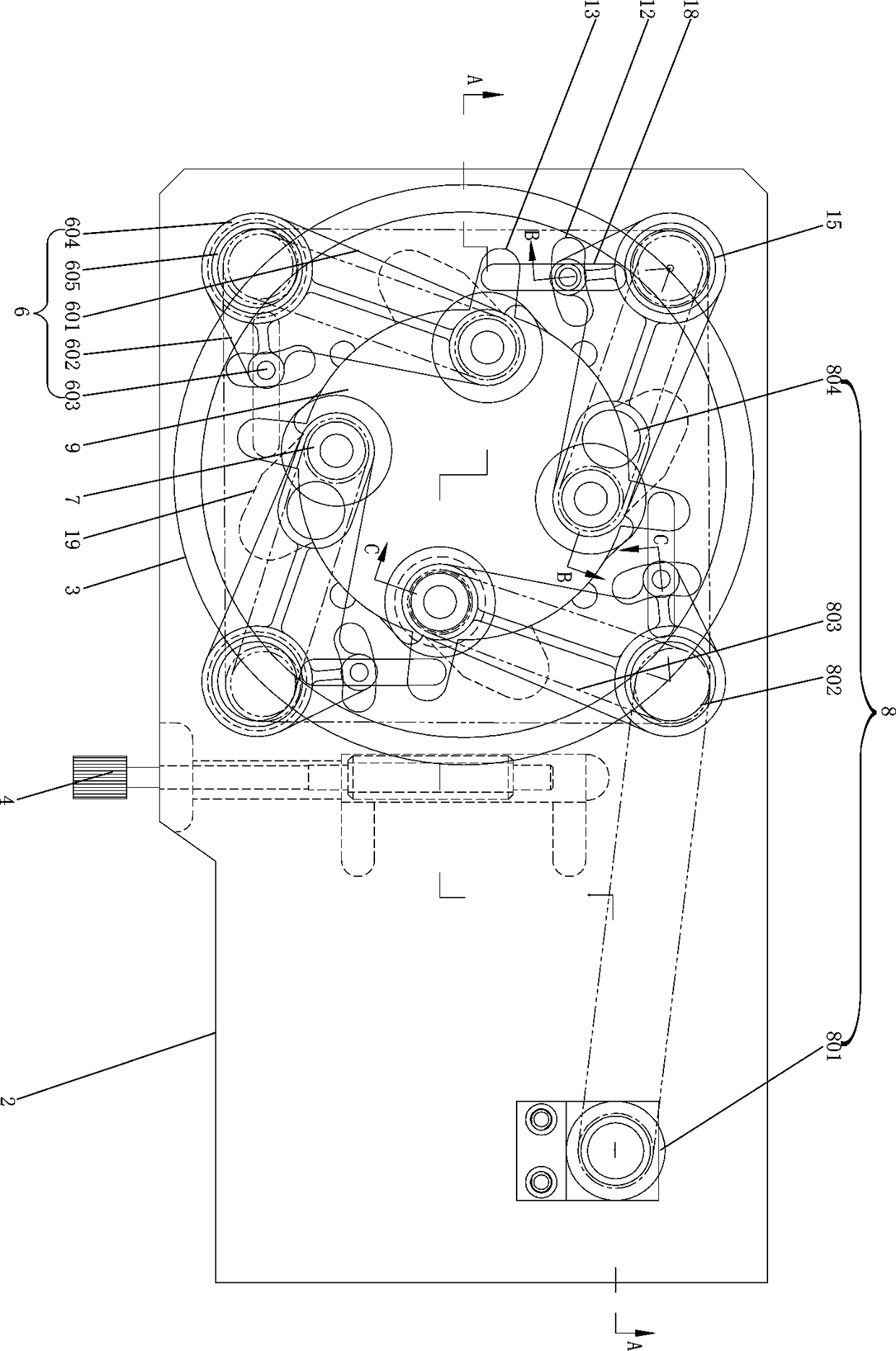

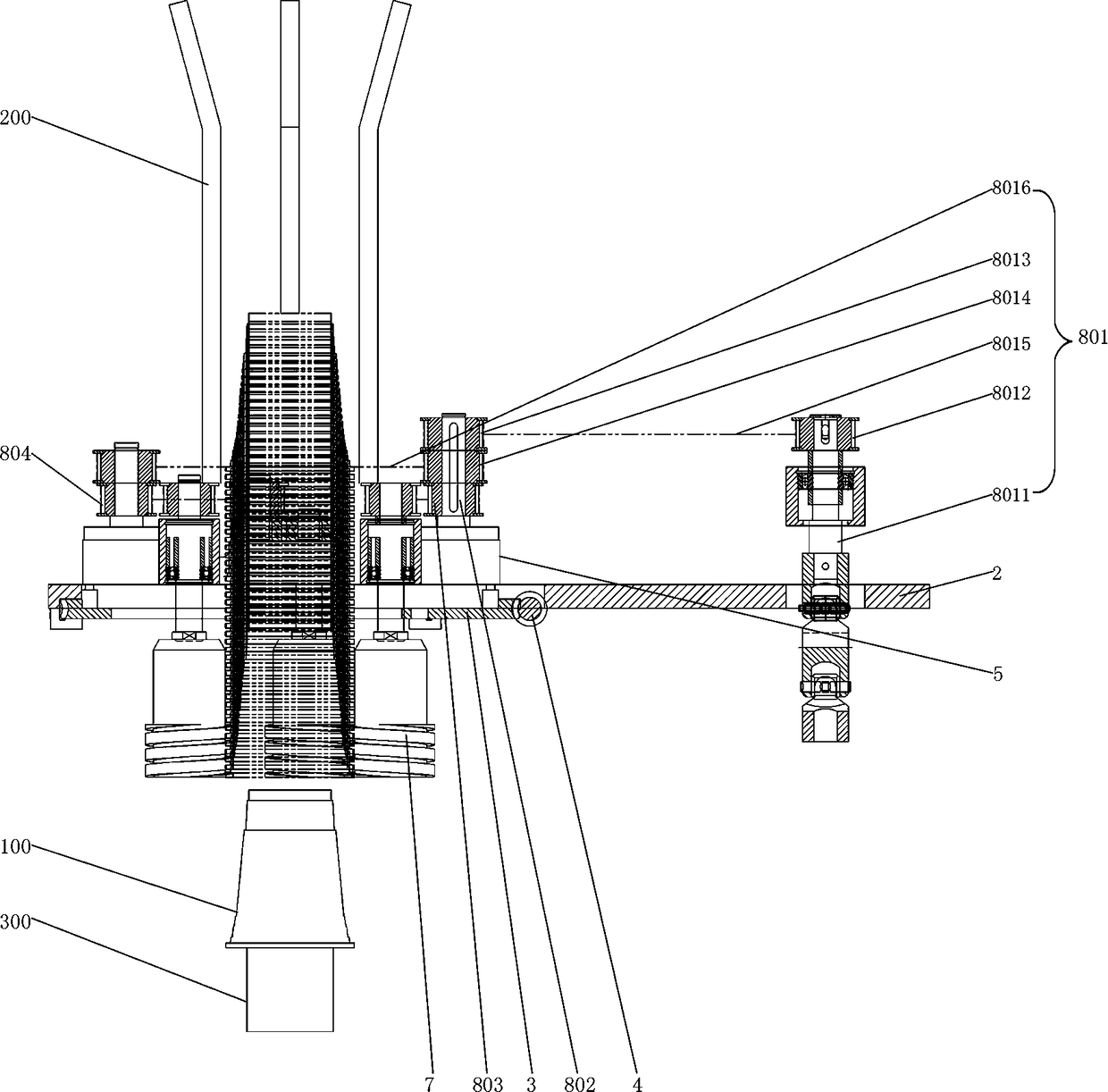

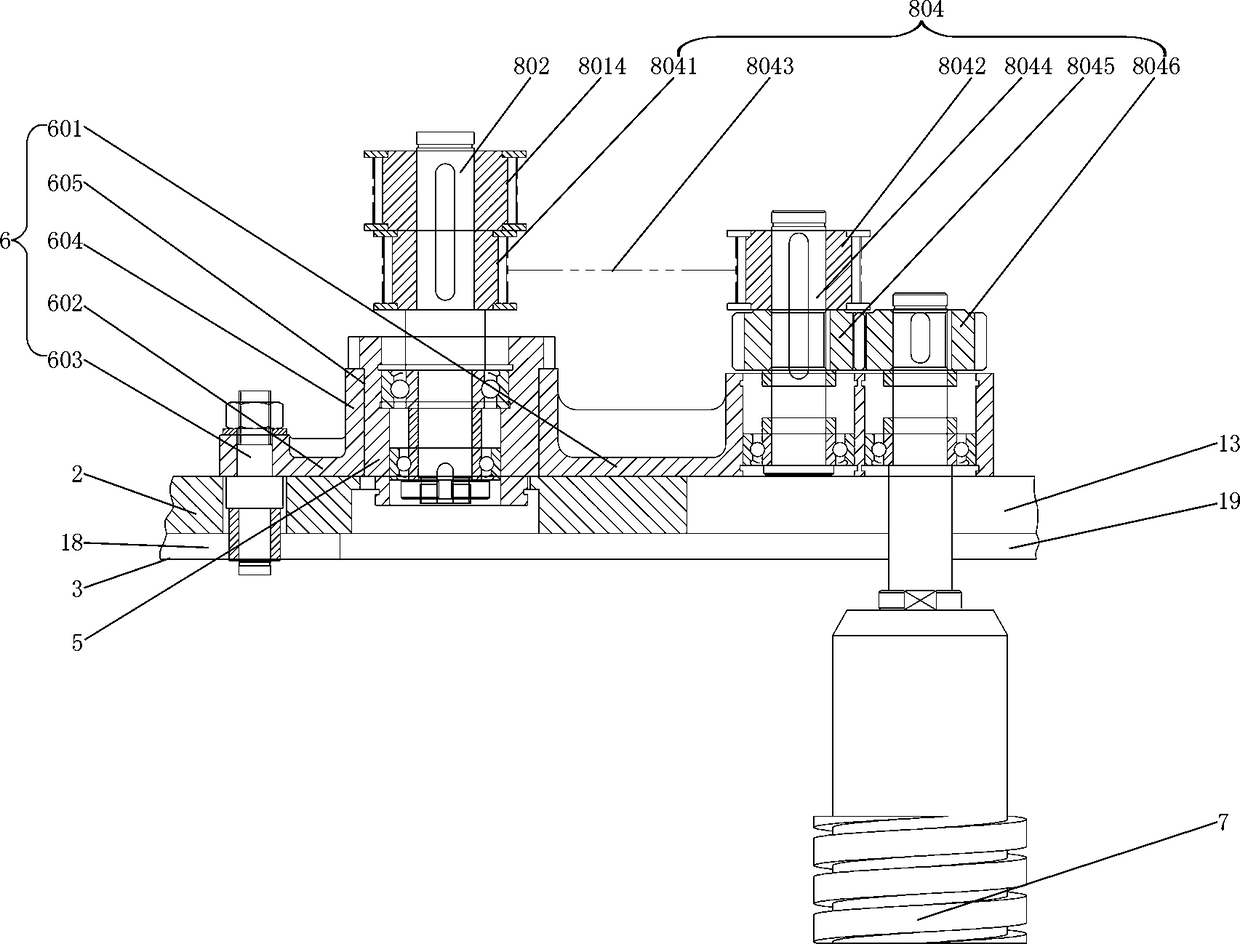

[0021] Such as figure 1 , figure 2 , image 3 As shown, the cup feeding mechanism of this cup printing machine, including the frame ( figure 1not shown in), supporting plate 2, turbine 3, worm 4, four fixed shafts 5, four swing arms 6, four screw rods 7, and a driving mechanism 8 capable of driving two adjacent screw rods 7 to rotate in opposite directions, swing arm 6 Including the long arm 601, the short arm 602 and the roller 603, the short arm 602 and the long arm 601 are connected at the connecting part 604 to form an L-shaped structure (the short arm 602, the long arm 601 and the connecting part 604 generally adopt an integrated structure) , a shaft hole 605 is provided at the connecting portion 604 of the short arm 602 and the long arm 601, and the connecting end of the roller 603 is installed at the end of the short arm 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com