Thermoforming process and equipment of aramid paper-based composite material

A composite material and thermoforming technology, applied in papermaking, papermaking machines, press parts, etc., can solve the problems of incomplete, cumbersome waste, uneven size of aramid composite paper, etc., and achieve the effect of improving efficiency and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

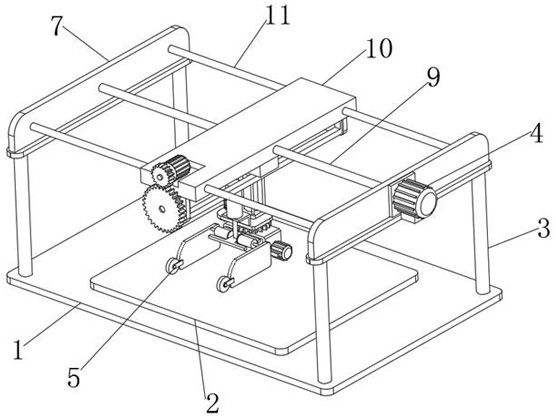

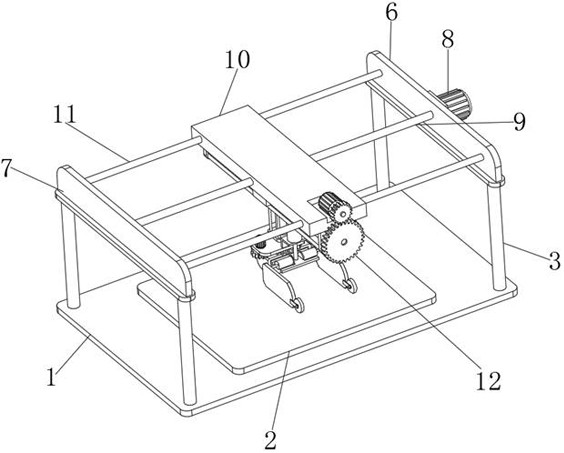

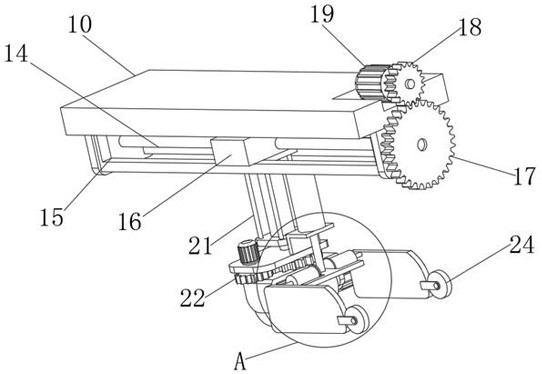

[0028] The invention provides a technical solution:

[0029] The thermocompression molding process of aramid paper-based composite materials includes the following preparation steps:

[0030] Step 1: Base material selection: Weigh out a certain proportion of aramid chopped fiber, aramid pulp and dispersant S, and chemically pretreat the aramid chopped fiber, and at the same time put the aramid pulp in a beater beating;

[0031] Step 2: beating and dispersing: the aramid chopped fiber and aramid pulp in step 1 are composed according to the ratio of 5:5 and put into the mixing pulp tank to mix evenly;

[0032] Step 3: Compression molding: Open the valve of the head box, put the slurry in step 2 into the inside of the head box, and use the slurry pump to transport the slurry to the inside of the headbox, and put it into the headbox at the same time Inclined wire, after soaking for a period of time, take out the inclined wire with pulp, put it into the press to squeeze the pulp ...

Embodiment 2

[0040] The invention provides a technical solution:

[0041] The thermocompression molding process of aramid paper-based composite materials includes the following preparation steps:

[0042] Step 1: Base material selection: Weigh out a certain proportion of aramid chopped fiber, aramid pulp and dispersant S, and chemically pretreat the aramid chopped fiber, and at the same time put the aramid pulp in a beater beating;

[0043] Step 2: beating and dispersing: the aramid chopped fiber and aramid pulp in step 1 are composed according to the ratio of 4:6 and put into the mixing pulp tank and mixed evenly;

[0044] Step 3: Compression molding: Open the valve of the head box, put the slurry in step 2 into the inside of the head box, and use the slurry pump to transport the slurry to the inside of the headbox, and put it into the headbox at the same time Inclined wire, after immersion for a period of time, take out the inclined wire with pulp, put it into a press to squeeze the pu...

Embodiment 3

[0052] The invention provides a technical solution:

[0053] The thermocompression molding process of aramid paper-based composite materials includes the following preparation steps:

[0054] Step 1: Base material selection: Weigh out a certain proportion of aramid chopped fiber, aramid pulp and dispersant S, and chemically pretreat the aramid chopped fiber, and at the same time put the aramid pulp in a beater beating;

[0055] Step 2: beating and dispersing: the aramid chopped fiber and aramid pulp in step 1 are composed according to the ratio of 3:7 and put into the mixing pulp tank to mix evenly;

[0056] Step 3: Compression molding: Open the valve of the head box, put the slurry in step 2 into the inside of the head box, and use the slurry pump to transport the slurry to the inside of the headbox, and put it into the headbox at the same time Inclined wire, after immersion for a period of time, take out the inclined wire with pulp, put it into a press to squeeze the pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com