Automatic device for machining two ends of shaft parts

A technology of shaft parts and automatic devices, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low labor productivity, universality of workpieces, inability to be universal, and inapplicability, etc., to achieve universality difficult problems, improve labor productivity, and solve the effect of low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

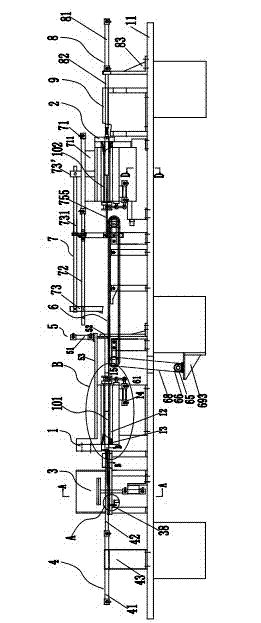

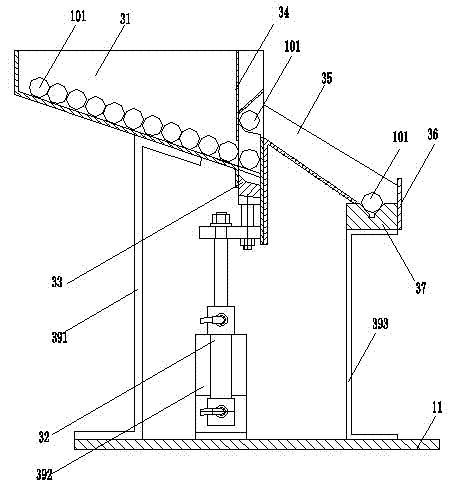

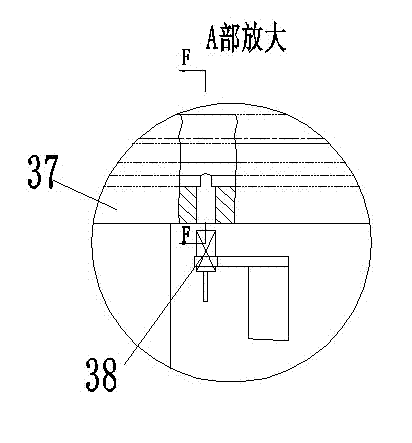

[0044] Each reference sign name among the accompanying drawings is:

[0045] The first lathe 1, the second lathe 2, the machine body 21, the dovetail groove 211, the nut 22, the base 23, the screw rod 24, the adjustment screw 25, the inlay 26, the bin 3, the bin body 31, the bin cylinder 32, the pusher Device 33, baffle plate 34, chute 35, baffle plate 36, V-groove 37, photoelectric sensor 38, bracket 391, 392, 393, feeding mechanism 4, feeding cylinder 41, cylinder piston push rod 42, sleeve 421, Push post 422, spring 423, screw 424, gasket 425, support 43, positioning mechanism 5, positioning cylinder 51, support frame 52, support plate 53, transmission mechanism 6, driving round pulley 61, wheel body 611, mandrel 612, Rolling bearing 613, retaining ring 614, inner spacer 615, outer spacer 616, screw 617, driven round pulley 62, round belt 63, 64, motor 65, driving sprocket 66, driven sprocket 67, transmission chain 68, Supports 691, 692, 693, feeding positioning mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com