Honing Tool

a honing tool and tool body technology, applied in the field of honing tools, can solve the problems of increasing the cost of honing stones and the small space available in the tool body, and achieve the effects of preventing tilting or canting, enhancing the torsion stiffness of the tool body in operation, and improving the mounting and exchange of honing stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

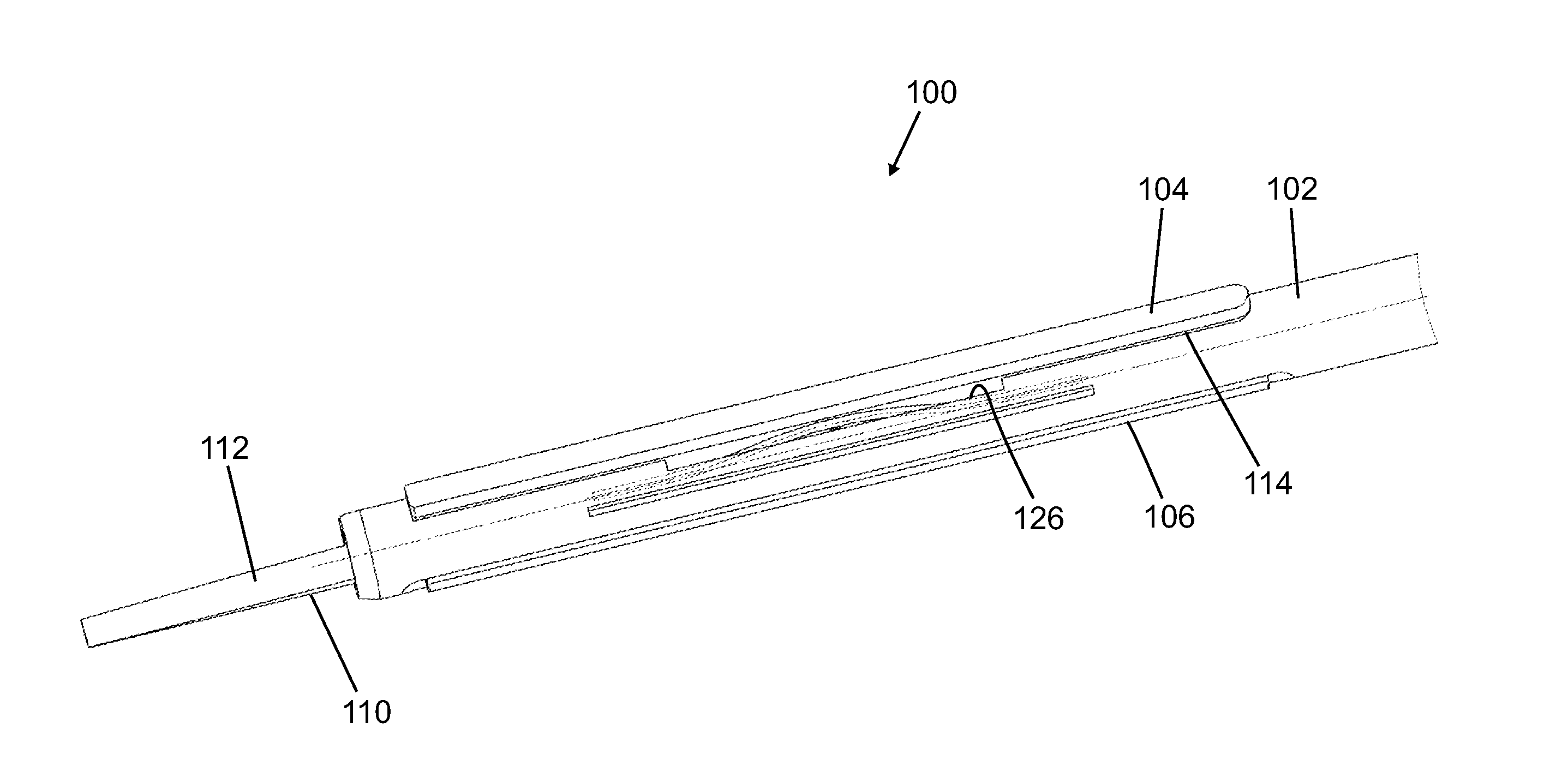

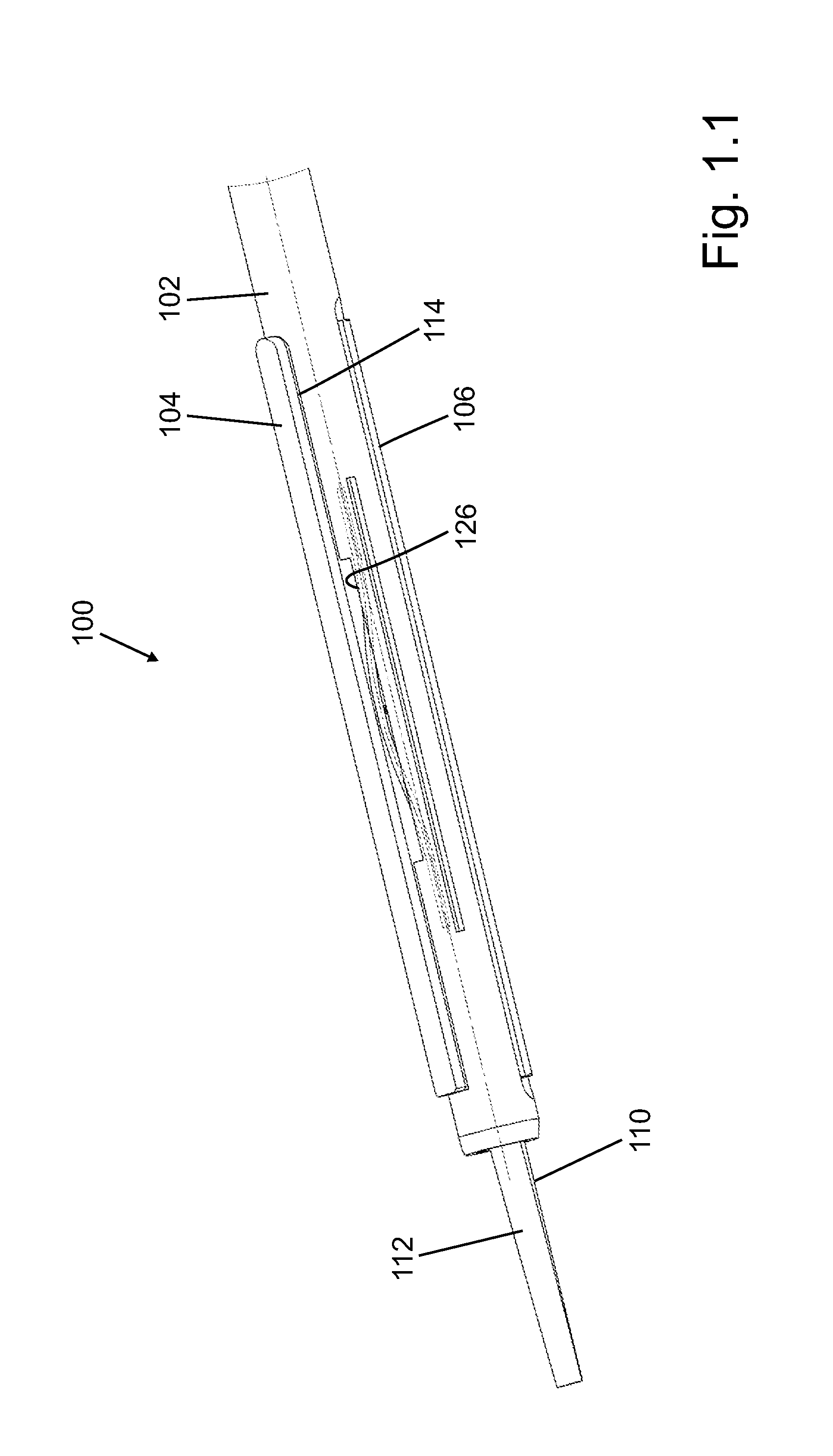

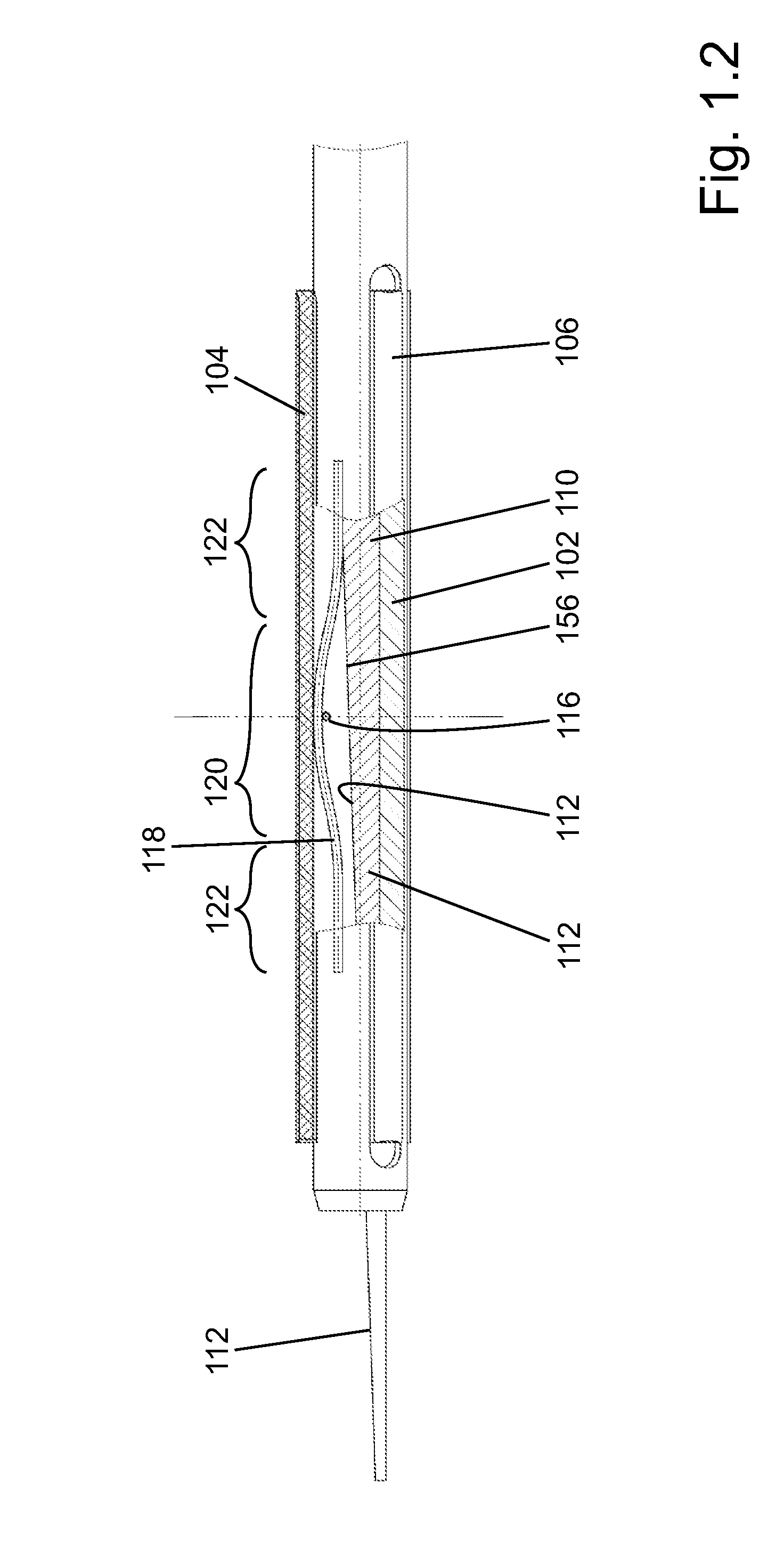

[0045]The honing tool 100 illustrated in FIG. 1 is used in particular for machining small bores, i.e., bores with a diameter of less than 15 mm. It is embodied as a single honing stone tool with tool body 102 and a radially adjustable honing stone 104. In order for the honing tool 100 to be centered within the bore to be machined (not illustrated), one or two guide bars 106 are attached to the tool body 102.

[0046]In order to effect radial feeding of the honing stone 104, in the interior of the tool body 102 a feed bore 108 is formed (see FIG. 1.3) in which a feed rod 110 is axially slidably guided. The feed rod 110 has a wedge surface 112 which is interacting with an appropriately slanted bottom side 156 of the honing stone 104 in such a way that, upon axial movement of the feed rod 110 relative to the tool body 102, the honing stone 104 is advanced radially in outward direction. This type of feeding action is known in the prior art and therefore requires no further explanation.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com