Method of honing bores

一种珩磨、珩磨条的技术,应用在珩磨工具、珩磨机床、金属加工设备等方向,能够解决高成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

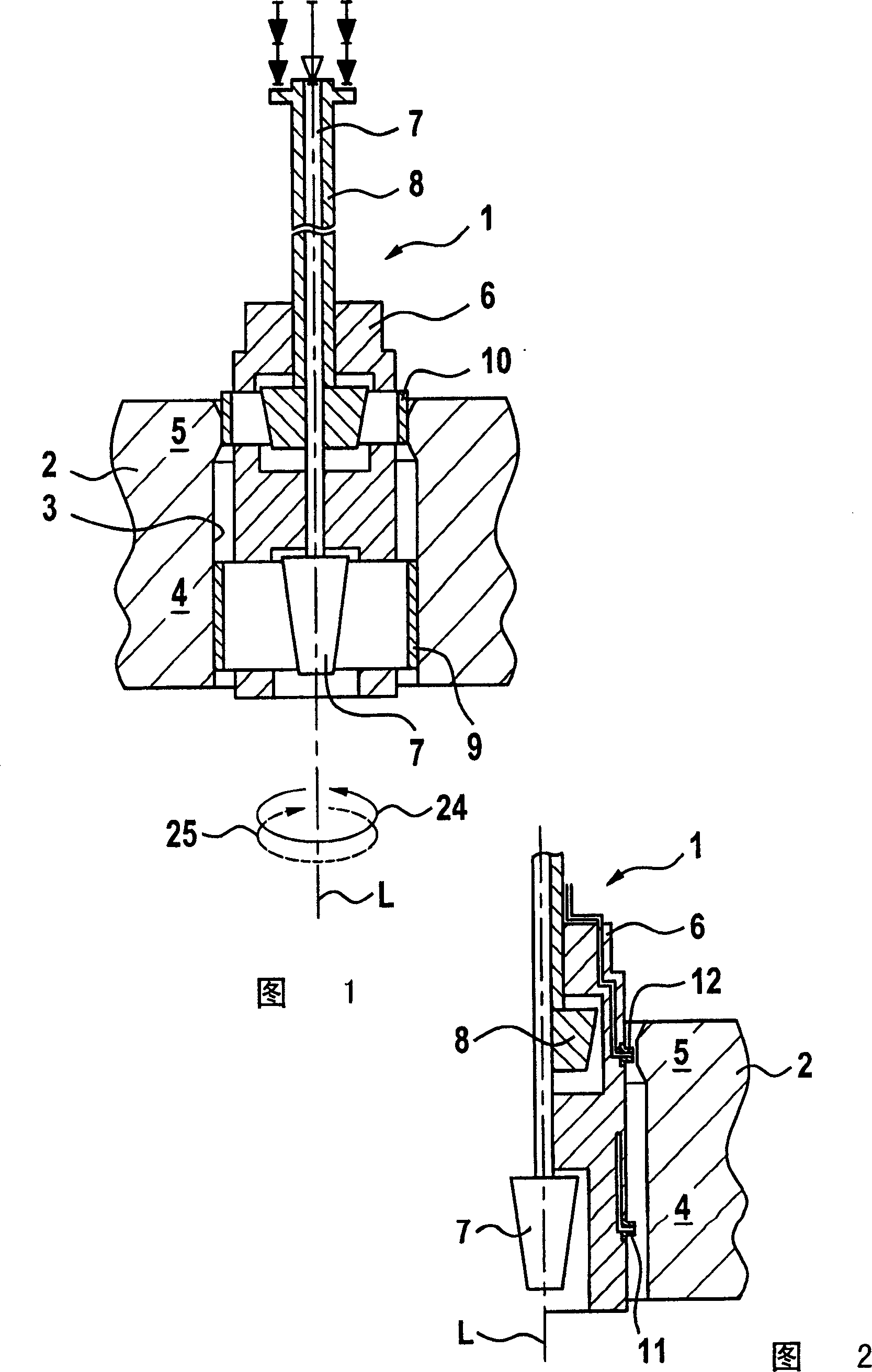

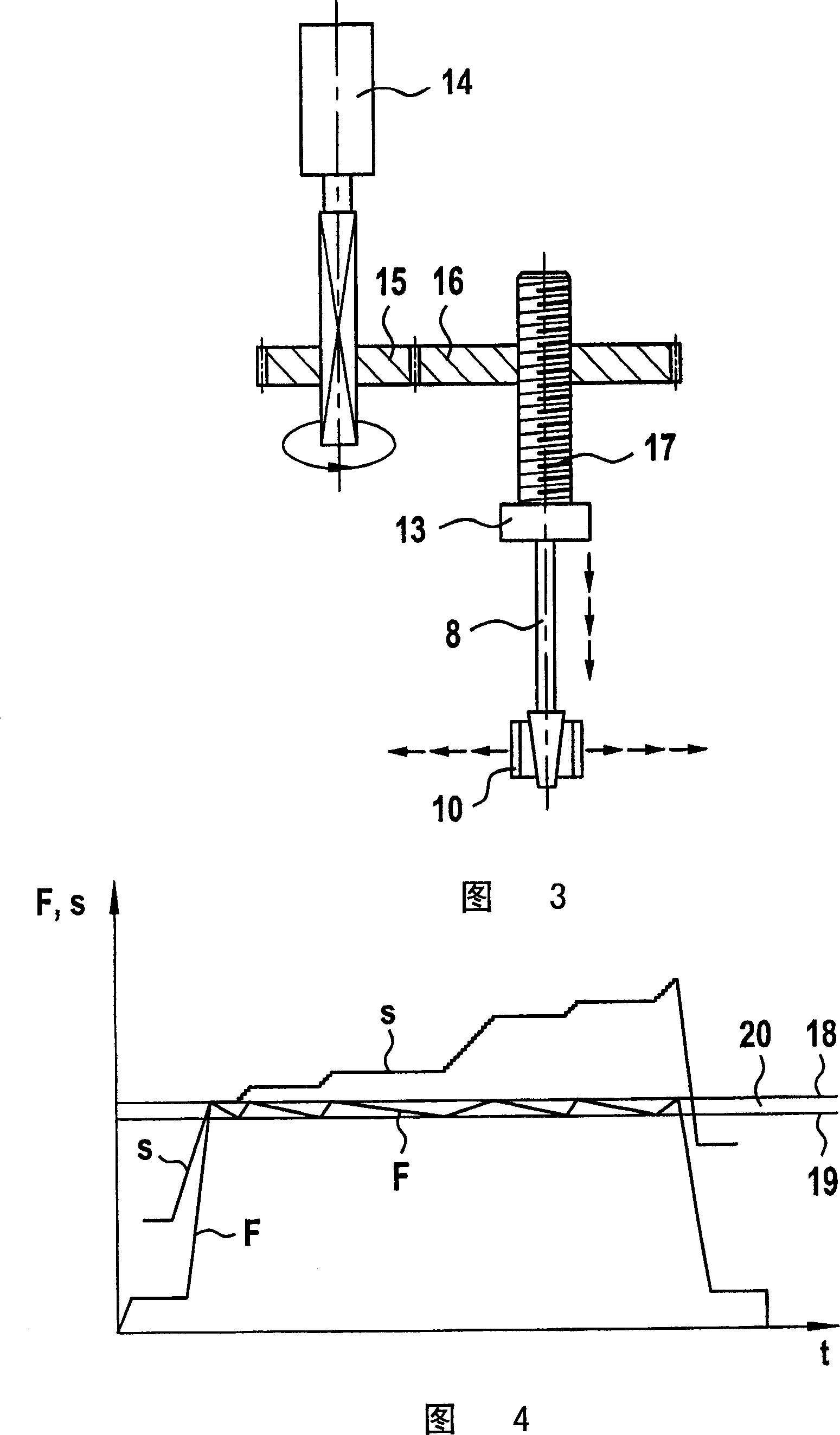

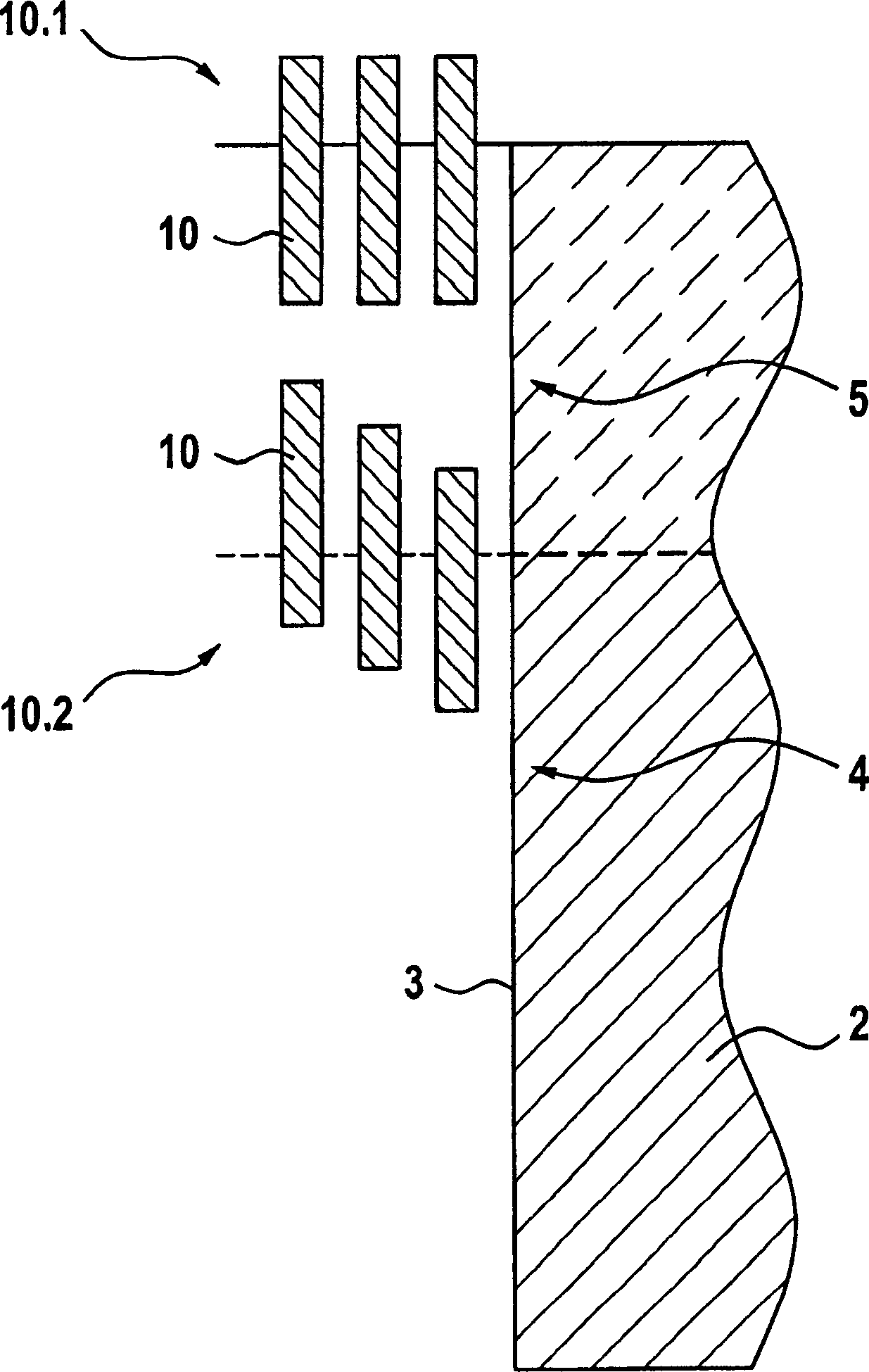

[0018] Figure 1 shows a longitudinal section through a honing tool suitable for coaxial honing. In this case, the honing tool 1 is located in a bore 3 of a workpiece 2, for example the crankcase of an internal combustion engine. The hole 3 comprises an unhardened hole section 4 and a hardened hole section 5 , wherein the hardened hole section 5 is formed at the upper end of the hole 3 in FIG. 1 . The hardened bore section 5 can be produced, for example, by induction hardening. The honing tool 1 comprises a tool head 6 with a radially expandable honing stone 10 and a radially expandable guide strip 9 . The guide bar 9 bears on the wall of the unhardened hole section 4 and applies a predetermined force to the honing stone 10 to press against the wall of the hardened hole section. A first feed device 7 for the guide strip 9 and a second feed device 8 for the honing stone 10 are provided. The second feeding device 8 may be a force-controlled electromechanical stepping feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com