Multi-functional honing head

A honing head, multi-functional technology, applied in the direction of honing tools, etc., can solve the problem that the honing head is single in use and can only be used for inner holes or outer holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

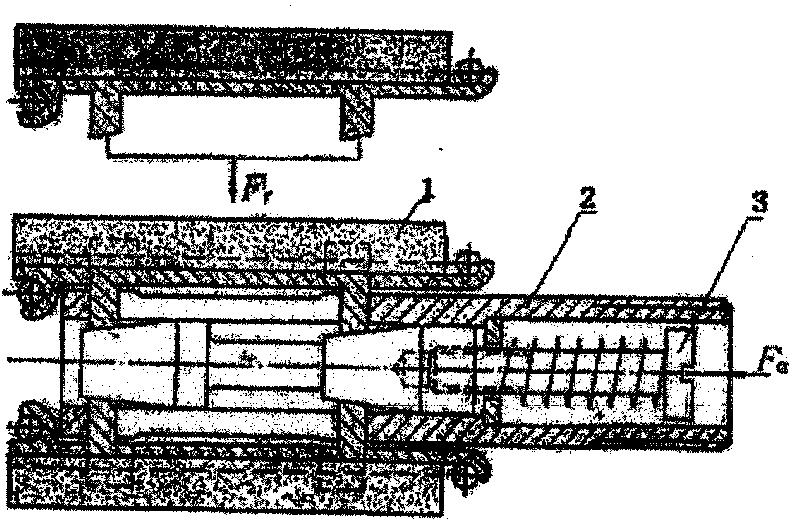

[0030] Such as Figure 6 As shown, the honing process of this honing head is relatively simple: just replace the turning tool with this honing head after turning the workpiece, align the honing wheel with the required grinding surface, and use the tool holder to pass through the honing head fixing frame (see Figure 6 "Honing head holder 9") and compression spring (see Figure 6 "Clamping spring 11") exerts a certain pressing force on the honing wheel, and the honing liquid is dripped on the honing wheel in a drop-by-drop manner.

[0031] Honing fluid: For rough honing, gasoline-added engine oil can be used; for fine grinding, machine oil or other existing honing fluids can be used directly.

[0032] There is also a wide range of honing speeds, depending only on the required workpiece quality and efficiency. However, the temperature of the honing wheel cannot be raised to such an extent that the honing wheel is damaged.

[0033] The dressing of the honing wheel can be done ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com