Veneer toothing machine

A technology of tooth connection and veneer, applied in the field of veneer tooth connection machine, can solve the problems of low work efficiency, large heat generation of the motor, inability to achieve high-speed operation, etc., and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, invention is described in further detail.

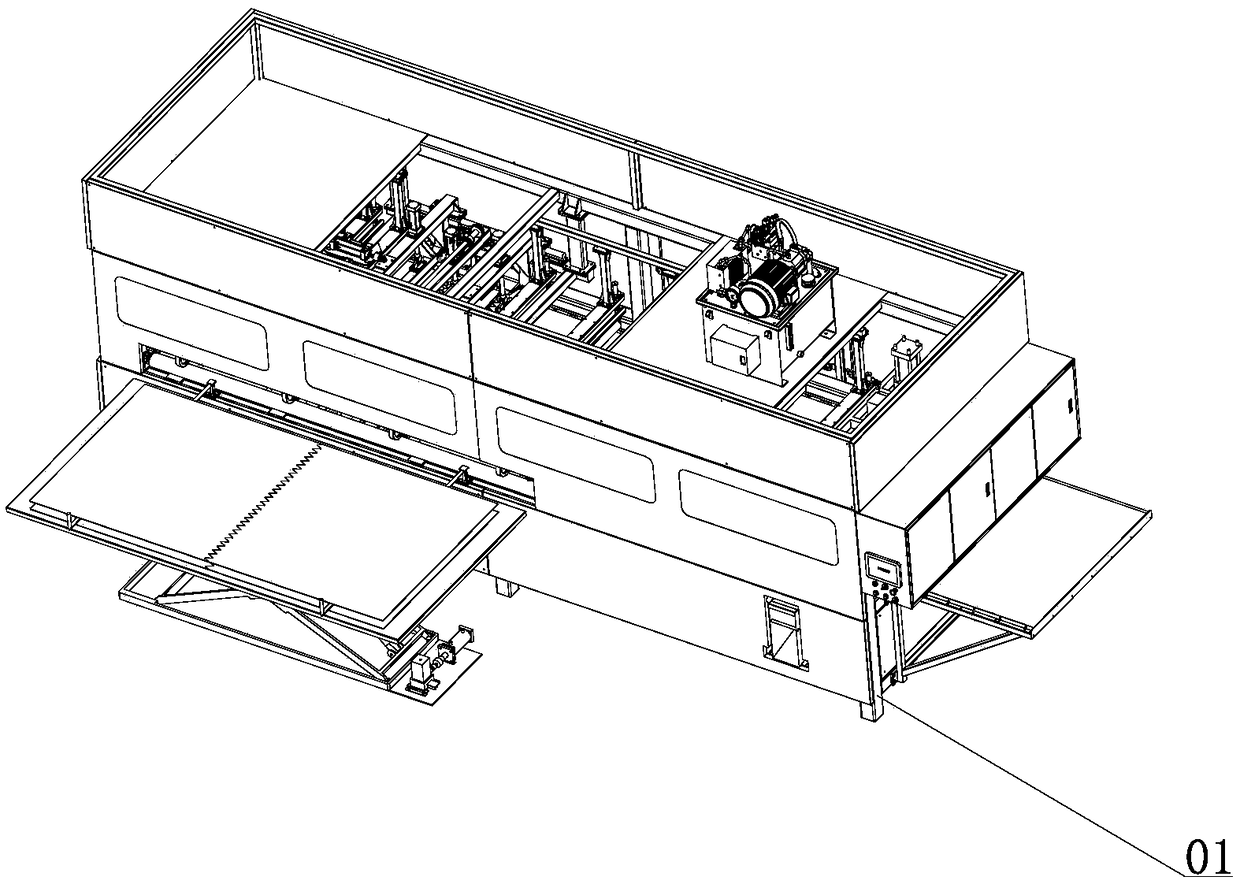

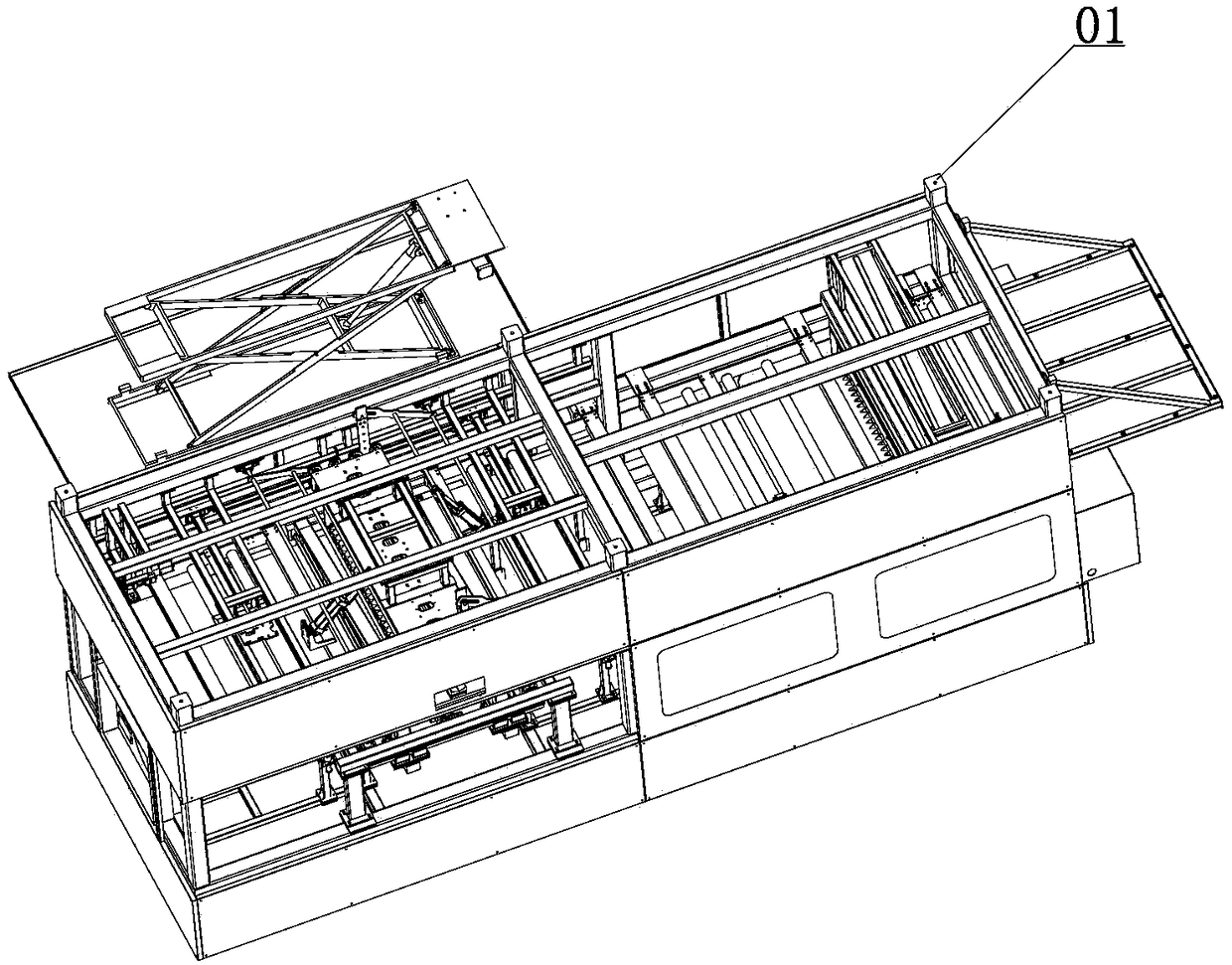

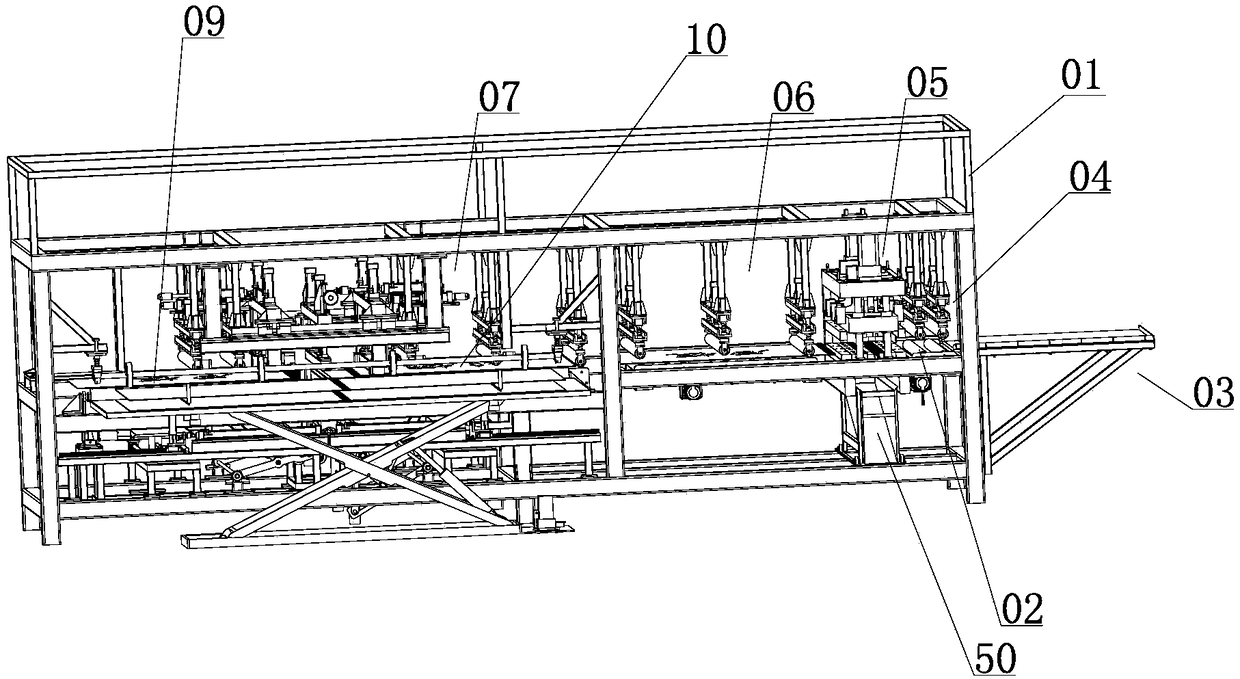

[0044] like Figure 1-12As shown in the figure, a single-plate toothed machine includes a frame 01, a roller conveyor belt 02 provided on the frame 01, a feeding table 03 provided at one end of the roller conveyor belt 02, and a roller conveyor belt 02. Above 02 are sequentially provided a feeding rolling conveying device 04, a plate tooth cutting device 05, a buffer rolling conveying device 06 and a panel assembling device 07 that cooperate with the roller conveyor belt 02 to convey the plate; Some lower bottom plate 51 and upper bottom plate 52, between the lower bottom plate 51 and the upper bottom plate 52 are provided with upright columns 53 supporting the lower bottom plate 51 and the upper bottom plate 52, and between the lower bottom plate 51 and the upper bottom plate 52 are provided with up and down along the column 53. The splint 54 is provided with two rows of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com