Method for purifying cobalt solution

A purification method and cobalt solution technology, which is applied in the field of cobalt solution purification, can solve the problems of difficult recovery of cobalt salts, pollution of activated carbon, low cobalt recovery rate, etc., and achieve the effects of improving recovery rate, reducing organic matter content, and accelerating extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The solvent consists of 0.17 kg of solid cobalt naphthenate and 1.0 m 3 1-bromo-3-chloropropane obtained by mixing (the mass percent concentration of solid cobalt naphthenate is 0.01%), and the volume ratio of solvent to mother liquor is 1:3.3.

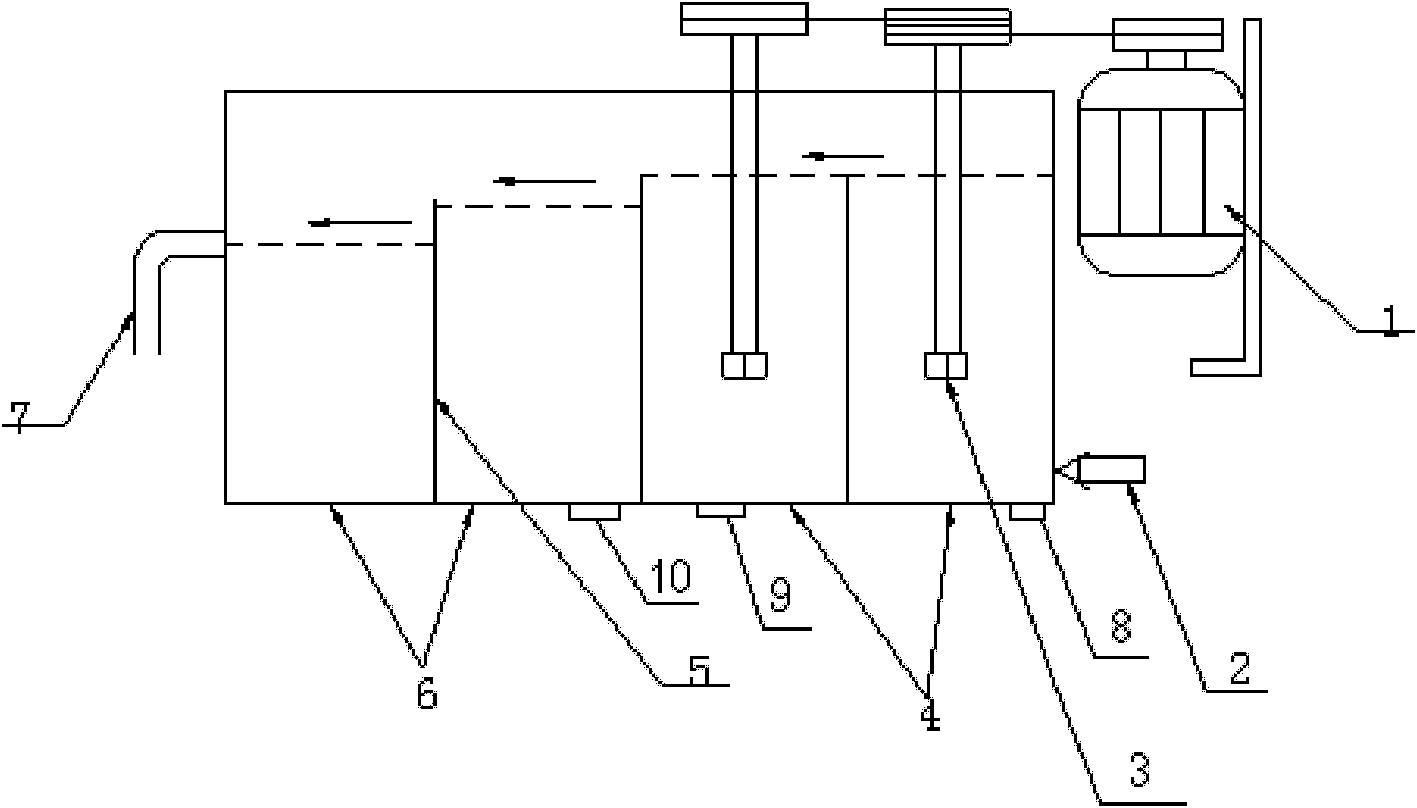

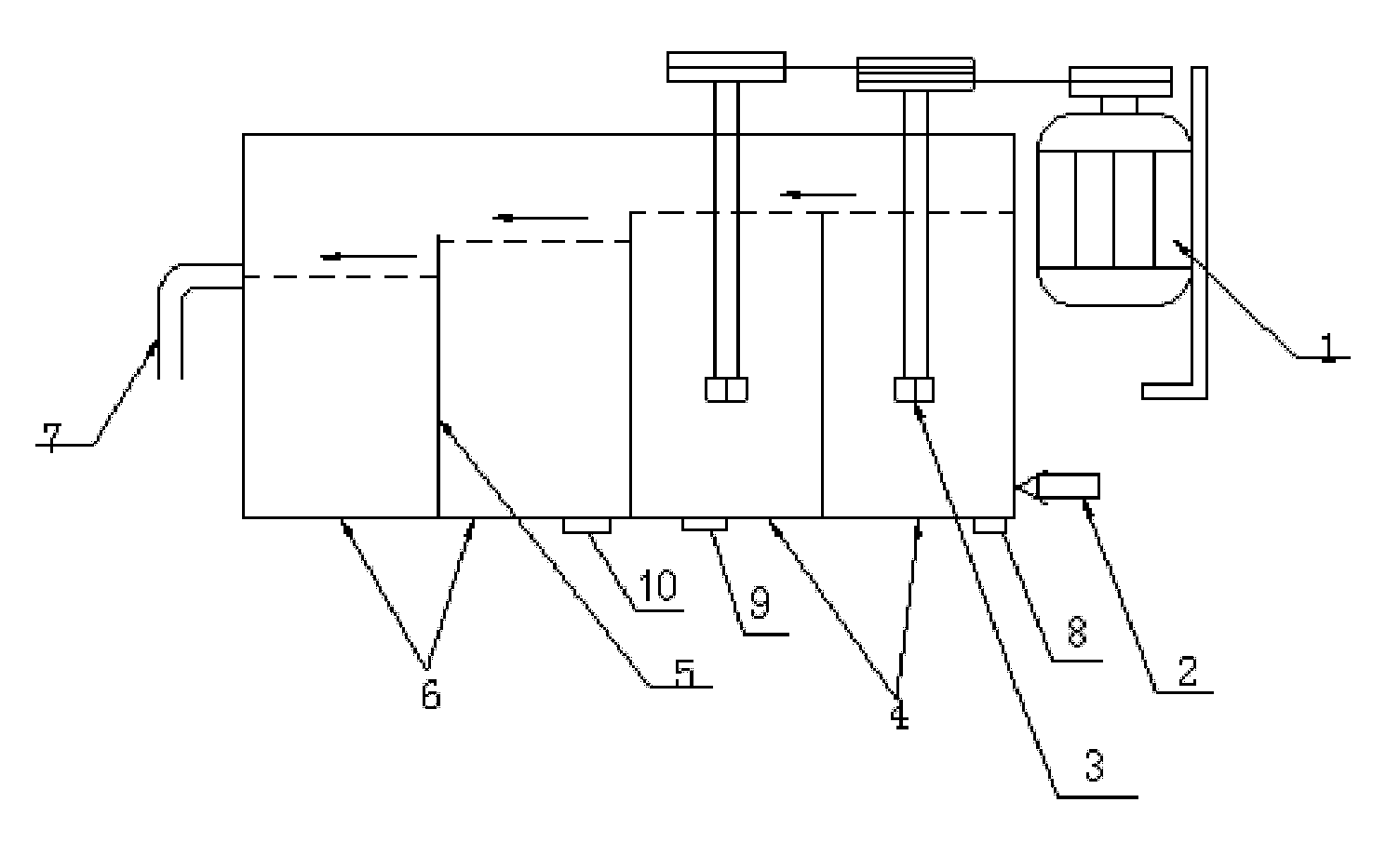

[0051] At a stirring speed of 180 rpm, the solvent and cobalt chloride mother liquor (pH value 1.5-2.5, temperature not greater than 35°C) are pumped into the mixing chamber 4 through the solution inlet 2 and stirred and mixed with the solvent. The mixing chamber carries out secondary extraction, the overflow enters the right part of the clarification chamber 6 and settles, and is filtered and separated by the filter plate 5, and then enters the left part of the clarification chamber 6, and flows out from the solution outlet 7 after settling. The inflow velocity of cobalt chloride mother liquor is 1.8m 3 / h, the outflow velocity is basically the same as the inflow velocity. The organic matter content of the obtained cobalt ch...

Embodiment 2

[0055] The solvent consists of 0.24 kg of solid cobalt naphthenate and 1.0 m 3 1-bromo-3-chloropropane obtained by mixing (the mass percent concentration of solid cobalt naphthenate is 0.015%), and the solvent:mother liquor volume ratio is 1:3.0.

[0056] At a stirring speed of 180 rpm, the solvent and cobalt chloride mother liquor (pH value 1.5-2.5, temperature not greater than 35°C) are pumped into the mixing chamber 4 through the solution inlet 2 and stirred and mixed with the solvent. The mixing chamber carries out secondary extraction, the overflow enters the right part of the clarification chamber 6 and settles, and is filtered and separated by the filter plate 5, and then enters the left part of the clarification chamber 6, and flows out from the solution outlet 7 after settling. The inflow velocity of cobalt chloride mother liquor is 1.9m 3 / h, the outflow velocity is basically the same as the inflow velocity. The organic matter content of the obtained cobalt chlorid...

Embodiment 3

[0059] The solvent consists of 0.225 kg of solid cobalt naphthenate and 1.0 m 3 1-bromo-3-chloropropane mixed to obtain (the mass percent concentration of solid cobalt naphthenate is 0.014%), and the solvent:mother liquor volume ratio is 1:3.5.

[0060] At a stirring speed of 180 rpm, the solvent and cobalt chloride mother liquor (pH value 1.5-2.5, temperature not greater than 35°C) are pumped into the mixing chamber 4 through the solution inlet 2 and stirred and mixed with the solvent. The mixing chamber carries out secondary extraction, the overflow enters the right part of the clarification chamber 6 and settles, and is filtered and separated by the filter plate 5, and then enters the left part of the clarification chamber 6, and flows out from the solution outlet 7 after settling. The inflow velocity of cobalt chloride mother liquor is 1.8m 3 / h, the outflow velocity is basically the same as the inflow velocity. The organic matter content of the obtained cobalt chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com