A special protective agent for post-spraying of aquatic feed and its application

A technology of aquatic feed and protective agent, which is applied in application, animal feed, animal feed, etc. It can solve the problems of increased pulverization rate and activity loss of pellet feed, and achieves the effects of reduced powder content rate, reduced dissolution loss, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

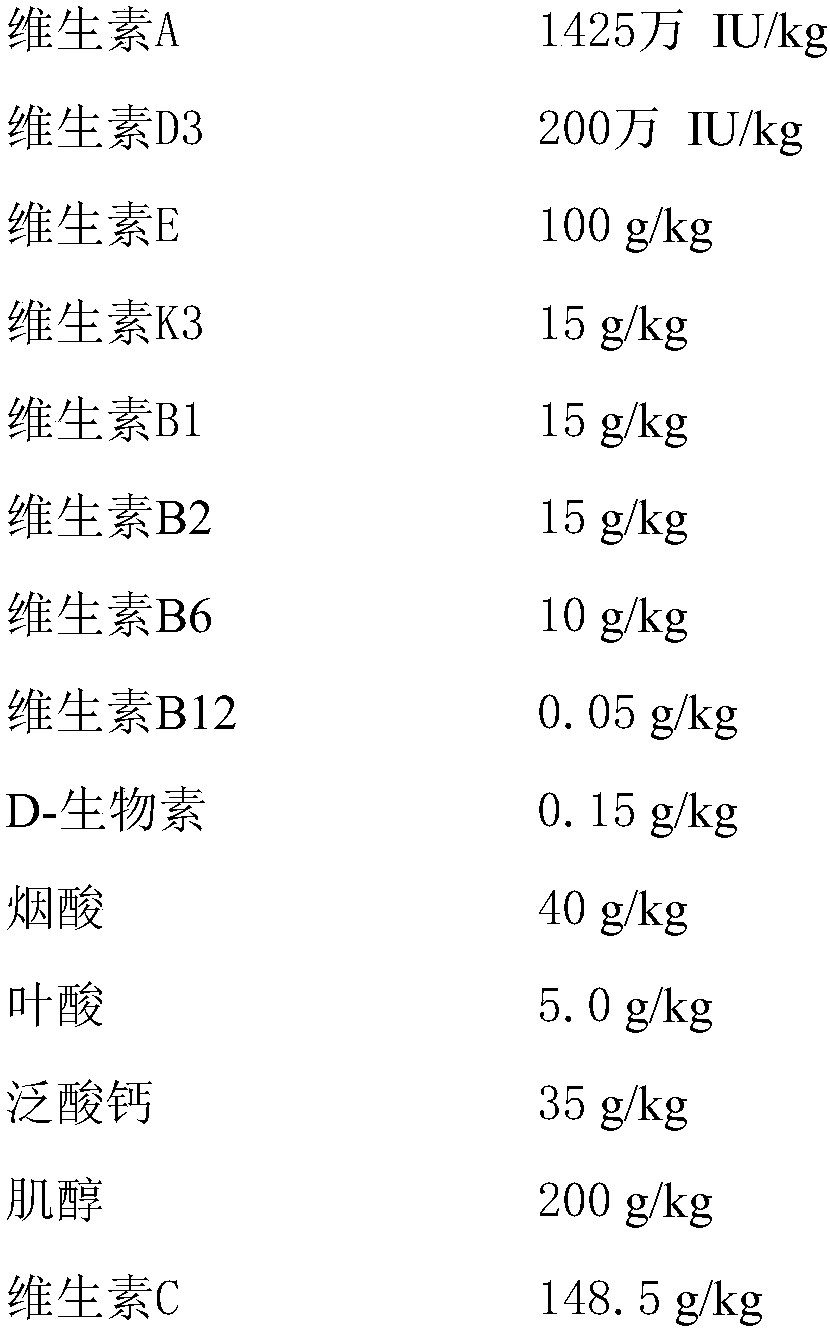

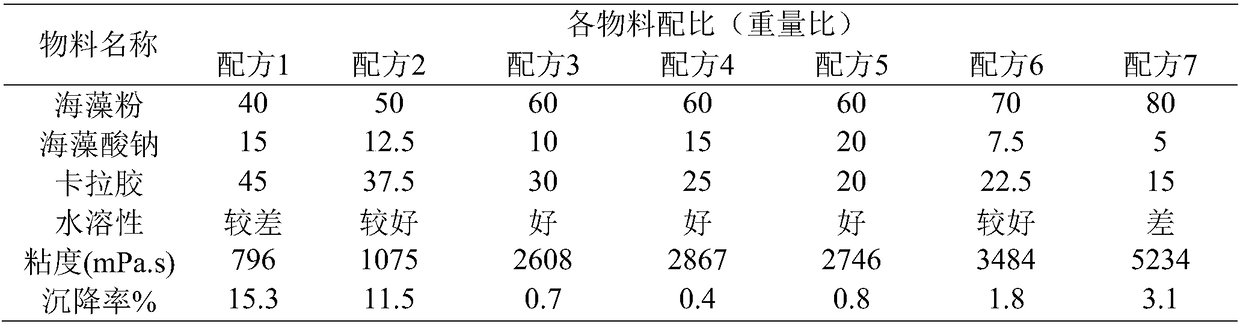

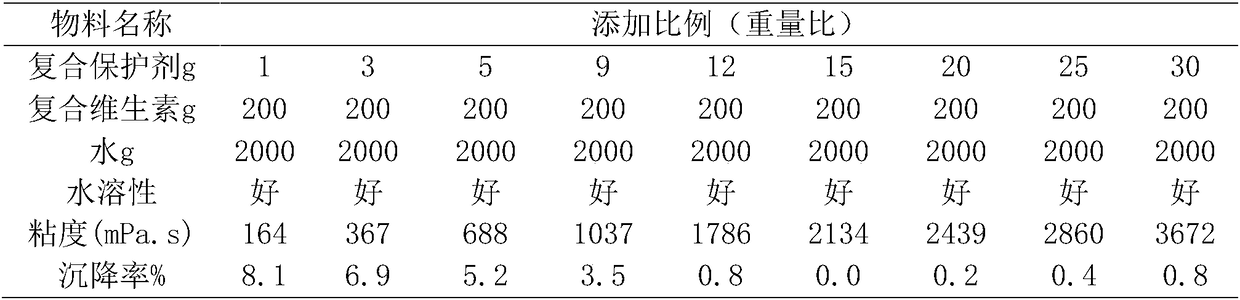

[0022] The screening of embodiment 1 compound protective agent and its influence on compound vitamin sedimentation rate

[0023] The raw materials used in the composite protective agent are seaweed powder, sodium alginate, and carrageenan, which are uniformly mixed according to different proportions and then added to the multivitamin. Use the following method to evaluate its performance: water solubility, take 12.5g of composite protective agent, put it in 1000ml water, stir at 100 rpm for 20min to mix, and compare the uniformity of mixing and the difficulty of dissolving in parallel. Viscosity, take 25g of compound protective agent, add 200g of compound vitamins and 2000g of water respectively, stir at 100 rpm for 20min and mix evenly, measure viscosity with NDJ digital display viscometer. Settling rate, start timing 0.5h after stirring evenly, observe the settling speed of the multivitamin solution and the settling rate after 12 hours, the good stability settles slowly and h...

Embodiment 11

[0027] Mix seaweed powder: sodium alginate: carrageenan evenly according to the weight ratio of 40:15:45 (formulation 1), take 12.5g of compound protective agent and put it in 1000ml water, stir at 100 rpm, the dissolution is slow and the water solubility is poor , after stirring for 20 minutes, there are obvious insoluble matter, which is in the form of agglomerates; take 25g of compound protective agent, add 200g of compound vitamins and 2000g of water, stir at 100 rpm for 20 minutes, and measure the viscosity to be 796mPa.s, the viscosity is too low, and the agglomeration will affect the spraying Atomization effect: After stirring evenly, the multivitamin solution began to settle slowly after 30 minutes, and the settlement rate after 12 hours was 15.3%.

Embodiment 12

[0029] Seaweed powder: sodium alginate: carrageenan is mixed evenly according to the weight ratio of 50:12.5:37.5 (Formulation 2). Take 12.5g of compound protective agent and put it in 1000ml water, stir at 100 rpm, the dissolution is slow, and the water solubility is good. After stirring for 20 minutes, there is a small amount of insoluble matter, which is in the form of small suspended lumps; take 25g of compound protective agent, add 200g of compound vitamins and 2000g of water, stir at 100 rpm for 20 minutes, and measure the viscosity to be 1075mPaf.s. The viscosity is low and does not affect the spray mist After stirring evenly, the multivitamin solution began to settle slowly after 40 minutes, and the settlement rate was 11.5% after 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com