Method and apparatus for finish machining crankshaft bearing borehole

A technology of crankshaft bearings and crankcases, applied in metal processing equipment, manufacturing tools, honing tools, etc., can solve the problems of power influence, emission and engine noise influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

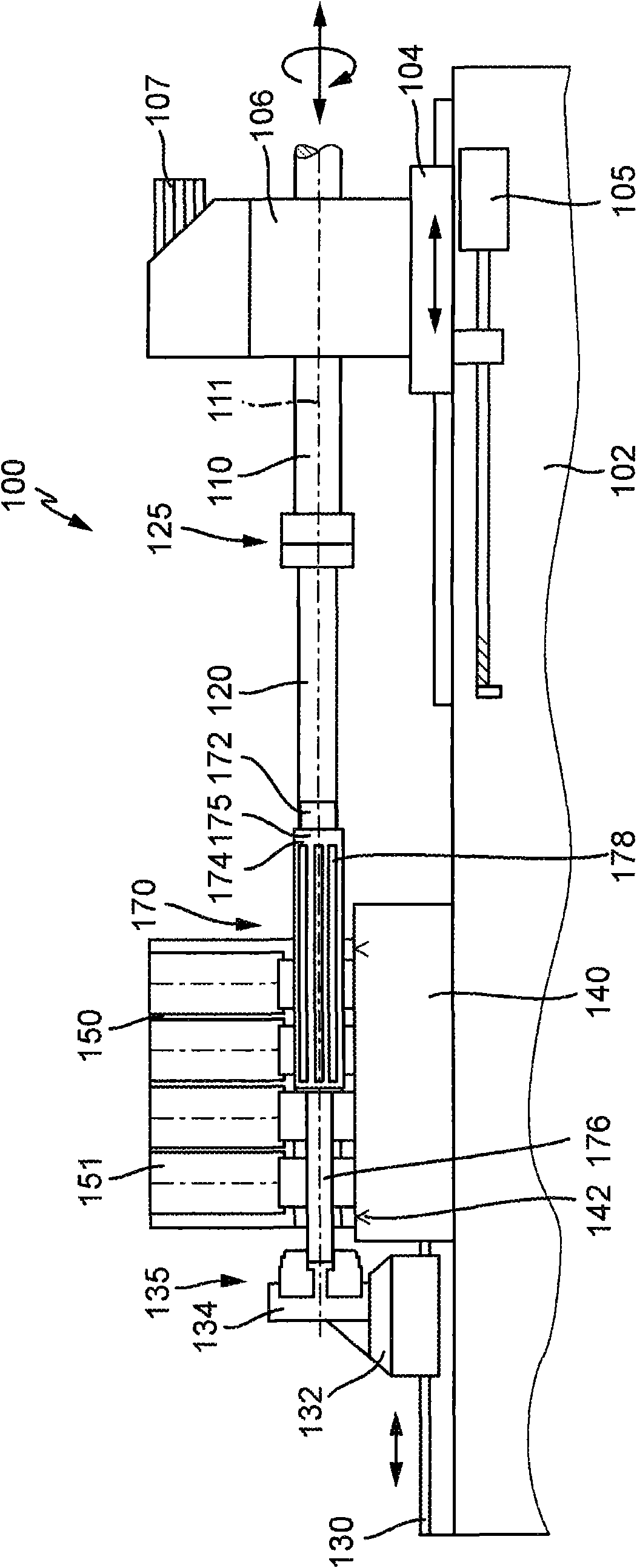

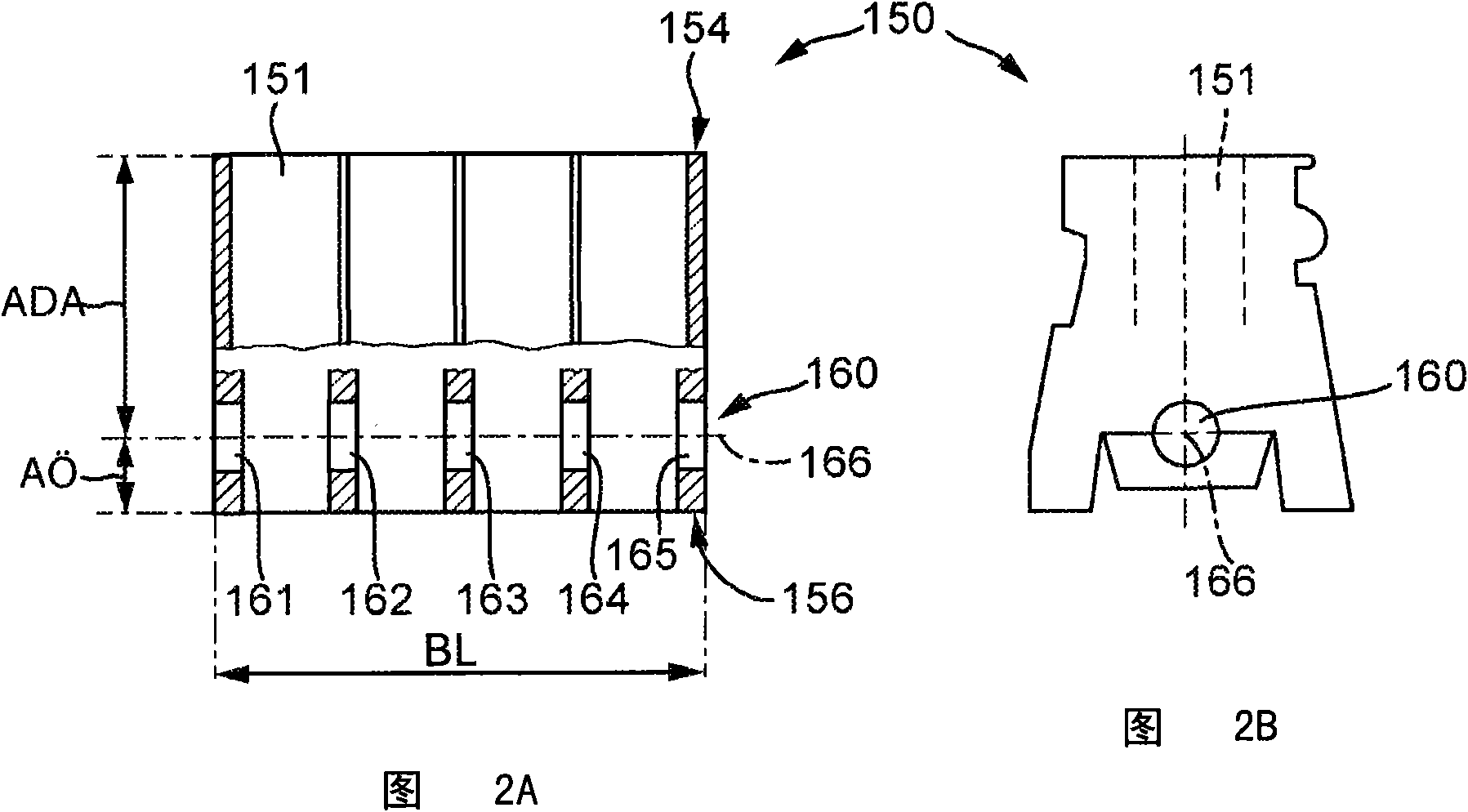

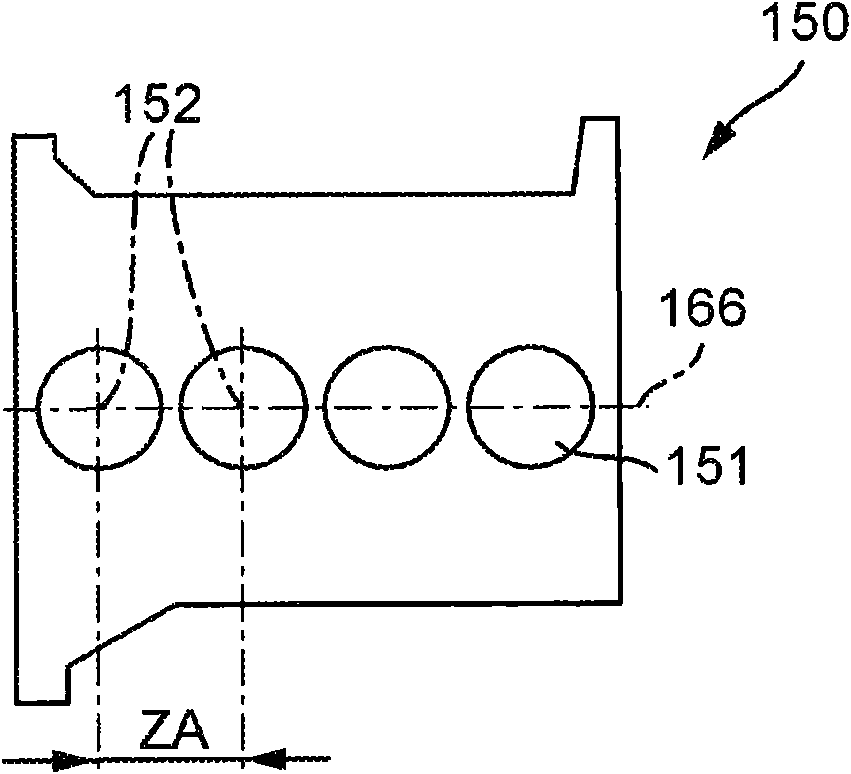

[0049] exist figure 1 shows a schematic side view of a device designed as a horizontal honing machine for finishing crankshaft bearing bores in a crankcase of a cylinder block. The honing machine is set up for complete finishing of the crankshaft bearing bore immediately after assembly of the parts of the engine block forming the crankshaft bearing bore. The honing machine is designed in such a way that by means of the honing manufacturing method it is possible, on the one hand, to adjust the correct position of the bore axis of the crankshaft bearing bore relative to a fixed reference system of the workpiece, and on the other hand to achieve (Lagerstelle) surface structure tolerances.

[0050] Mounted on a machine tool 102 of a honing machine 100 is a horizontally movable spindle slide 104 which has a headstock 106 in which a honing spindle 110 of the honing machine with a horizontal spindle center line 111 is rotatably mounted . An electronic rotary drive 107 for spindle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com