Patents

Literature

49 results about "Carbon nanowalls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

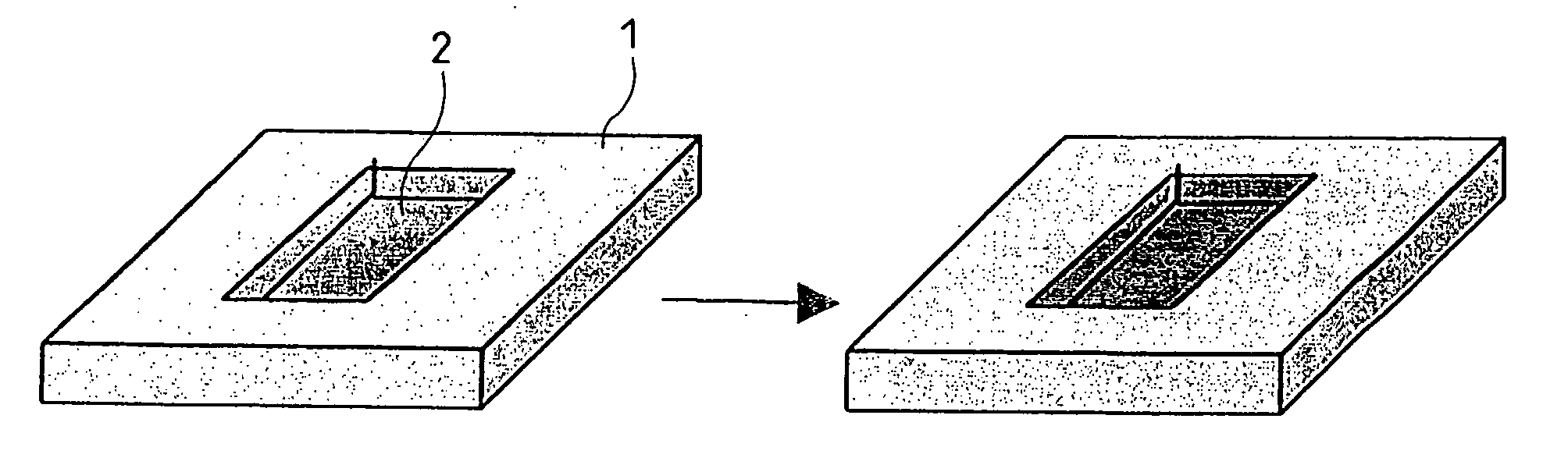

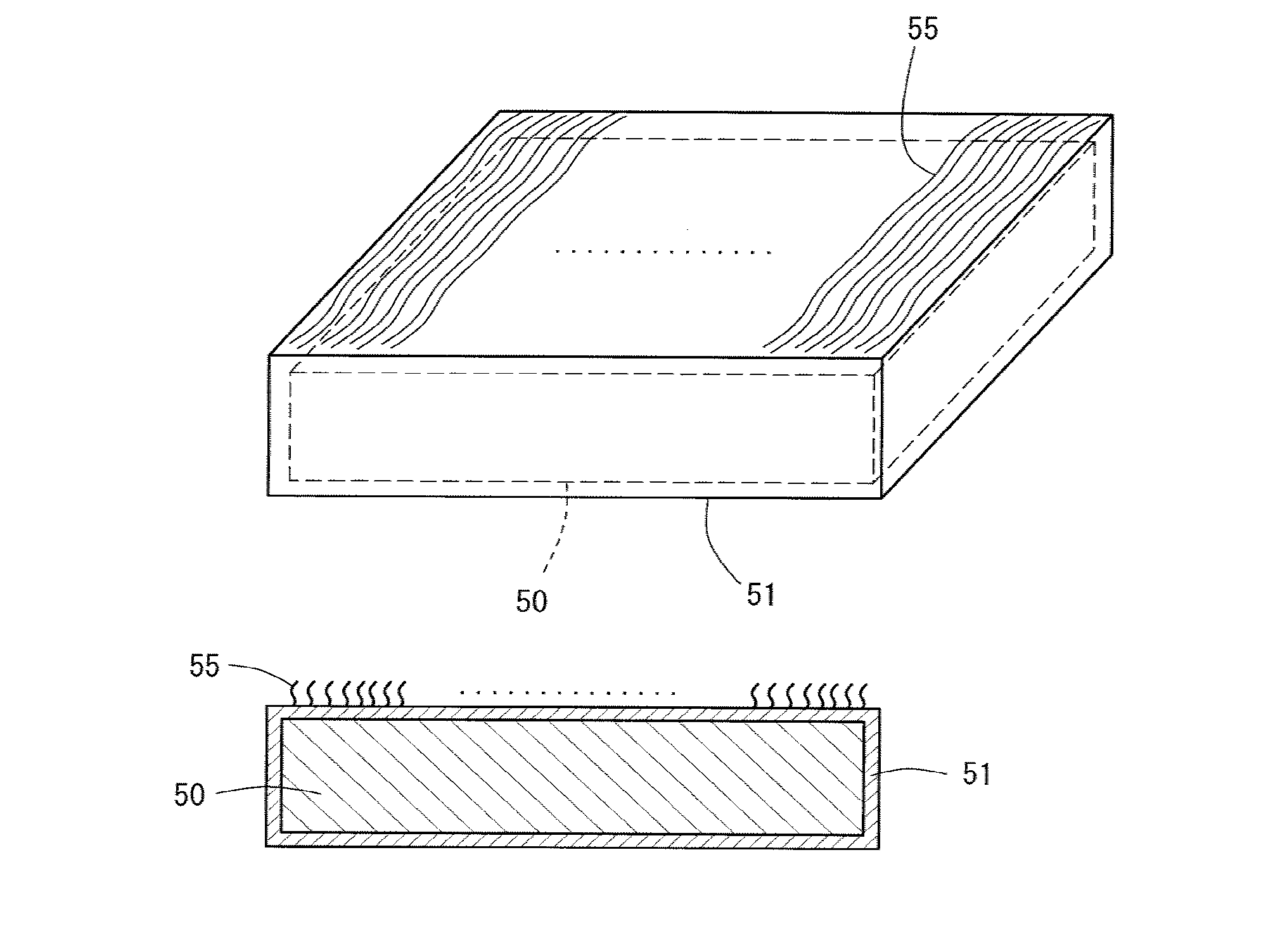

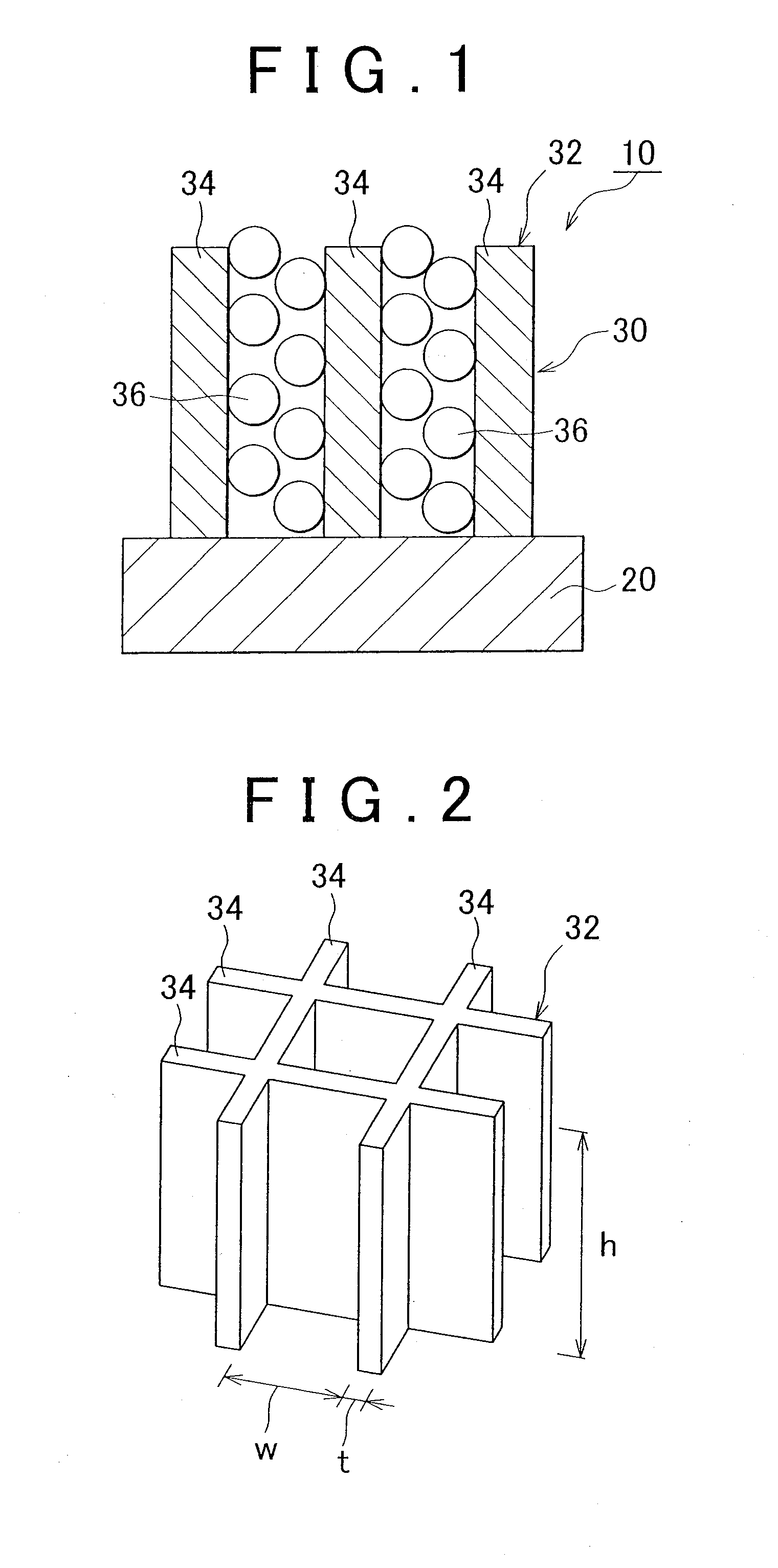

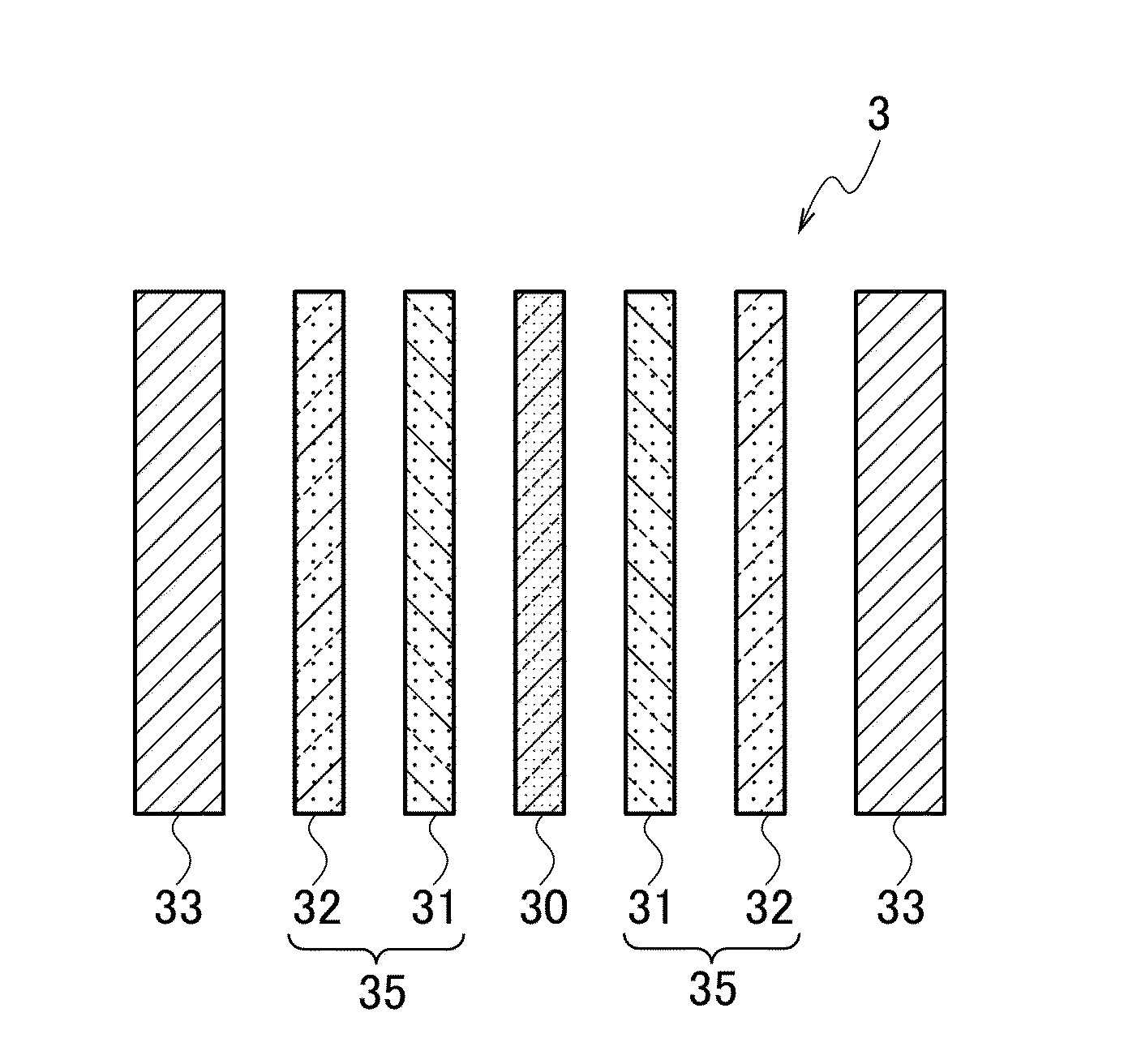

Negative electrode for lithium secondary battery, method for preparing the negative electrode, lithium secondary battery having the negative electrode, and vehicle having the lithium secondary battery

ActiveUS8551657B2Filling tube/pocket electrodesElectrode carriers/collectorsCarbon nanowallsElectrical battery

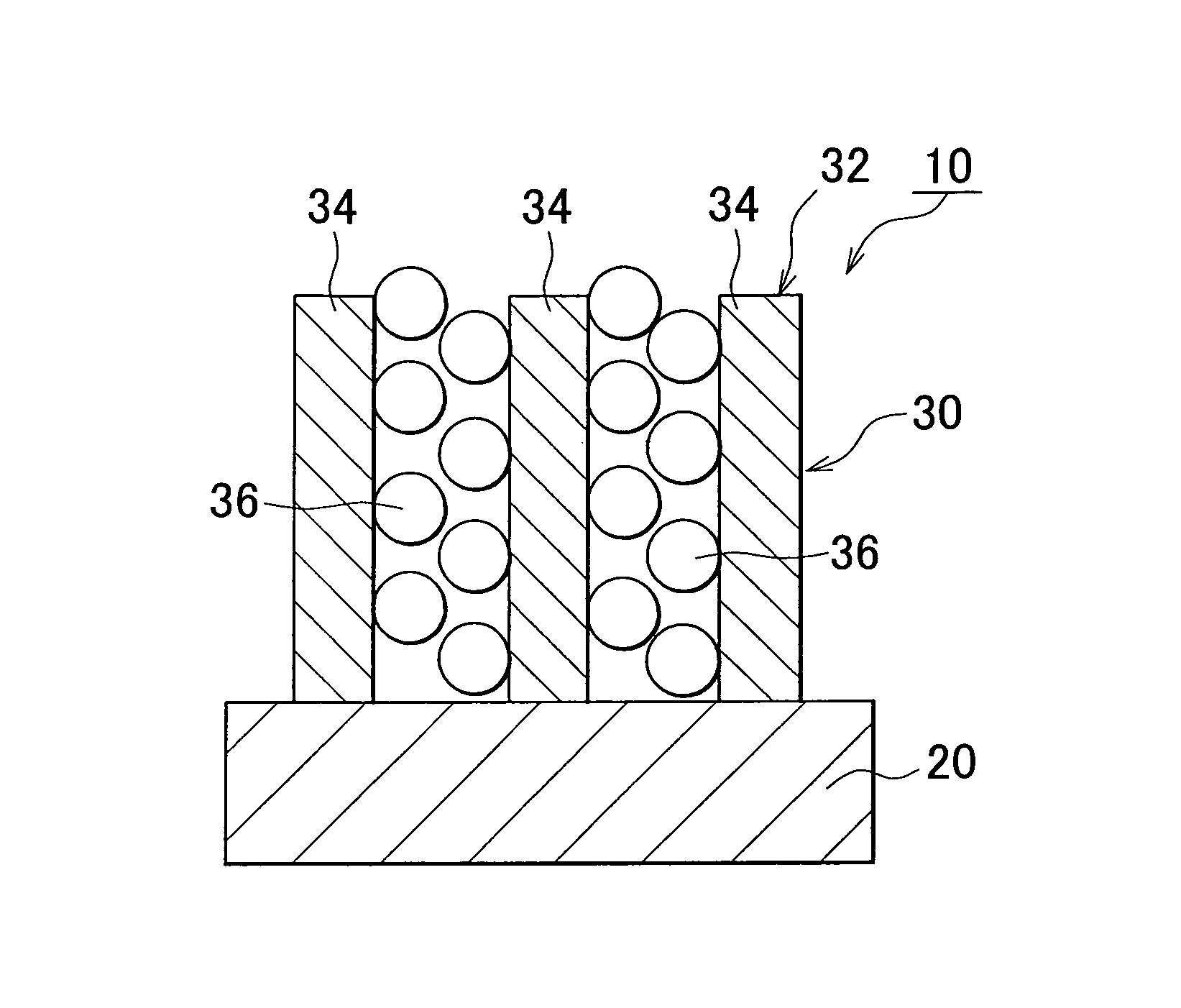

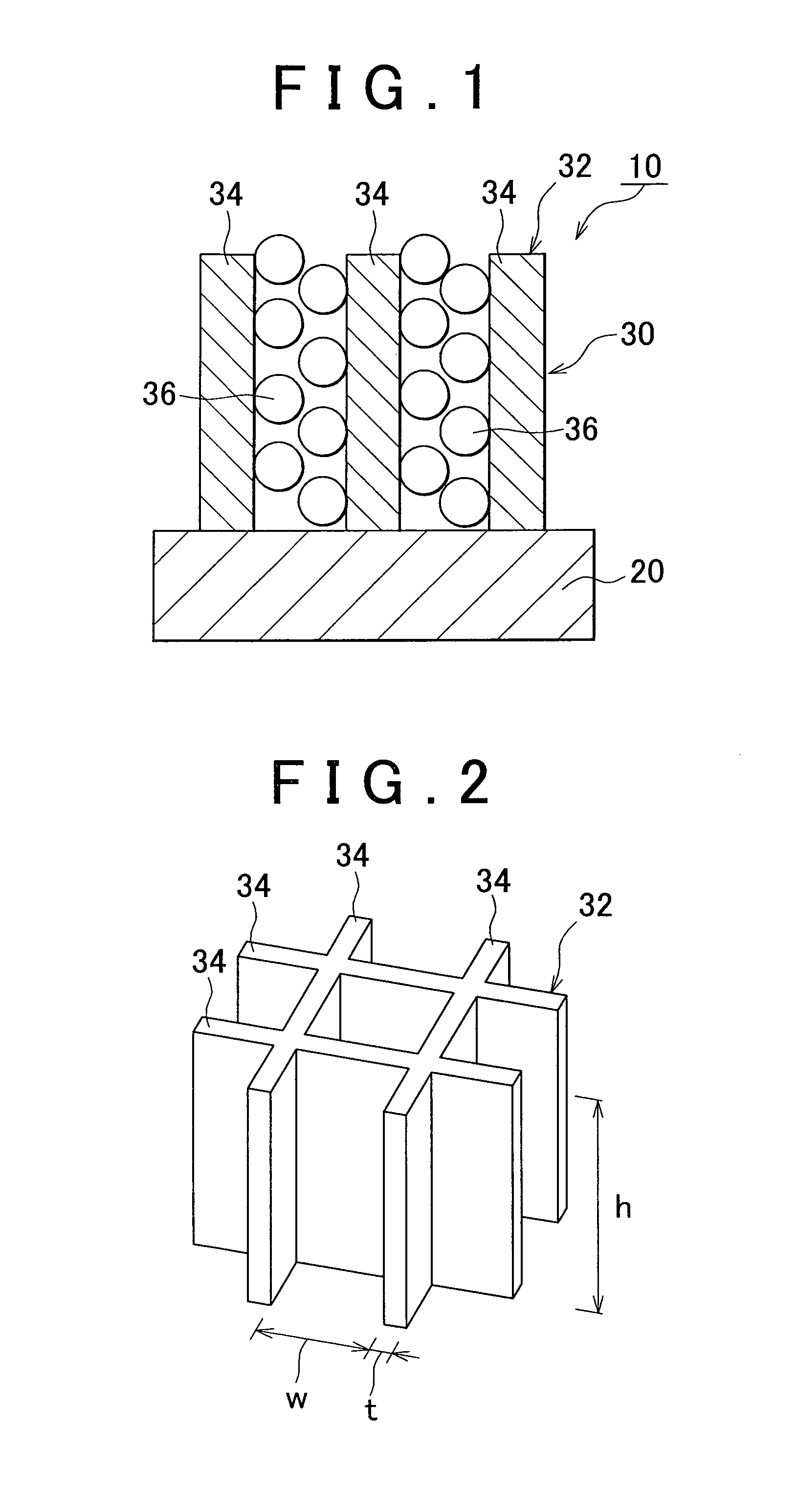

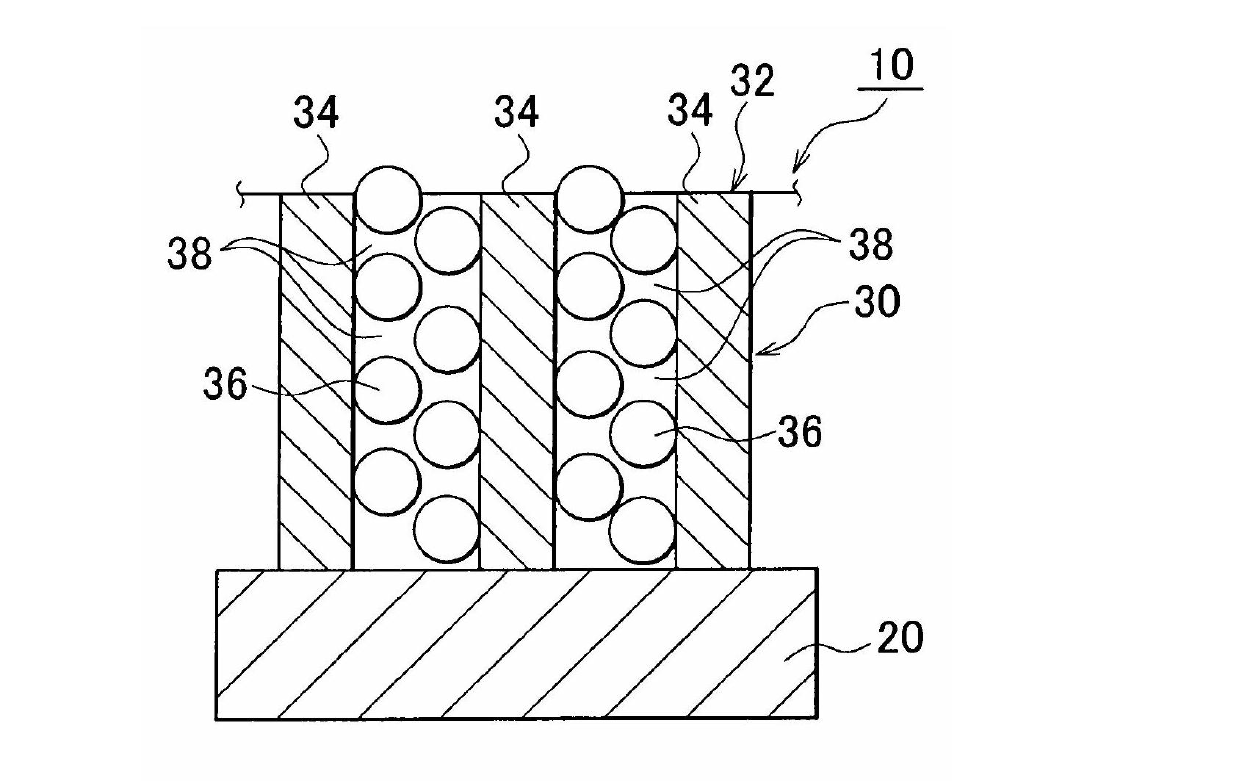

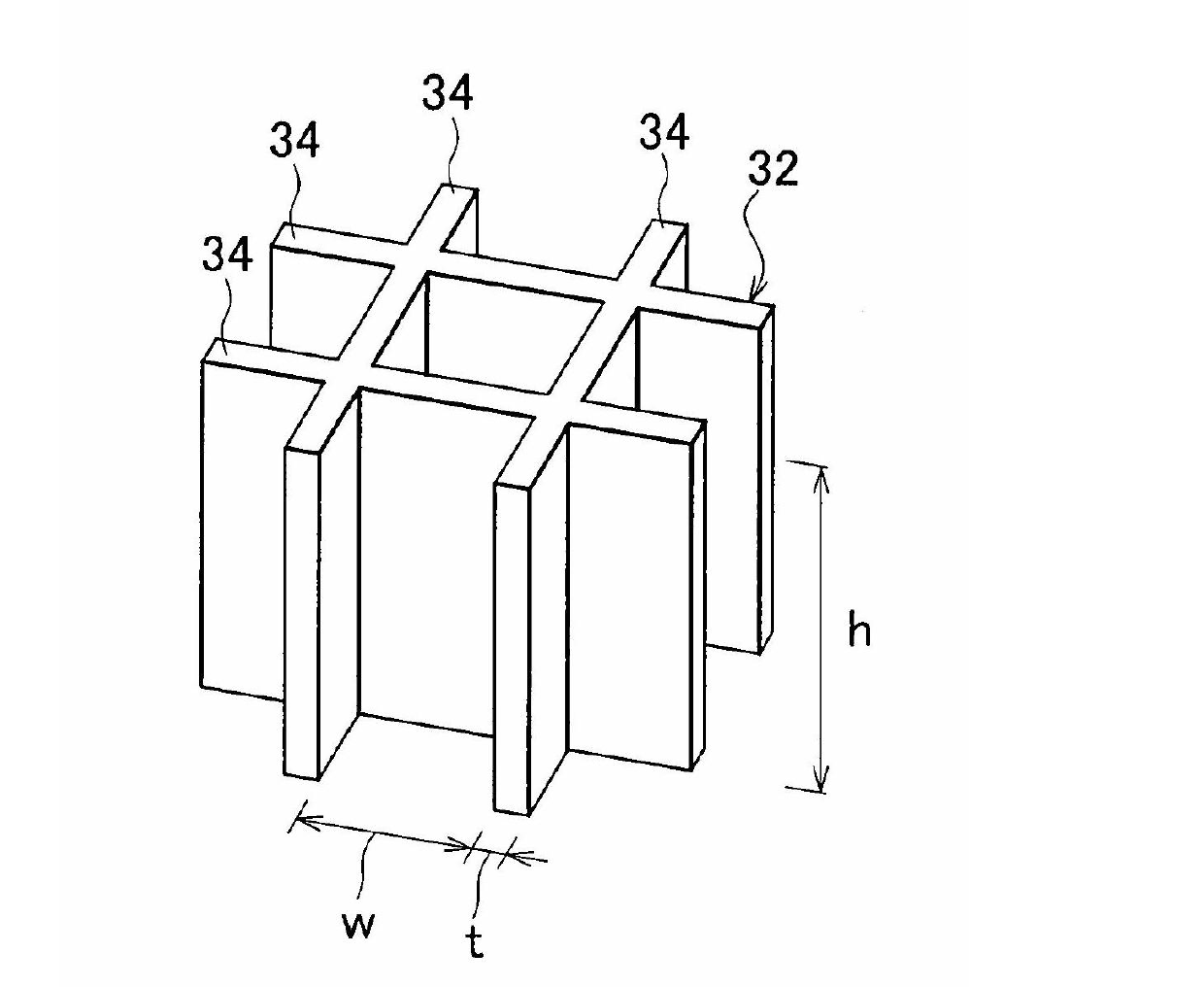

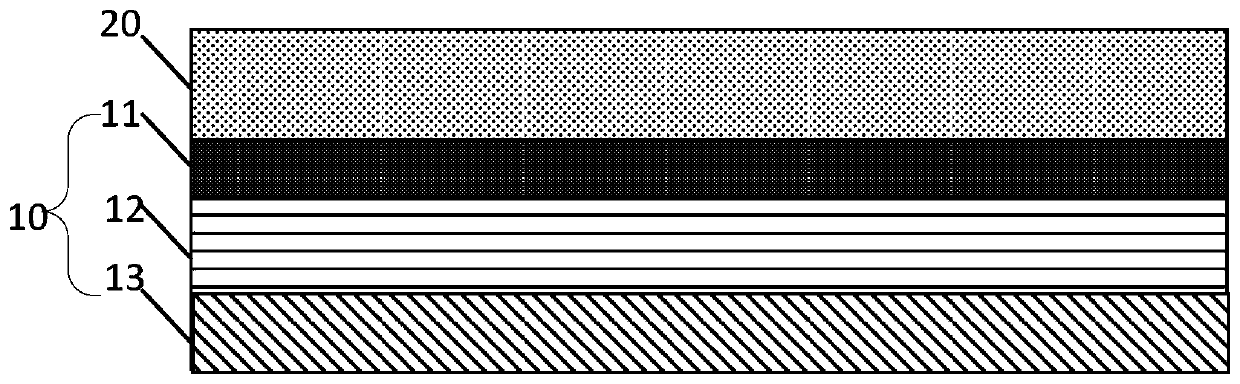

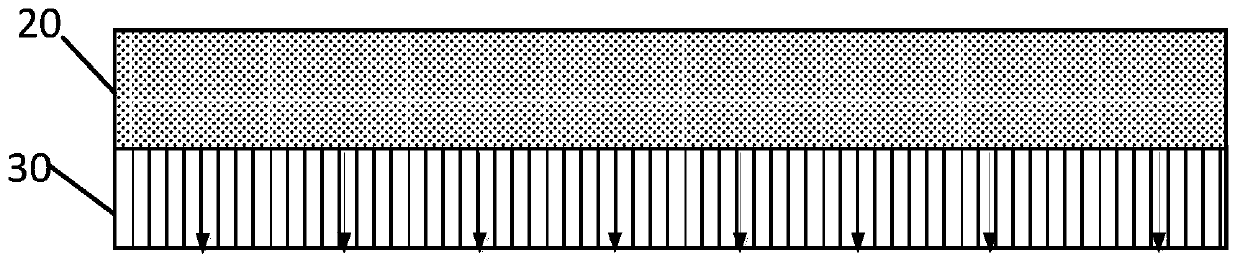

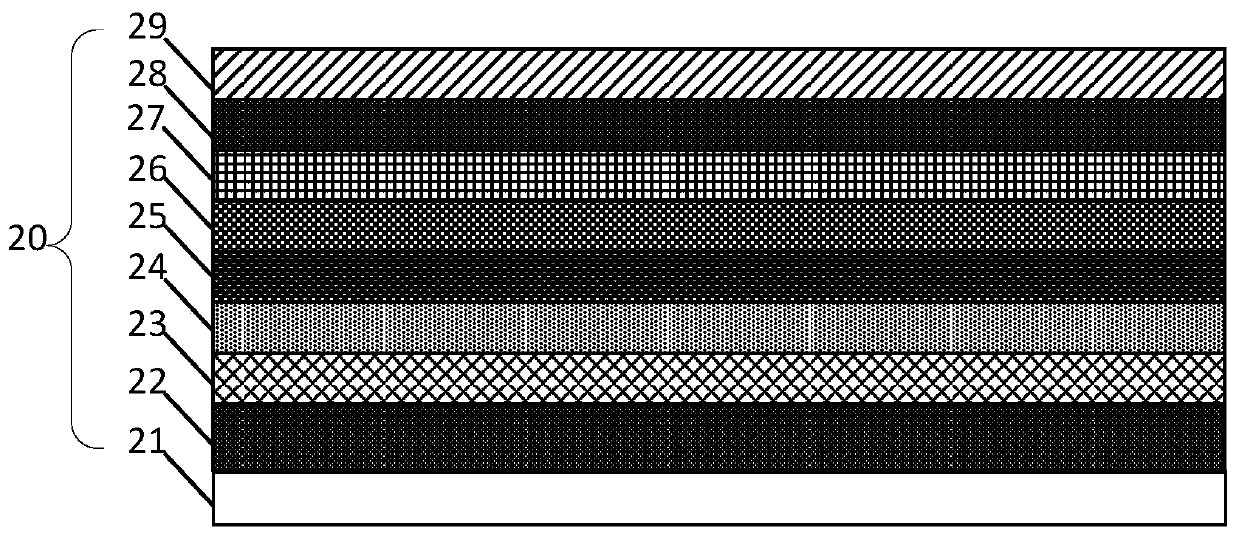

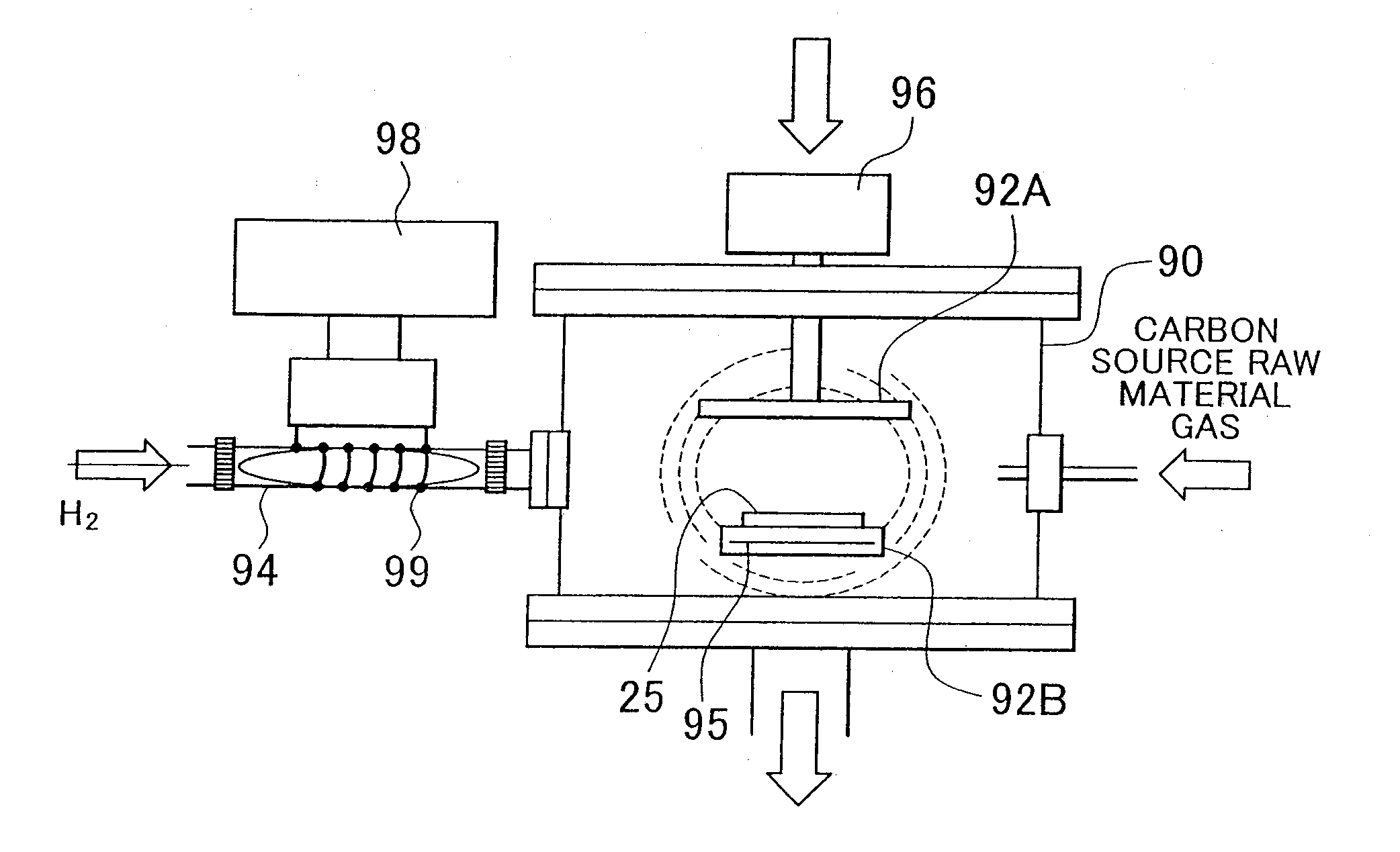

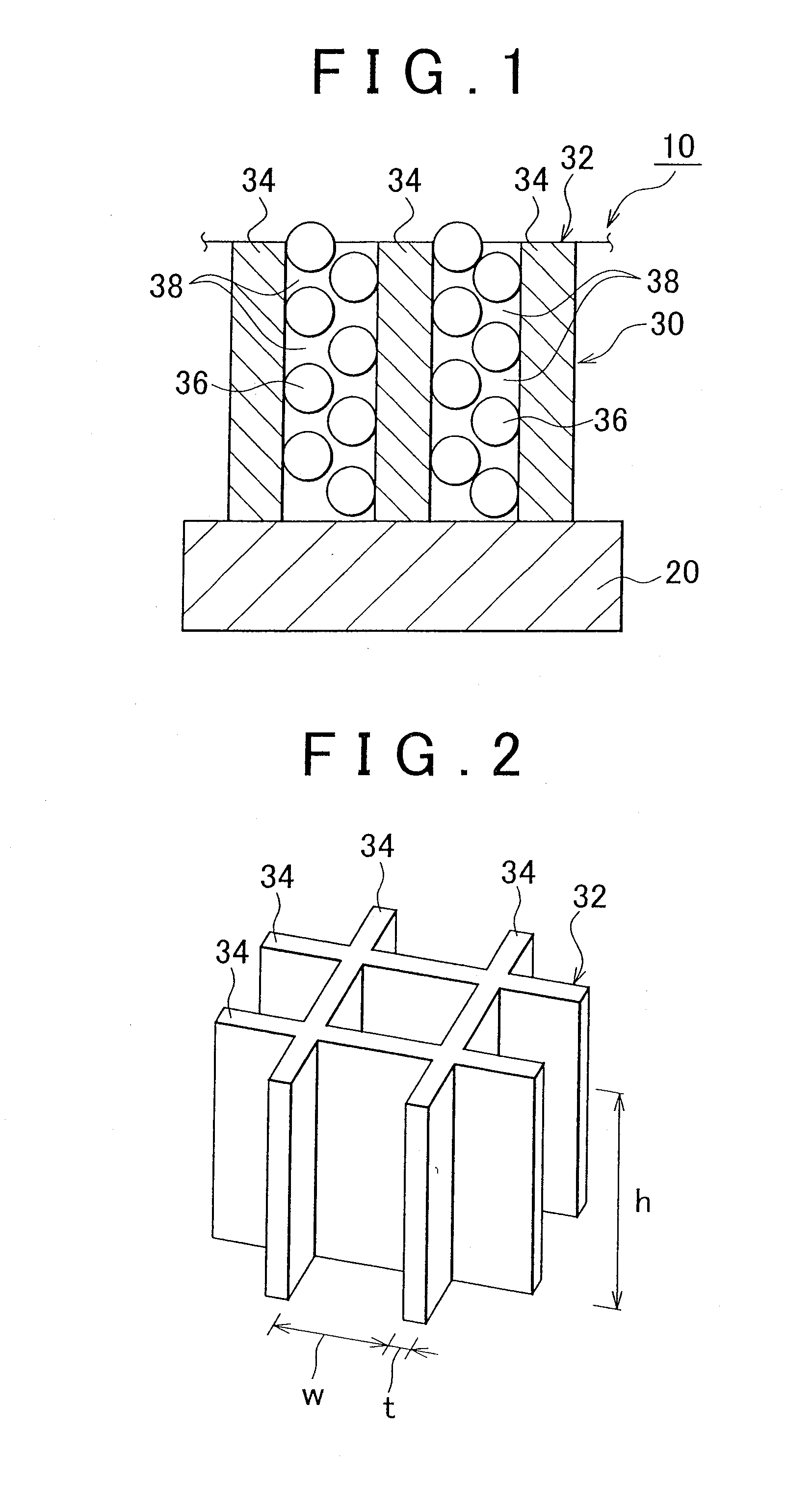

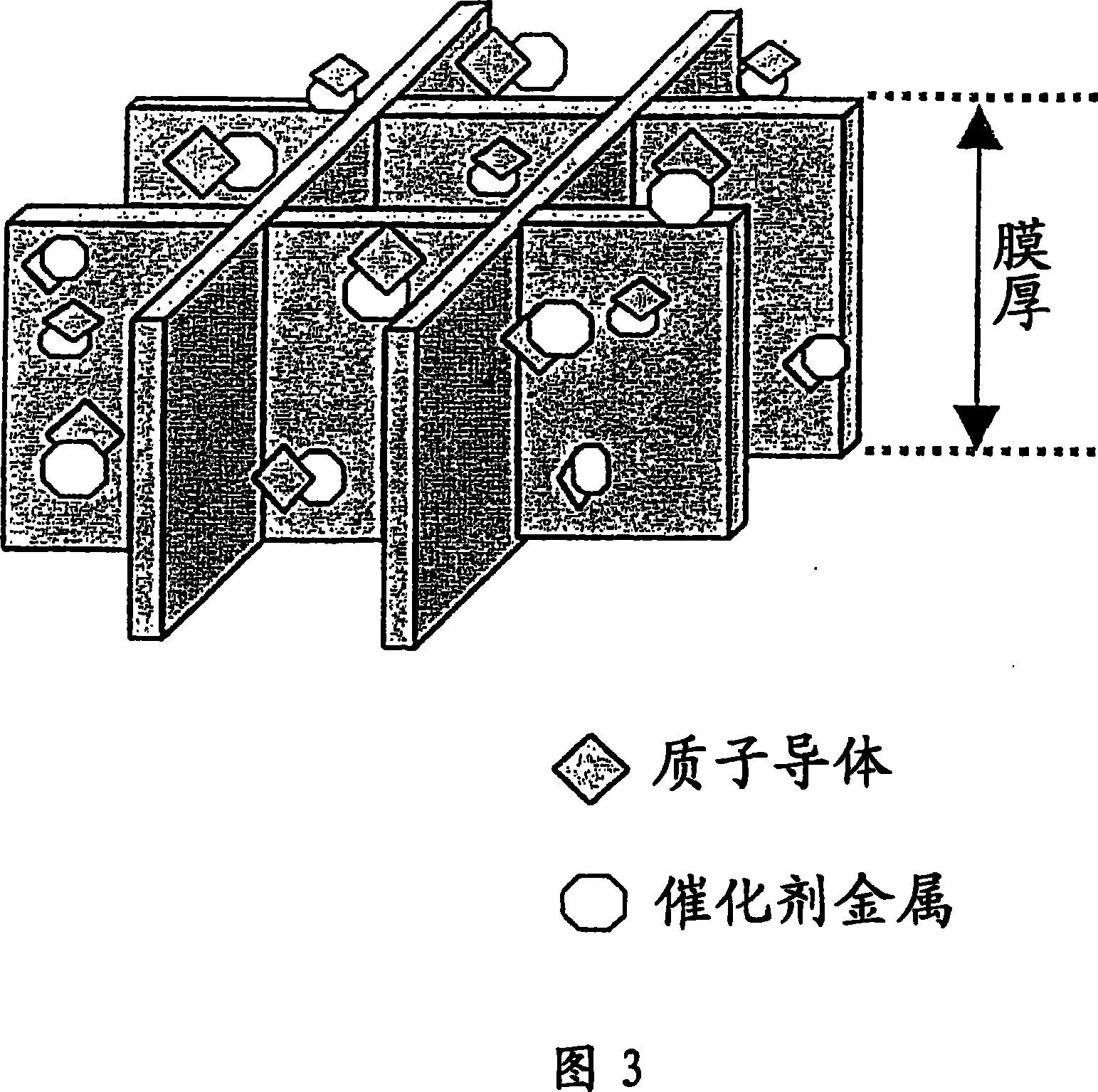

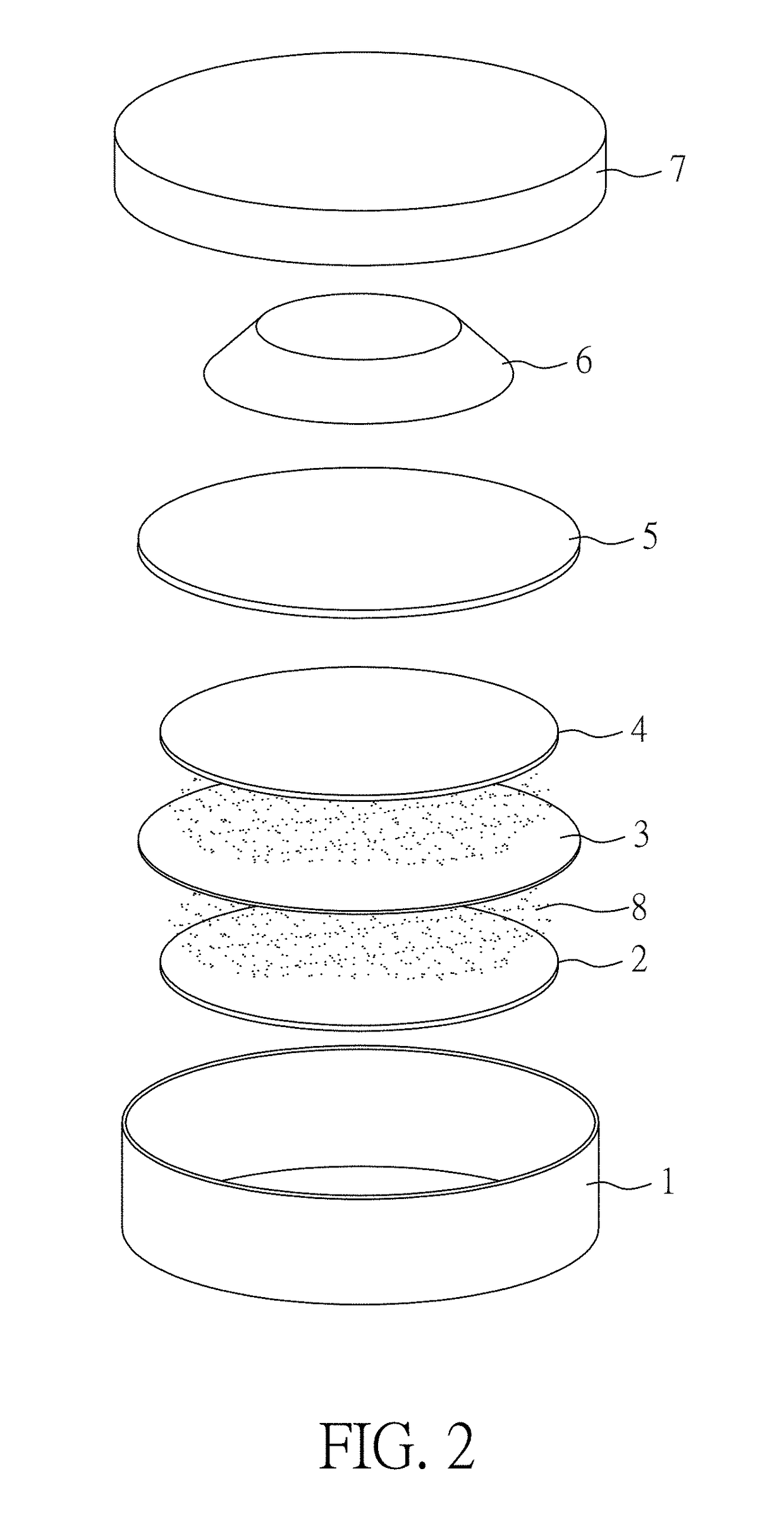

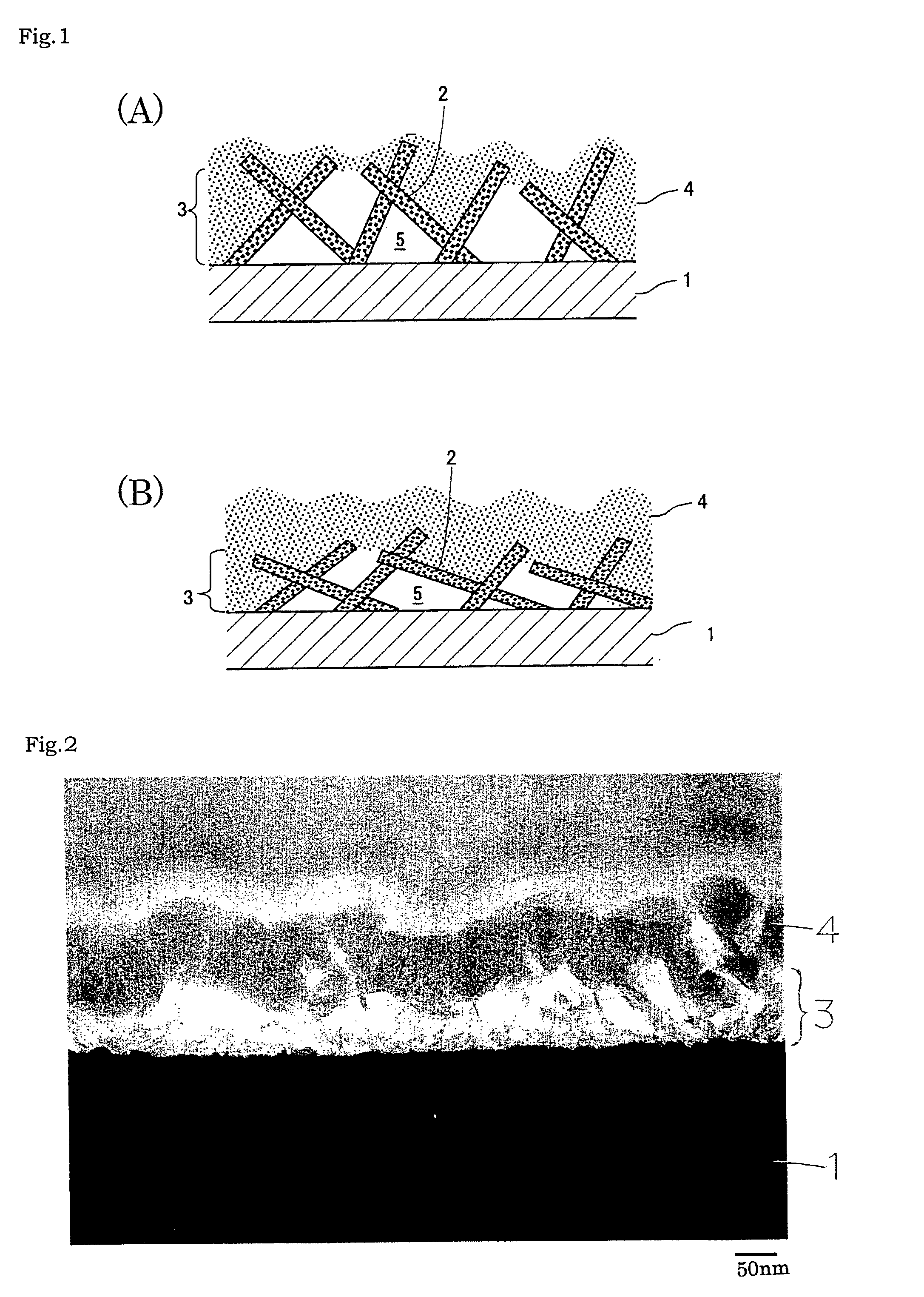

A negative electrode (10) for a lithium secondary battery, including a negative electrode collector (20), and a negative electrode active substance layer (30) that is supported on the negative electrode collector (20) and includes carbon nanowalls (32) which are formed on the negative electrode collector (20), and a negative electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

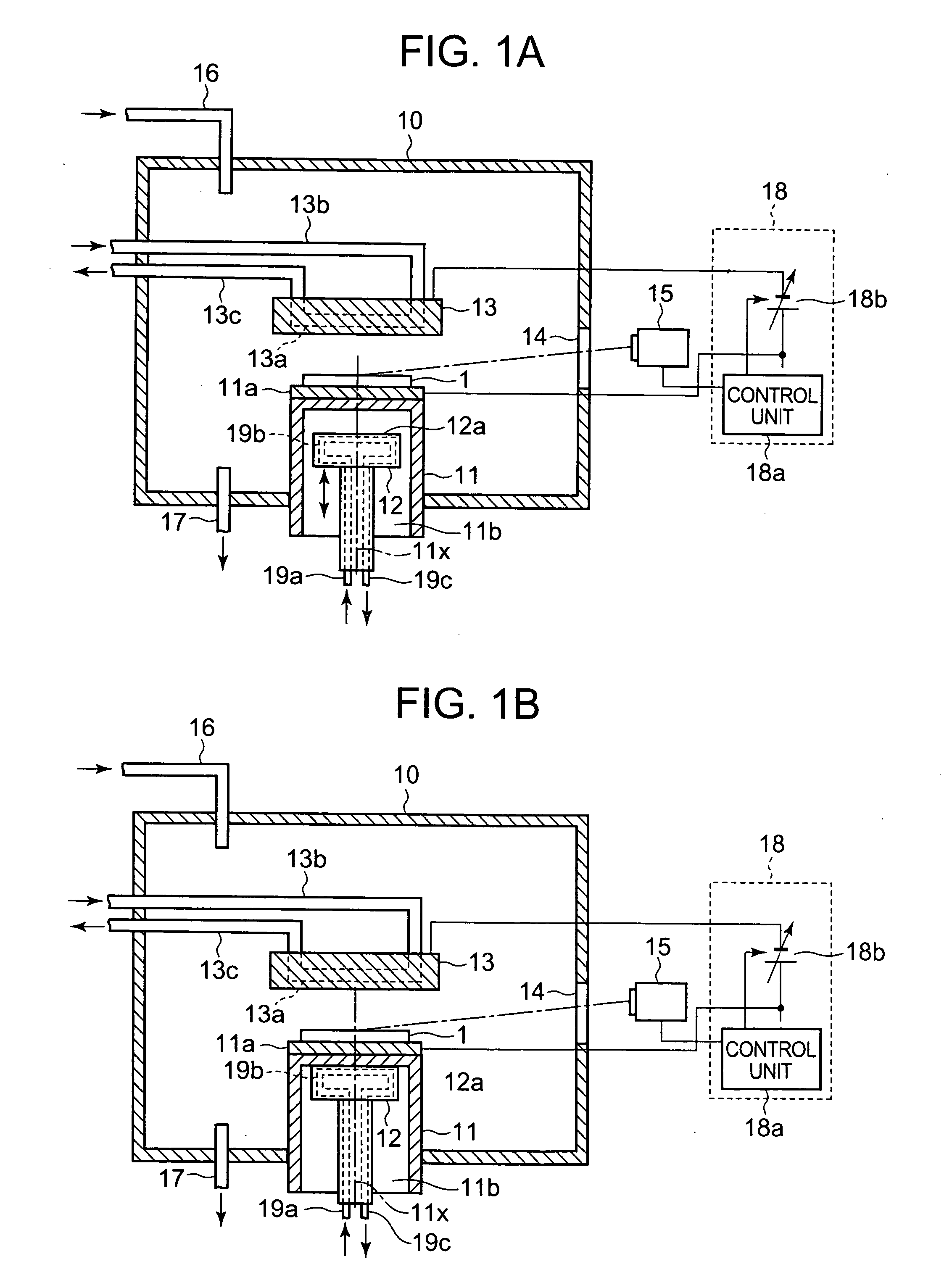

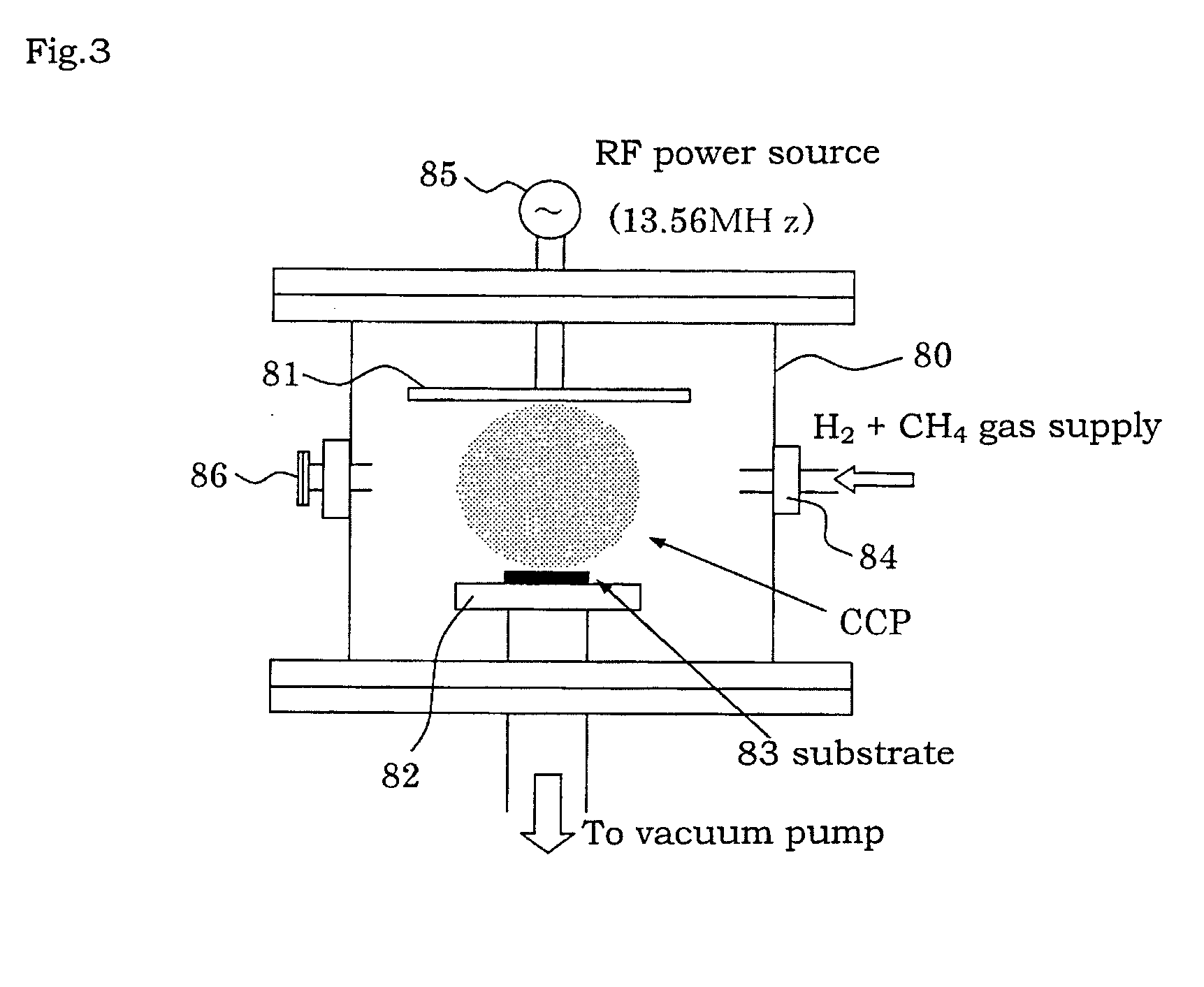

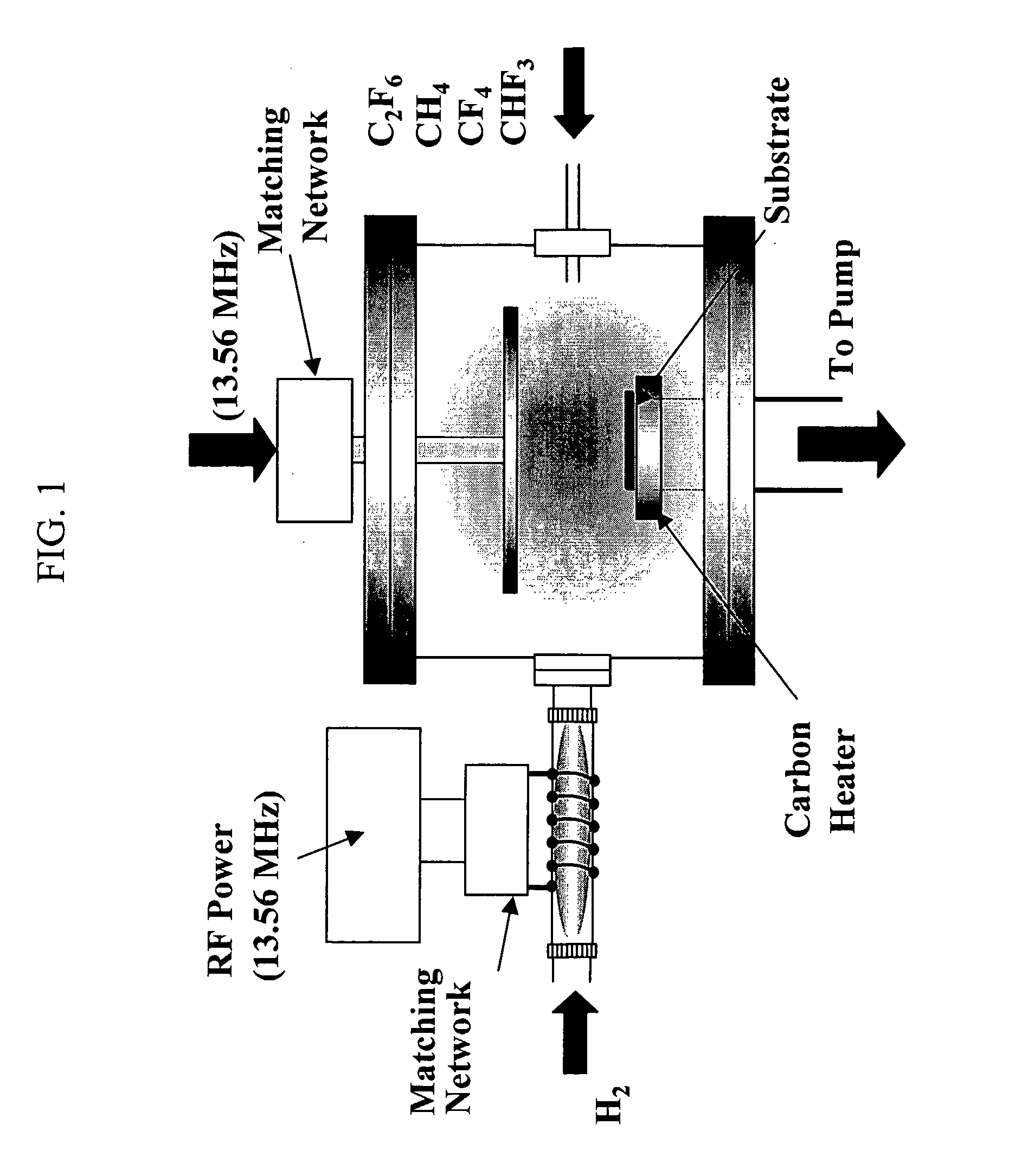

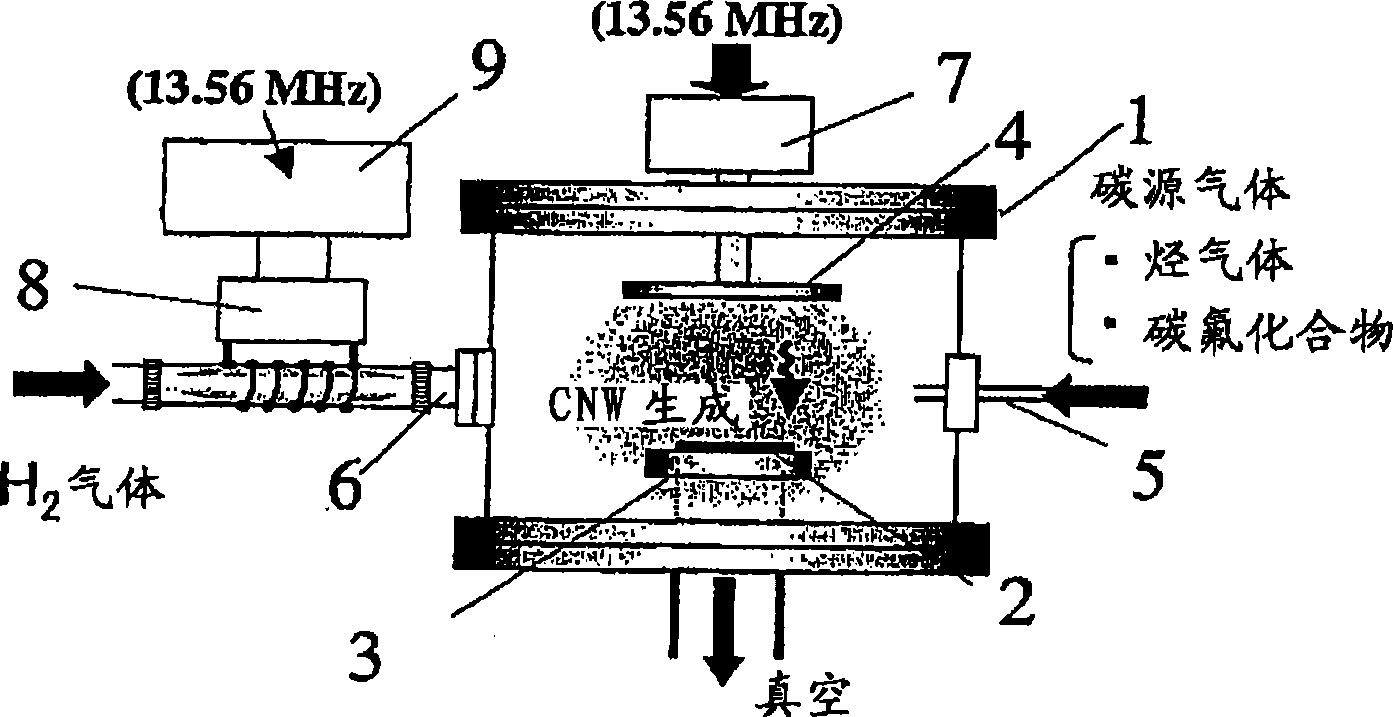

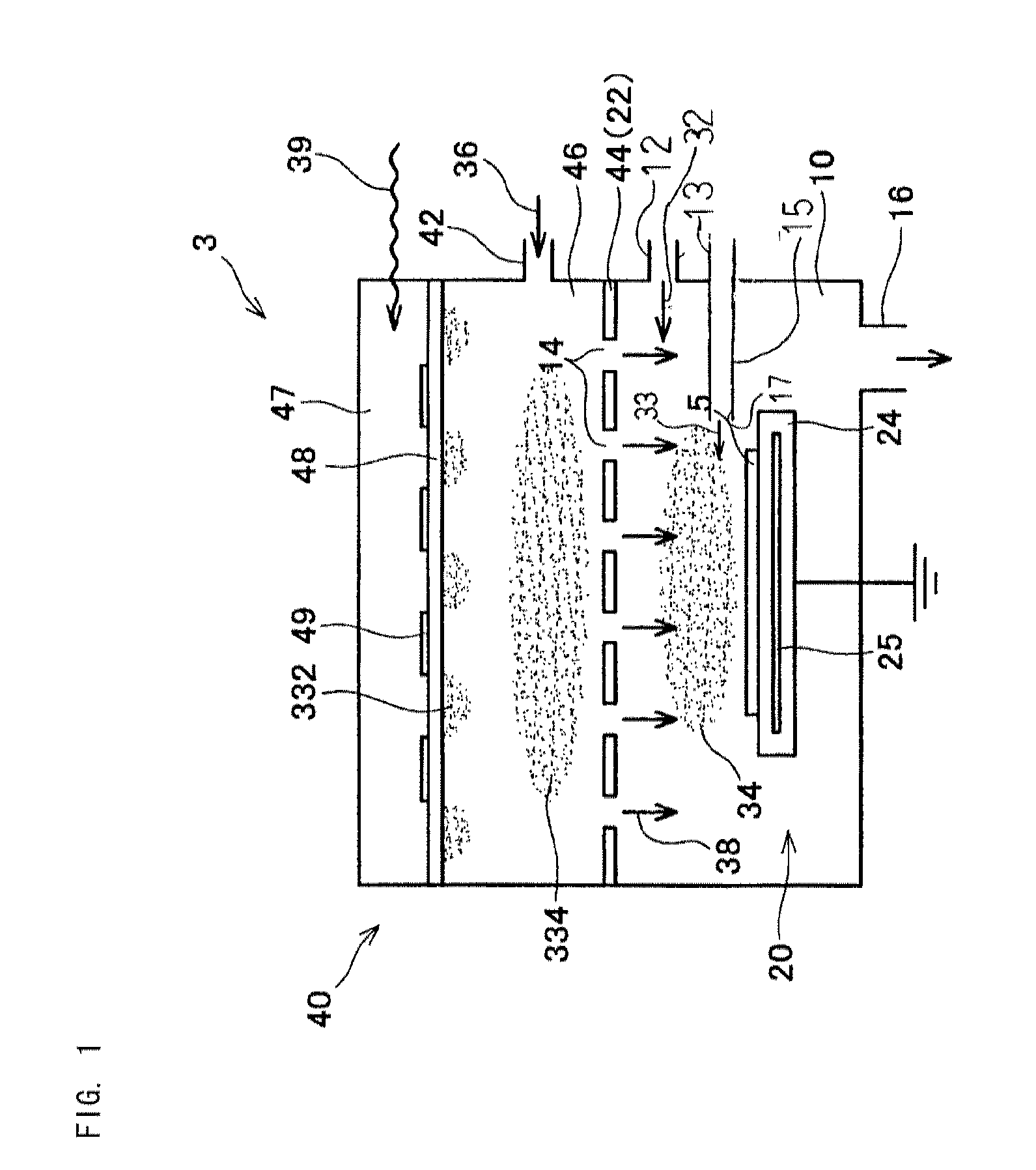

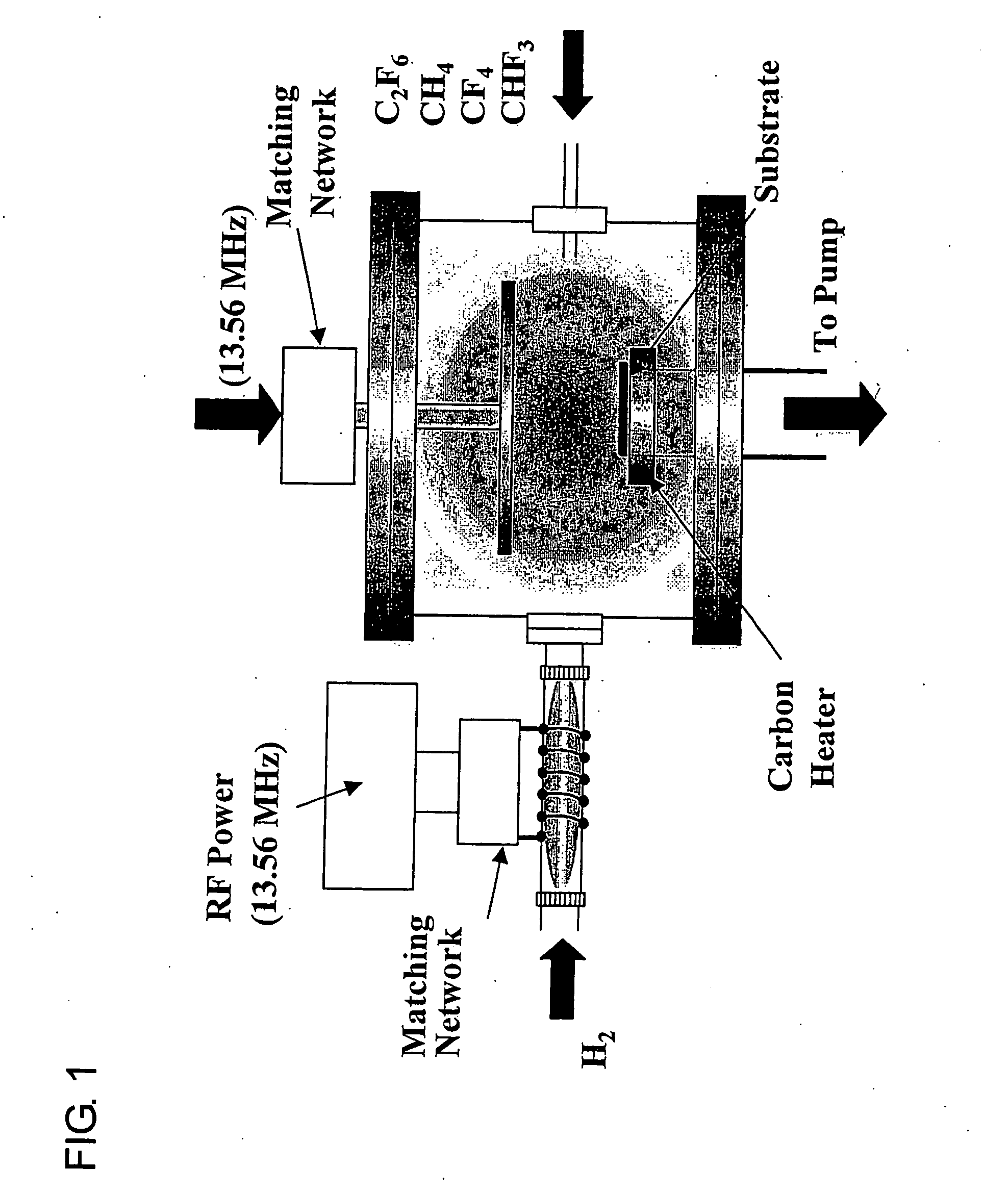

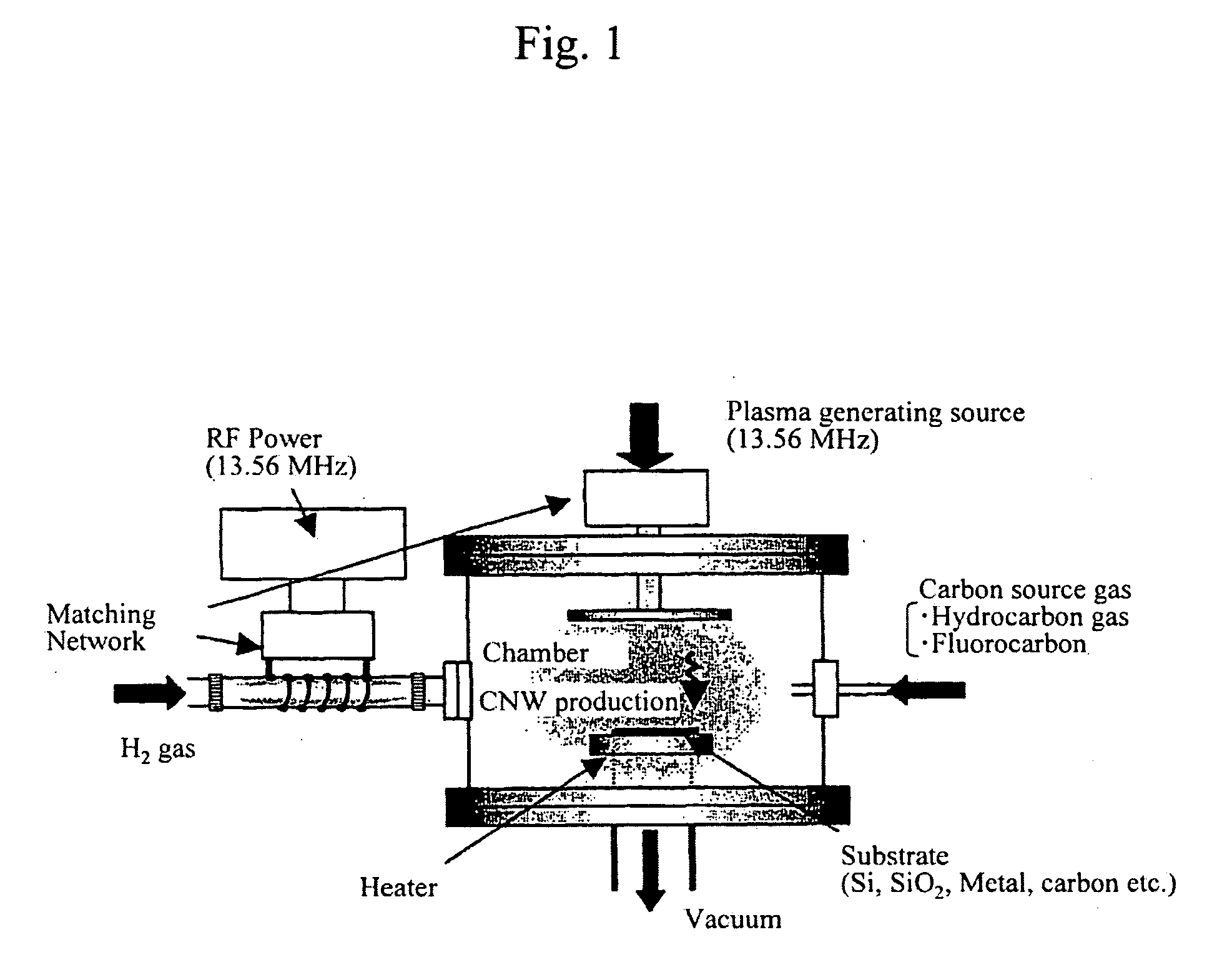

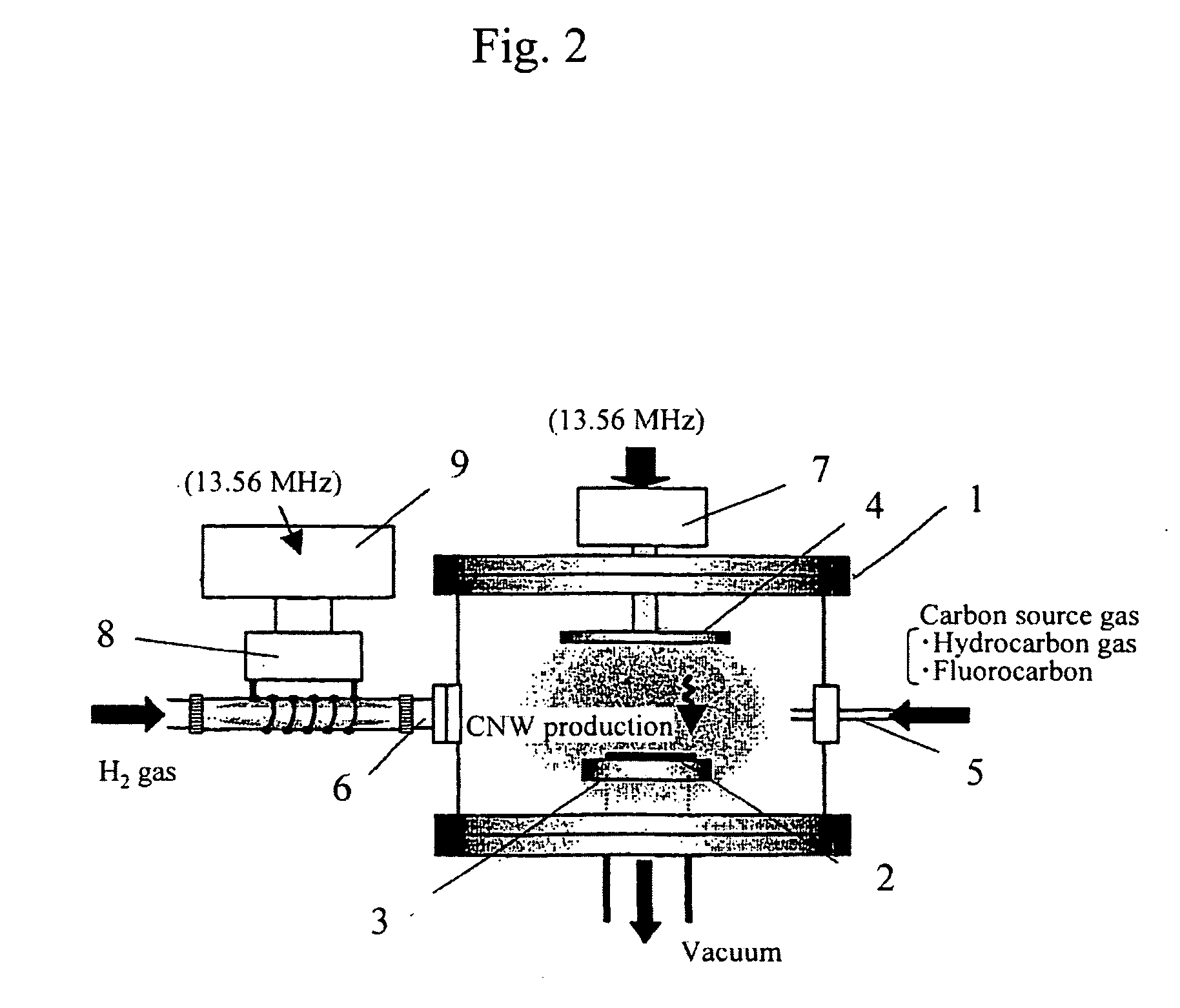

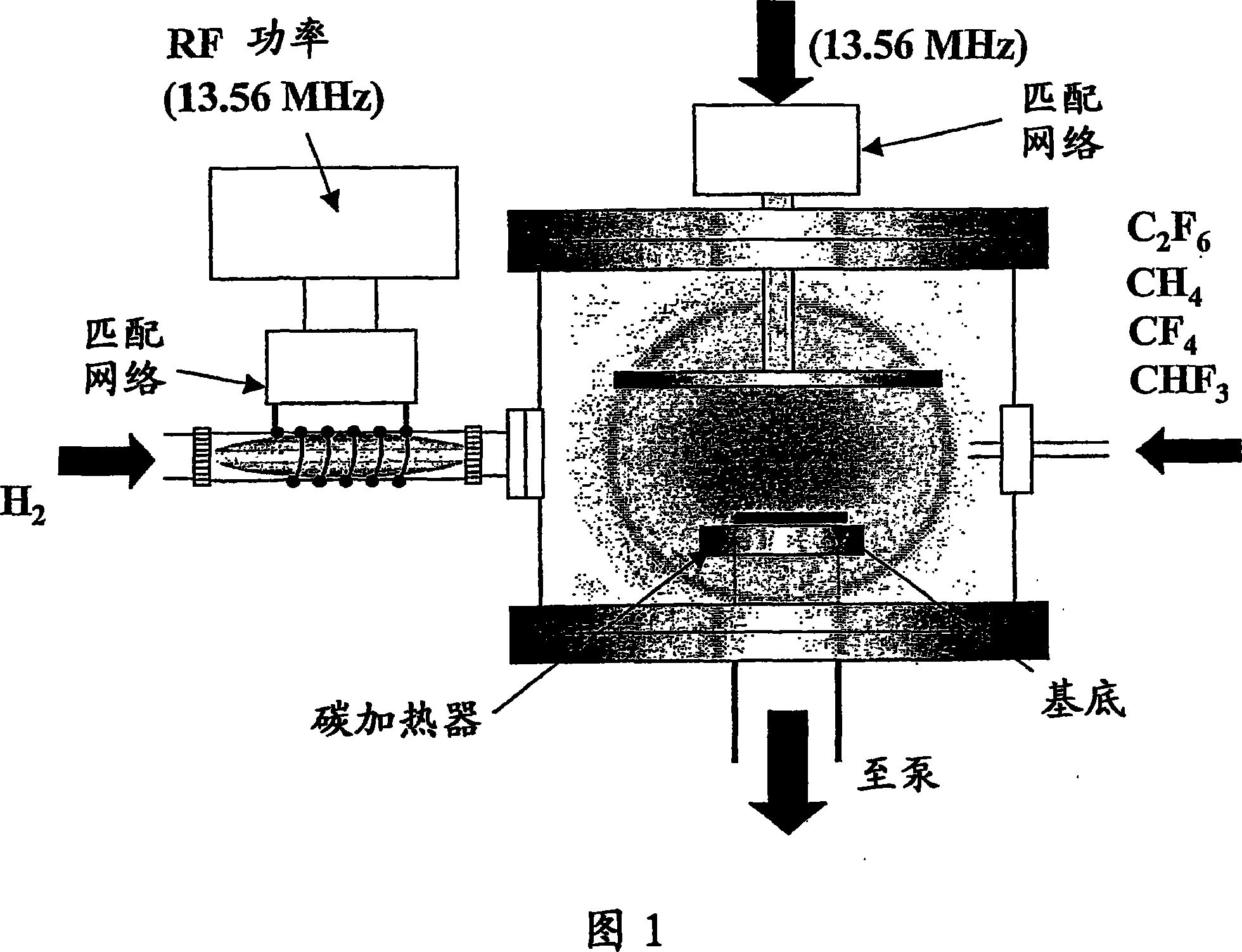

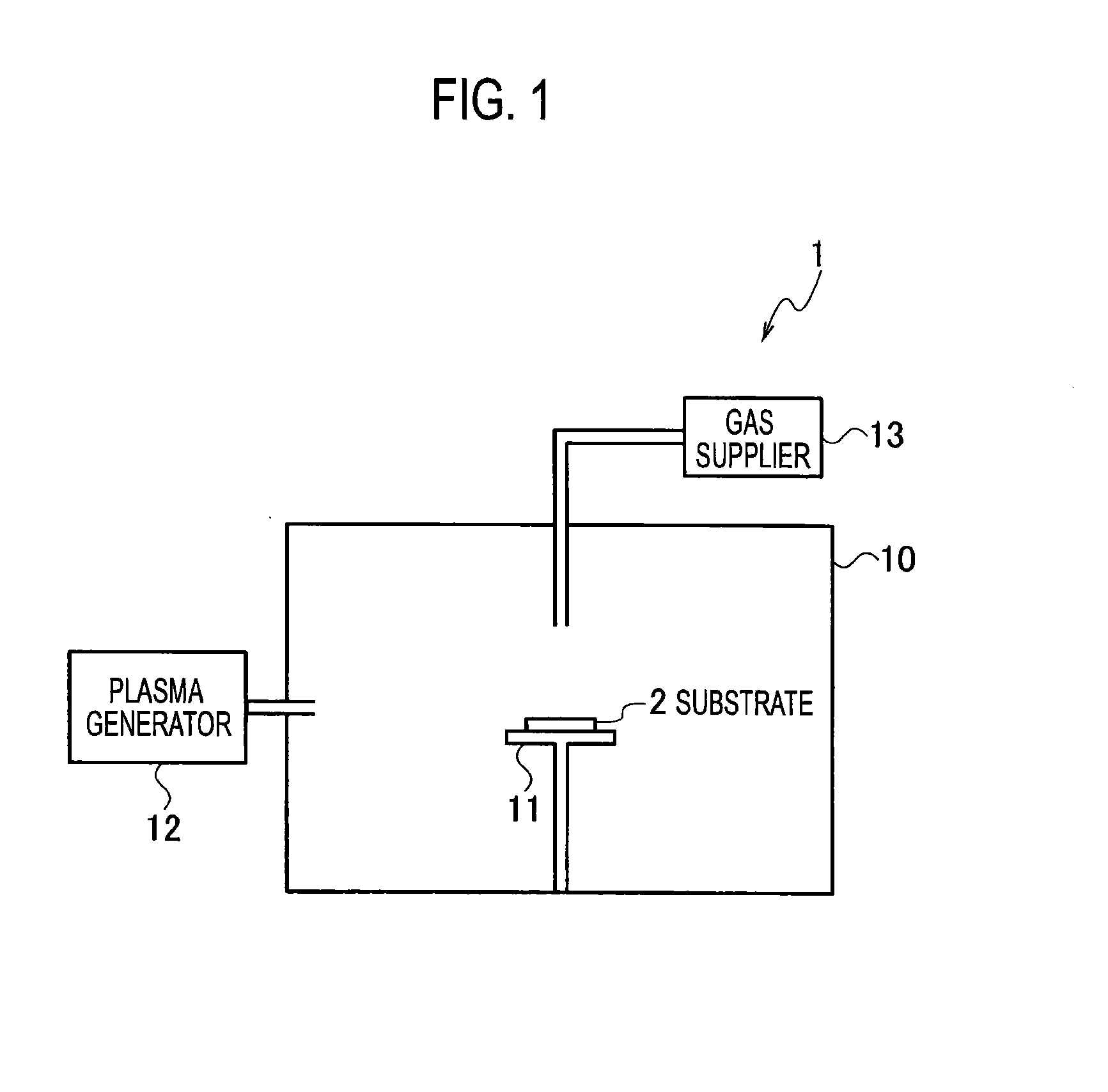

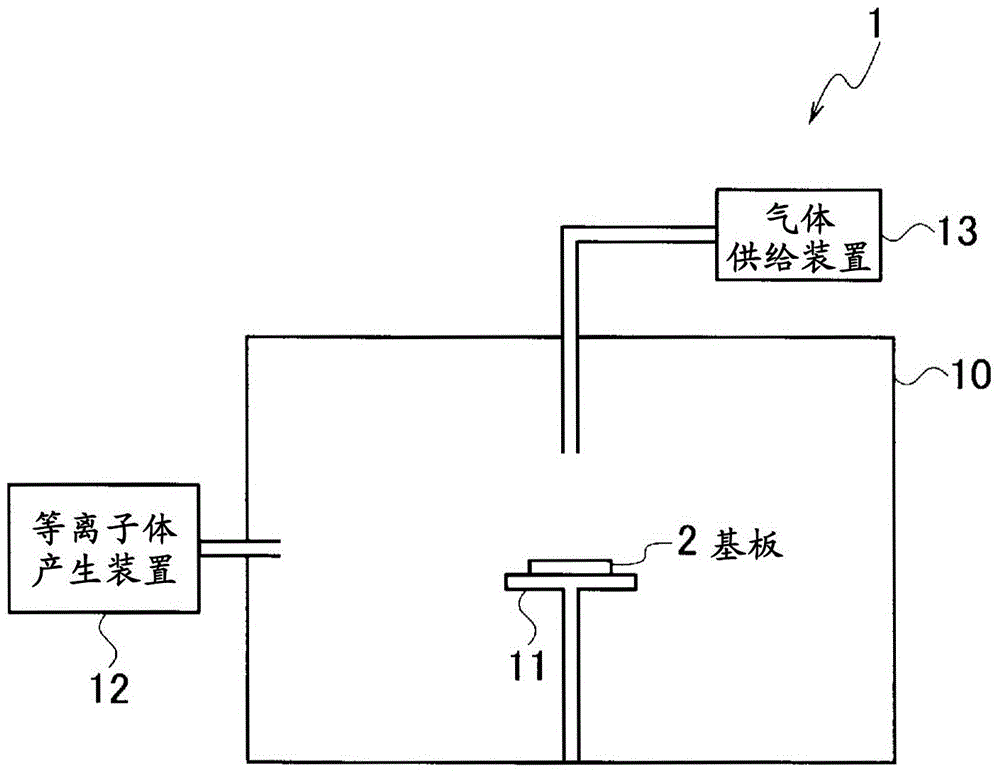

Plasma CVD apparatus and plasma surface treatment method

InactiveUS20070074664A1Low process temperatureQuick changeElectric discharge tubesChemical vapor deposition coatingCarbon nanowallsOptoelectronics

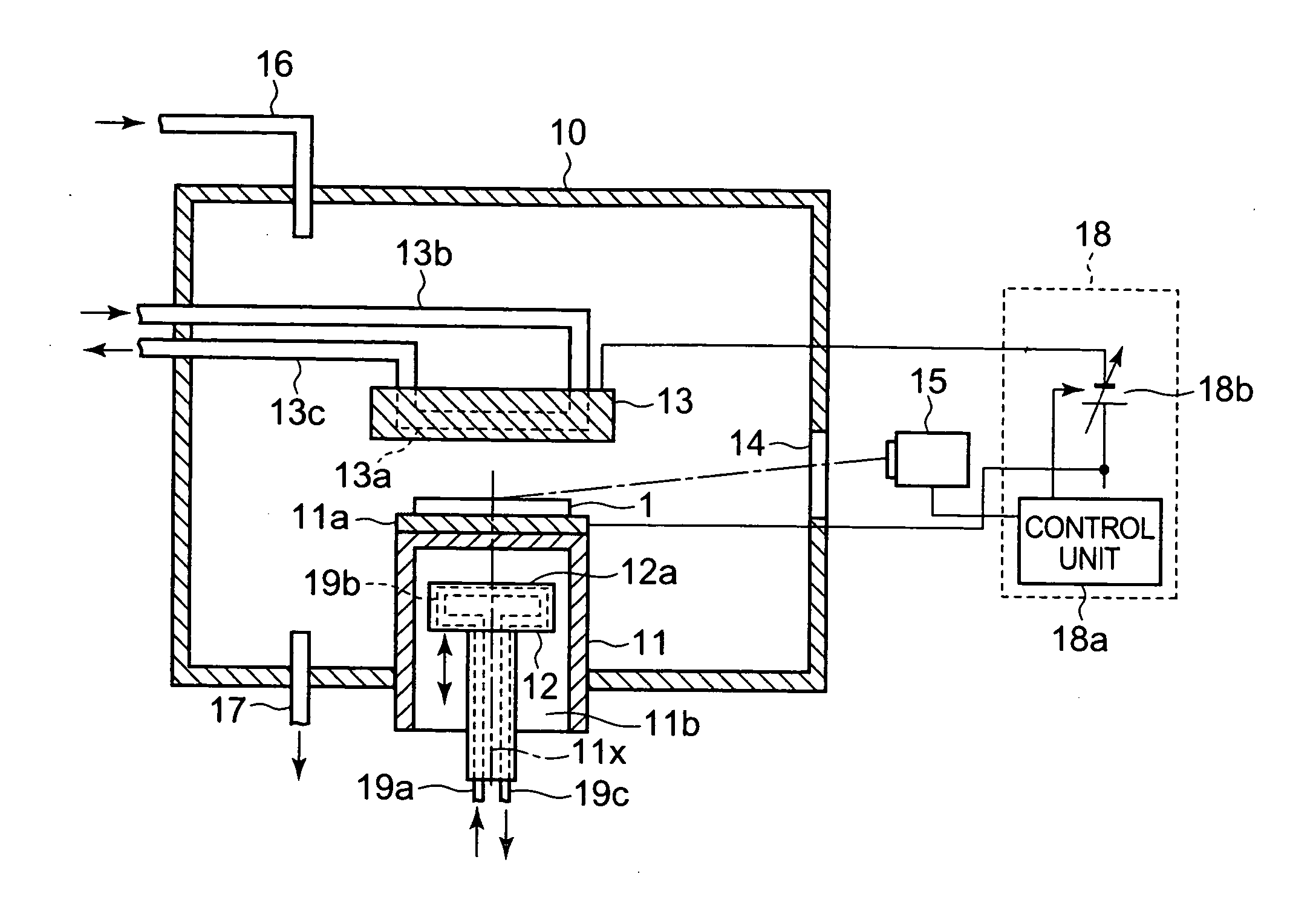

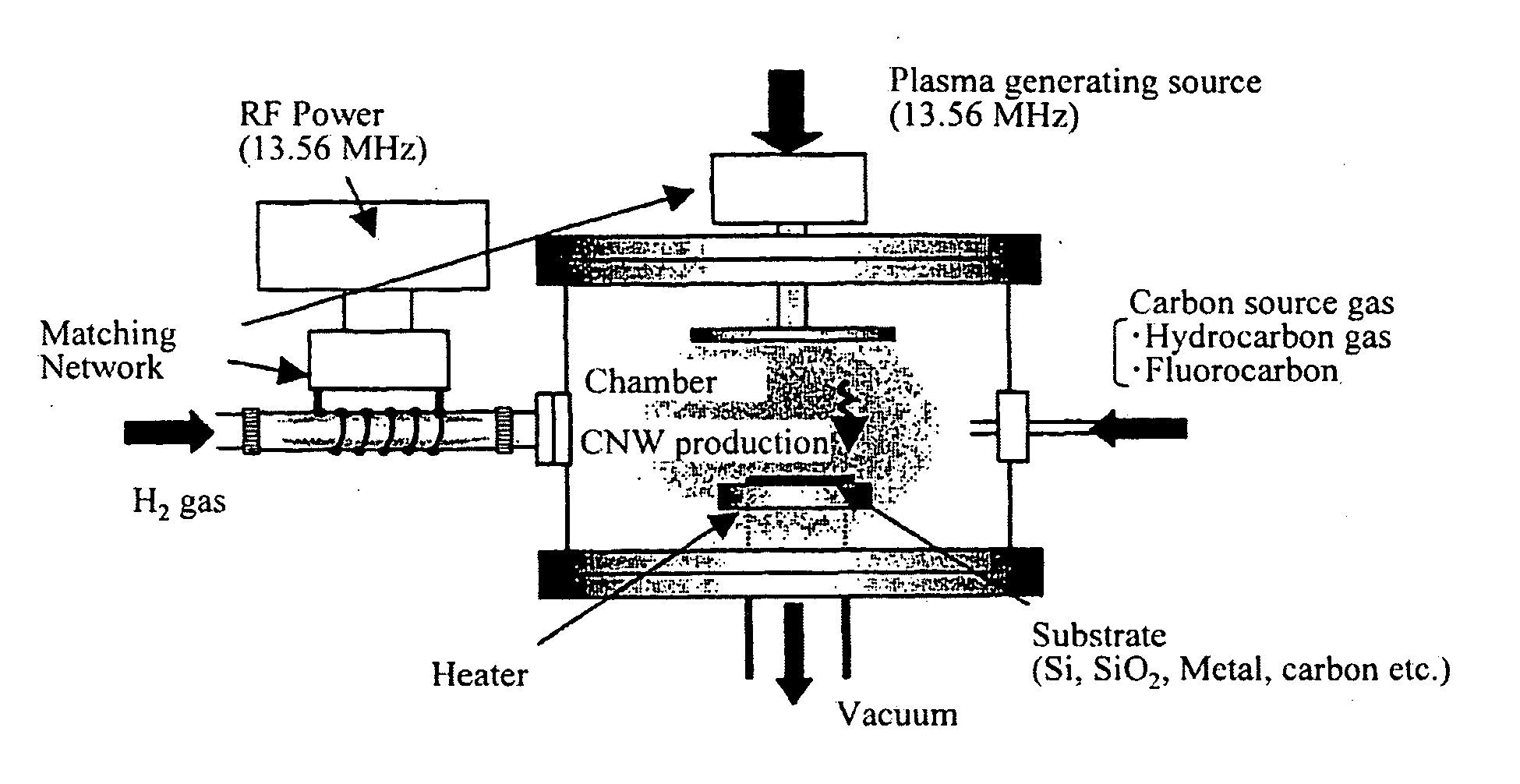

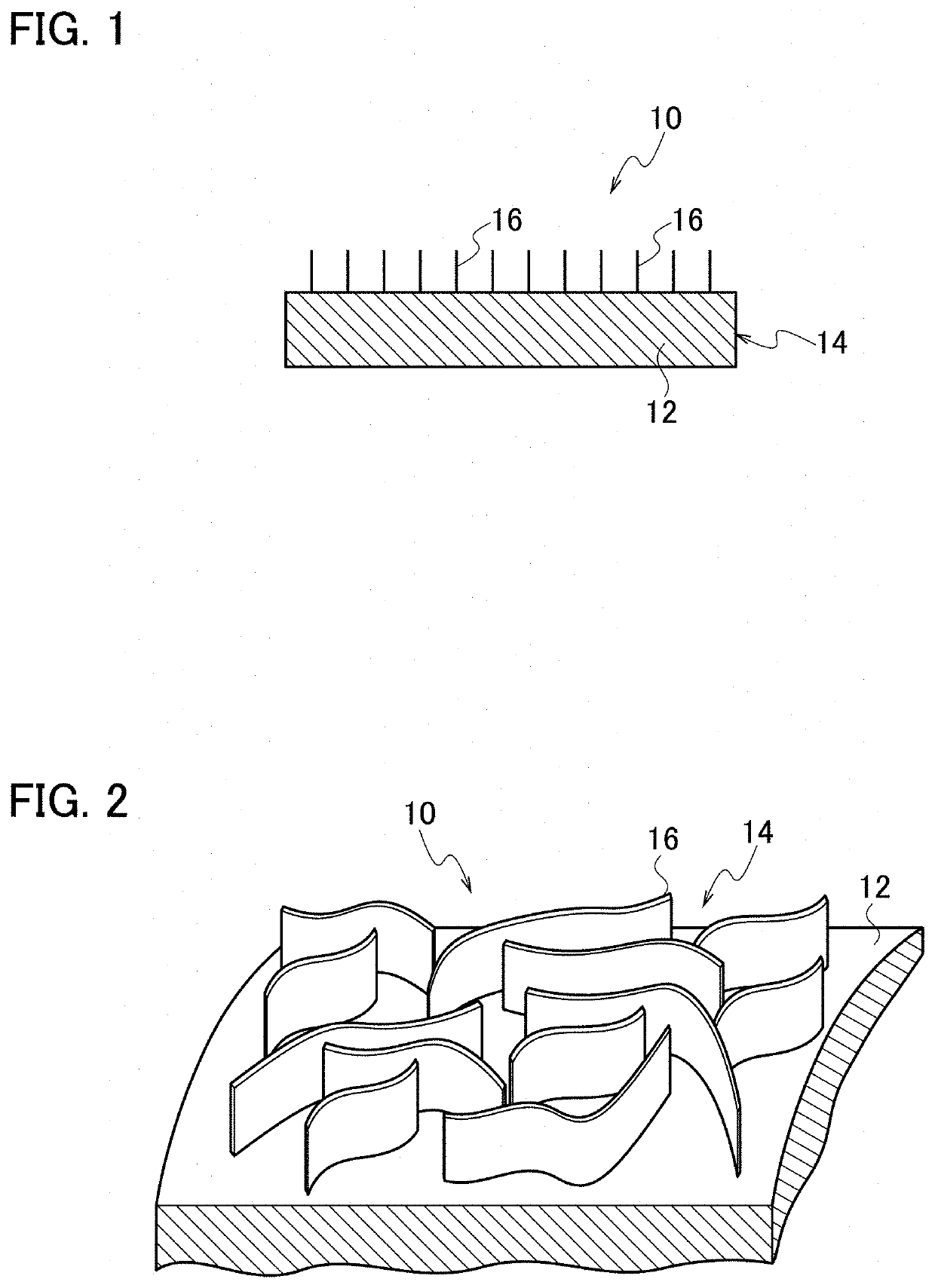

A substrate is mounted on a mount surface of an anode in a chamber. A flow path is formed in a cathode facing the anode, and cooling water is circulated therethrough. A voltage is applied across the anode and the cathode to form a layer of carbon nanowall on the substrate by plasma, and thereafter the anode is cooled by a cooling member to rapidly cool the substrate to a predetermined temperature.

Owner:KOICHI IND PROMOTION CENT +1

Lithium secondary battery negative electrode and method for manufacturing the same

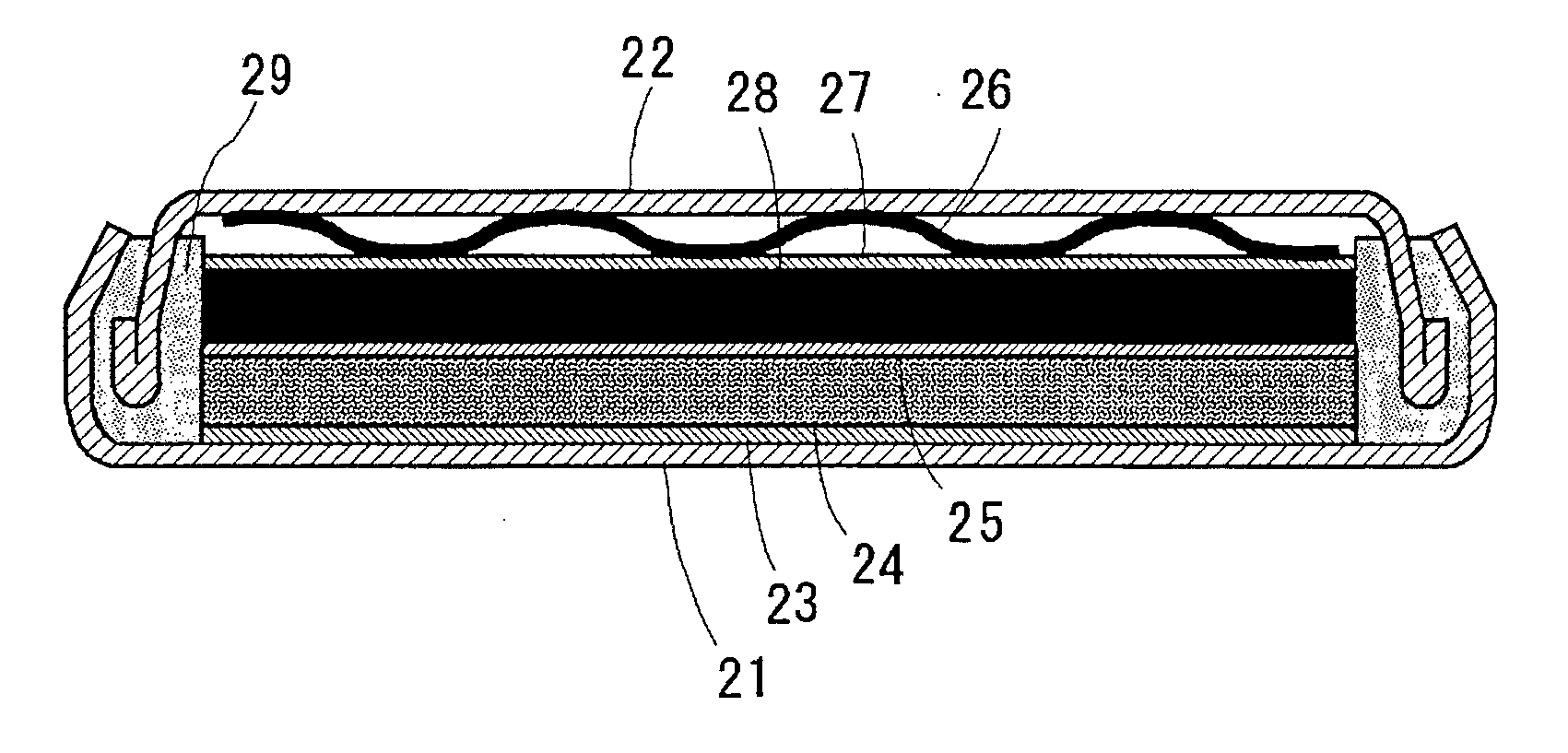

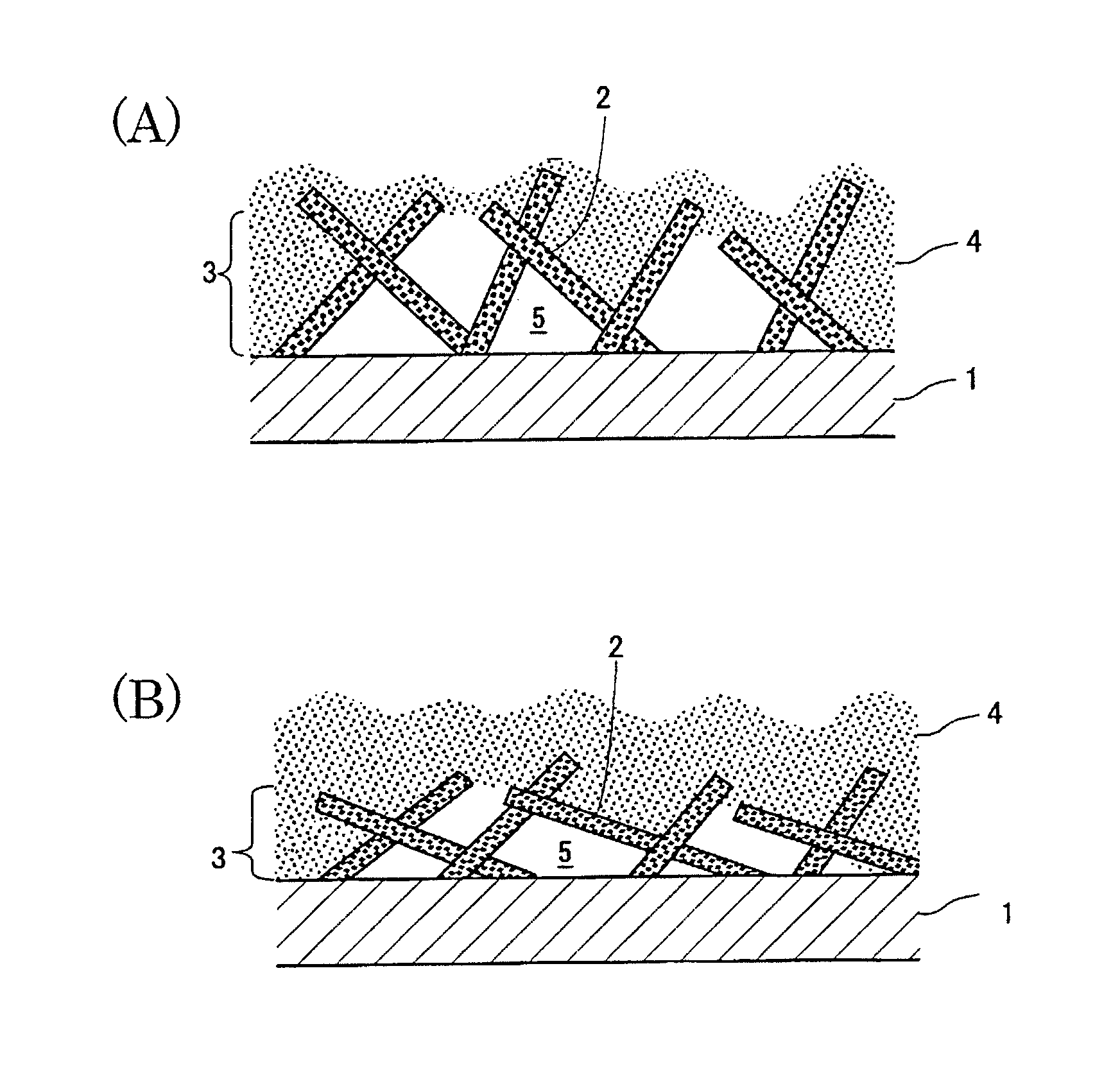

ActiveUS20140170490A1Large charge-discharge capacityReduce battery capacityFinal product manufactureActive material electrodesLithiumCarbon nanowalls

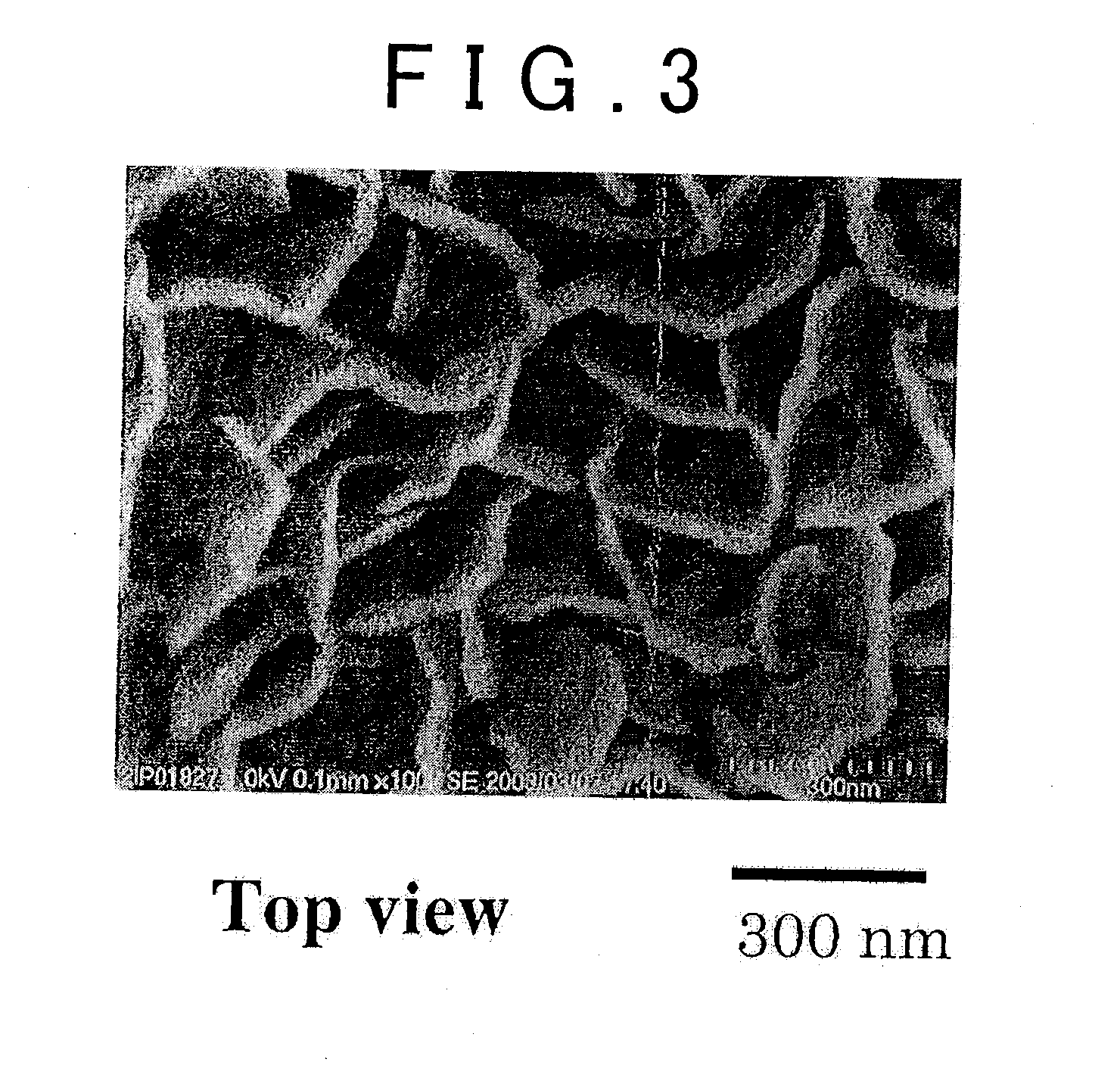

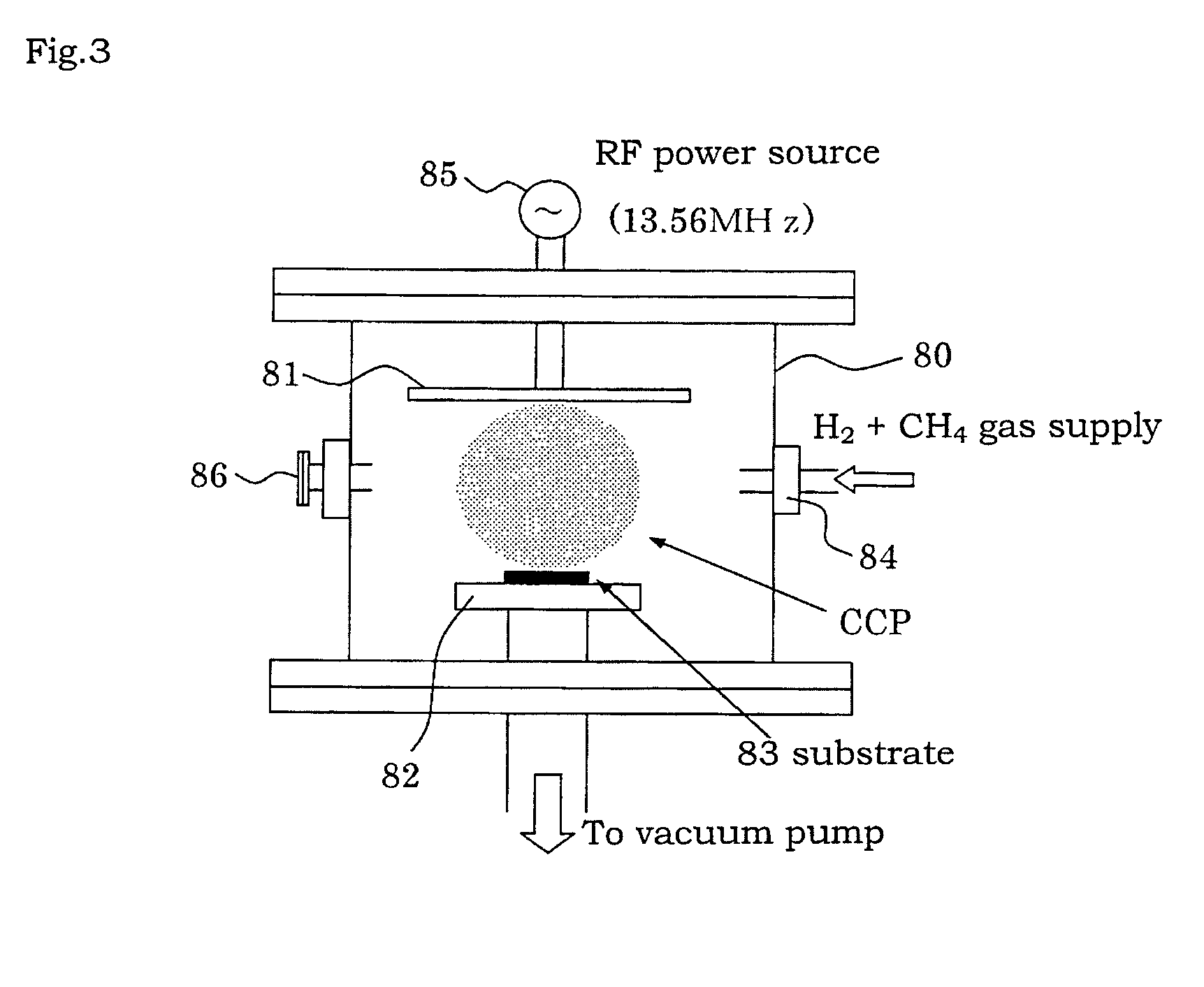

Provided is a negative electrode having a new structure for realizing a lithium secondary battery having increased charging / discharging capacities and a battery capacity that is reduced less due to repeated charging / discharging. The negative electrode for a lithium secondary battery includes a current collector substrate; a carbon nanochips layer including graphene sheets grown to incline in irregular directions independently from the current collector substrate; and a silicon thin film layer on the carbon nanochips layer, in which gaps among the carbon nanochips are formed between the silicon thin film layer and the current collector substrate. The Raman spectrum of graphite forming the carbon nanochips layer has a g / d ratio of 0.30 to 0.80, both inclusive, and the crystallinity level of the graphite is lower than that of graphite forming carbon nanowalls. The carbon nanochips layer can be formed by a plasma CVD method using a gaseous mixture of methane and hydrogen, for example.

Owner:SANGO CO LTD +1

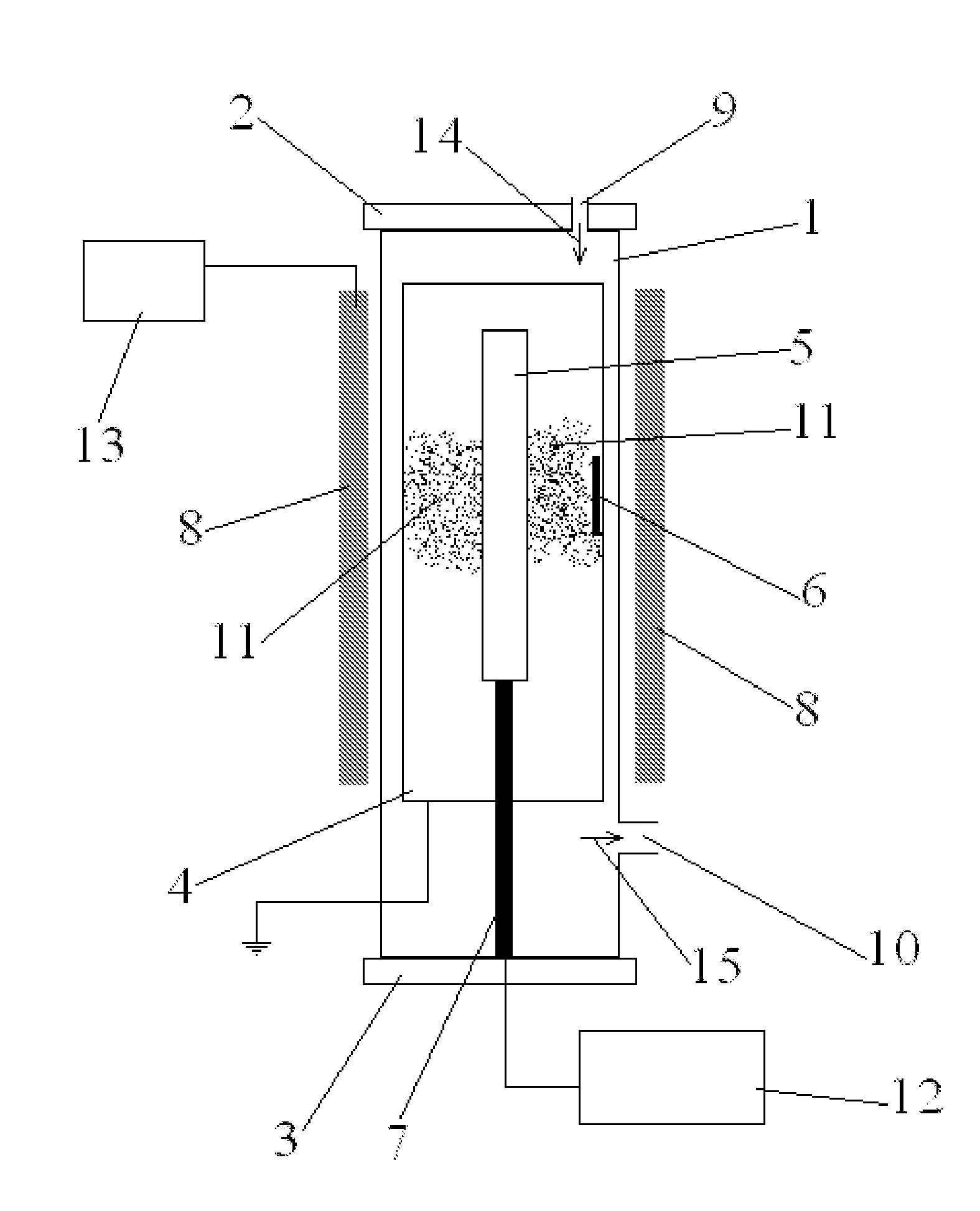

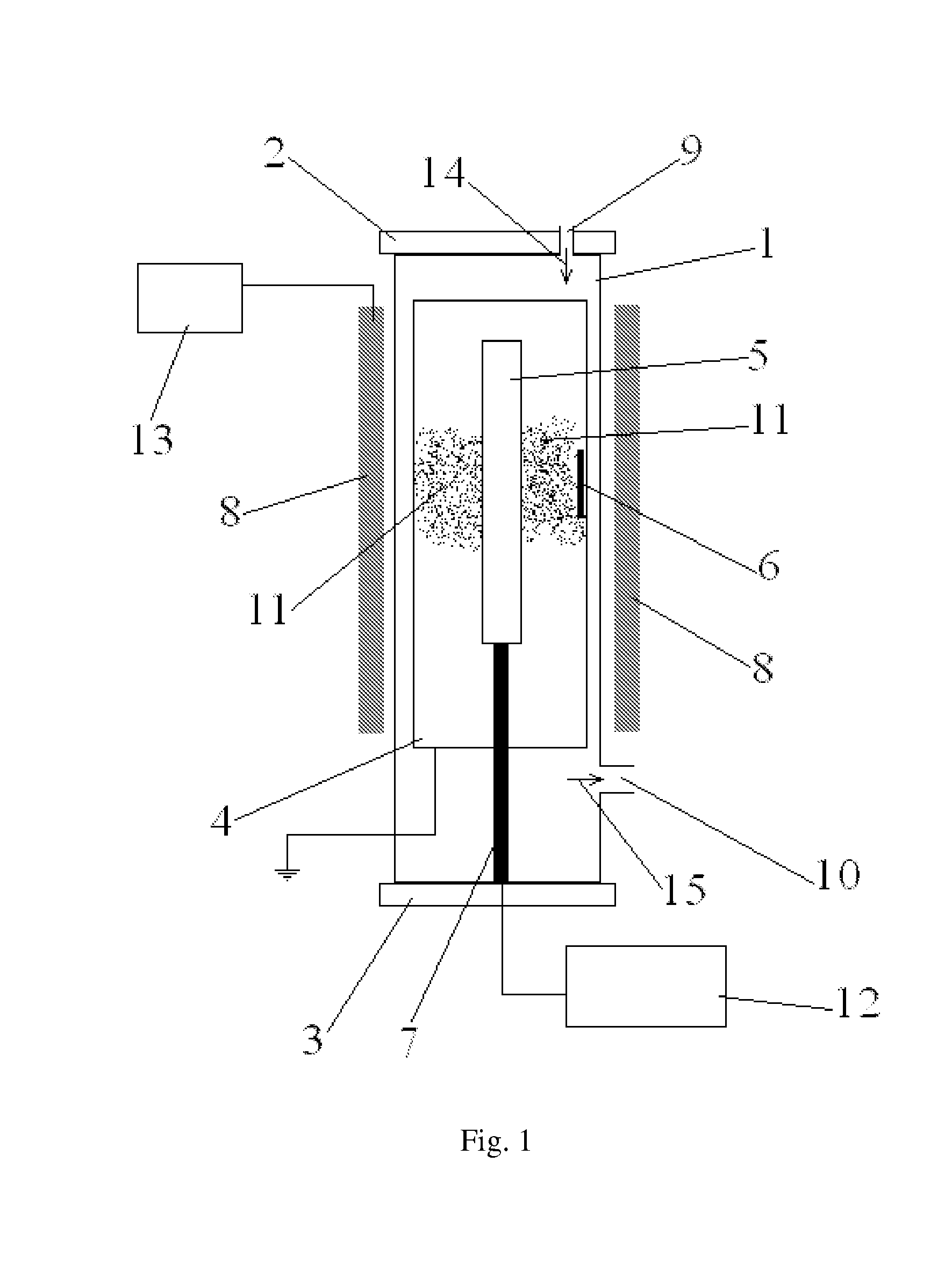

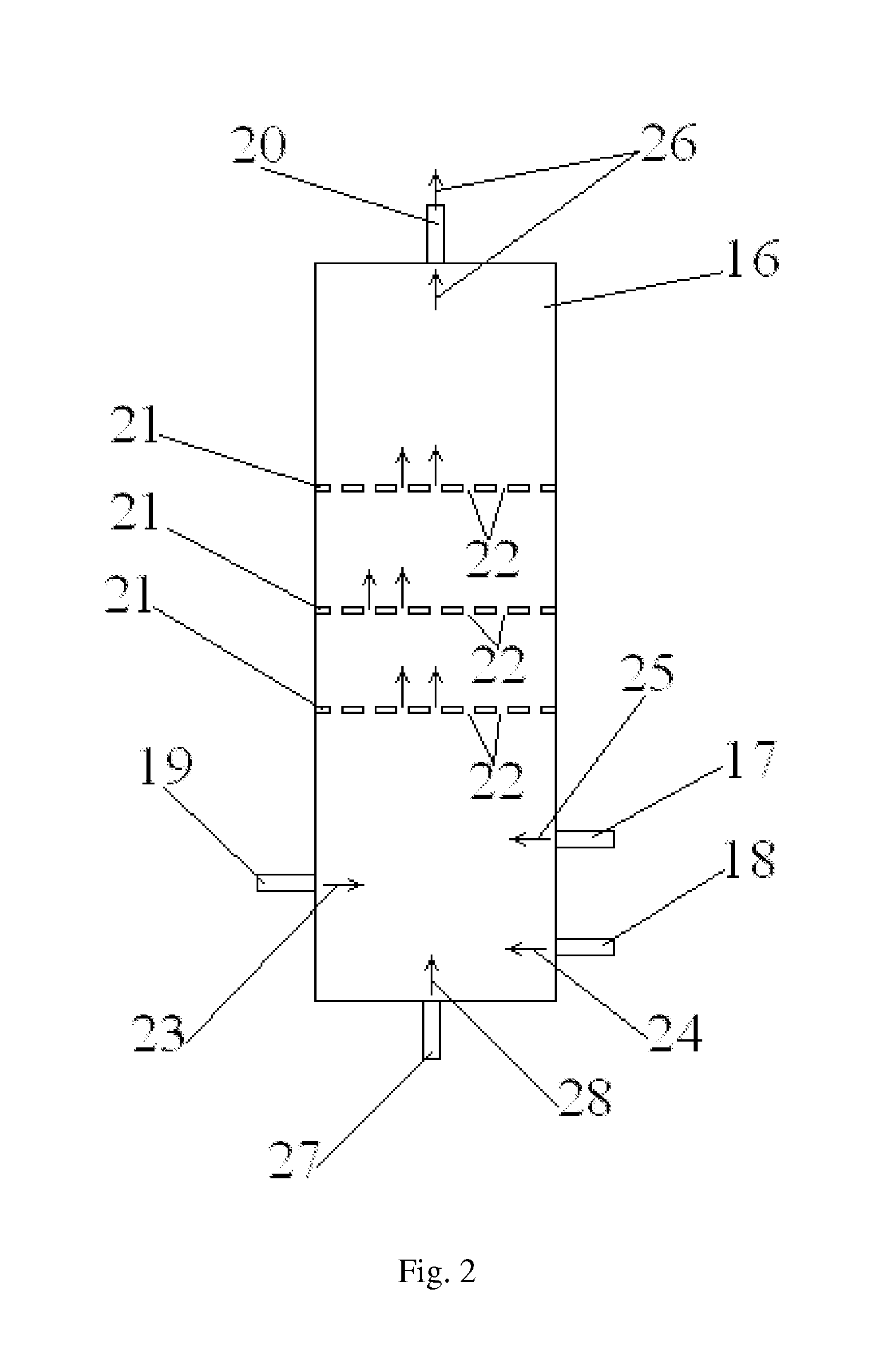

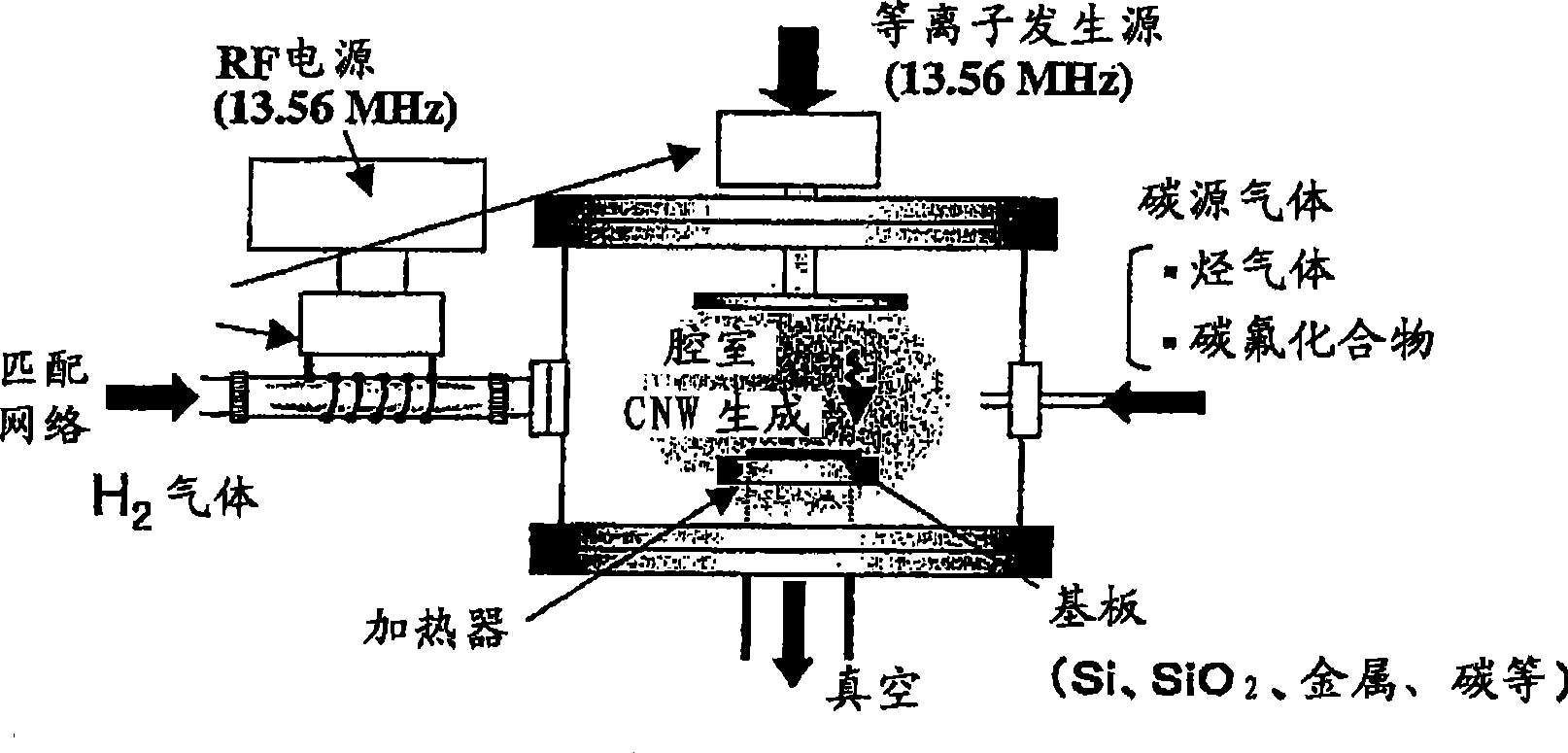

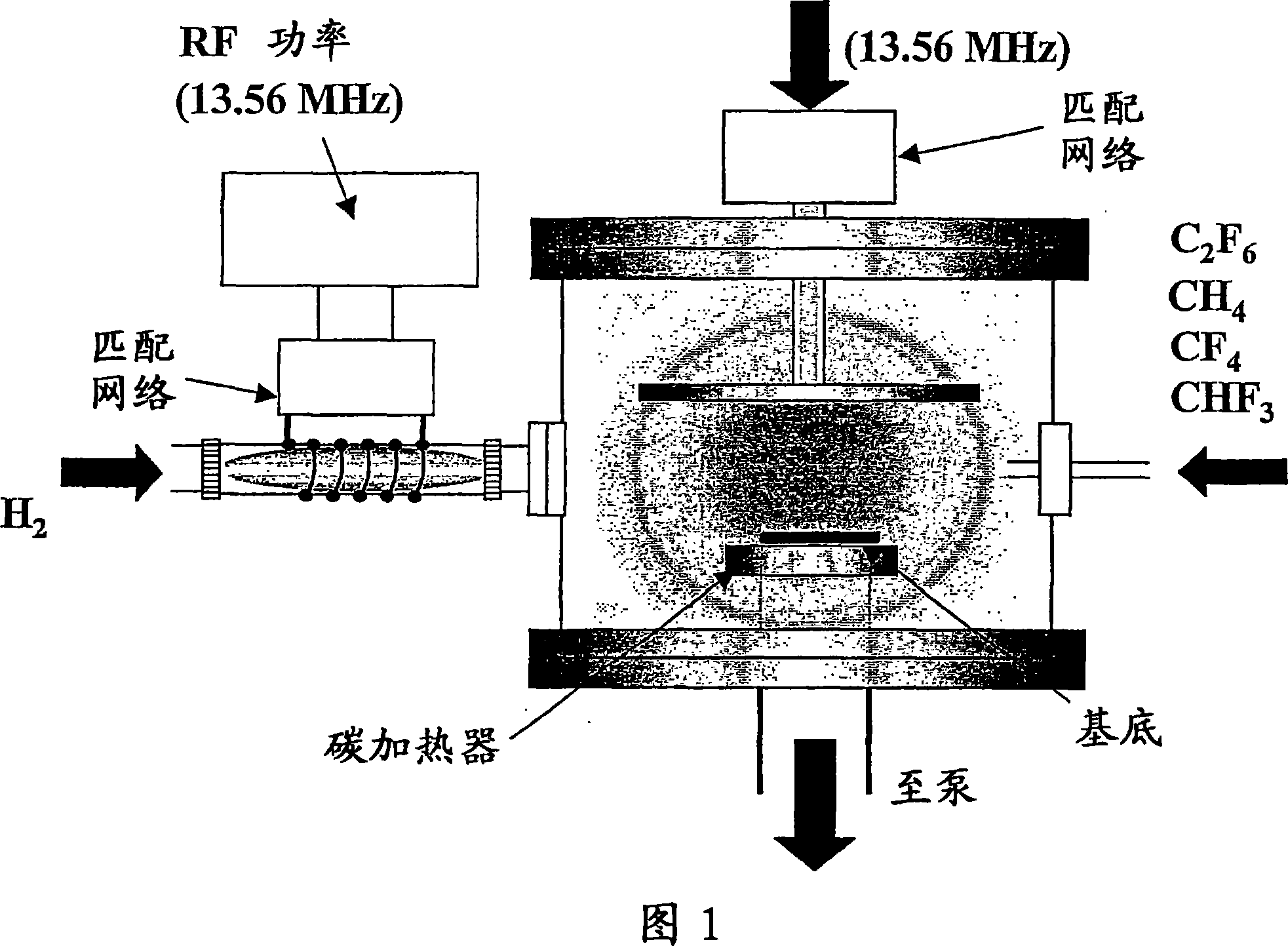

Method for growing carbon nanowalls

InactiveUS20090274610A1Control feed rateMaterial nanotechnologyCarbon compoundsCarbon nanowallsProduct gas

A method for growing carbon nanowalls on a base material is disclosed. The method comprises mixing a predetermined amount of a hydrocarbon gas with a predetermined amount of at least one non hydrocarbon gas; placing said base material in a reaction chamber having a first portion and a second portion, first portion is extended from a first end of reaction chamber to first end of base material; creating a radical in reaction chamber which comprises a hydrocarbon radical and a non hydrocarbon radical; applying the radical to the base material; and growing carbon nanowalls on said base material based on said hydrocarbon radical.

Owner:GHOANNEVISS MAHMOOD +2

Nanoimprint Mold, Method of Forming a Nonopattern, and a Resin-Molded Product

InactiveUS20080090052A1Superior releasabilityIncreased durabilityMaterial nanotechnologyNanostructure manufactureCarbon nanowallsNanometre

Owner:MASARU HORI +2

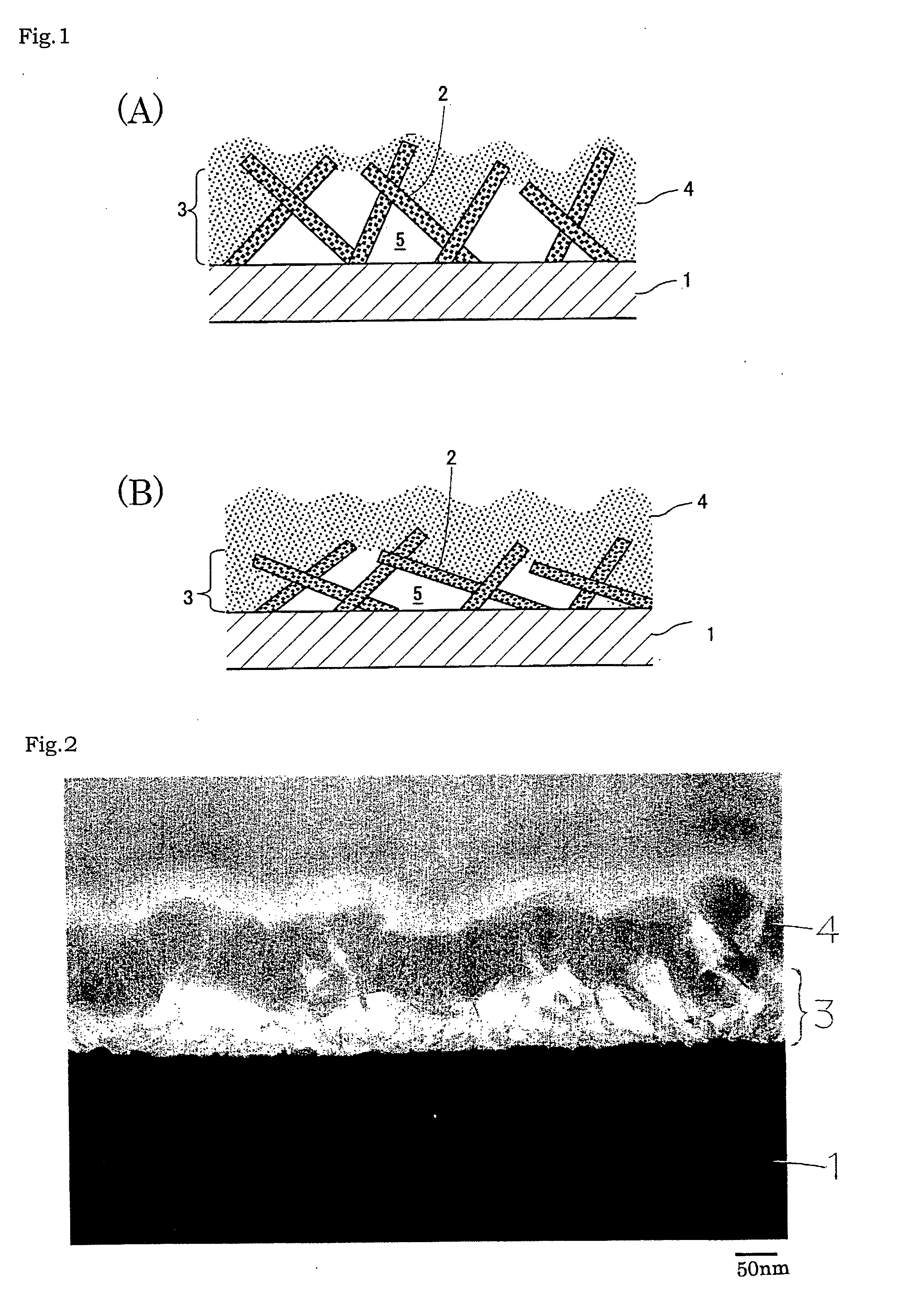

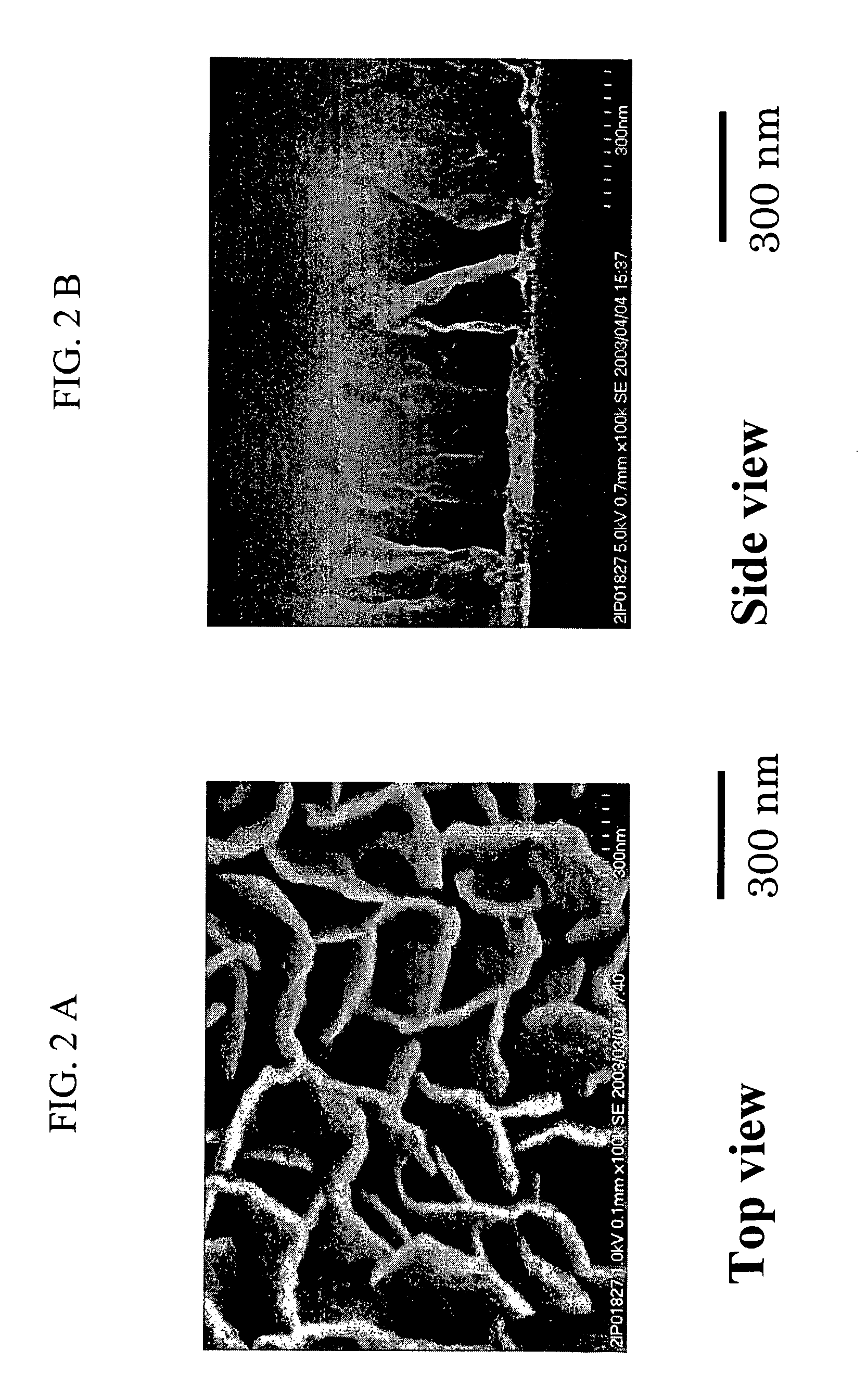

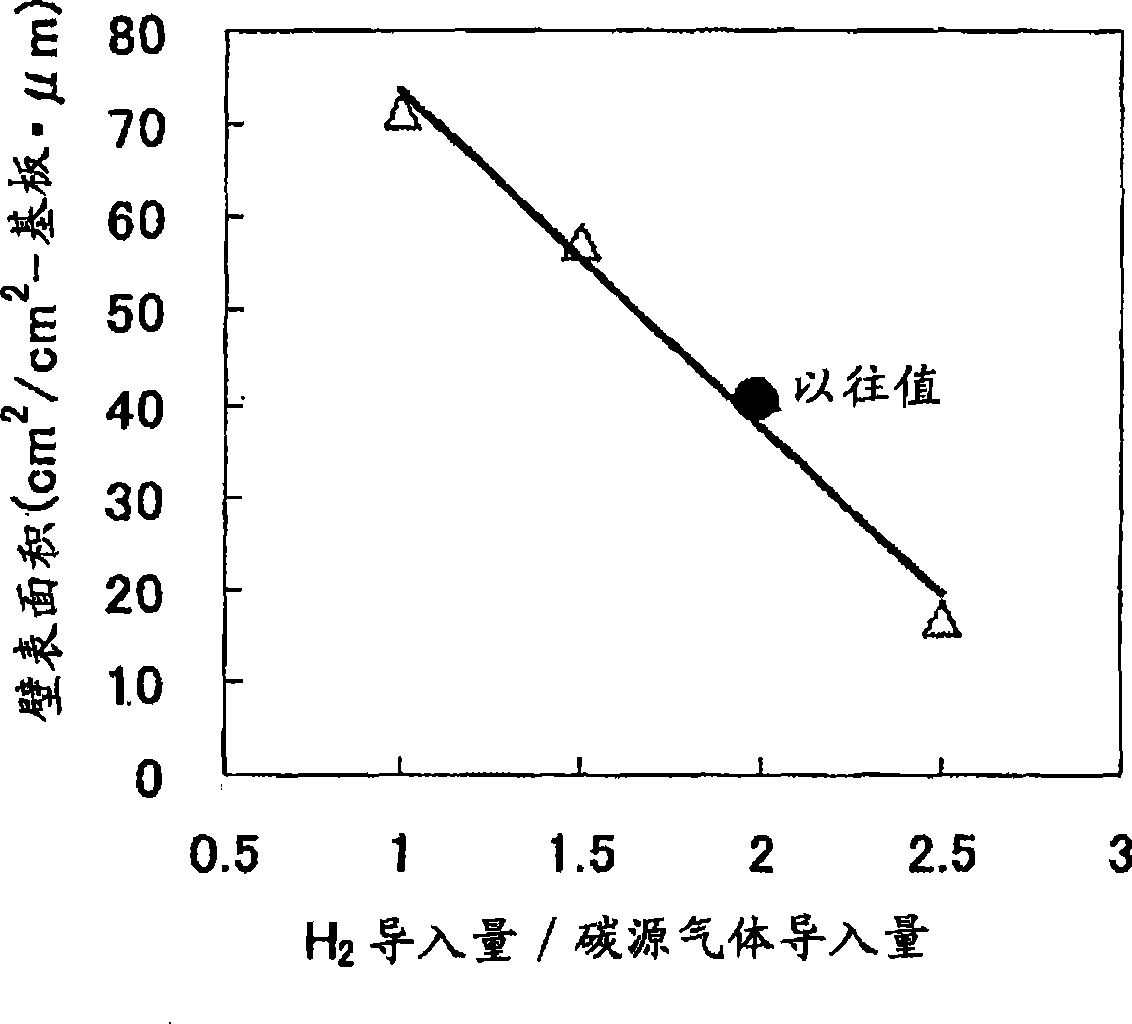

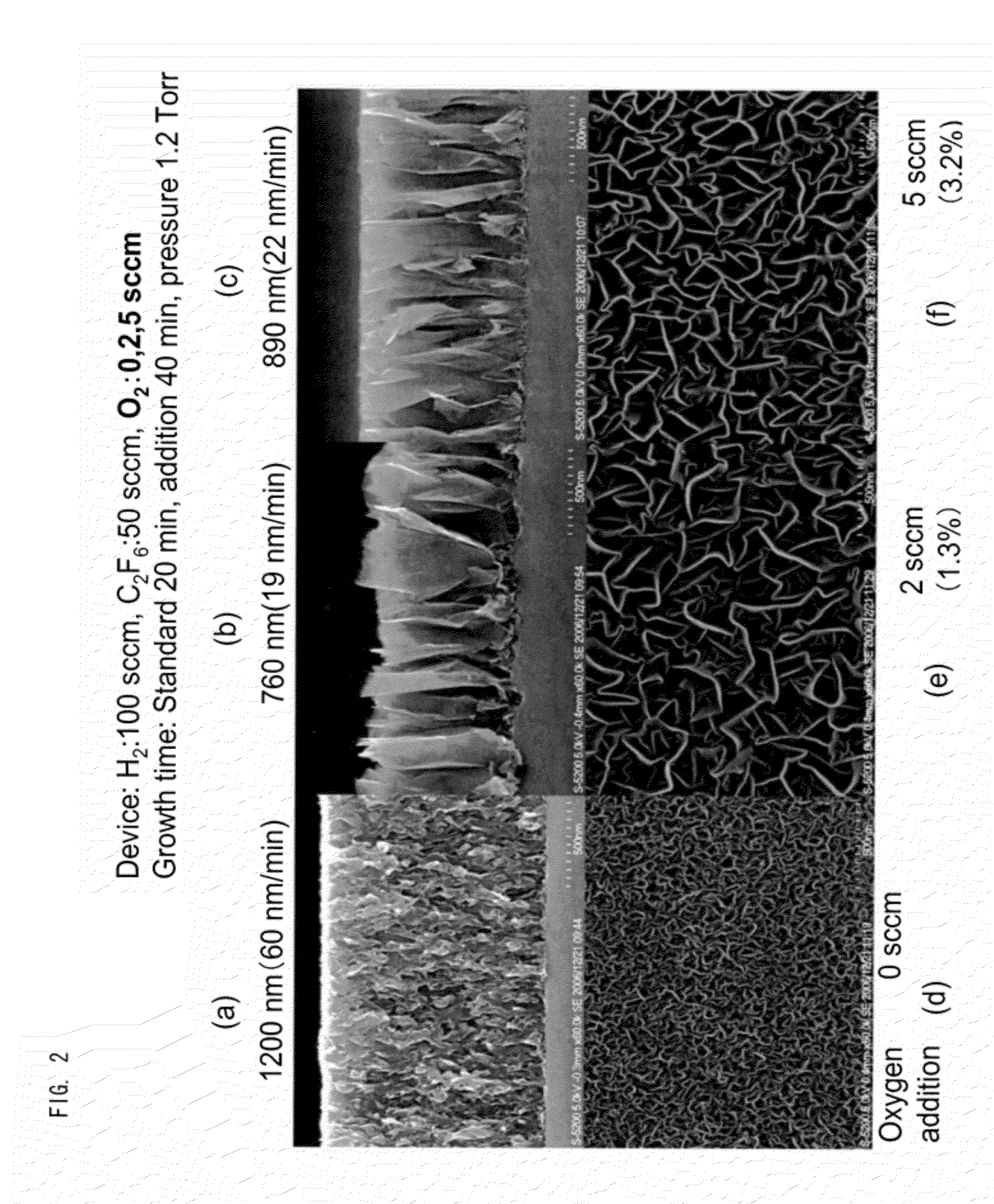

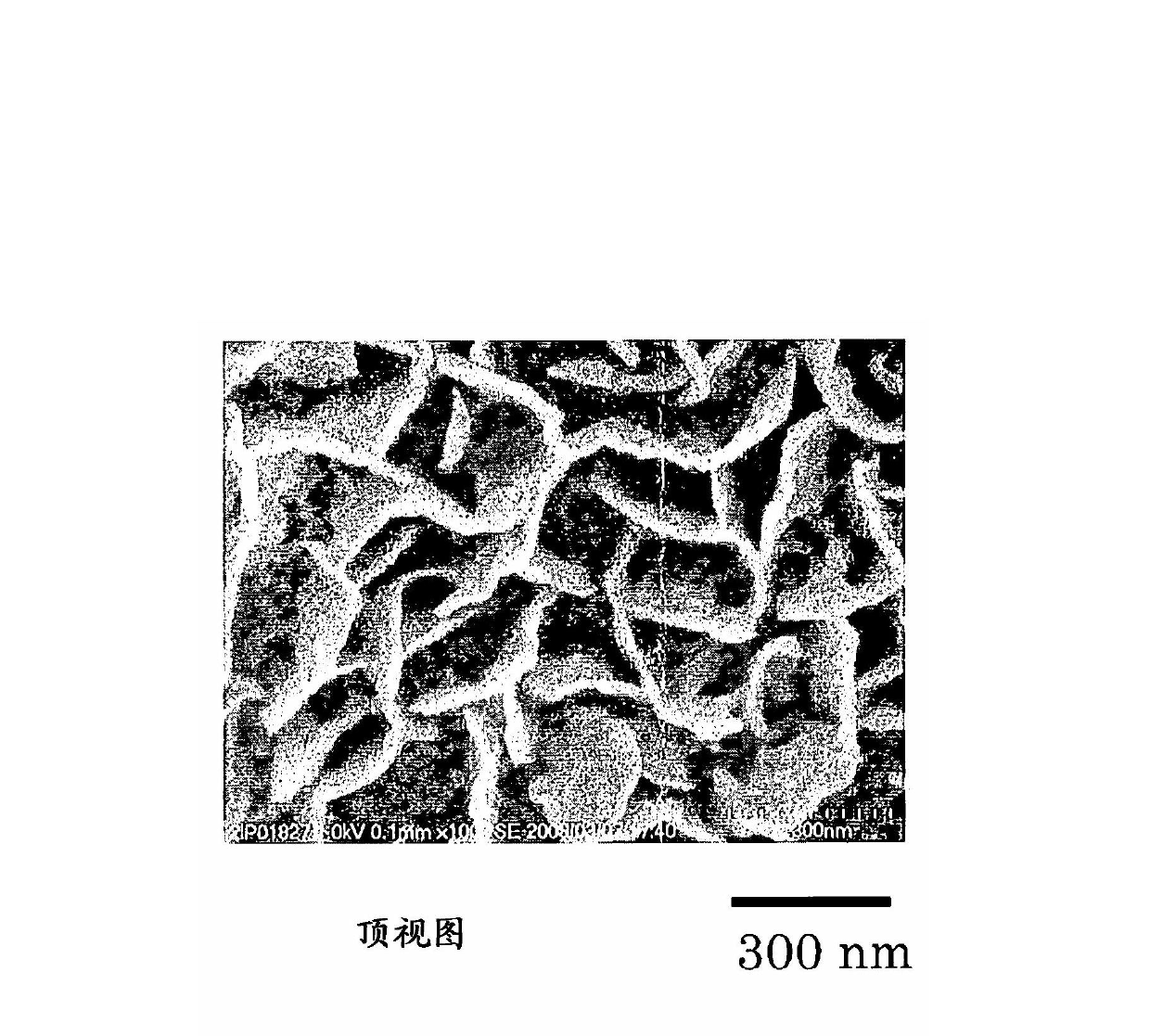

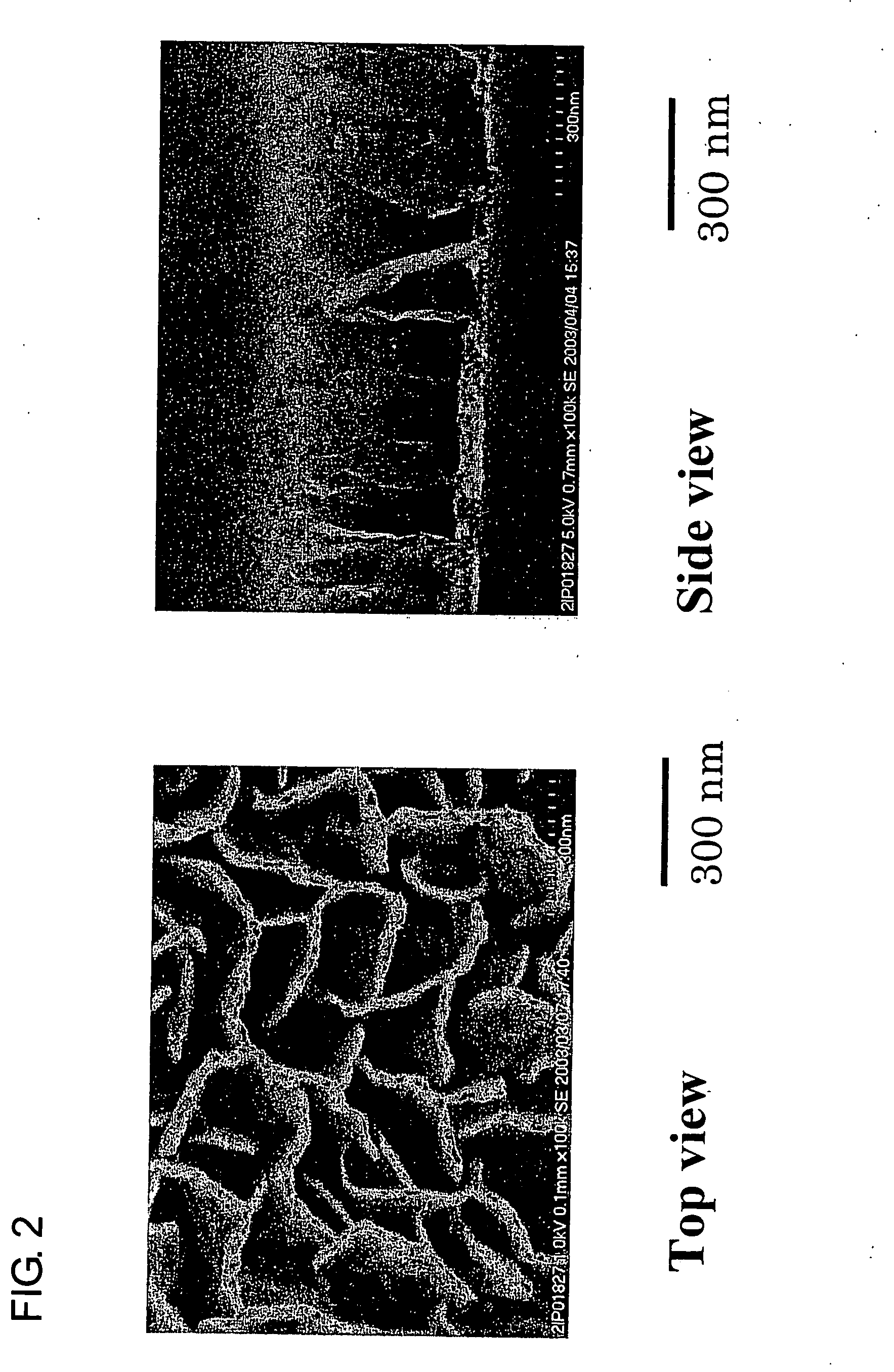

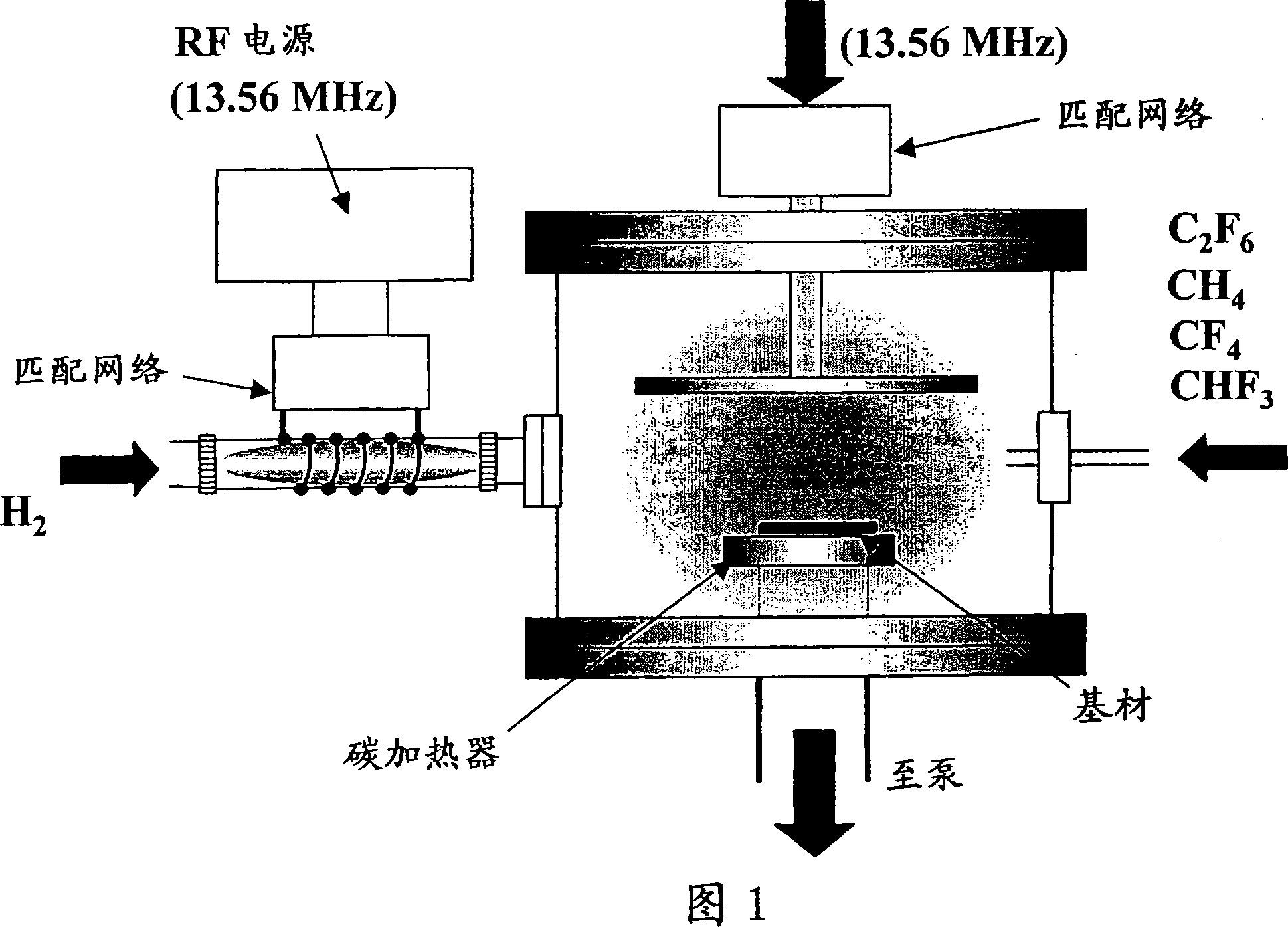

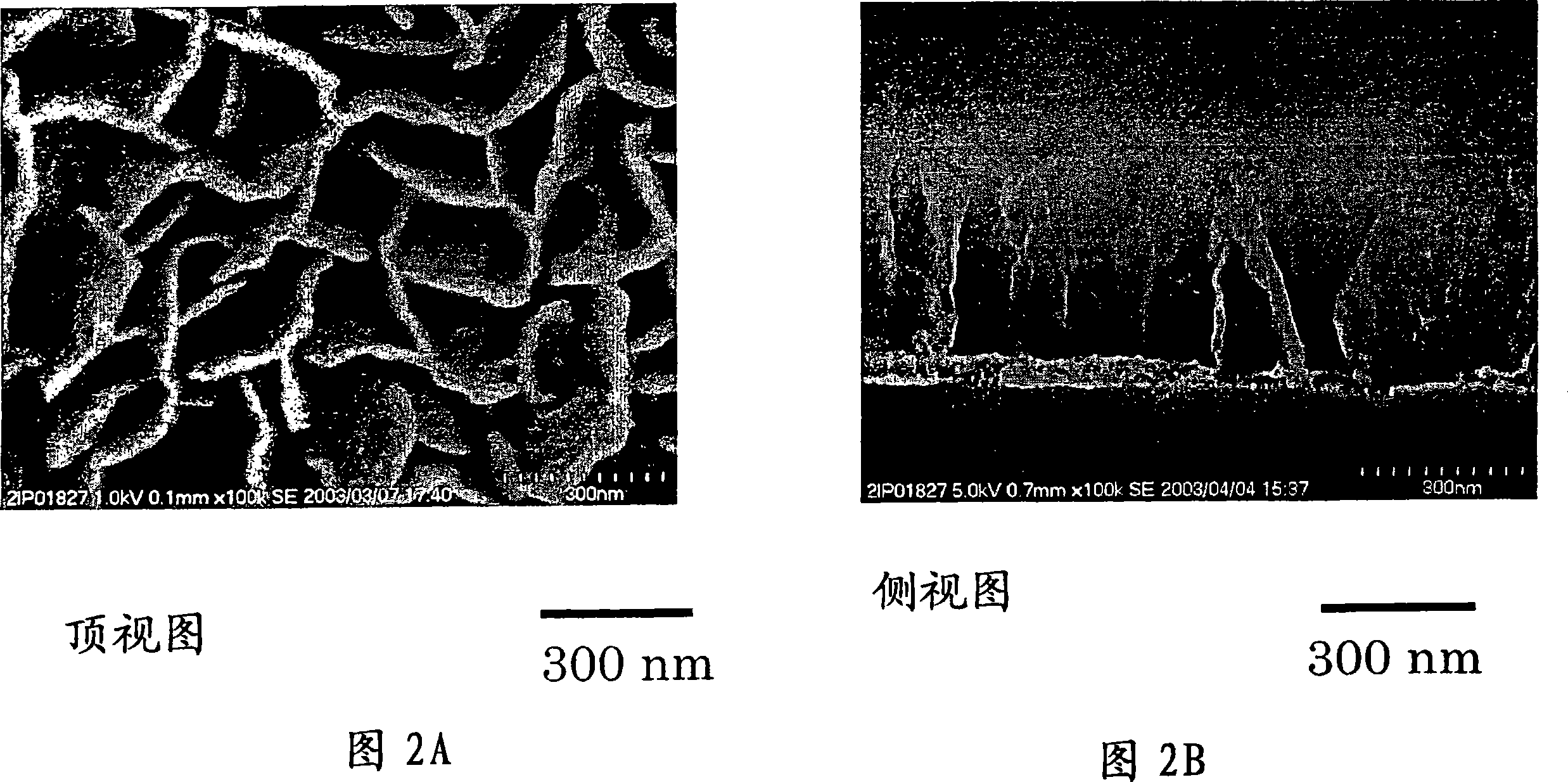

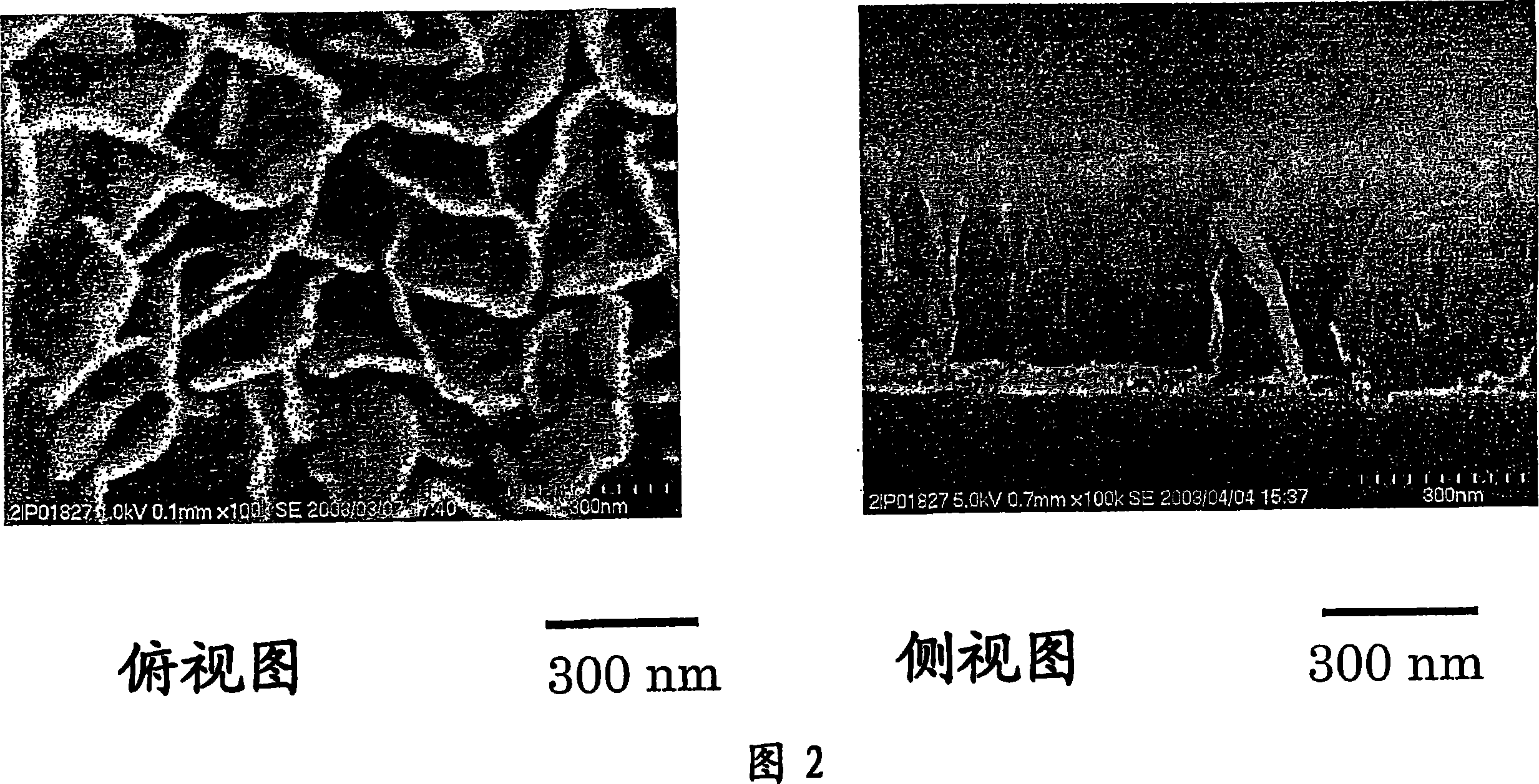

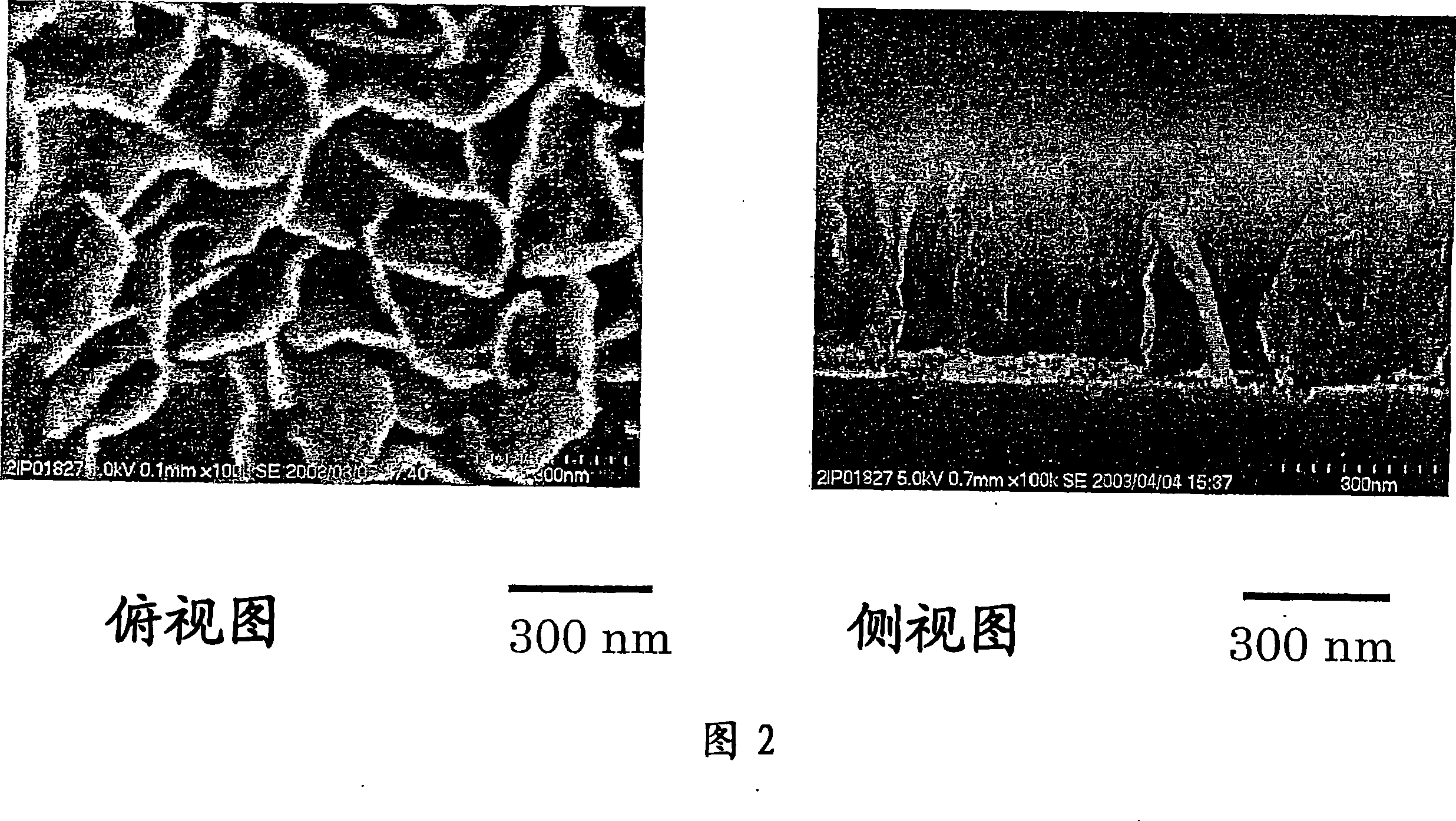

Carbon nanowall with controlled structure and method for controlling carbon nanowall structure

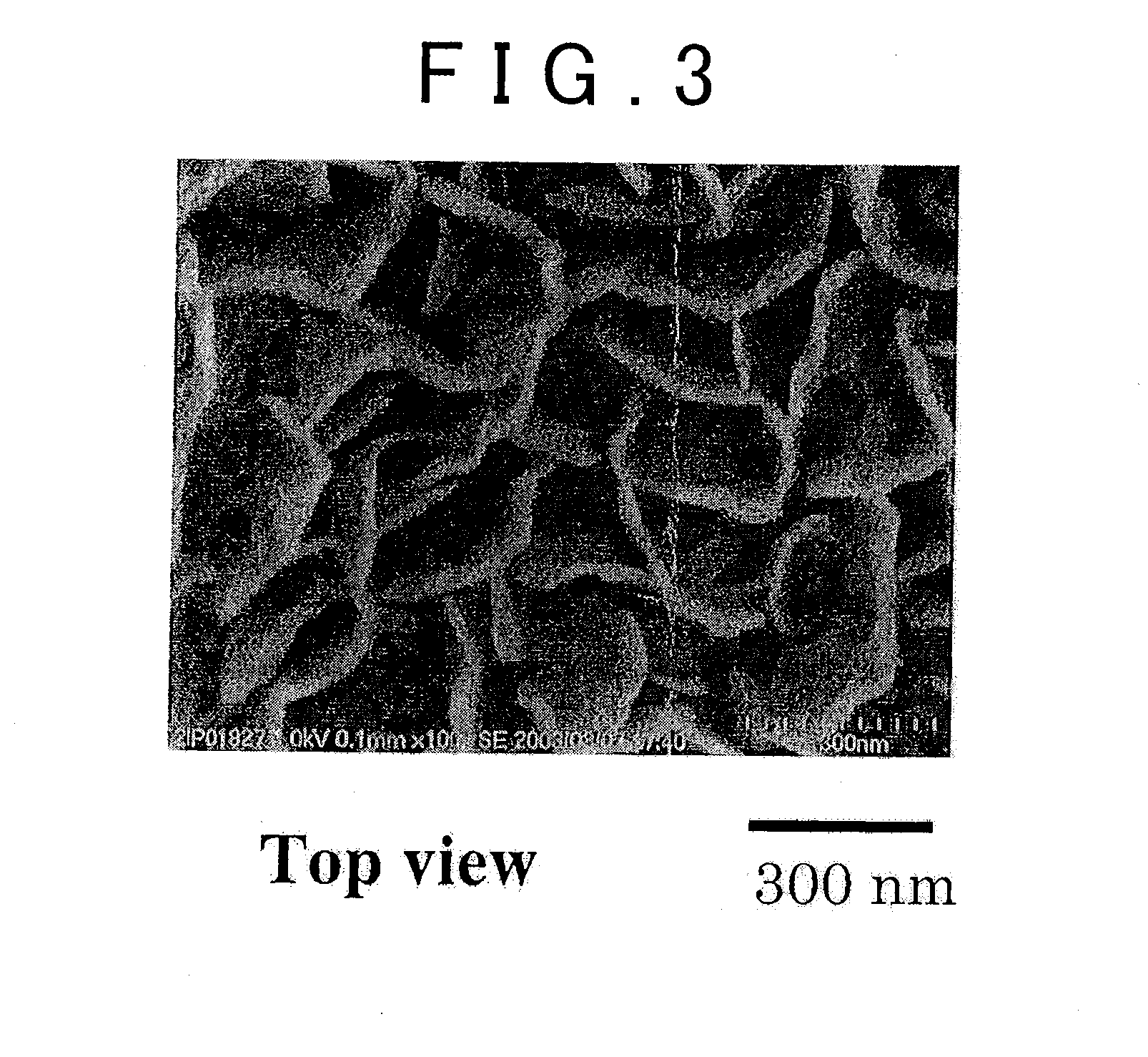

InactiveCN101489926AIncrease loading capacityControl surface areaMaterial nanotechnologyCatalyst carriersCarbon nanowallsIrradiation laser

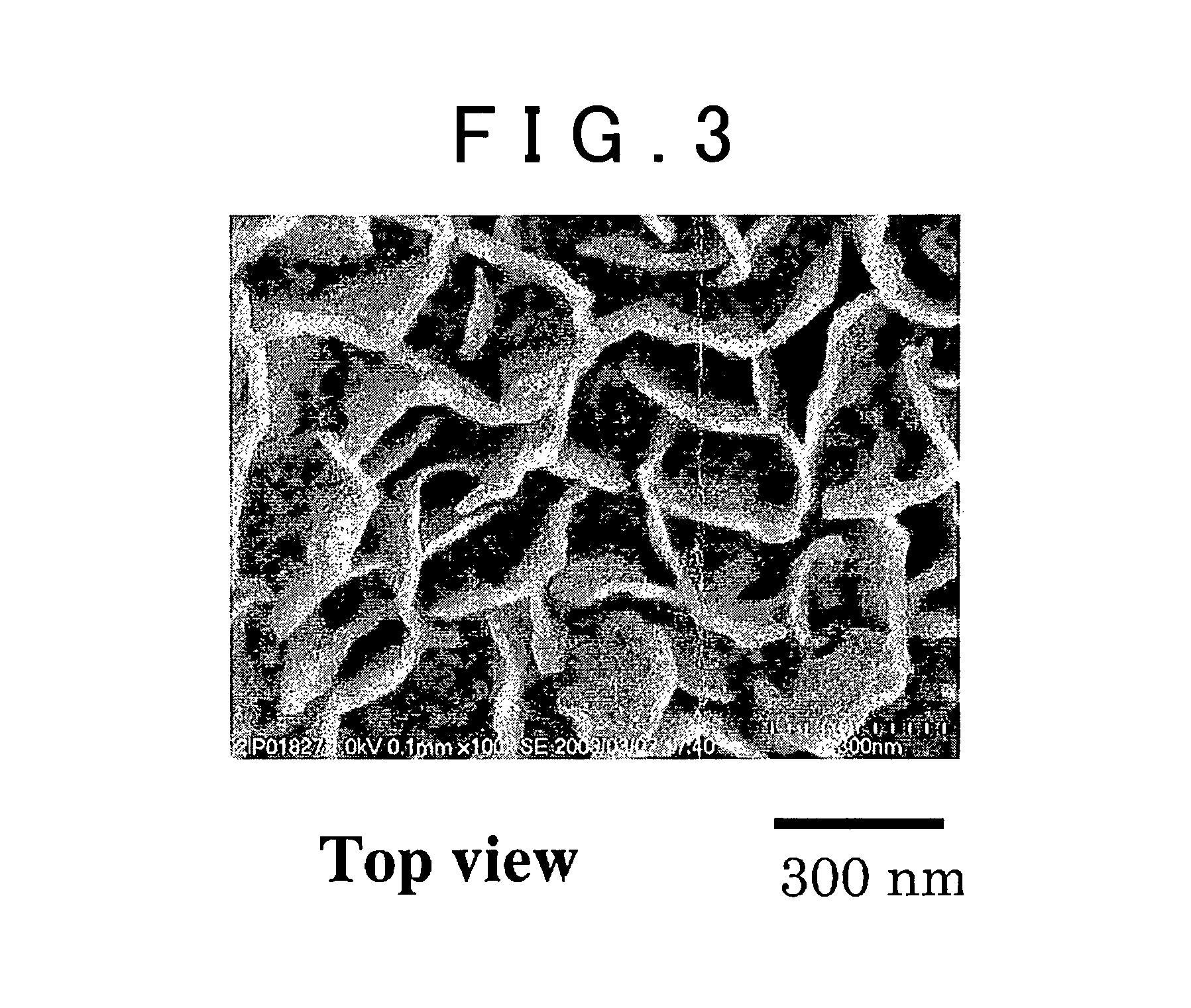

The invention provides a method of controlling the structure of carbon nanowall (CNW) in which the interwall spacing of carbon nanowall (CNW) is varied so as to control the surface area thereof or control the crystallinity thereof, thereby enhancing the corrosion resistance at high potential; and a highly crystalline carbon nanowall (CNW) and carbon nanowall (CNW) of large surface area with controlled structure. There are provided (1) carbon nanowall characterized by having a wall surface area of 50 cm / cm-substrate mum or greater, (2) carbon nanowall characterized by having a crystallinity such that the D-band half value width of Raman spectrum measured with an irradiation laser wavelength of 514.5 nm is 85 cm or less; and (3) carbon nanowall characterized by having not only a wall surface area of 50 cm / cm-substrate mum or greater but also a crystallinity such that the D-band half value width of Raman spectrum measured with an irradiation laser wavelength of 514.5 nm is 85 cm or less.

Owner:TOYOTA JIDOSHA KK

Sample substrate for laser desorption ionization-mass spectrometry, and method and device both using the same for laser desorption ionization-mass spectrometry

InactiveUS8558169B2Accurate measurementLarge specific surface areaParticle separator tubesMaterial analysis by electric/magnetic meansLaser desorption ionization mass spectrometryCarbon nanowalls

An object of the present invention is to provide a sample substrate for laser desorption ionization mass spectrometry for LDI-MS which substrate enables mass spectrometric analysis of a sample correctly at high sensitivity without generating interference peaks upon irradiation of the sample to laser light and uniform application of the sample onto a base. Another object of the invention is to provide a mass spectrometer (device) employing the sample substrate.In the sample substrate for laser desorption ionization mass spectrometry, the sample substrate is formed of a base and carbon nanowalls having wall surfaces onto which a sample to undergo mass spectrometry is applied, wherein the carbon nanowalls are formed on the base so as to stand on the base. The surfaces of carbon nanowalls serve as an ionization medium and hydrophilized. By use of the sample substrate, mass spectrometry of a sample having a wide range (high to low) molecular weight can be reliably performed at high precision and sensitivity.

Owner:HORI MASARU

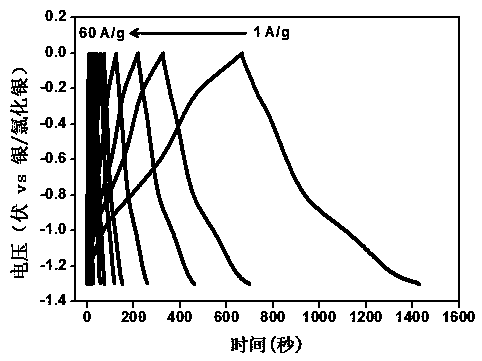

Preparation method of water system high-voltage electrode material, and application

ActiveCN109786126AImprove electrochemical performanceExcellent rate performanceHybrid capacitor electrolytesHybrid capacitor electrodesNon symmetricHigh energy

The invention discloses a preparation method of a water system high-voltage electrode material. The preparation method comprises the following steps: preparing carbon cloth / carbon nanometer wall withhigh conductivity and high specific surface as a base material; preparing Na0.5MnO2 nanosheet array through electrochemical deposition and electrochemical oxidation method; obtaining the carbon cloth / carbon nanometer wall / Na0.5MnO2 nanosheet positive material; preparing the carbon-clad porous VN nanosheet array through hydrothermal method and subsequent annealing; and obtaining the carbon cloth / carbon nanometer wall / carbon-clad porous VN nanosheet negative material. The above material is applied to preparing the asymmetric water system super capacitor. The working voltage of the asymmetric water system super capacitor prepared through the invention can achieve 2.6V, and the super capacitor has the energy density of 96.7 Whkg-1, excellent cyclic stability, and security, and an effective method is provided for designing and preparing the high-energy density super capacitor.

Owner:NANCHANG UNIV

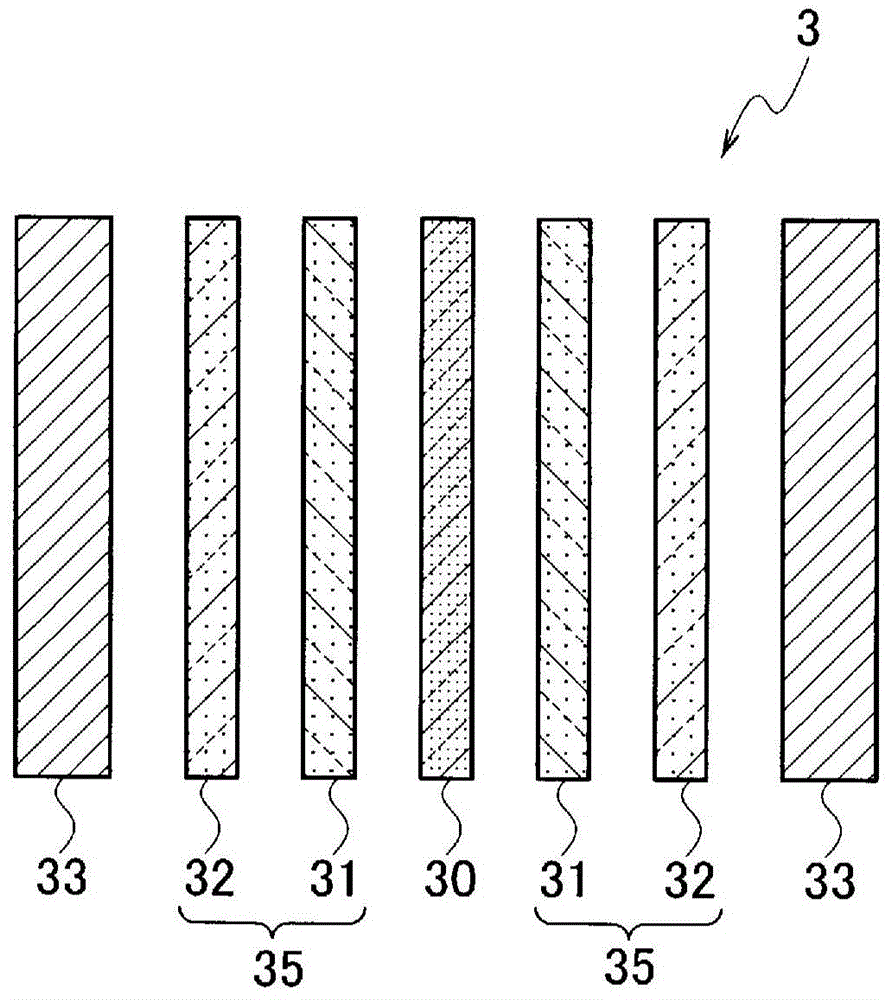

Positive electrode for lithium secondary battery, method for preparing the positive electrode, lithium secondary battery having the positive electrode, and vehicle having the lithium secondary battery

InactiveCN102668181AFilling tube/pocket electrodesElectrode carriers/collectorsCarbon nanowallsEngineering

A positive electrode (10) for a lithium secondary battery, including a positive electrode collector (20), and a positive electrode active substance layer (30) that is supported on the positive electrode collector (20) and includes carbon nanowalls (32) which are formed on the positive electrode collector (20), and a positive electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

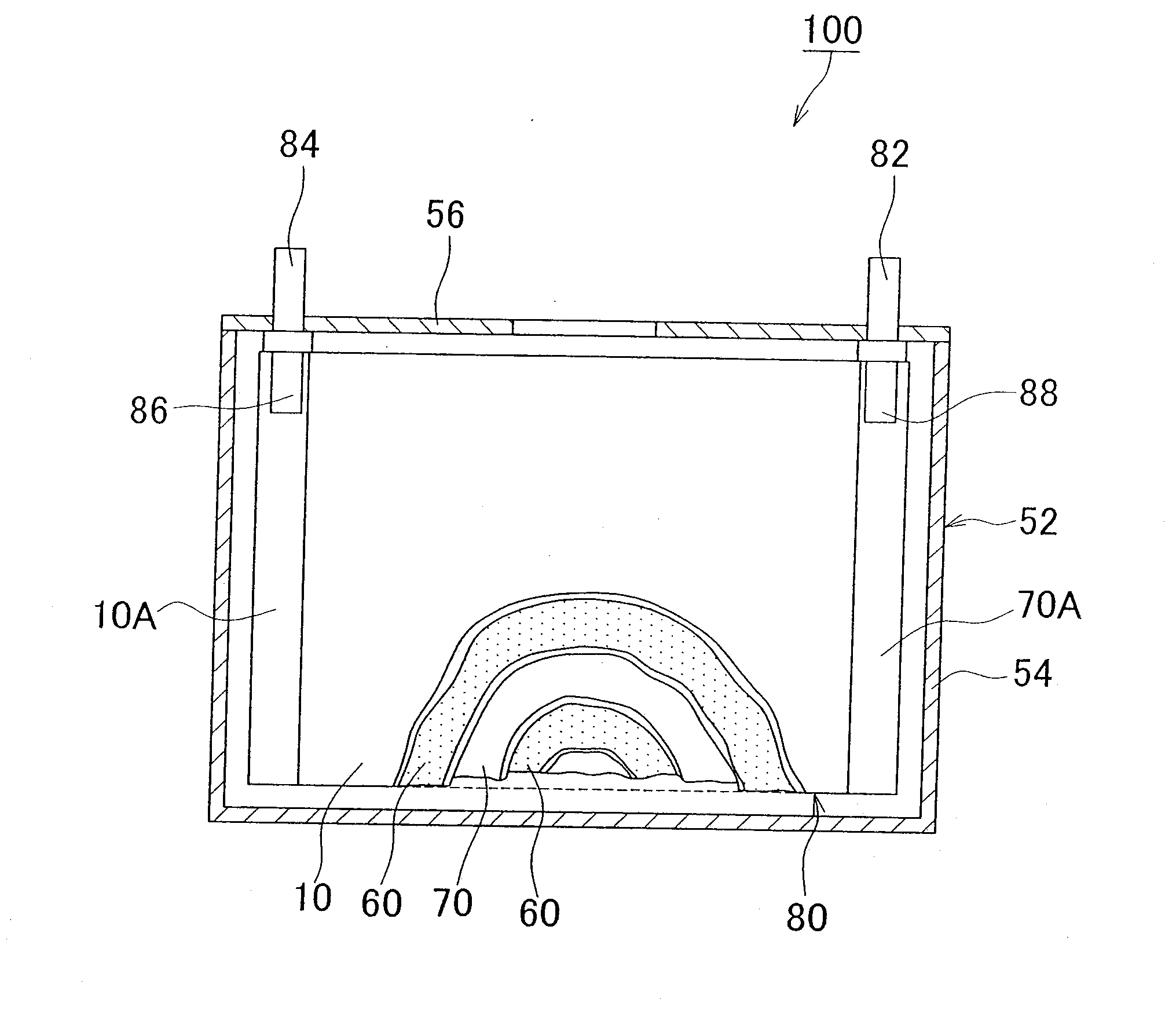

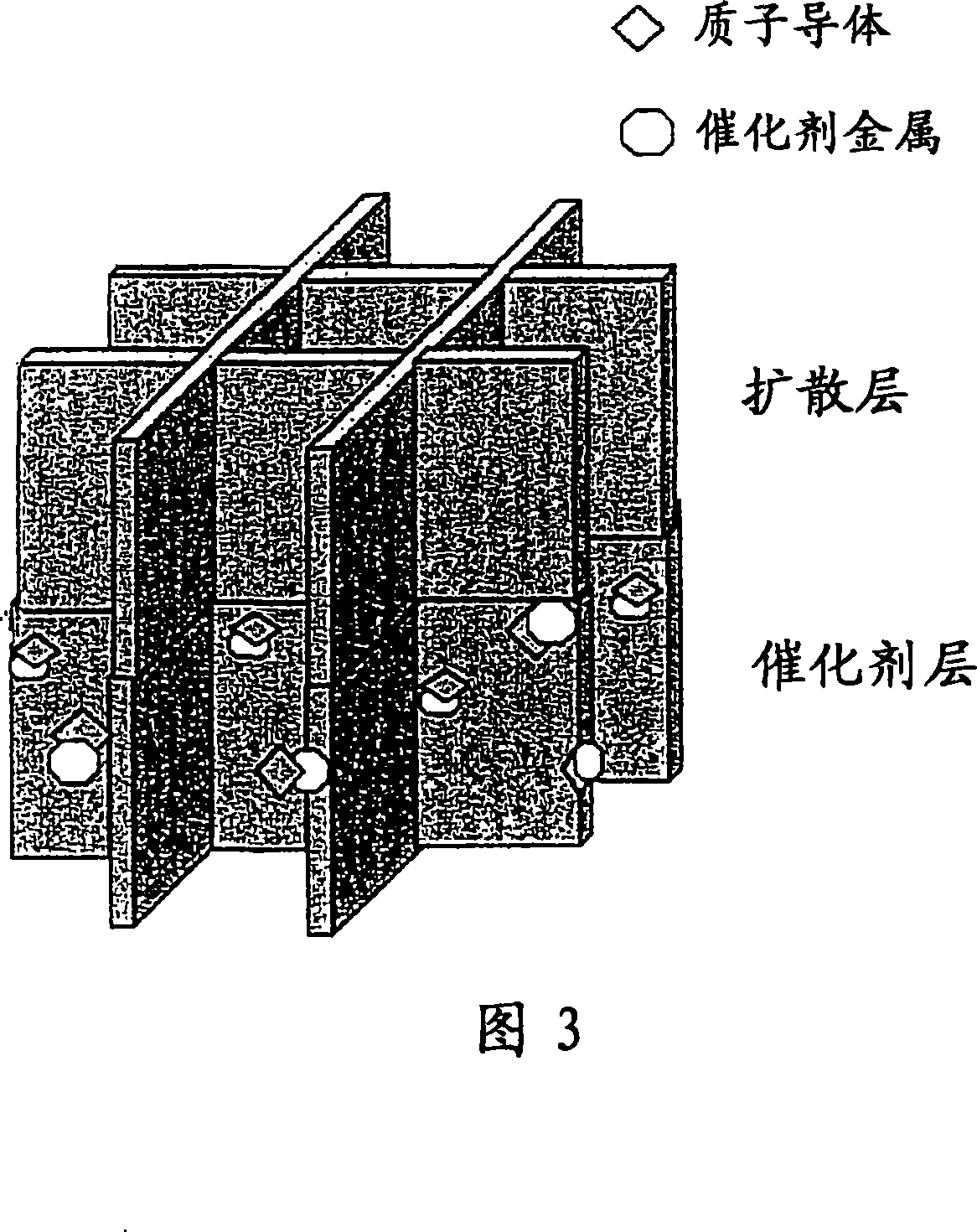

Fuel Cell Structure and Method of Manufacturing Same

InactiveUS20080187814A1Simplified cell structureReduce manufacturing costFinal product manufactureElectrode carriers/collectorsCarbon nanowallsNano size

Owner:HORI MASARU +2

Negative electrode for lithium secondary battery, method for preparing the negative electrode, lithium secondary battery having the negative electrode, and vehicle having the lithium secondary battery

ActiveUS20120225353A1Material nanotechnologyFilling tube/pocket electrodesCarbon nanowallsLithium-ion battery

A negative electrode (10) for a lithium secondary battery, including a negative electrode collector (20), and a negative electrode active substance layer (30) that is supported on the negative electrode collector (20) and includes carbon nanowalls (32) which are formed on the negative electrode collector (20), and a negative electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

Display screen and electronic device

InactiveCN110164323AShorten the cooling pathImprove cooling effectSolid-state devicesIdentification meansCarbon nanowallsHeat conducting

The invention provides a display screen and an electronic device. The display screen comprises a display panel and a heat dissipating film, the heat dissipating film is arranged on the back face of the display panel, the heat dissipating film comprises a heat conducting layer, and the heat conducting layer comprises one or more of a carbon nanowall, a metal nanowall and an oxide nanowall. According to the display screen and the electronic device, the heat dissipating effect can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Positive electrode for lithium secondary battery, method for preparing the positive electrode, lithium secondary battery having the positive electrode, and vehicle having the lithium secondary battery

InactiveUS20120214065A1Avoid breakingMaterial nanotechnologyFilling tube/pocket electrodesCarbon nanowallsEngineering

A positive electrode (10) for a lithium secondary battery, including a positive electrode collector (20), and a positive electrode active substance layer (30) that is supported on the positive electrode collector (20) and includes carbon nanowalls (32) which are formed on the positive electrode collector (20), and a positive electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

Carbon nanowall with controlled structure and method for controlling carbon nanowall structure

InactiveUS20100009242A1Increased amount of supportedLarge specific surface areaMaterial nanotechnologyCatalyst carriersCarbon nanowallsHigh surface

Provided is a method for controlling a carbon nanowall (CNW) structure having improved corrosion resistance against high potential by varying the spacing between the carbon nanowall (CNW) walls so that its surface area and crystallinity are controlled. Also provided is a carbon nanowall (CNW) with a high surface arca and a carbon nanowall (CNW) with a high crystallinity, both of which have a controlled structure. According to the present invention, provided are: (1) a carbon nanowall, characterized by having a wall surface area of 50 cm2 / cm2-substrate·μm or more; (2) a carbon nanowall, characterized by having a crystallinity such that the D band half value width in the Raman spectrum measured with an irradiation laser wavelength of 514.5 nm is 85 cm−1 or less: and (3) a carbon nanowall, characterized by having not only a wall surface area of 50 cm2 / cm2-substrate·μm or more but also a crystallinity such that the D-band half value width in the Raman spectrum measured with an irradiation laser wavelength of 14.5 nm is 85 cm−1 or less.

Owner:TOYOTA JIDOSHA KK

Metallic mold for nano-imprint, forming method of nano-pattern, and resin molding

InactiveCN101014903AIncrease surface areaImprove adhesionNanostructure manufacturePhotomechanical apparatusCarbon nanowallsNanometre

Owner:堀胜 +2

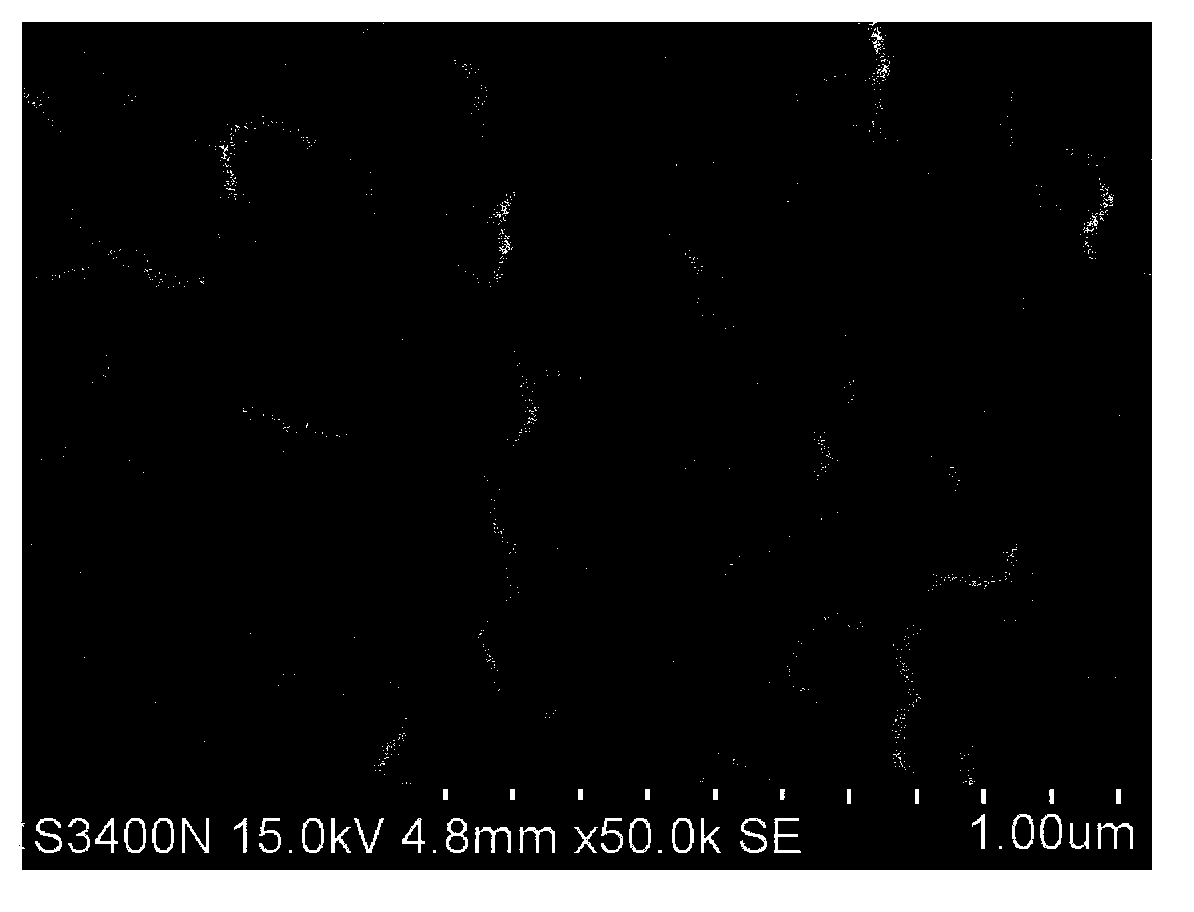

Carbon nanowall and graphene nanoribbon preparation method

ActiveCN103935975AUniform structureComplete structureMaterial nanotechnologyCarbon compoundsCarbon nanowallsGraphene nanoribbons

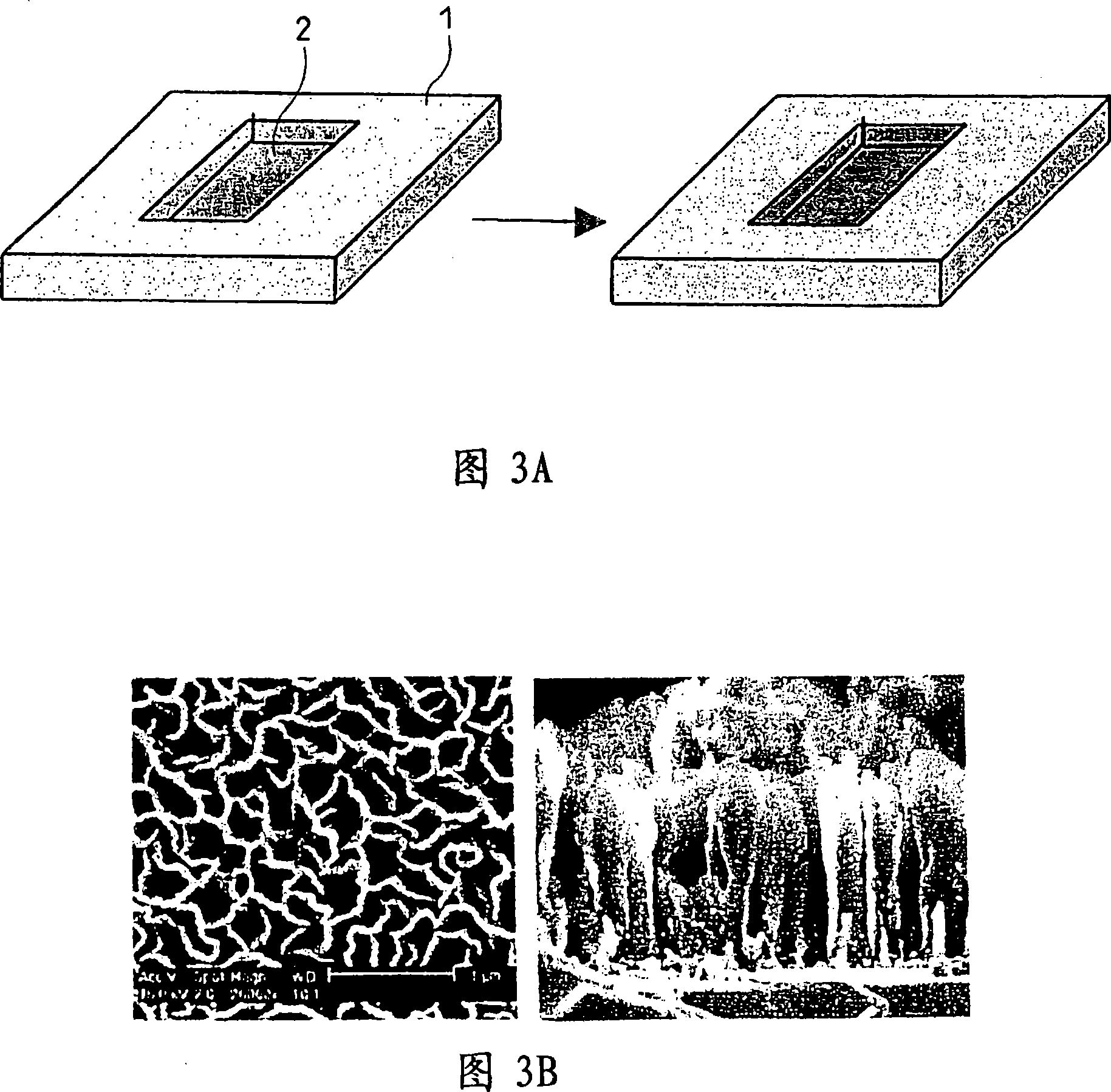

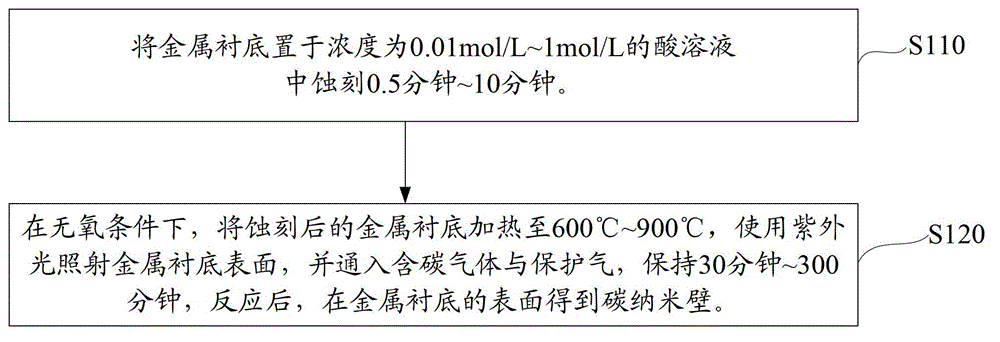

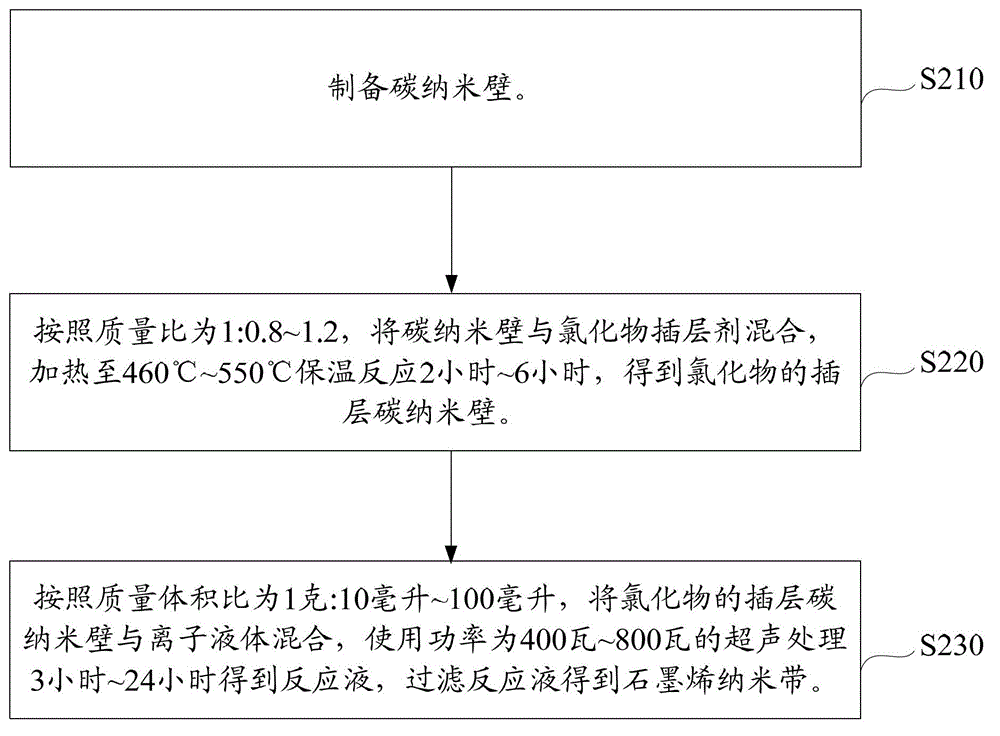

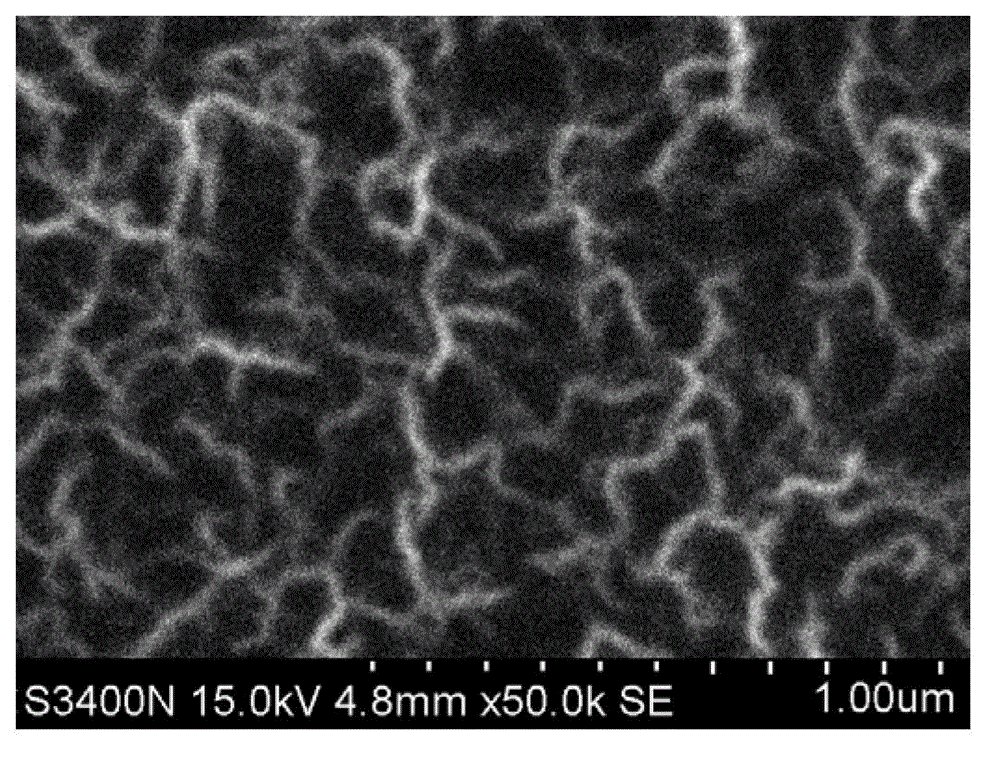

The present invention relates to a carbon nanowall and graphene nanoribbon preparation method, which comprises steps as follows: etching a metal substrate in an acid solution with a concentration between 0.01 mol / L and 1 mol / L for 0.5 minute to 10 minutes; heating the etched metal substrate to between 600 and 900 DEG C under -oxygen-free conditions, exposing the metal substrate to ultraviolet radiation for 30 minutes to 300 minutes under flux of a carbon-containing gas and a protective gas, after the reaction, and obtaining carbon nanowalls on the surface of the metal substrate; wherein the flow rate of the carbon-containing gas is between 10 sccm to 1000 sccm, the flow rate ratio of the carbon-containing gas to the protective gas is 2 to 10:1. According to the present invention, the carbon nanowalls prepared by the method above have the characteristics of uniform thickness and more complete structure. In addition, a method for preparing graphene nanoribbons is provided.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

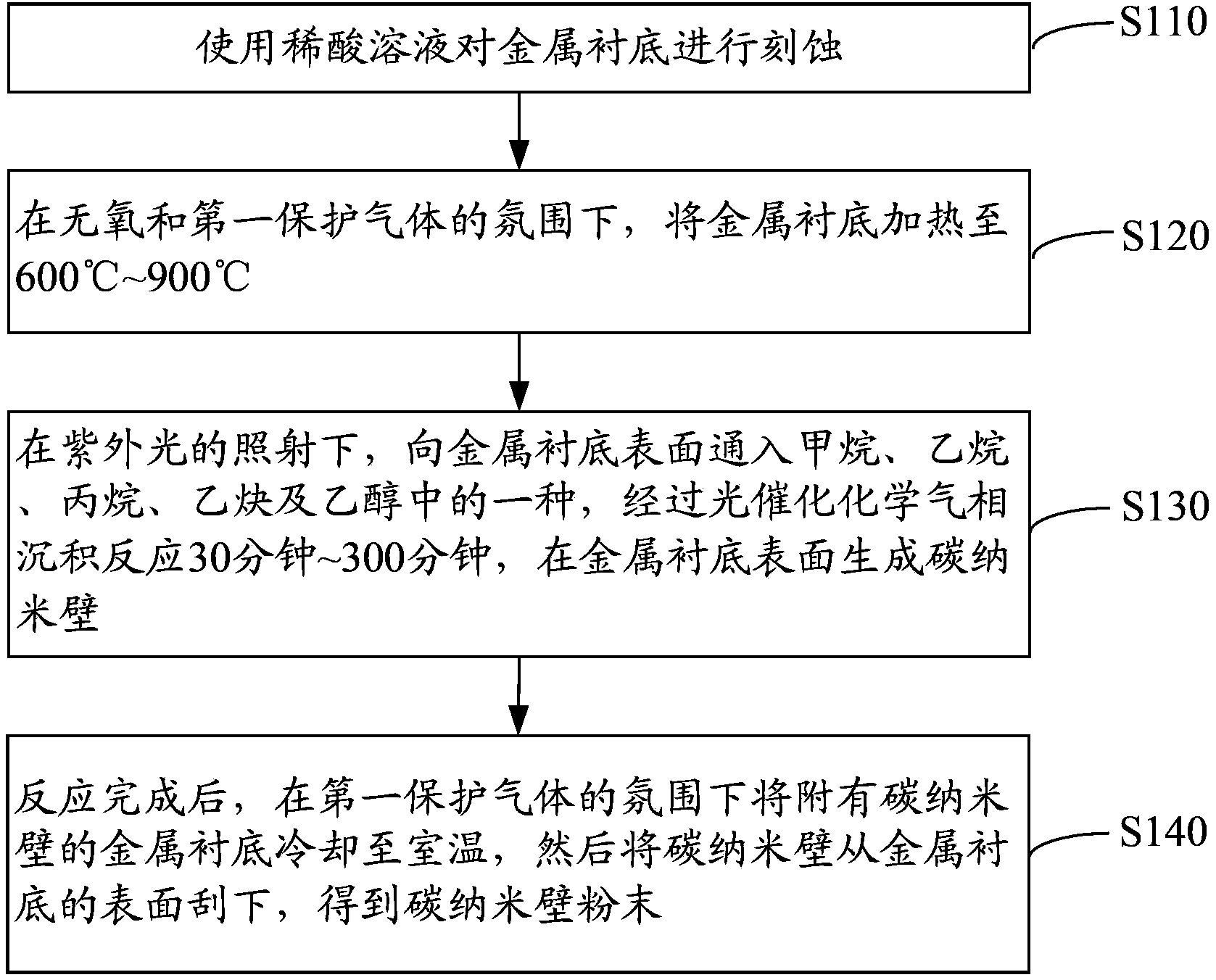

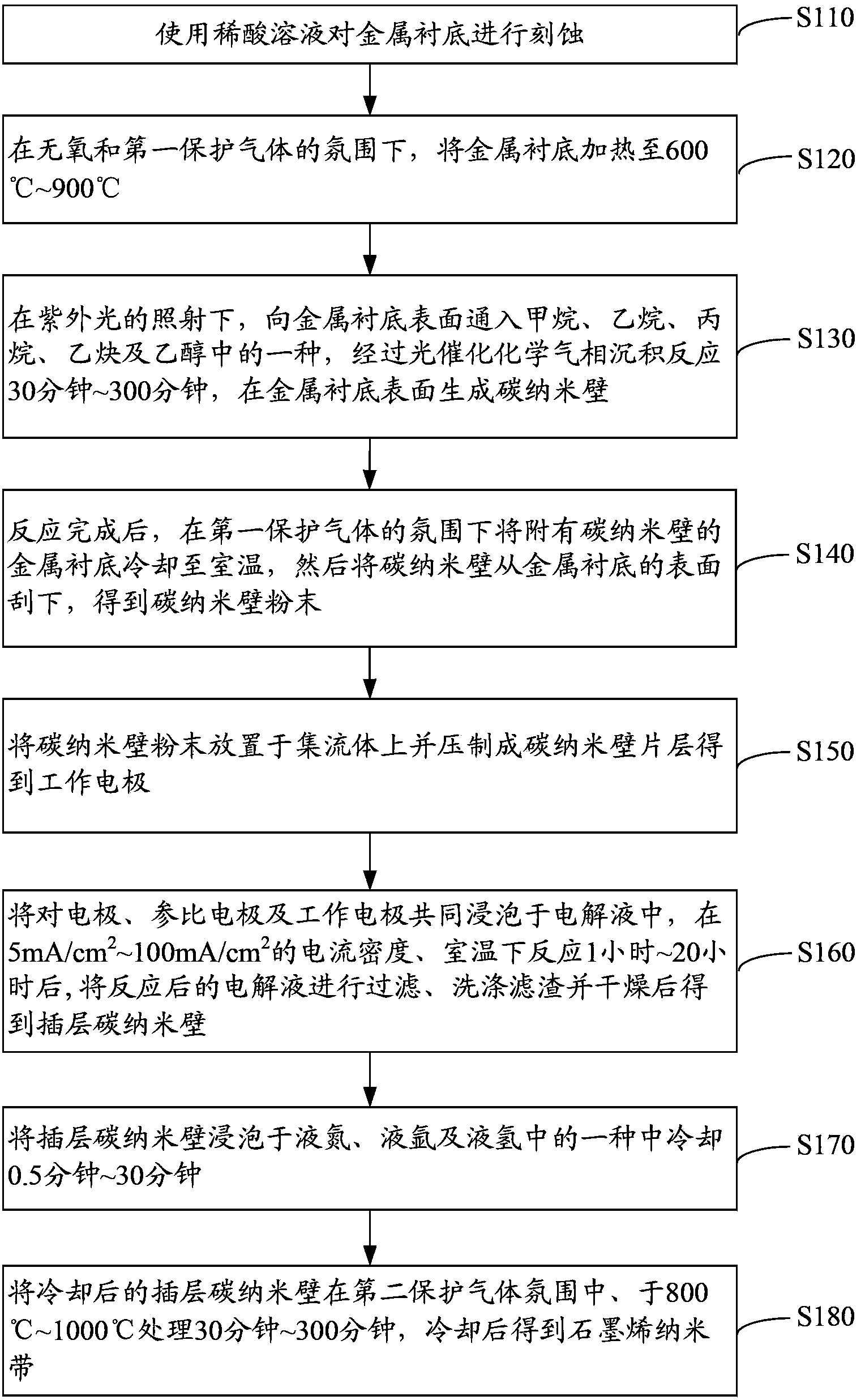

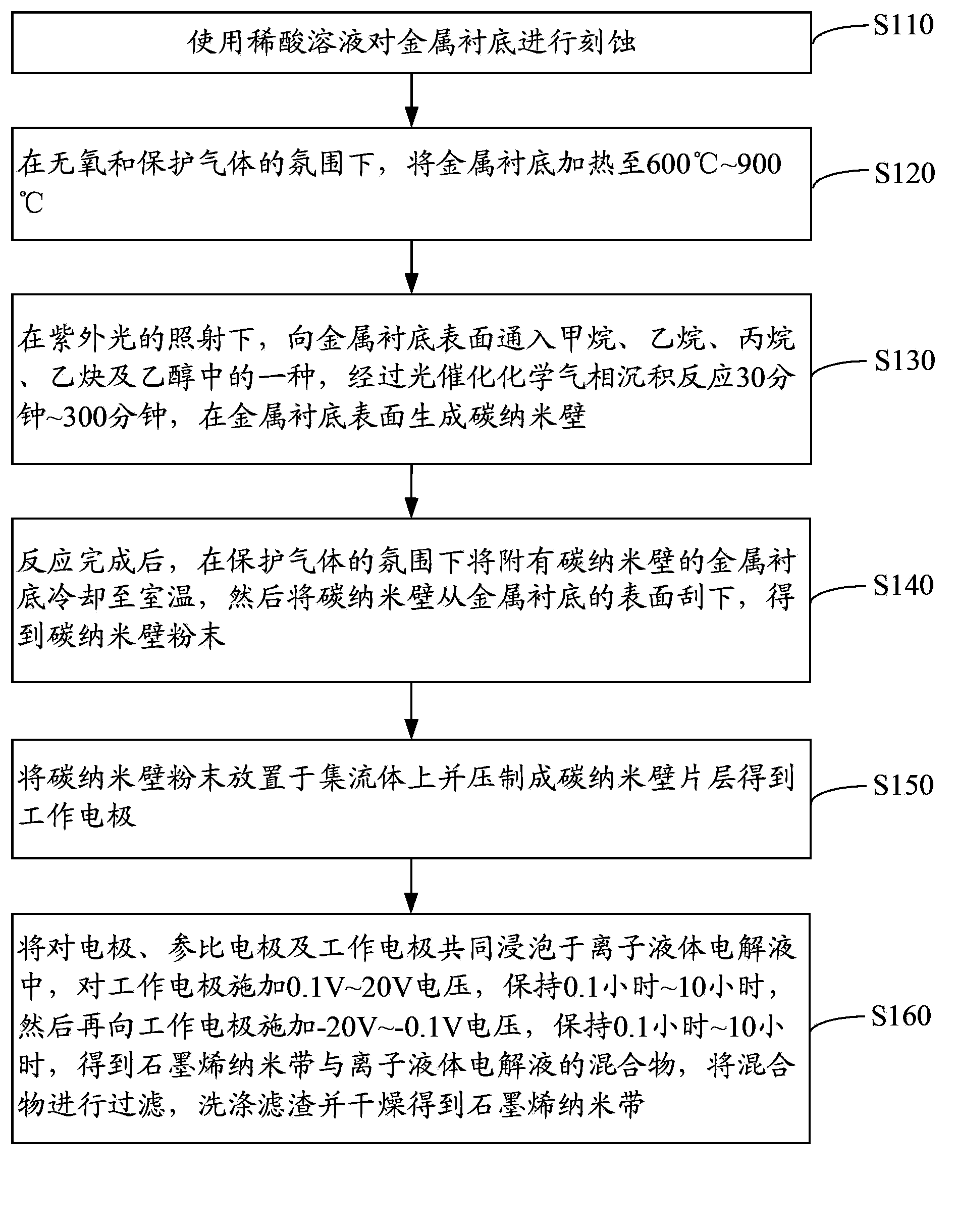

Preparation method of carbon nanowall powder, and preparation method of graphene nanobelt

ActiveCN103879995AComplete structureAvoid destructionMaterial nanotechnologyGrapheneGas phaseShielding gas

The invention provides a preparation method of carbon nanowall powder. The method comprises the following steps: etching a metal substrate by a dilute acid solution; heating the metal substrate in anoxic and first protection gas atmosphere to 600-900DEG C; introducing one of methane, ethane, propane, acetylene and ethanol to the surface of the metal substrate under the irradiation of ultraviolet light, and carrying out a photocatalytic chemical vapor deposition reaction for 30-300min to generate a carbon nanowall on the surface of the metal substrate; and cooling the metal substrate attached with the carbon nanowall in the first protection gas atmosphere to room temperature, and scraping off the carbon nanowall from the surface of the metal substrate to obtain the carbon nanowall powder. The carbon nanowall with a complete structure can be obtained through the method. The invention also provides a preparation method of a graphene nanobelt.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

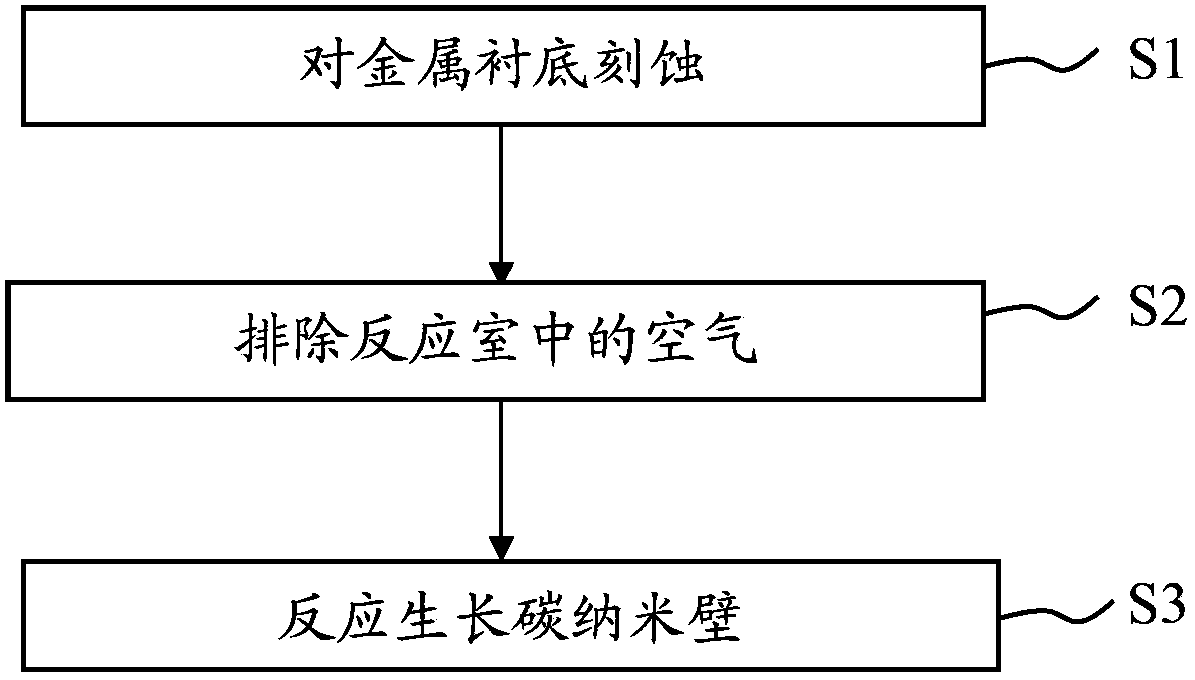

Preparation method of carbon nanowalls

InactiveCN103420354AUniform surface thicknessSimple preparation processNanotechnologyNano-carbonCarbon nanowallsTwo step

The invention discloses a preparation method of carbon nanowalls. The method comprises steps of etching a metal substrate with an acid solution having a concentration of 0.01-1 mol / L; placing the etched metal substrate into a reaction chamber, and eliminating air in the reaction chamber; and heating the metal substrate in the reaction chamber to 700-1100 DEG C, then continuously inletting a gas mixture containing a protective gas and a carbon source gas in a volume ratio of 1:2-10 into the reaction chamber that has eliminated air to perform a reaction, and maintaining for 1-300 min to grow the carbon nanowalls on the surface of the metal substrate. The preparation method adopts an etching and chemical vapor deposition two-step method to prepare the carbon nanowalls. The preparation method has simple preparation technology and easily controllable conditions. The preparation method is capable of shortening the etching time, improving the production efficiency, reducing the production cost, and effectively avoiding usage of plasma in the prior art to prepare the carbon nanowalls. The carbon nanowalls prepared by the method are dense.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

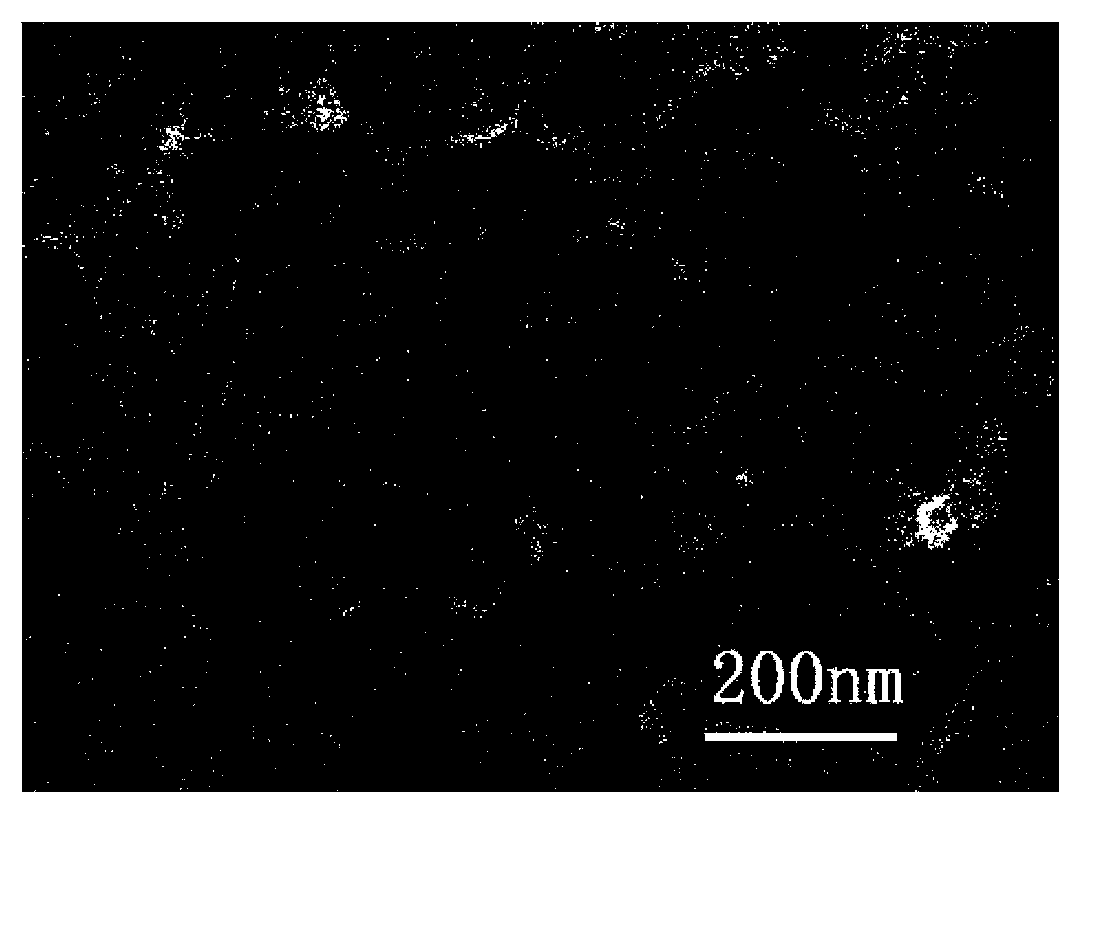

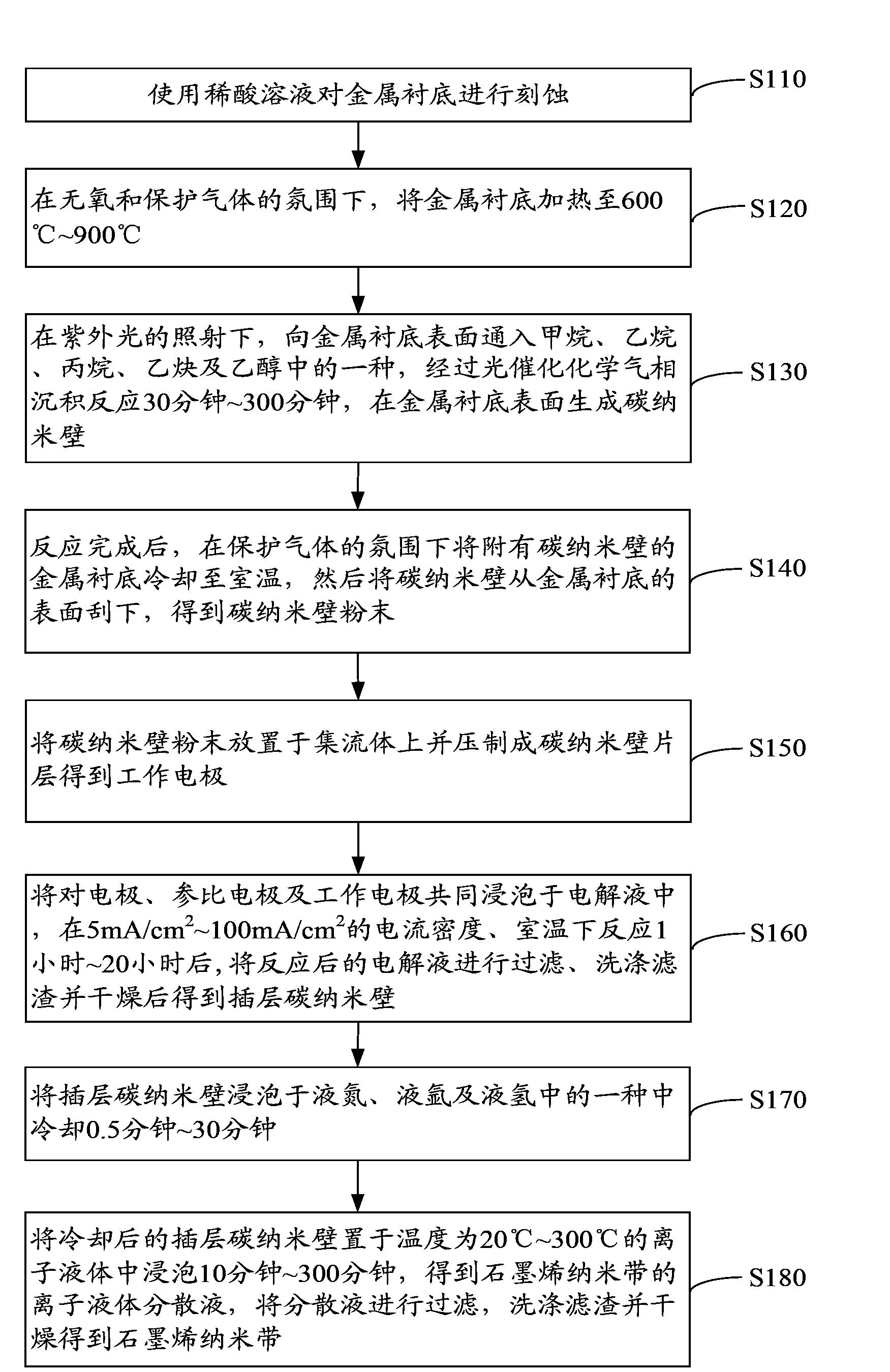

Preparation method of graphene nanobelt

ActiveCN103879993AEnsure Structural IntegrityQuality improvementGrapheneNanotechnologyCarbon nanowallsGas phase

A preparation method of a graphene nanobelt comprises the following steps: carrying out a photocatalytic chemical vapor deposition reaction on a carbon source under the action of ultraviolet light as a photocatalyst in order to generate a carbon nanowall on an etched metal substrate, scrapping off the carbon nanowall to obtain carbon nanowall powder, using the carbon nanowall powder as a raw material for preparing the graphene nanobelt, and peeling through an instant huge intercalation carbon nanowall temperature difference caused by alternated cooling and heating in order to obtain the graphene nanobelt with a high dimensional homogeneity. The method can maximally maintain the structural integrity of the graphene nanobelt, and makes no oxygen-containing groups introduced into the finally obtained graphene nanobelt, and the graphene nanobelt with a good quality can be prepared through the method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

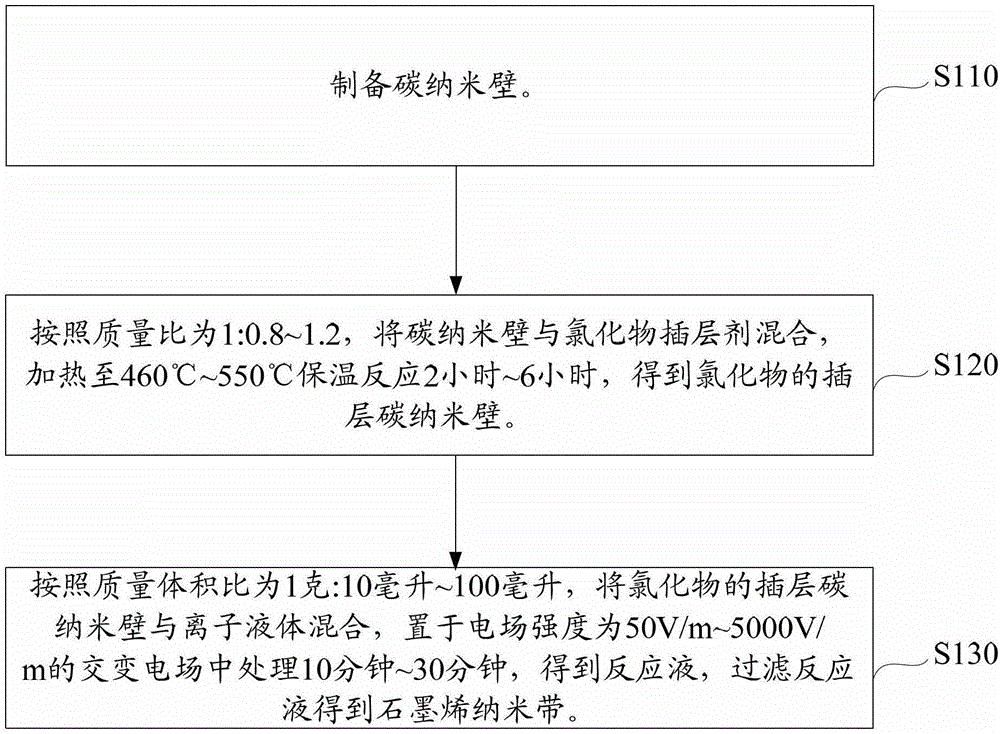

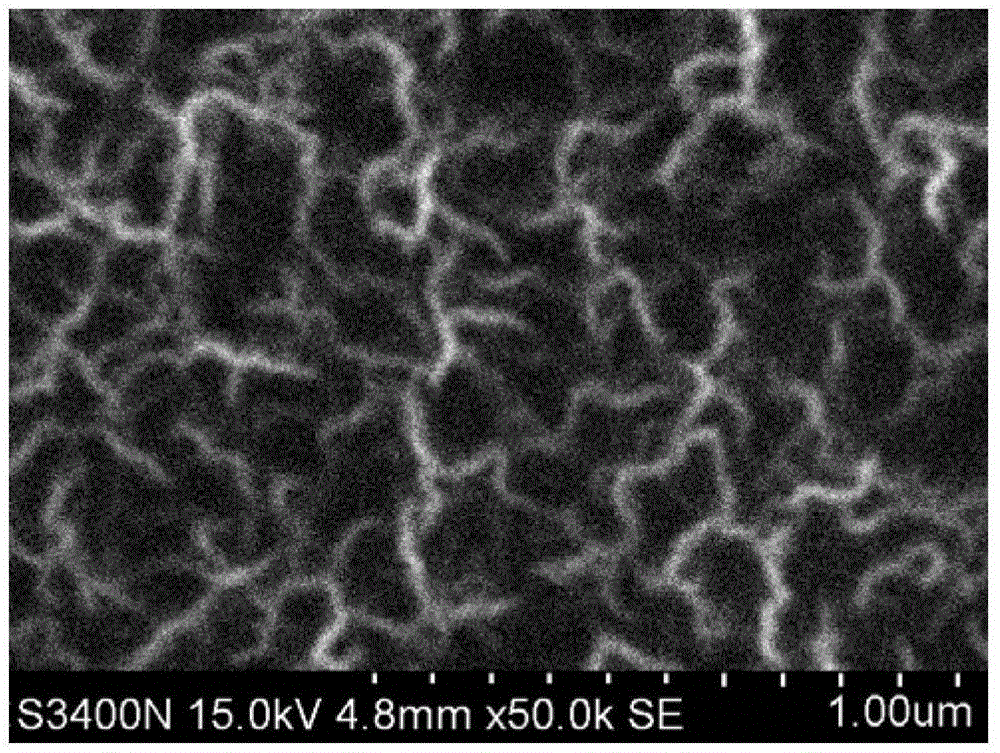

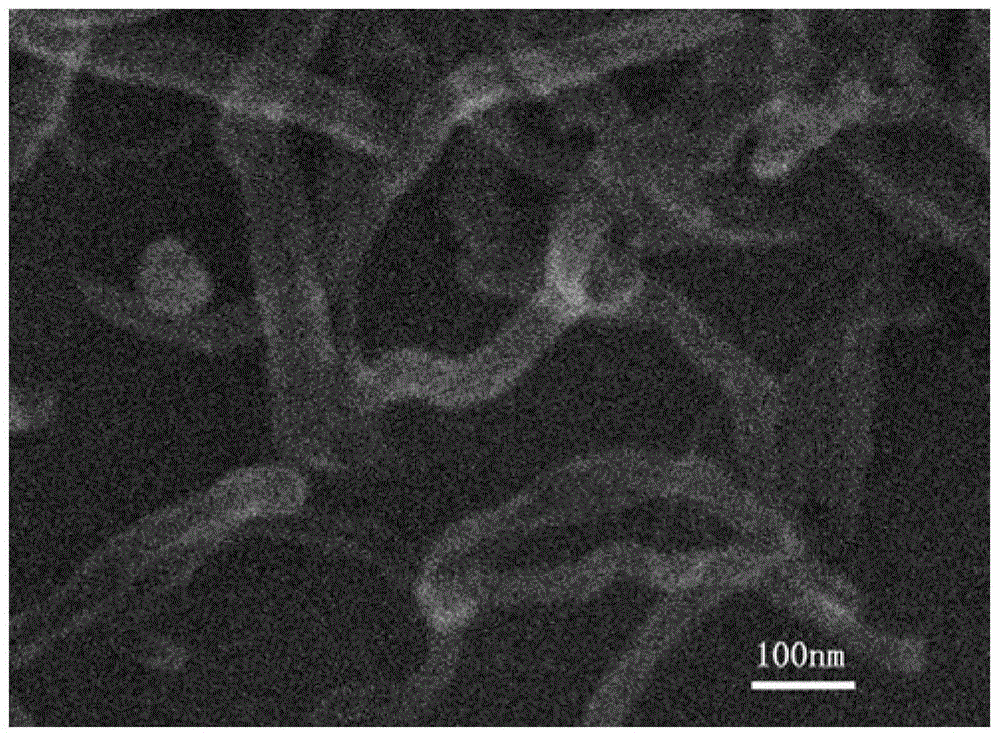

Graphene nanoribbon preparation method

ActiveCN103935983AAvoid reunionImprove integrityMaterial nanotechnologyGrapheneCarbon nanowallsElectrical field strength

The present invention relates to a graphene nanoribbon preparation method, which comprises steps as follows: etching a metal substrate in an acid solution; then heating the etched metal substrate to between 600 and 900 DEG C under anaerobic conditions, exposing the metal substrate to ultraviolet radiation under flux of a carbon-containing gas and a protective gas; after the reaction, obtaining carbon nanowalls on the surface of the metal substrate; mixing the carbon nanowalls and a chloride intercalating agent at a mass ratio of 1 : (0.8 to 1.2), heating to between 460 and 550 DEG C, and maintaining the temperature and reacting for 2 hours to 6 hours to obtain the chloride intercalated carbon nanowalls; and mixing the chloride intercalated carbon nanowalls and an ionic liquid at a volume / mass ratio of 1 g: 10 ml to 100 ml, and processing the mixture in an alternating electric field with intensity of 50 V / m to 5000 V / m for 10 minutes to 30 minutes to obtain a reaction solution, which is filtered to obtain graphene nanoribbons. The graphene nanoribbons prepared by the method mentioned above have high electrical conductivity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

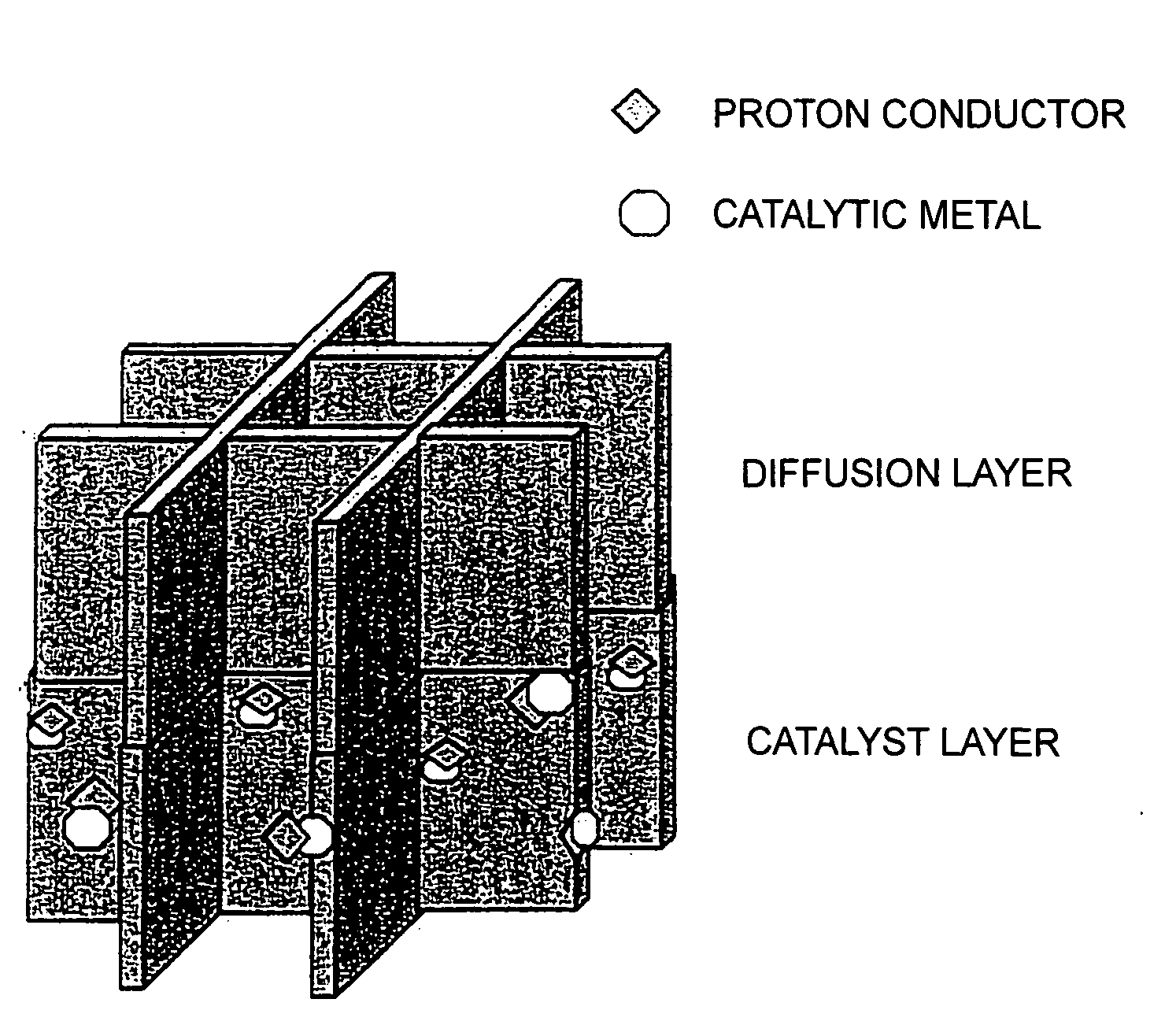

Method and apparatus for producing catalyst layer for fuel cell

InactiveCN101120468AImprove performanceSimplify the manufacturing processMaterial nanotechnologyCell electrodesCarbon nanowallsFuel cells

A method for manufacturing a catalyst layer for a fuel cell support for a catalyst layer comprises the steps of vapor-growing a carbonaceous porous material having a nano-size structure, such as carbon nanowalls (CNWs), and supporting and dispersing a catalyst component and / or an electrolyte component on the support for a catalyst layer. The method simplifies the process for manufacturing an electrode layer for fuel cells and improves the dispersibility of the catalyst component and the electrolyte, whereby the generation efficiency of a fuel cell can be improved.

Owner:堀胜 +2

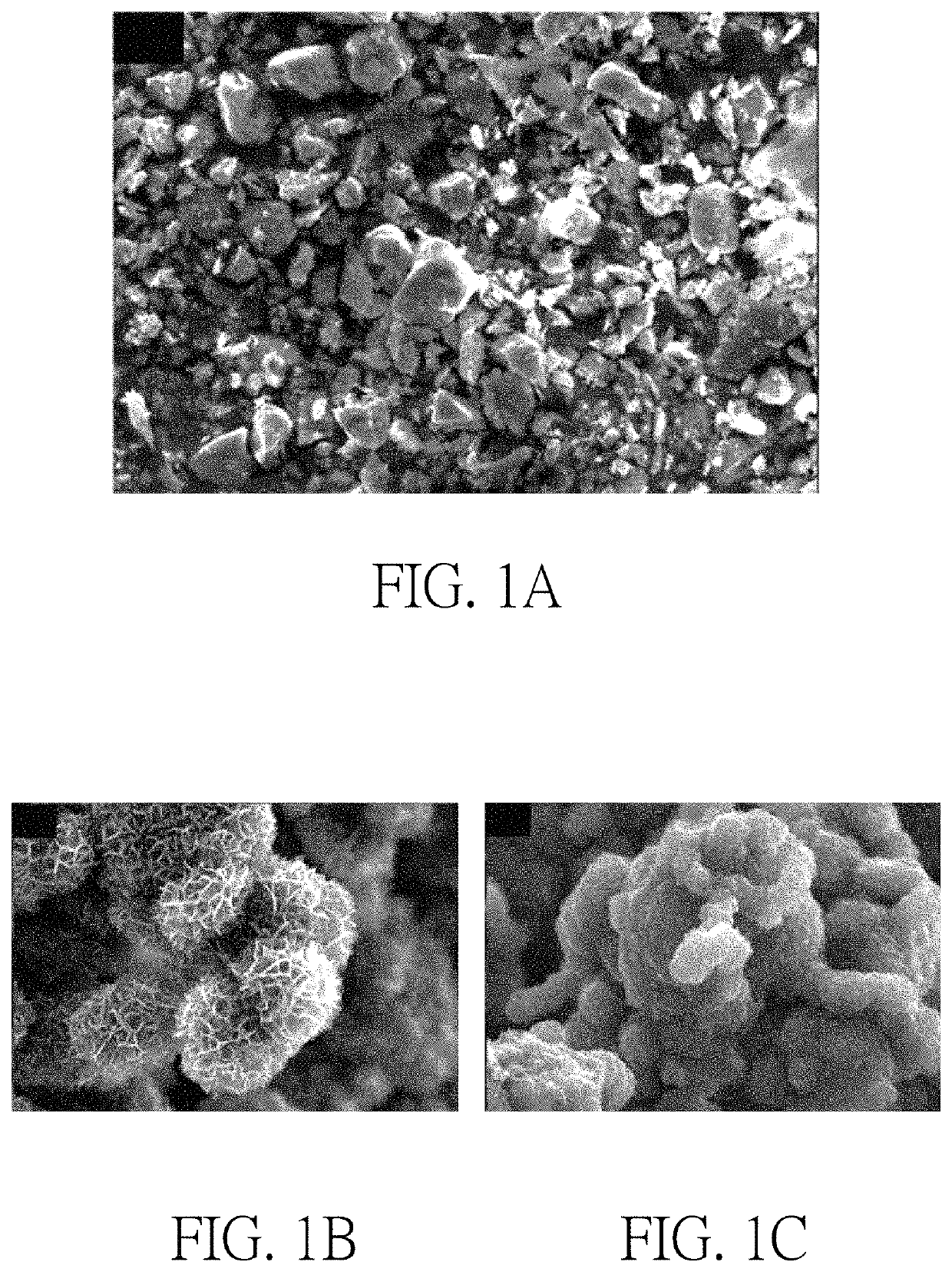

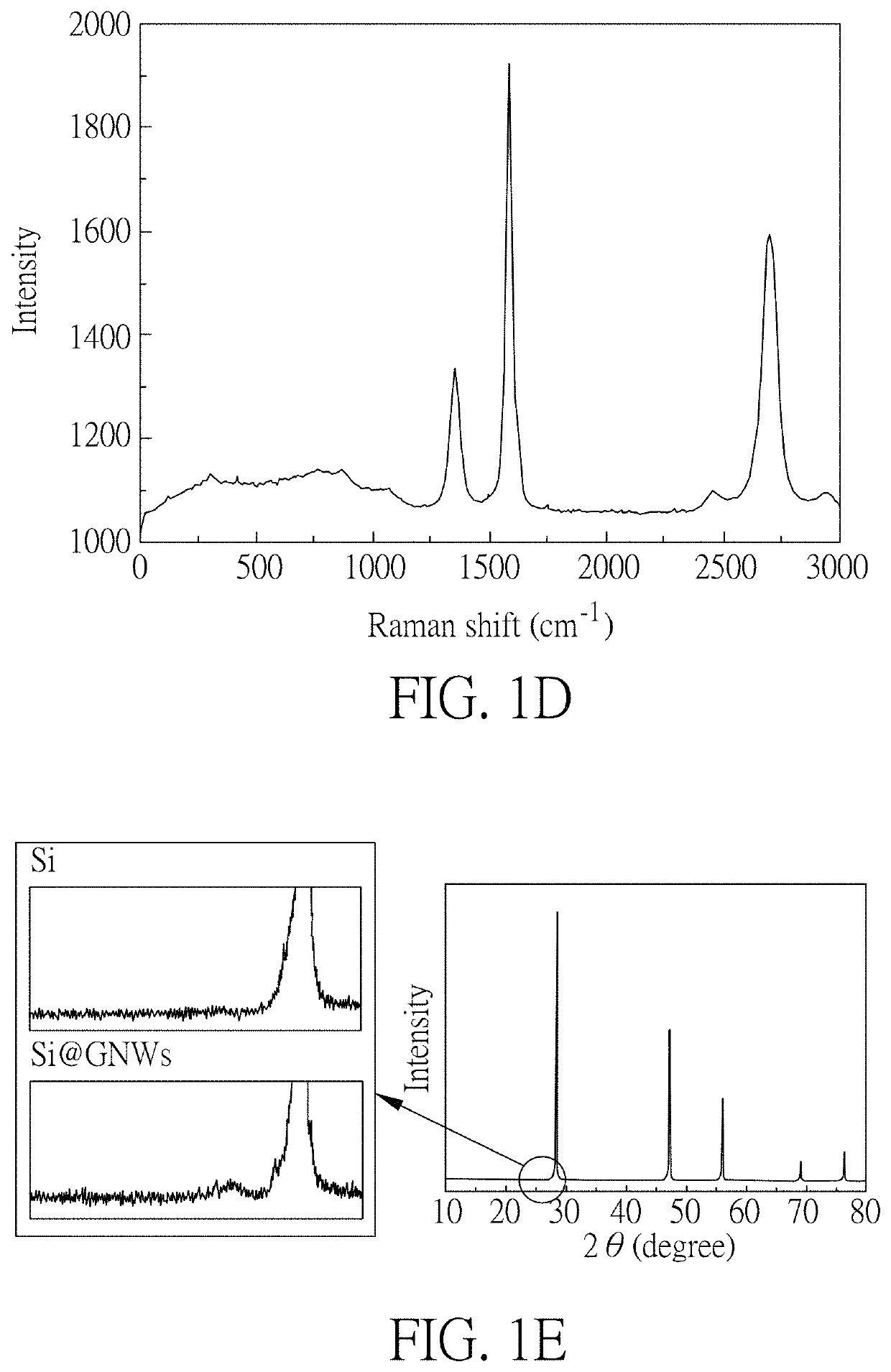

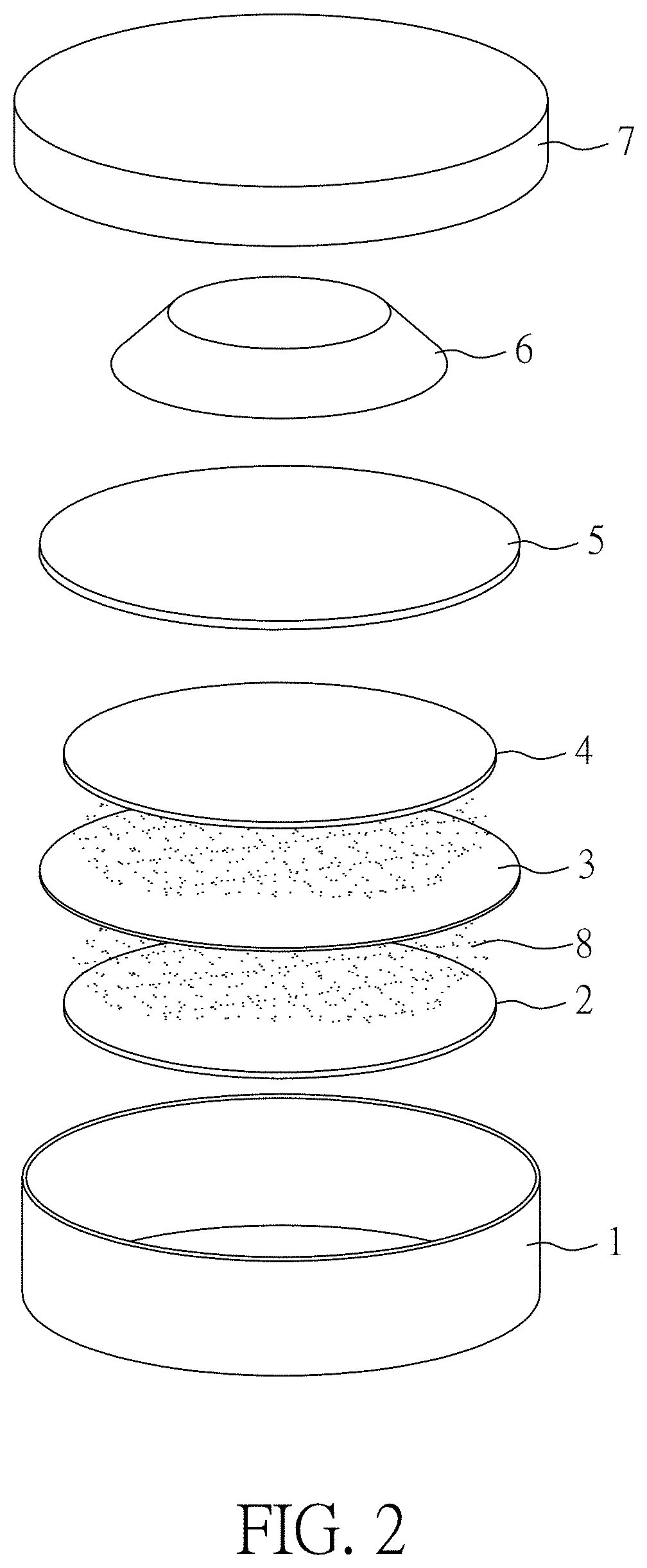

Composite electrode material and method for manufacturing the same, composite electrode containing said composite electrode material, and Li-based battery comprising said composite electrode

ActiveUS11245109B2Improve efficiencyProlong lifeSiliconActive material electrodesCarbon nanowallsComposite electrode

Owner:NAT CHENG KUNG UNIV

Fuel cell structure and method for manufacturing same

InactiveCN101120469AEasy to drainSimplify the manufacturing processCell electrodesFinal product manufactureCarbon nanowallsFuel cells

Disclosed is a fuel cell structure wherein a nanosized porous carbon material such as carbon nanowall (CNW) is used as a diffusion layer and / or a catalyst layer. Also disclosed is a method for manufacturing such a fuel cell structure. This fuel cell structure enables to simplify production process of an electrode for fuel cells which is composed of an electrode catalyst layer and a gas diffusion layer, while increasing conductivity of the catalyst layer and improving diffusion efficiency of the diffusion layer. Consequently, there can be obtained a fuel cell which is improved in power generation efficiency.

Owner:堀胜 +2

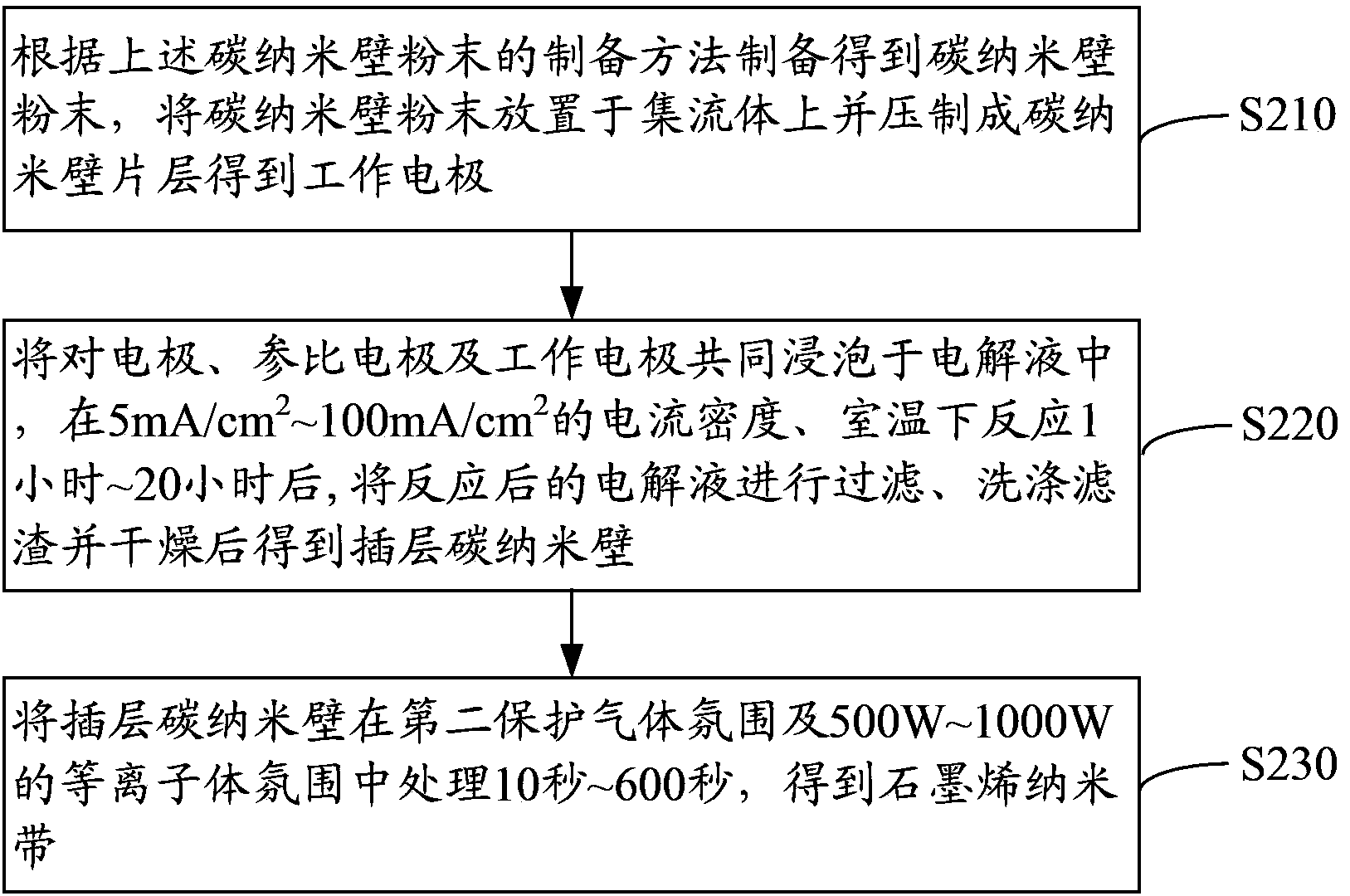

Preparation method of graphene nanobelt

The invention provides a preparation method of a graphene nanobelt. The method comprises the following steps: carrying out photocatalytic chemical vapor deposition to prepare carbon nanowall powder with a complete structure and a good dimensional homogeneity, placing the carbon nanowall powder on a current collector, compacting to form a carbon nanowall sheet in order to obtain a work electrode, and carrying out electrochemical peeling to obtain the graphene nanobelt with a good dimensional homogeneity. An ionic liquid electrolyte is inserted between carbon nanowall layers under the action of a forward voltage, and then a backward voltage is applied to realize the shedding of the ionic liquid electrolyte from the carbon nanowall in order to obtain the graphene nanobelt. The method makes no oxygen-containing groups introduced into the finally obtained graphene nanobelt, and the graphene nanobelt with a good quality can be prepared through the method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method of graphene nanobelt

A preparation method of a graphene nanobelt comprises the following steps: carrying out a photocatalytic chemical vapor deposition reaction on a carbon source under the action of ultraviolet light as a photocatalyst in order to generate a carbon nanowall on an etched metal substrate, scrapping off the carbon nanowall to obtain carbon nanowall powder, carrying out a three-electrode system reaction on the carbon nanowall powder as a raw material to prepare an intercalation carbon nanowall, dispersing the intercalation carbon nanowall in an ionic liquid, and peeling by utilizing a cold and hot temperature difference to obtain the graphene nanobelt with a high dimension homogeneity. The method makes no oxygen-containing groups introduced into the finally obtained graphene nanobelt, and the graphene nanobelt with a good quality can be prepared through the method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

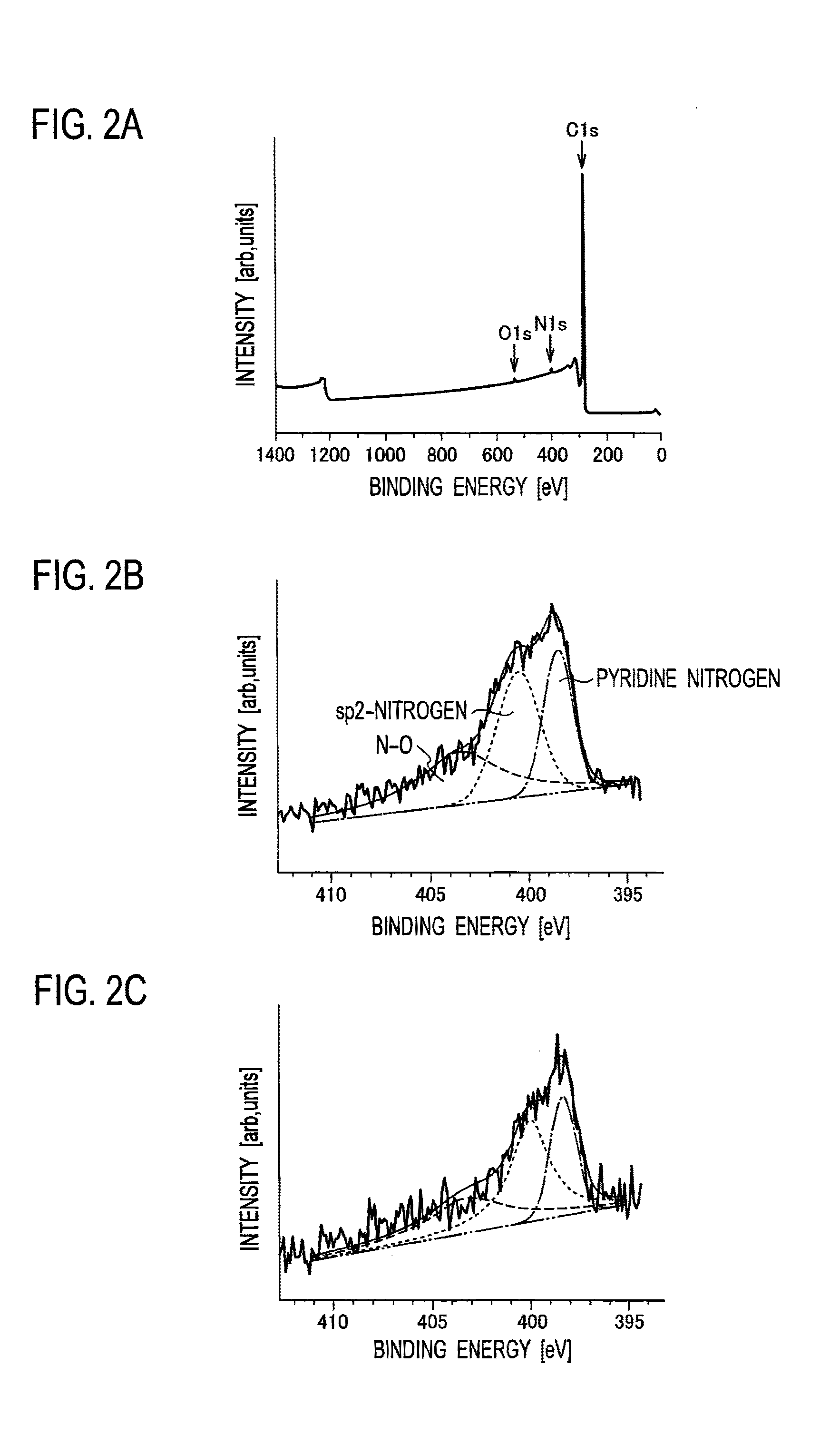

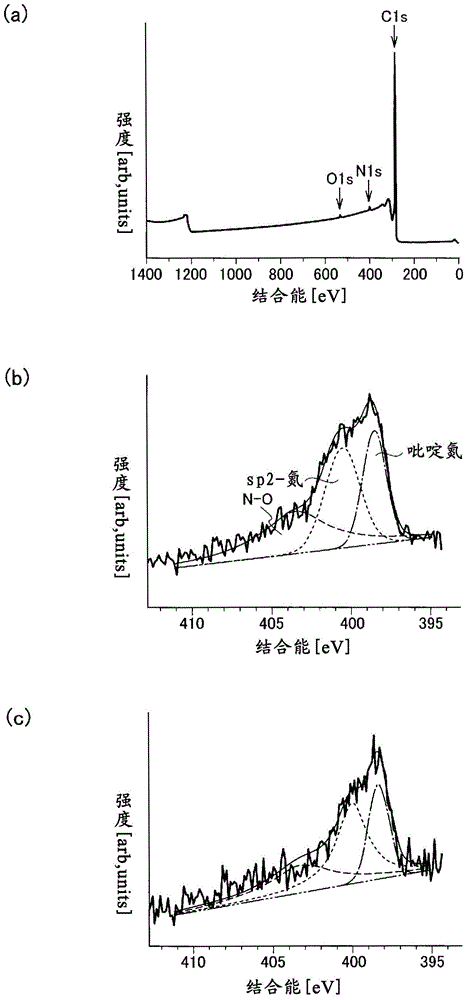

Carbon nanowall and production method thereof, oxygen reduction catalyst, oxygen reduction electrode and fuel cell

InactiveUS20150340707A1Low costActive material electrodesCatalyst activation/preparationCarbon nanowallsFuel cells

Owner:IHI CORP +1

Composite electrode material and method for manufacturing the same, composite electrode containing said composite electrode material, and li-based battery comprising said composite electrode

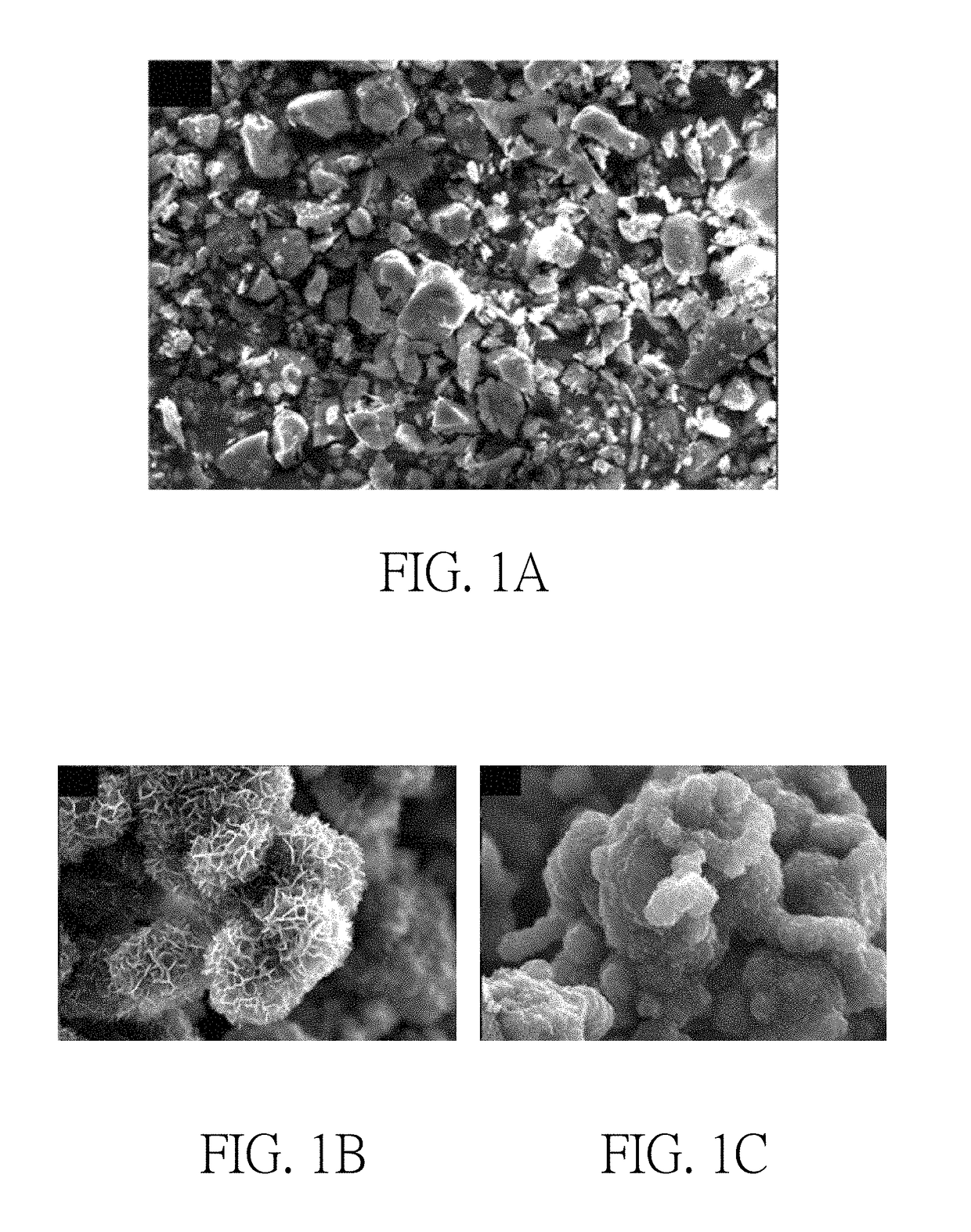

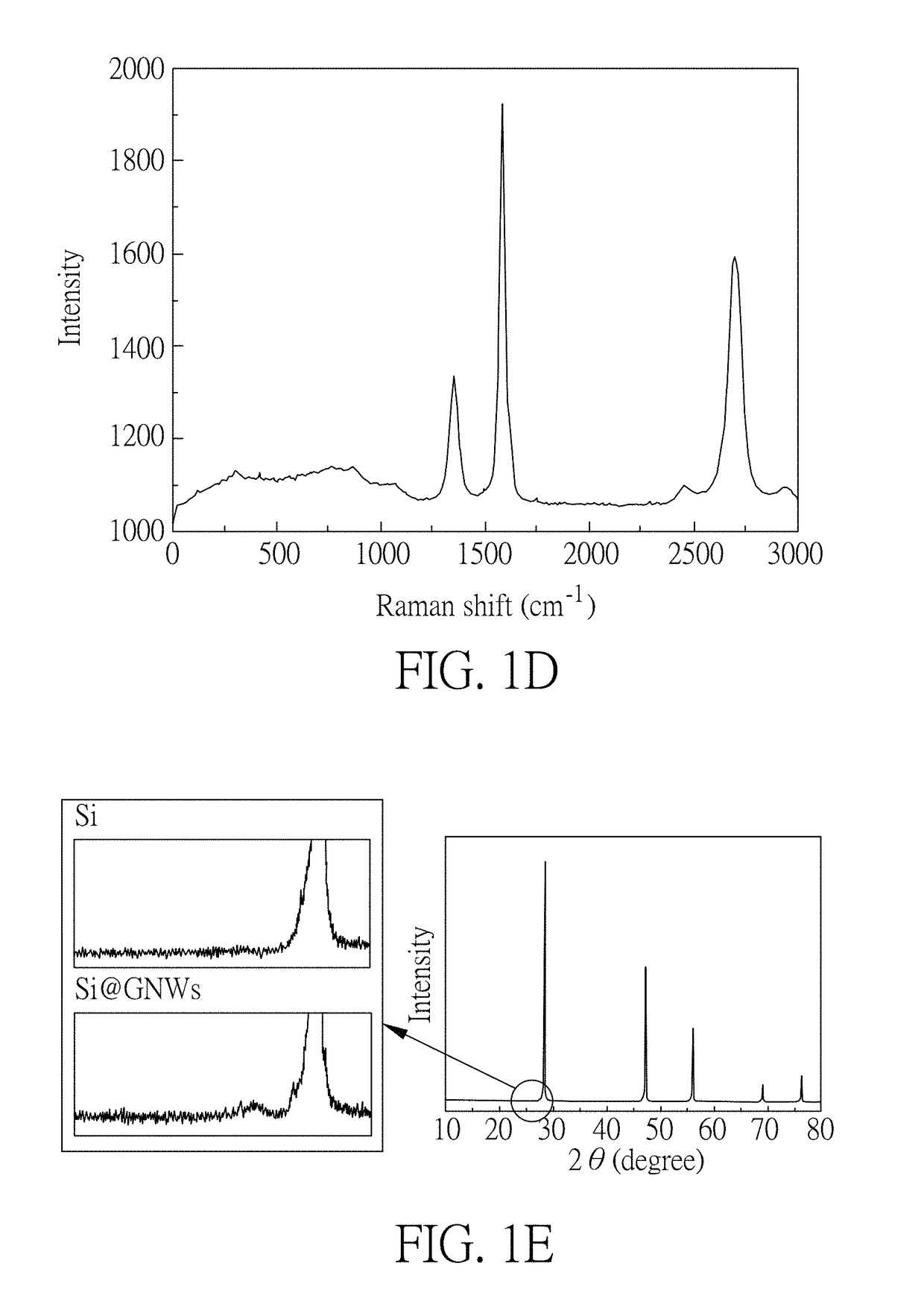

ActiveUS20190088937A1Improve battery efficiencyImprove cycle lifeSiliconCell electrodesCarbon nanowallsComposite electrode

A novel composite electrode material and a method for manufacturing the same, a composite electrode containing said composite electrode material, and a Li-based battery comprising said composite electrode are disclosed. Herein, the composite electrode material of the present invention comprises: a core, wherein a material of the core is at least one selected from the group consisting of Sn, Sb, Si, Ge, and compounds thereof; and a graphene nanowall or a graphene-like carbon nanowall; wherein the graphene nanowall or the graphene-like carbon nanowall grows on a surface of the core.

Owner:NAT CHENG KUNG UNIV

Lithium secondary battery negative electrode and method for manufacturing the same

ActiveUS9368795B2Large capacityReduce capacityElectrode carriers/collectorsBatteries manufactureCrystallinitySilicon thin film

Owner:SANGO CO LTD +1

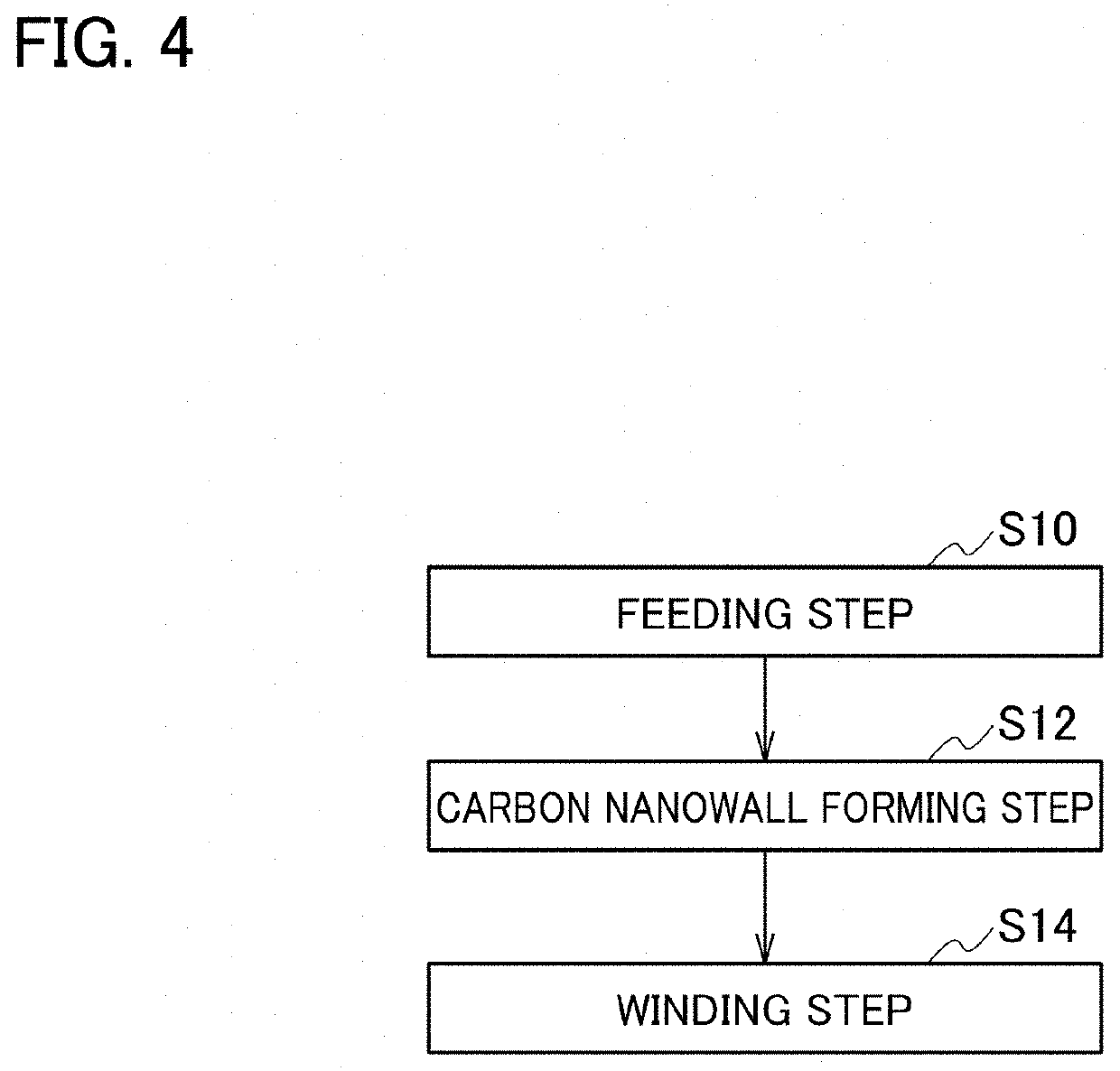

Carbon fiber complex material and manufacturing method thereof, manufacturing apparatus for carbon fiber complex material, prepreg, and carbon fiber reinforced plastic composite material

ActiveUS20200208341A1Improve adhesionPhysical treatmentCarbon fibresCarbon nanowallsFibrous composites

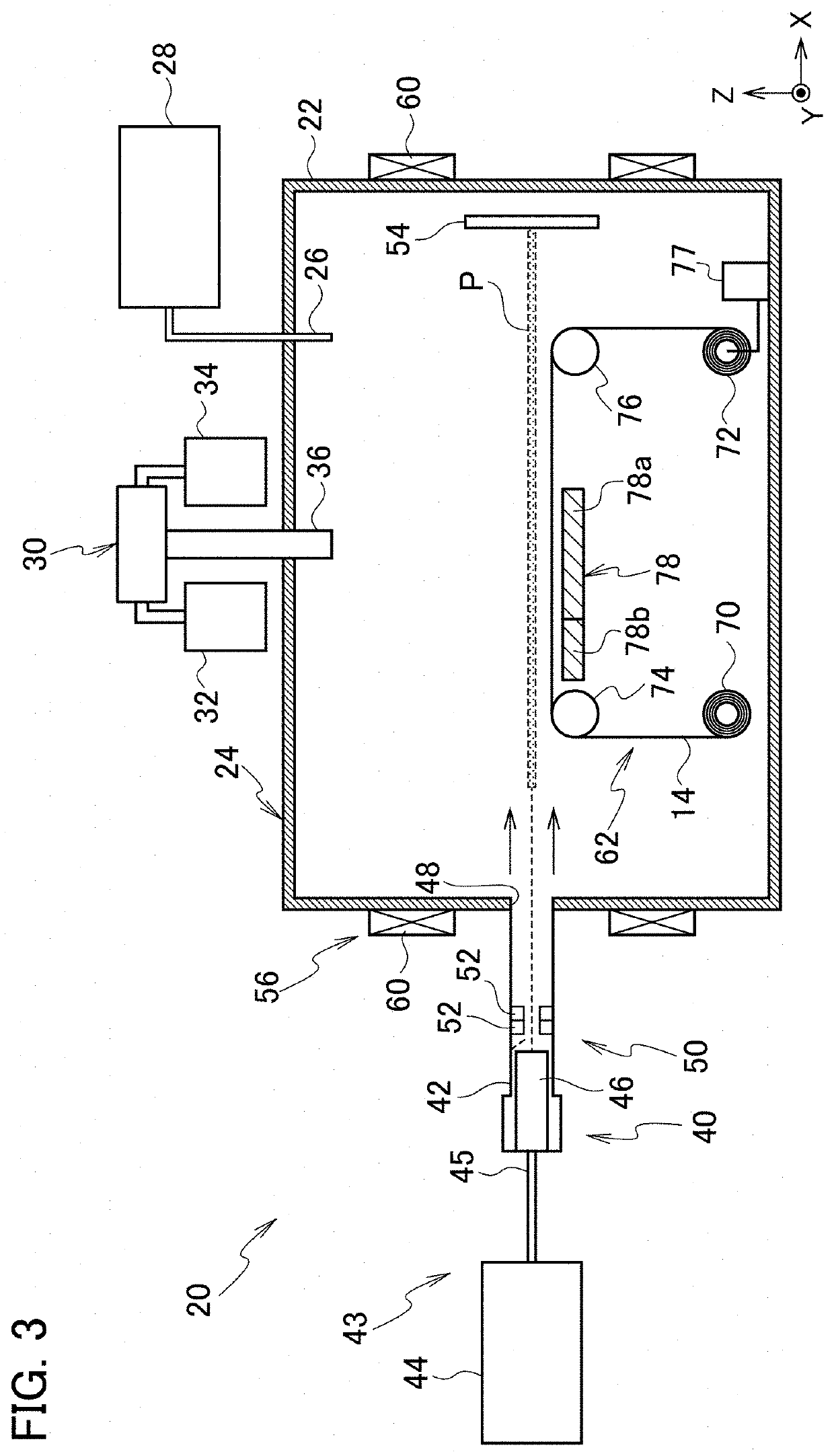

A carbon fiber complex material for a carbon fiber reinforced plastic composite material includes a carbon fiber material formed from a continuous carbon fiber, and carbon nanowalls formed on a surface of the continuous carbon fiber.

Owner:IHI CORP

Oxygen reduction catalyst, oxygen reduction electrode, and fuel cell

The present invention relates to an oxygen reduction catalyst, an oxygen reduction electrode, and a fuel cell that have nitrogen-doped carbon nanowalls. The present invention can provide, at a low cost, an oxygen reduction catalyst, an oxygen reduction electrode, and a fuel cell.

Owner:IHI CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com