Honing method and honing tool

A honing and tool technology, applied in honing tools, honing machine tools, manufacturing tools, etc., can solve problems such as leakage, oil consumption, increased friction, deterioration of sealing function, difficulty in control, etc., to ensure uniform wear, promote removal, and avoid unsightly The effect of uniform wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

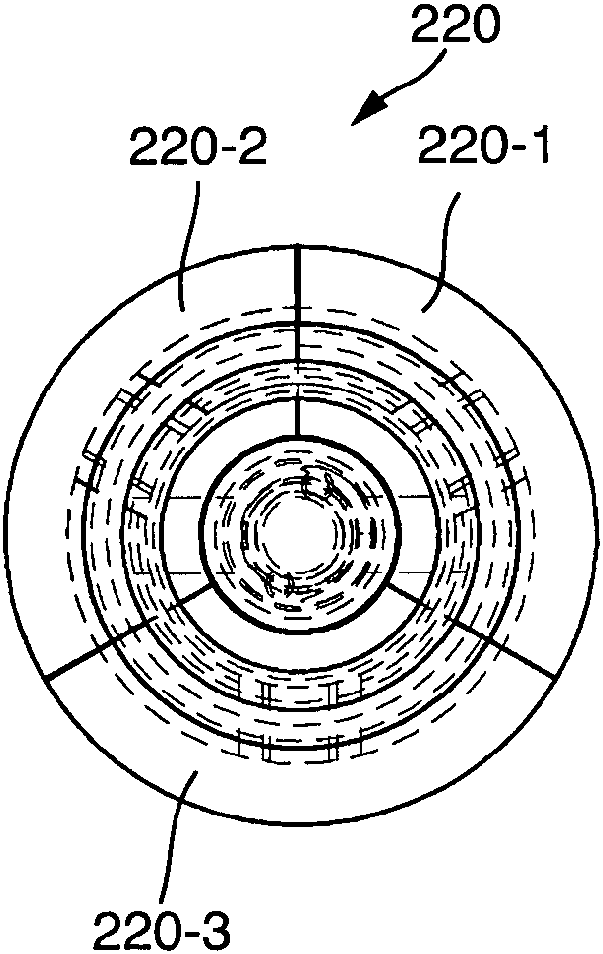

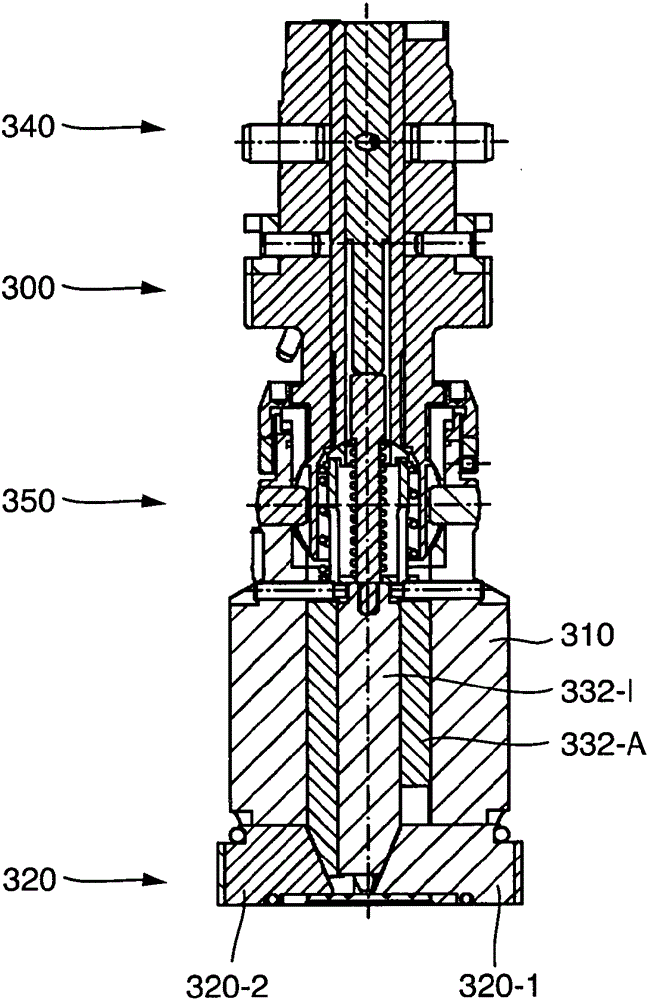

[0049] A description of exemplary embodiments of a honing method and of a honing tool that can be used within the context of an embodiment of the invention in the material removal machining of a workpiece having one or more boreholes in the finished machining state follows The lower image has the macroscopic shape of a bottle.

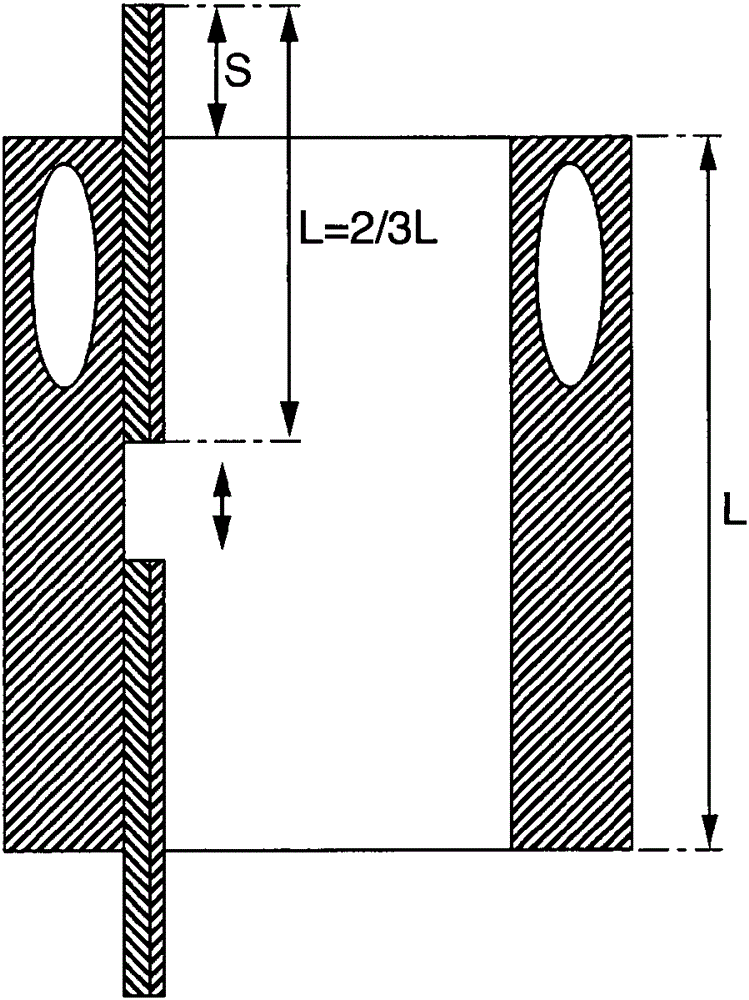

[0050] figure 1 A schematic longitudinal section through one such bottle bore 110 in a workpiece 100 in the form of an engine local (cylinder crankcase) for an internal combustion engine is shown. The borehole is rotationally symmetrical with respect to its borehole axis 112 and extends over a borehole length L from a borehole inlet 114 facing the cylinder head in the installed state to a borehole outlet 116 at the opposite end. It is possible to divide the borehole into three mutually adjacent sections of different functions, which merge in a sliding manner within each other, ie without the formation of steps or edges.

[0051] The first bore portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com