Metallic mold for nano-imprint, forming method of nano-pattern, and resin molding

A technology of nano-imprinting and nano-patterning, which is applied in the field of resin molding to achieve the effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

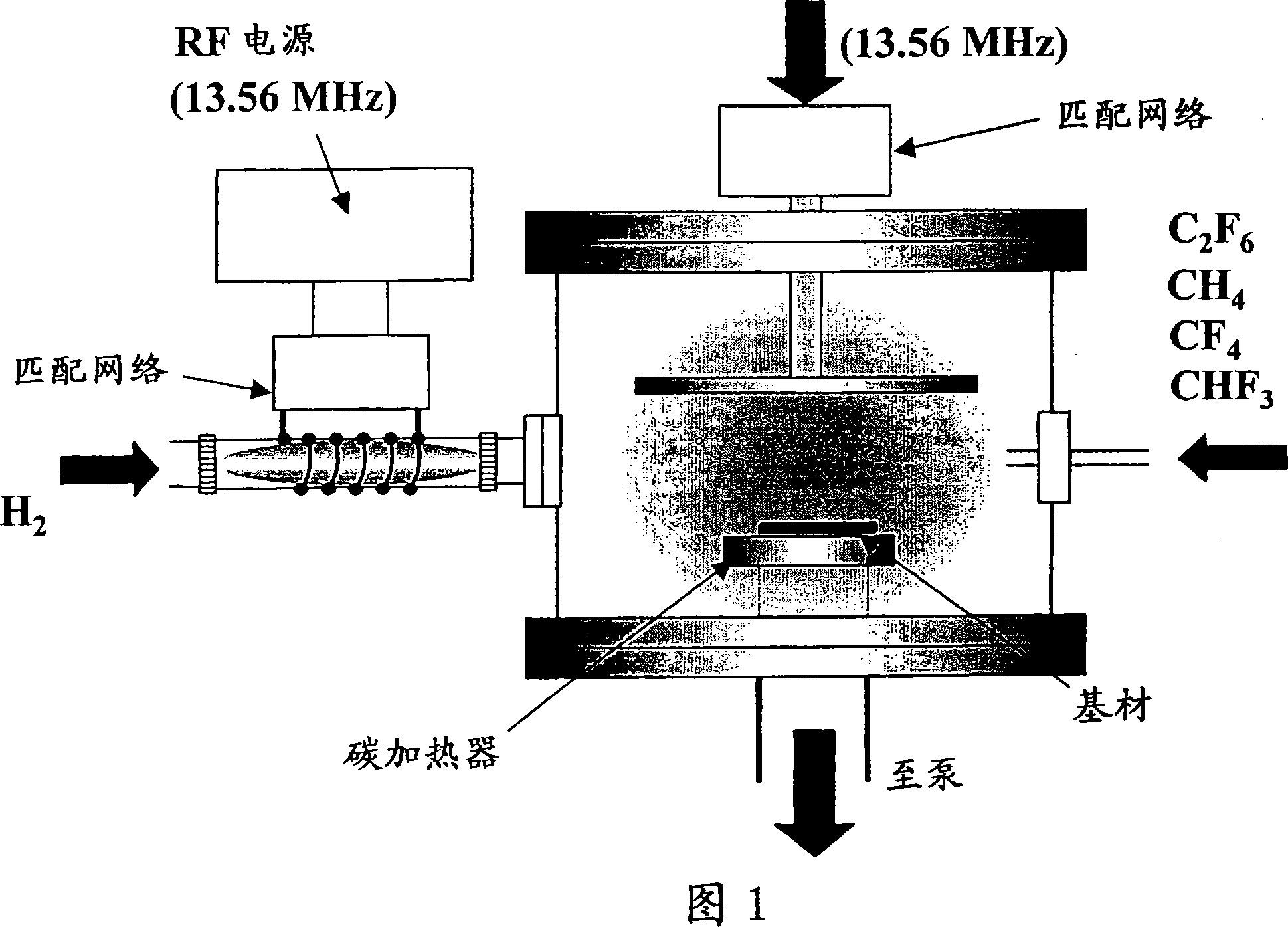

Method used

Image

Examples

Embodiment approach 1

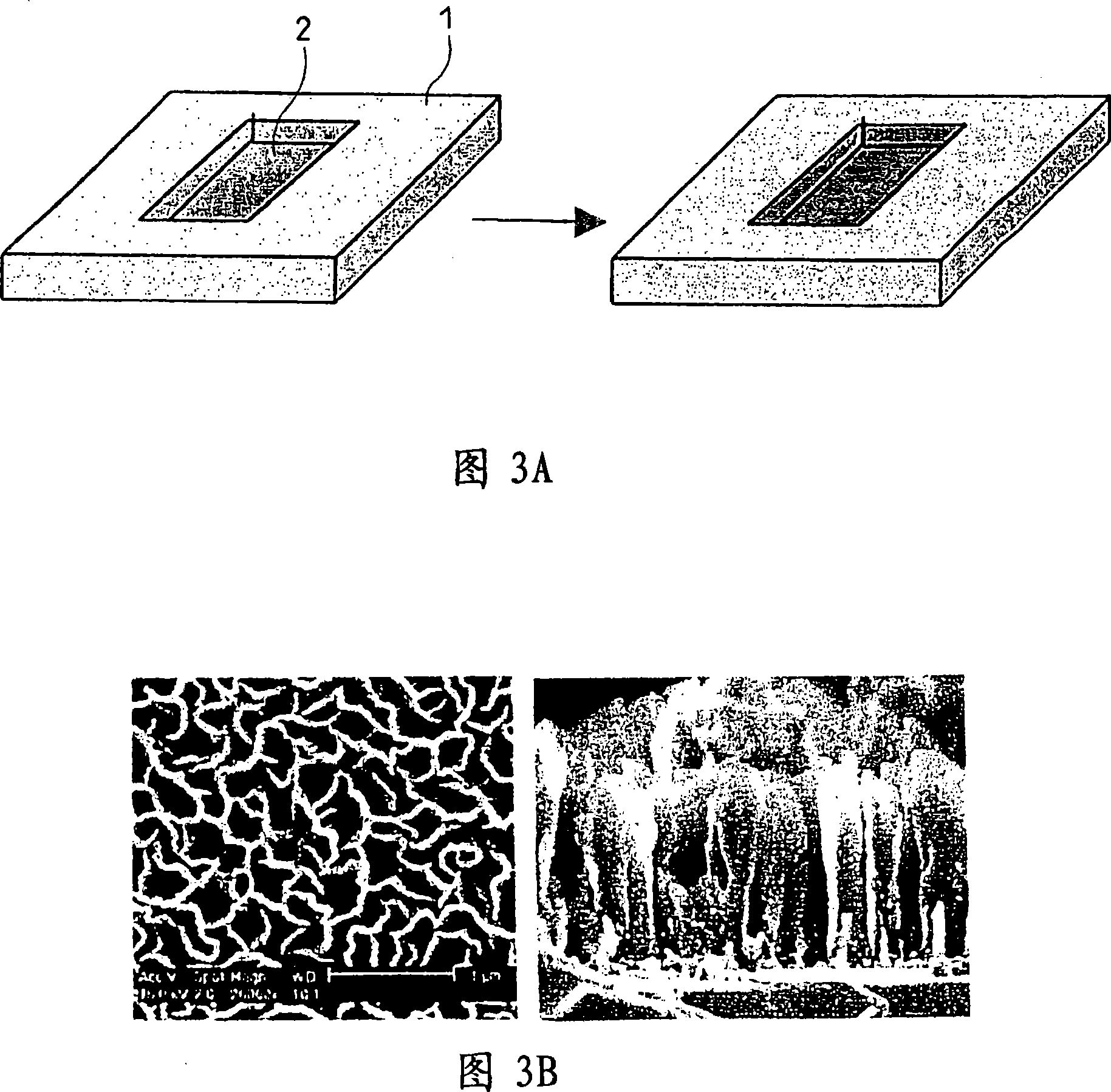

[0041] Mold structures with CNW patterned stencils were prepared. In this embodiment, the convex portion of the CNW corresponds to the concave portion of the molded article. Referring to FIG. 6 , CNWs ( 1 ) were produced on a substrate for producing CNWs under the conditions described above for the method of producing CNWs. This is followed by nickel plating (2) on the surface of the CNW. Plating methods may involve substances other than nickel. Then, the CNWs are peeled off from the substrate (3). Alternatively, the CNW can be partially combusted. Finally, fix the CNWs onto the mold surface.

[0042] In this embodiment, as shown in the conceptual image in the figure, the white portion of the SEM image of CNW corresponds to the convex portion of the resin molded article.

Embodiment approach 2

[0044] As shown schematically in Figure 7, a mold structure with a reverse CNW patterned mold was prepared. In this embodiment, the raised portion of the CNW corresponds directly to the raised portion of the molded article. First, CNWs (1) were produced on a substrate for producing CNWs under the conditions described above in the method of forming CNWs. Figure 8 shows the SEM image of the CNW surface before the electroless nickel plating method. Then, a Ni plating layer (2) is provided to the surface of the CNW. Figure 9 shows the SEM image of the CNW surface after the electroless nickel plating method. Plating methods may involve substances other than nickel. The CNWs are then peeled off from the substrate (3). Figure 10 shows a SEM image of the surface on the CNW removed side after removing the CNWs by firing. From Figure 10, it is clear that there is an inverse pattern of CNWs. The remaining CNWs were fired at 700°C in air. Finally, fix the CNW onto the mold surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com