Lightweight maglev train driver's cab cover and integral molding process

An integral molding, magnetic levitation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

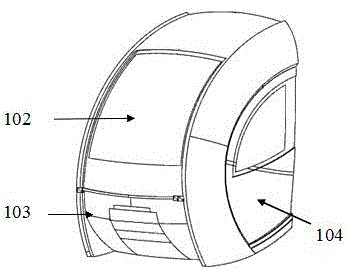

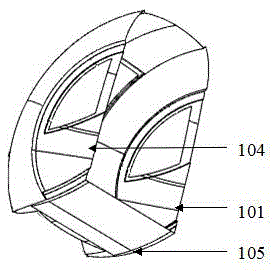

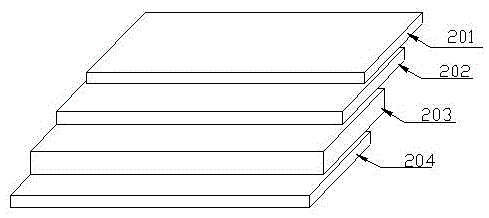

[0044] like figure 1 box figure 2 As shown, the present embodiment provides a lightweight maglev passenger car driver's outdoor cover, including a cover body, and the cover body includes a right side cover plate 101, a front cover plate 102, a coupler cover plate 103, a left side cover plate 104 and a bottom cover Plate 105, the outer cover body is made of hybrid fiber composite material with glass fiber and carbon fiber as reinforcement and thermosetting resin as matrix. like image 3 As shown, the cover body is a multi-layer composite structure, and the cover body includes a surface flame-retardant gel coat layer 201, a flame-retardant glass fiber outer layer 202, a main structural layer 203, and a flame-retardant glass fiber inner layer 204 arranged in sequence. The main structural layer 203 includes a carbon fiber reinforced layer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com