Method and device for producing thermoelectric semiconductor device and its products obtained thereof

A technology of thermoelectric semiconductors and manufacturing methods, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems of increased material resistivity, low production efficiency, and increased material loss, and achieve production The effect of simple process, high production efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

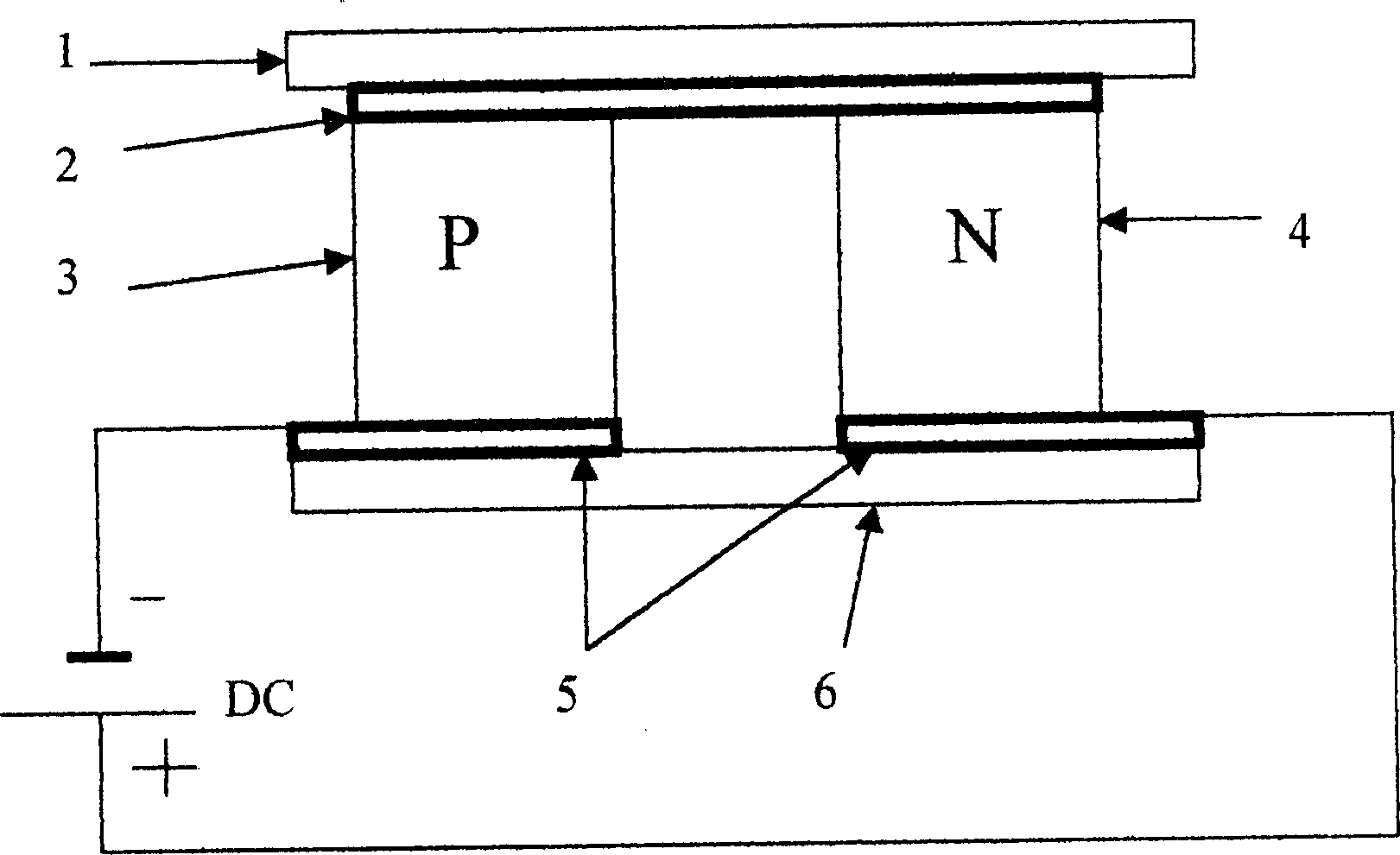

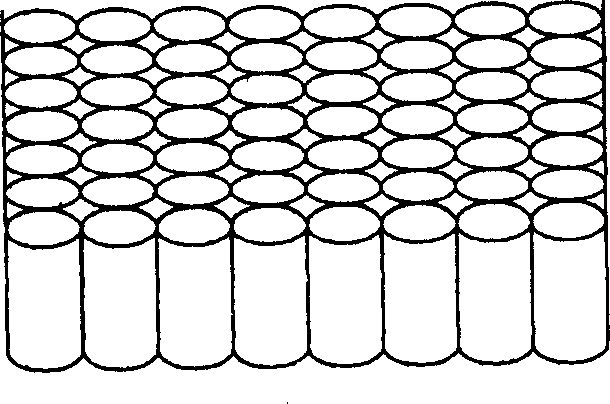

[0050] The basic unit of the thermoelectric semiconductor device of the present invention is a temperature difference thermocouple composed of a pair of P-type and N-type thermoelectric semiconductor elements, and the thermoelectric semiconductor elements are connected by metal strips. The finished thermoelectric semiconductor device is formed by connecting several pairs of thermoelectric semiconductor elements, and its composition is a series structure on the circuit, and a parallel structure in terms of heat conduction.

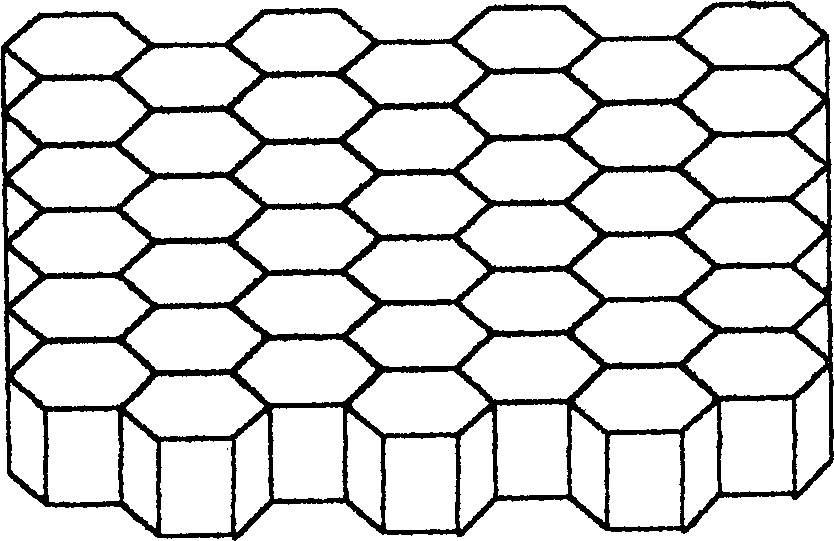

[0051] Figure 5 It is a structural schematic diagram of an upper base plate for installing a rectangular thermoelectric semiconductor element with a heat-conducting insulating substrate (1) equipped with a metal connecting piece (2);

[0052] Figure 6 It is a schematic diagram of the lower bottom plate structure and thermoelectric element installation of the rectangular thermoelectric semiconductor element installed with the thermally conductive insulati...

Embodiment approach 2

[0066] Such as Figure 8 Shown: the structure schematic diagram of the thermoelectric semiconductor device that the present invention proposes to be installed with another type of novel metal connecting piece (2b), (5b): among the figure (3) is a P-type thermoelectric semiconductor element, (4) N-type thermoelectric semiconductor element , (1), (6) are the upper and lower bottom plates respectively, (7b) is the partition (before casting is the casting model, after casting is the partition); after the metal connecting piece is bent, it penetrates into the P-type and N-type thermoelectric semiconductors element.

[0067] Others are the same as Embodiment 1, the thermoelectric semiconductor casting model is a disposable model: the specification of the model is consistent with the final product size of the thermoelectric semiconductor (supporting), and it is installed on the product to form a part of the product (before casting, it is a casting model, and after casting, it is a ther...

Embodiment approach 3

[0072] The thermoelectric semiconductor material melting furnace of the present invention adopts a specially designed melting furnace with constant temperature control, equipped with vacuum pumping and gas protection devices, and melts in a vacuum state, for example, heating and melting after vacuuming to 2Pa; transporting in a gas protection environment, such as using High-purity nitrogen or inert gas is used as a protective gas; the heating method of the melting furnace can use resistance heating methods: for example, heating by resistance heating elements such as resistance wires, electric heating tubes, and silicon carbide rods; induction eddy current heating methods can also be used: for example, frequency conversion Heating equipment uses electromagnetic waves to heat and melt raw materials. The working temperature range of the smelting furnace is controlled from 550°C to 850°C; the smelting process needs to be fully stirred to make the materials evenly combined. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com