Preparation method of carbon nanowalls

A carbon nanowall and carbon source gas technology, applied in the field of carbon nanometers, can solve problems such as complex process, high requirements for carbon nanowall equipment, and uneven thickness of carbon nanowall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

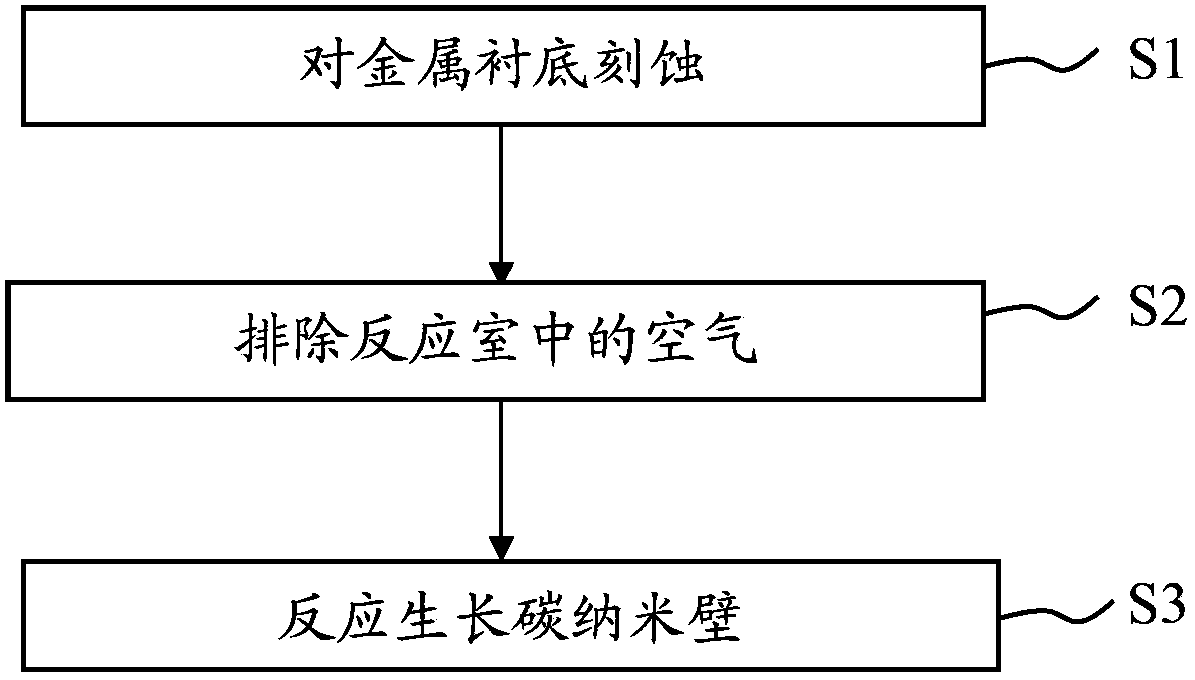

[0014] The example of the present invention provides a method for preparing carbon nanometer walls with easy controllable conditions, simple process and low cost. Please refer to the technical process of the preparation method of the carbon nanowall figure 1 , the method includes the following steps:

[0015] S01: Etching the metal substrate: etching the metal substrate with an acid solution with a concentration of 0.01 to 1mol / L;

[0016] S02: remove the air in the reaction chamber: place the metal substrate etched in step S01 in the reaction chamber, and remove the air in the reaction chamber;

[0017] S03: Reactive growth of carbon nanowalls: After heating the metal substrate placed in the reaction chamber to 700-1100° C., continuously inject a protective film with a volume ratio of 1:2-10 into the reaction chamber that excludes air. react with the mixed gas of inert gas and carbon source gas, and keep it for 1-300 minutes, and grow the carbon nanometer wall on the surfac...

Embodiment 1

[0027] A method for preparing a carbon nanowall, the specific steps are as follows:

[0028] S11: Put the iron foil into a dilute hydrochloric acid solution with a concentration of 0.01mol / L and etch for 180 seconds, and clean it with deionized water, ethanol, and acetone after etching;

[0029] S12: Put the cleaned iron foil into the reaction chamber and feed nitrogen gas with a flow rate of 10 sccm for 60 minutes;

[0030] S13: Heat the iron foil placed in the reaction chamber to 1100°C, and react with methane with a flow rate of 250 sccm, and grow carbon nanowalls on the surface of the iron foil, wherein, in the reaction chamber, the volume of methane and nitrogen gas The ratio is 5:1, keep it for 10 minutes;

[0031] S14: After the reaction is completed, stop feeding methane and heating the iron foil, stop feeding nitrogen after cooling the reaction chamber to room temperature, and obtain carbon nanowalls.

[0032] The carbon nanowall prepared in the present embodiment 1...

Embodiment 2

[0034] A method for preparing a carbon nanowall, the specific steps are as follows:

[0035] S21: Put the nickel foil into a dilute sulfuric acid solution with a concentration of 0.1mol / L to etch for 120 seconds, and clean it with deionized water, ethanol, and acetone after etching;

[0036] S22: Put the cleaned nickel foil into the reaction chamber and inject hydrogen gas at 200 sccm for 5 minutes;

[0037] S23: Heating the nickel foil to 700°C, passing 20 sccm of acetylene, the volume ratio of acetylene to hydrogen is 2:1, and keeping it for 300 minutes;

[0038] S24: After the reaction is completed, stop feeding the acetylene and heating the nickel foil, stop feeding the hydrogen gas after cooling the reaction chamber to room temperature, and obtain the carbon nanowall.

[0039] Electronic scanning of the carbon nanowalls prepared in this example showed that the carbon nanowalls had the same shape as the carbon nanowalls prepared in Example 1, which grew straight on the nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com