Dressing, honing and grinding tool

a technology applied in the field of honing and grinding tools, can solve the problem of limiting the economic efficiency of the processes in which they are currently used, and achieve the effect of improving the economic efficiency of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

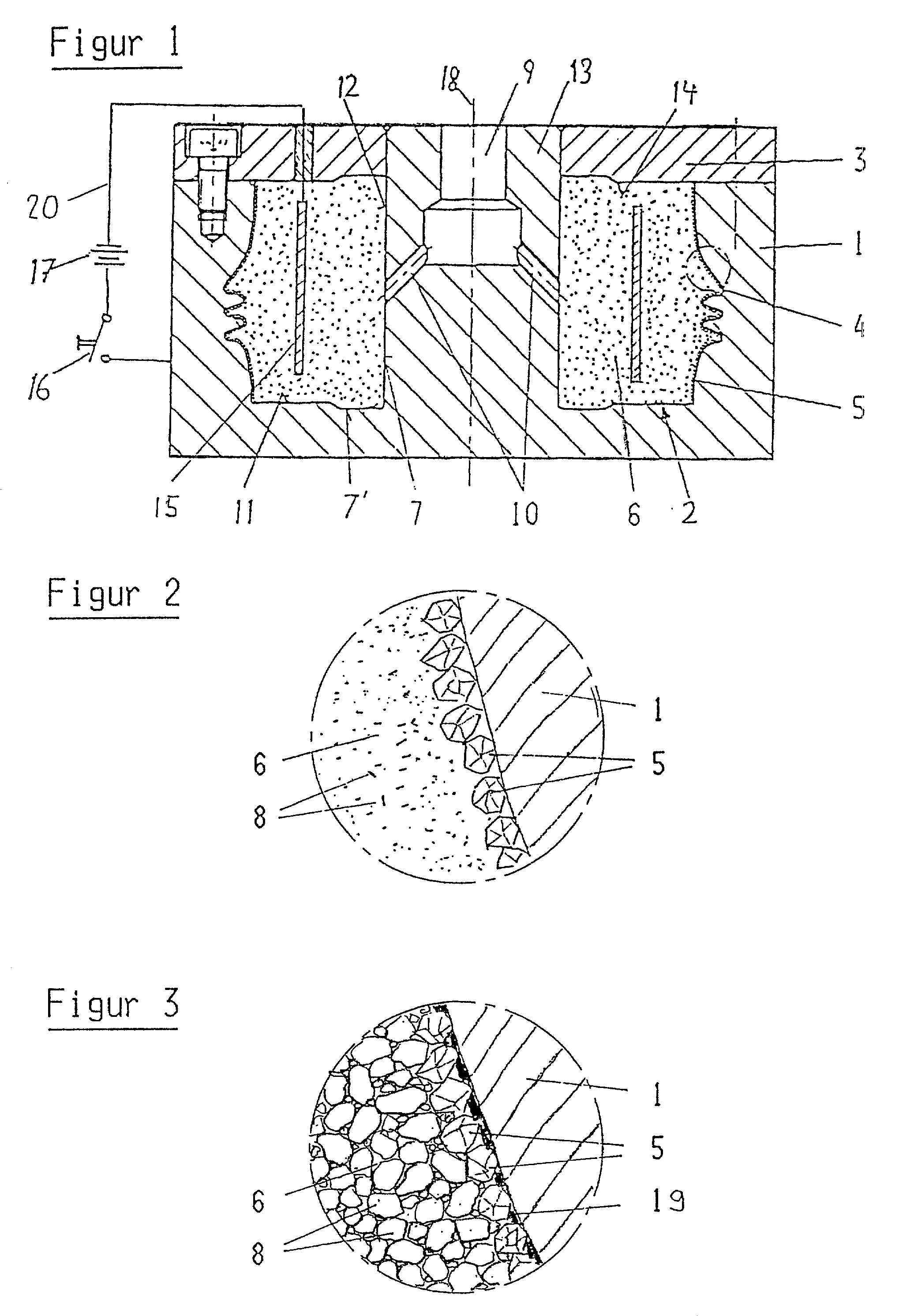

[0010] In the embodiment of the invention selected here, the negative mould 1 for the tool 2 is a pot-shaped metal body produced directly or by the reversal process, which is closed by a lid 3. In cross-section the inner contour of the negative mould 1 corresponds with the peripheral, end face and bore contour trace of the axial section through the tool. The bottom 11 of the hollow space of the negative mould 1, the enveloping surface 12 of the central cylindrical core 13 and the inner face 14 of the lid 3 are provided with an electrically insulating coating. In the closed inside space there are for example one or more annular electrodes 15, which are connected via an insulated conductor to one pole of a direct current source 17, the other pole of which is connected to the negative mould via the switch 16.

[0011] Lying on the peripheral inner surface 4 of the negative mould 1 are the hard material abrasive grains 5. The inside space of the negative mould 1 is filled with a naturally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

| hard | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com