Tubular grid stirring type paste extruding apparatus

A stirring and grid technology is applied in the field of tubular grid stirring paste extrusion device, which can solve problems such as affecting the health of operators, affecting battery performance, uneven paste volume, etc., achieving uniform pressure, easy disassembly and cleaning, Avoid the effects of death cream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

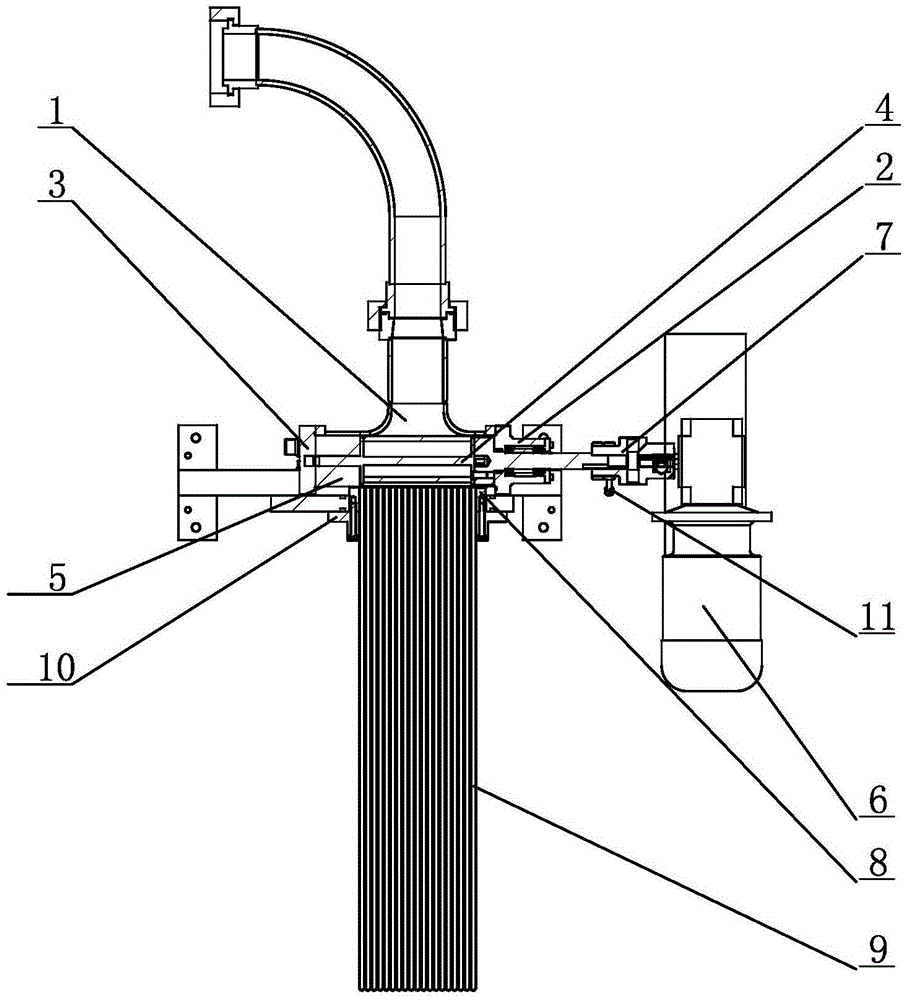

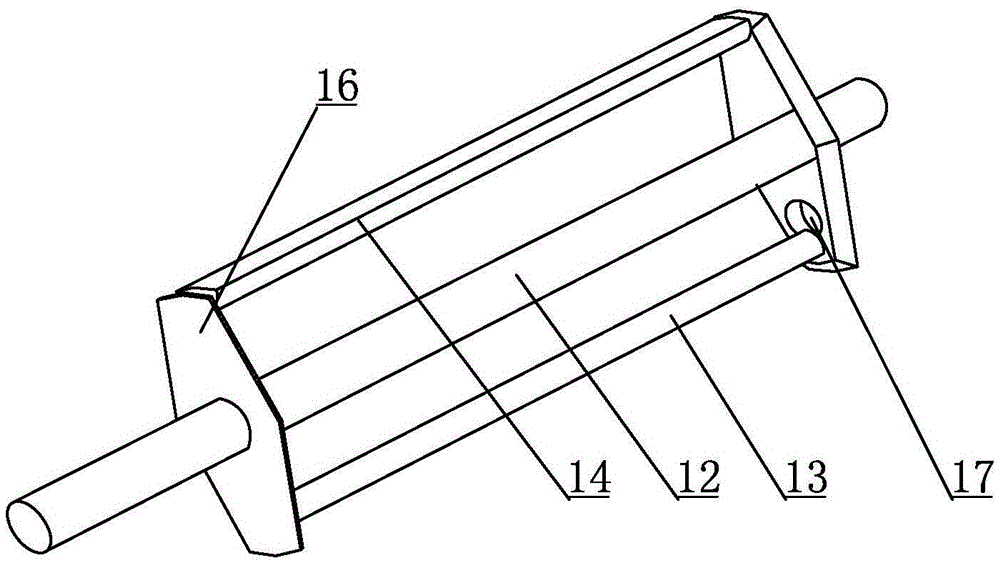

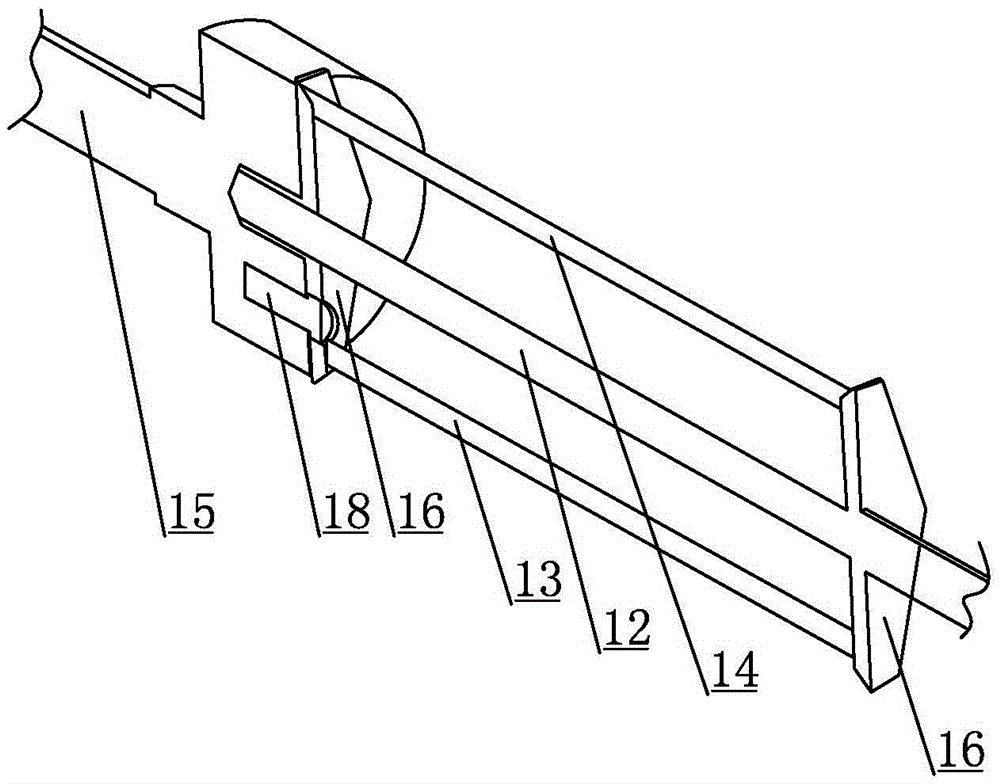

[0022] like Figure 1-2 As shown, the tubular grid agitating paste extruding device of the present invention includes a paste extruding head 1, and the extruding paste head 1 is connected to an extruding paste pipe 9. A stirring blade 4 is arranged in the extruding paste head 1, and the agitating blade 4 includes a center Shaft 12, mixing blade 13 and mixing barrier blade 14, mixing blade 13 and mixing barrier blade 14 are respectively arranged on the two sides of central axis 12, central axis 12 is connected with motor 6 rotating shaft, and described mixing barrier blade 14 and extruding paste head 1 lead plaster The side where the inlet is in contact with is set as a plane, and the position detection part 11 is arranged on the outside of the extruding head 1 corresponding to the mixing barrier blade 14 .

[0023] Wherein, the central shaft 12 is connected to the rotating shaft of the motor 6 through the coupling 7, and the outer wall of the coupling 7 is provided with a dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com