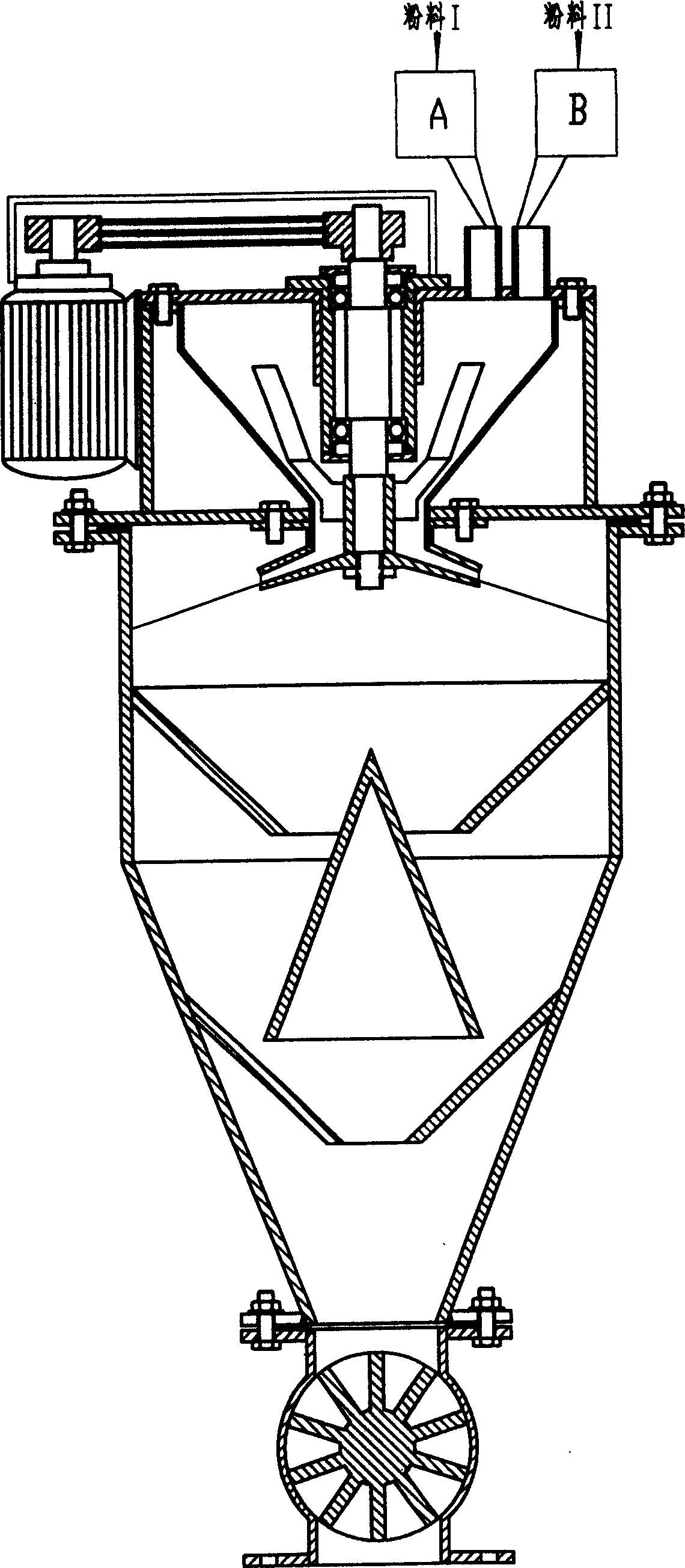

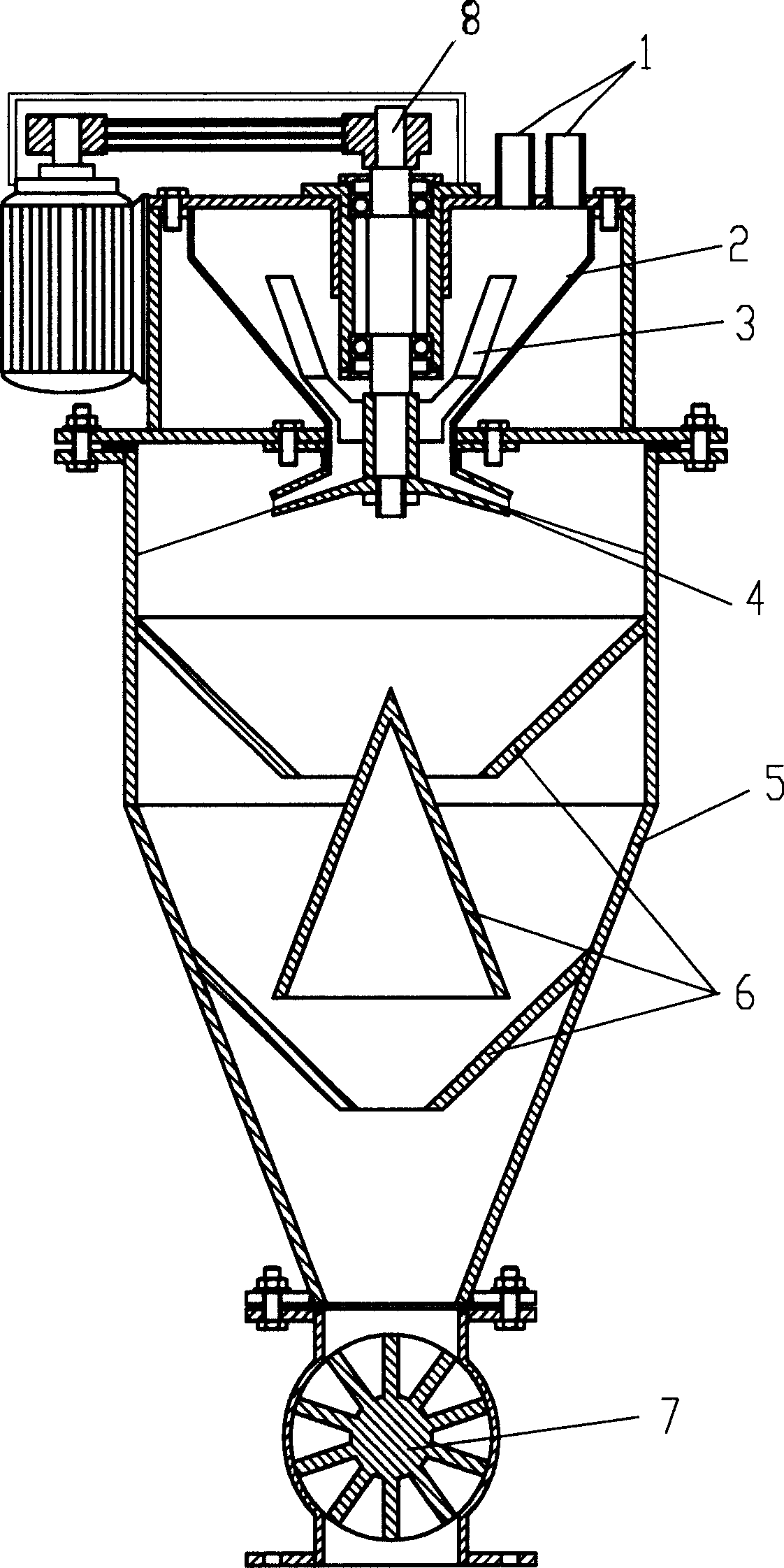

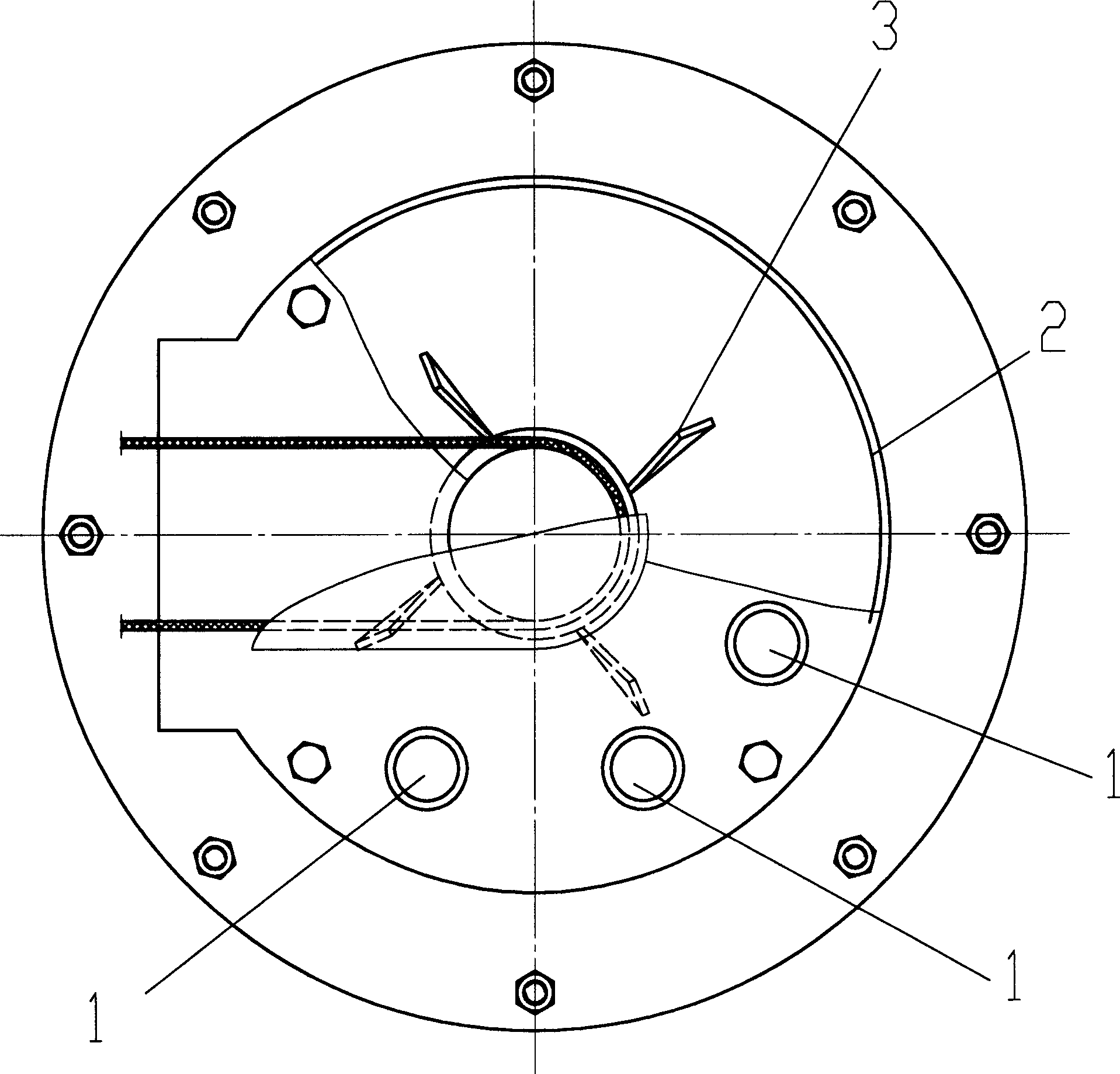

Solid powder continuous mixing machine

A mixer and solid powder technology, applied in mixers, mixing methods, fluid mixers, etc., can solve problems such as small processing capacity, achieve uniform and stable content, flexible adjustment means, and good mixing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment illustrates: the mixing effect of the mixer provided by the present invention.

[0029] Cracking catalyst MLC-2300, MLC-500 (trade name, both industrially produced by Qilu Petrochemical Company Catalyst Factory) two kinds of powder, of which the bulk ratio of MLC-2300 is 670Kg / M 3 , the median particle size is 76 microns; the bulk ratio of MLC-500 is 700Kg / M 3 , with a median particle size of 68 microns. Get above-mentioned two kinds of catalyzers by the ratio of 1: 1 and use the continuous mixer of the present invention to mix now, through 20 times of sampling analysis, the density after recording mixing is 687Kg / M 3 , the median particle size is 71 microns; the average heap ratio of the theoretical mixture is 685Kg / M 3 , the median particle size is very close to 71 microns, and the standard deviation of the density of each sample is 1.2%. After 20 times of sampling, the chemical composition of the powder after mixing is analyzed, and the standard dev...

Embodiment 2

[0033] This embodiment illustrates: the mixing effect of the mixer provided by the present invention.

[0034] Adopt two kinds of powders identical with comparative example 1, mix on the device of the present invention, according to the same ratio, through mixing once, the time used is 2-3 minutes, the average density after recording mixing is 708Kg / M 3 , and the average heap ratio of the theoretical mixture is 706.7Kg / M 3 Very close, the median particle size is 68.3 microns, which is also close to the ideal mixing median particle size of 67.7 microns; multi-point sampling of the output, chemical composition analysis, the standard deviation of each powder after mixing is 1.4%, This shows that the mixing time used in the present invention is short and the mixing uniformity is good.

Embodiment 3

[0039] Adopt four kinds of powders identical with comparative example 2, mix on the device of the present invention, in the same proportion, through one mixing, the time used is 2-3 minutes, the average density after the mixing is recorded as 661Kg / M 3 , with a median particle size of 67.4 microns. Multi-point sampling is carried out on the discharge, and chemical composition analysis is carried out. The standard deviation of each powder after mixing is 1.8%. It can be seen that the mixing time used in the present invention is short and does not need multiple cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com