Auxiliary standing device on hollow composite flat plate production line

An auxiliary standing and production line technology, applied in the field of auxiliary standing devices on the hollow composite flat plate production line, can solve the problems of high manufacturing cost, long production cycle, and inability to continuously automate production, and achieve improved standing and high uniformity and continuous automation The effect of production and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

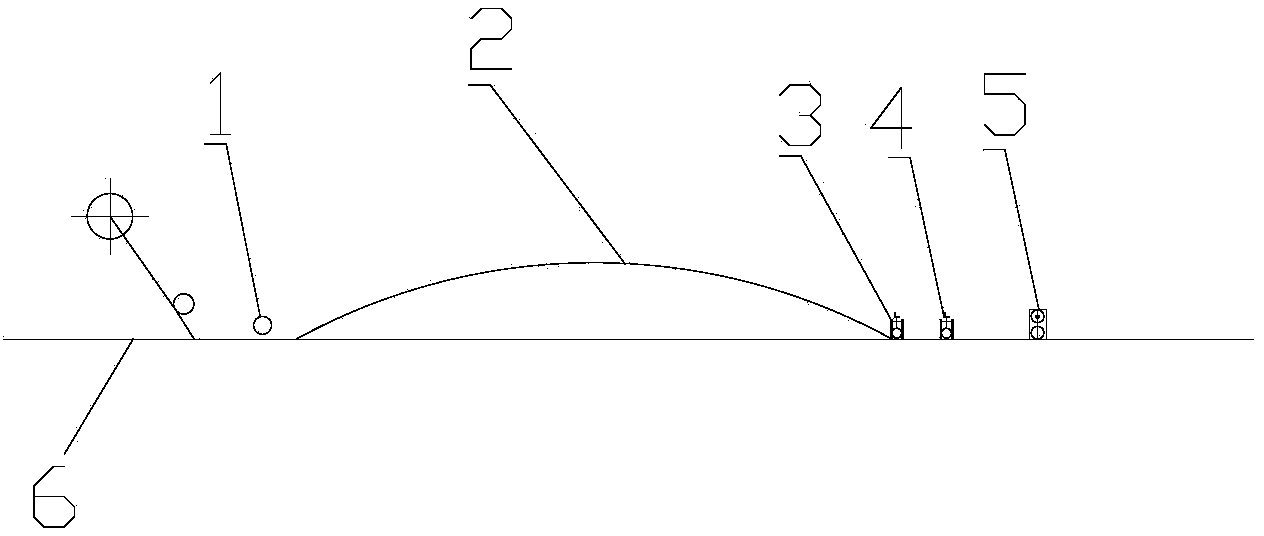

[0029] Such as figure 1 The auxiliary standing device on the hollow composite flat panel production line shown includes a frame platform, on which a soaking roller, an arched soaking platform, a longitudinal stretching roller, a transverse stretching roller, and a height control roller are sequentially arranged along the horizontal direction.

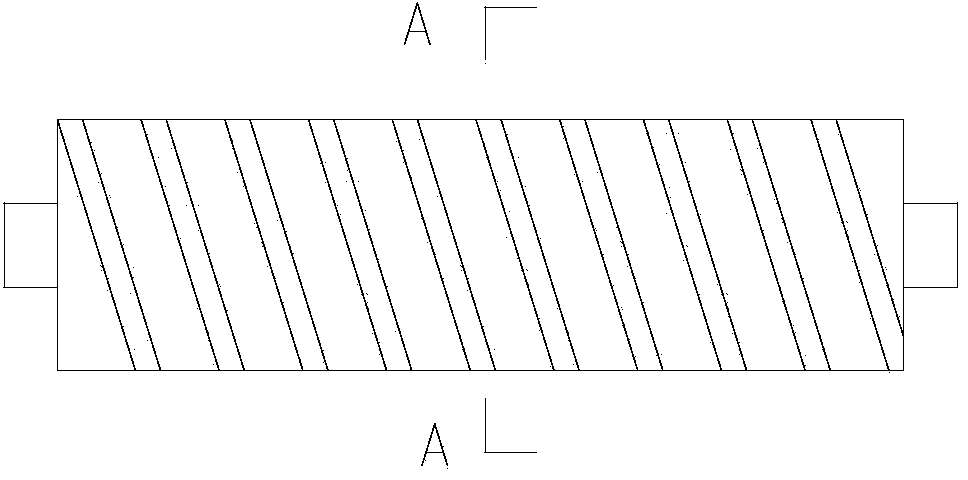

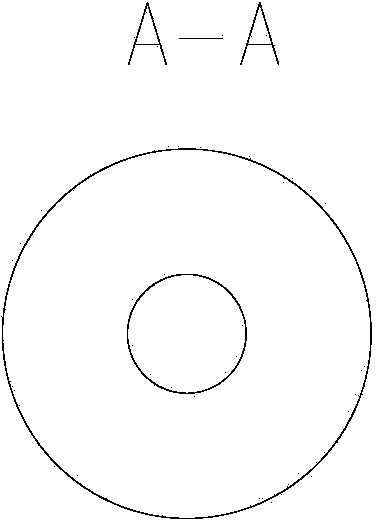

[0030] The height control roller is composed of two cylindrical rollers arranged up and down, and the distance between the two cylindrical rollers is not greater than the height of the hollow composite flat plate; the surface of the soaking roller is uniformly provided with a first rectangular groove along the axial direction; the first rectangular groove The depth is 2.5mm and the width is 4.2mm; the surface of the dipping roller is provided with Teflon coating.

[0031] The surface of the longitudinal stretching roller is evenly provided with a second rectangular groove along the axial direction; the depth of the second rectangular gr...

Embodiment 2

[0039] It is basically the same as Example 1, except that the depth of the first rectangular groove is 2.1mm and the width is 3.0mm; the depth of the second rectangular groove is 2.0mm and the width is 1.0mm; the groove depth of the spiral groove is 4.1mm, and the groove width is 1.0mm.

Embodiment 3

[0041] Basically the same as embodiment 1, different: the depth of the first rectangular groove is 2.9mm, and the width is 5.9mm; the depth of the second rectangular groove is 2.9mm, and the width is 5.2mm; the groove depth of the spiral groove is 4.5mm, and the slot width is 5.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com