Patents

Literature

474results about "Batteries manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purification of as-produced single-wall carbon nanotubes

InactiveUS20020127169A1High yieldNanostructure manufactureSpecial paperSolar cellSingle-Walled Nanotube

A method for purifying a mixture comprising single-wall carbon nanotubes and amorphous carbon contaminate is disclosed. The method includes the steps of heating the mixture under oxidizing conditions sufficient to remove the amorphous carbon, followed by recovering a product comprising at least about 80% by weight of single-wall carbon nanotubes. A method for producing tubular carbon molecules of about 5 to 500 nm in length is also disclosed. The method includes the steps of cutting single-wall nanotube containing-material to form a mixture of tubular carbon molecules having lengths in the range of 5-500 nm and isolating a fraction of the molecules having substantially equal lengths. The nanotubes may be used, singularly or in multiples, in power transmission cables, in solar cells, in batteries, as antennas, as molecular electronics, as probes and manipulators, and in composites.

Owner:RICE UNIV

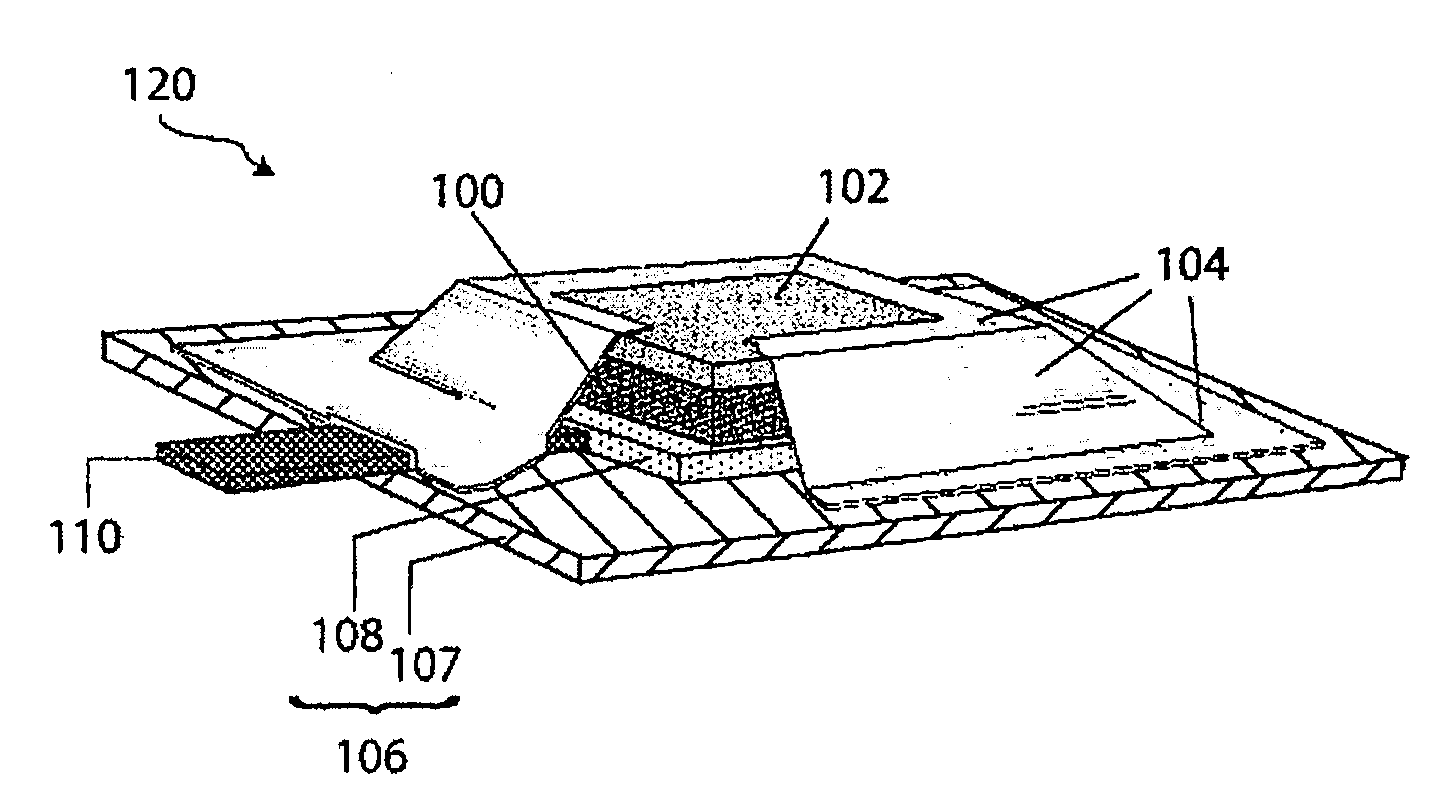

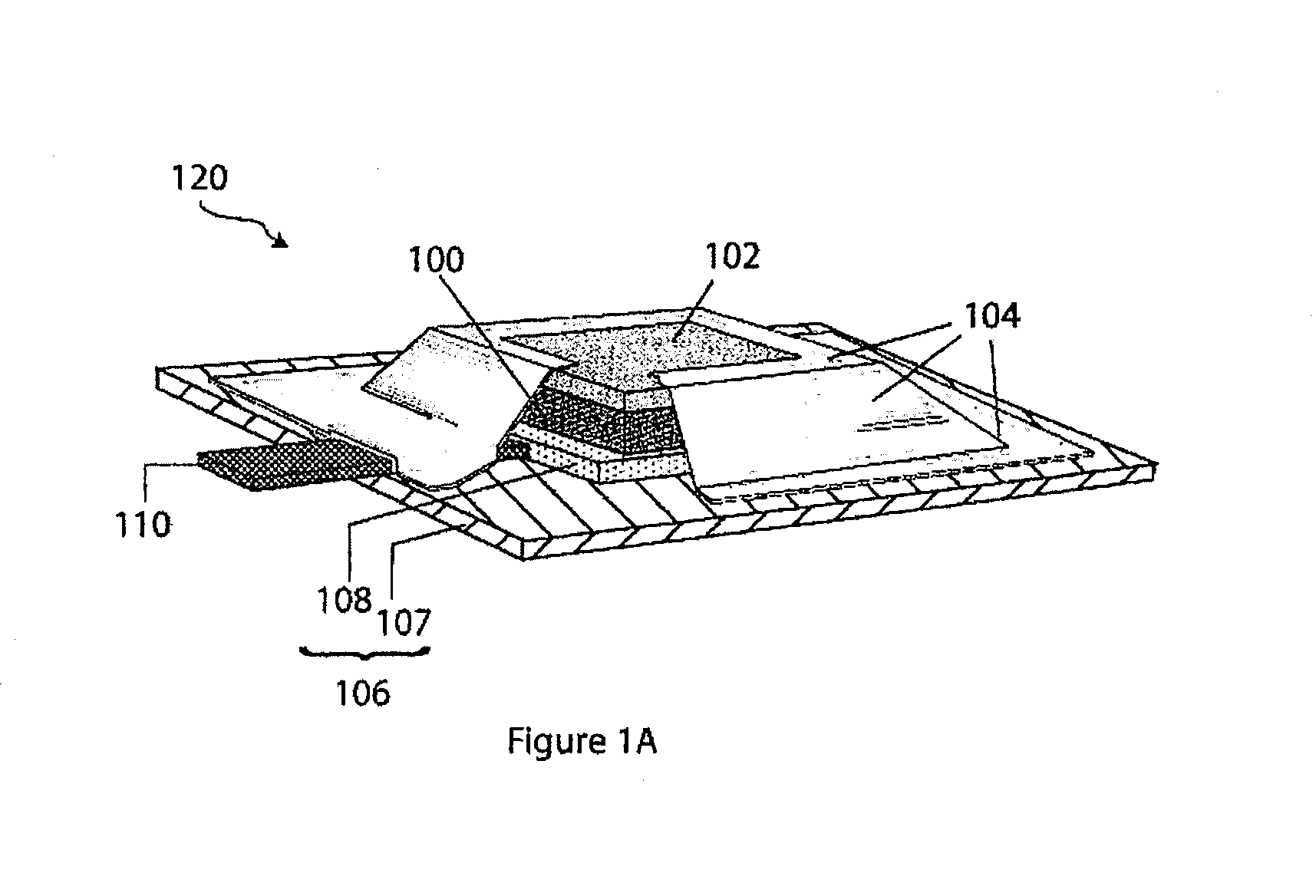

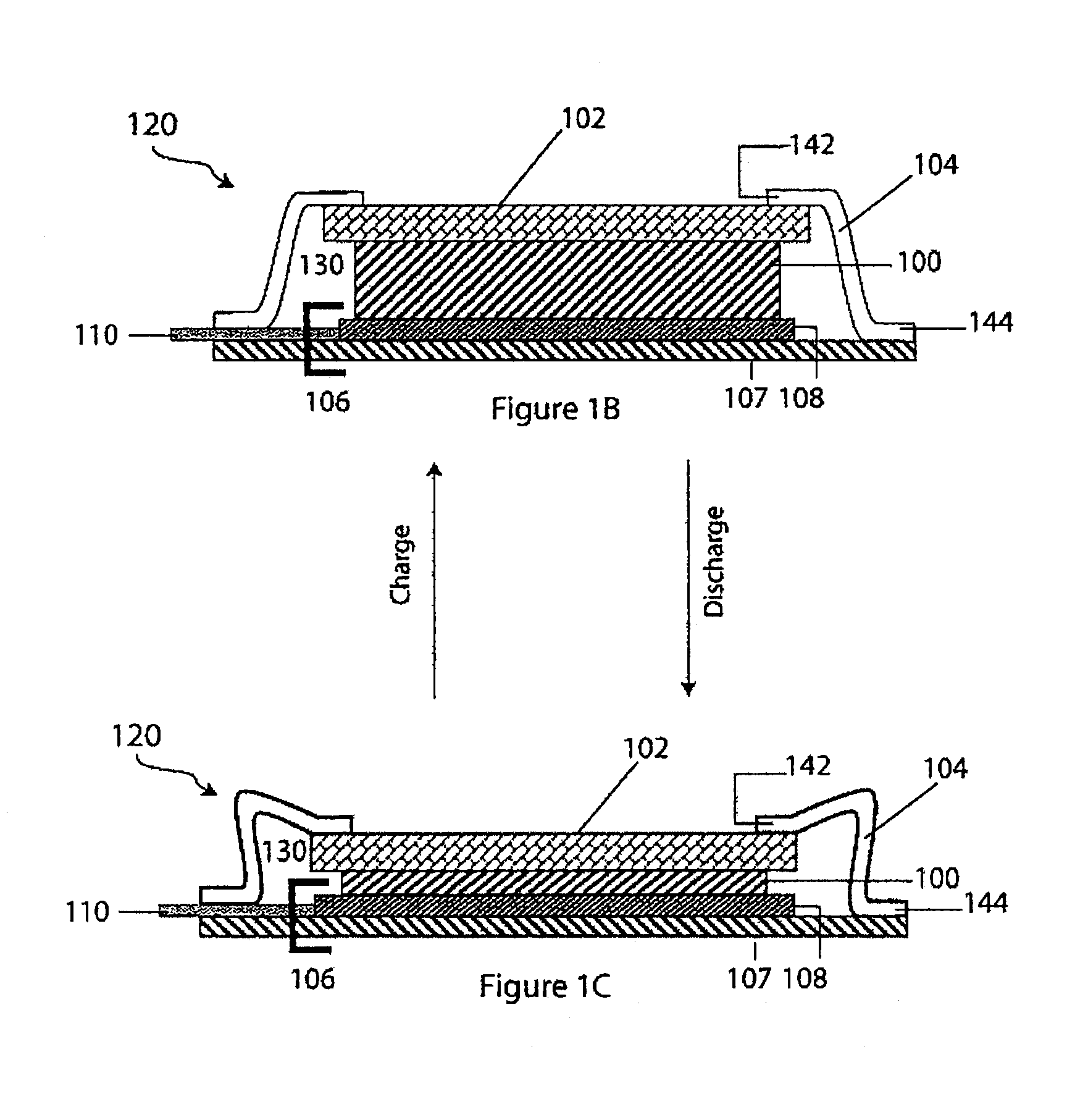

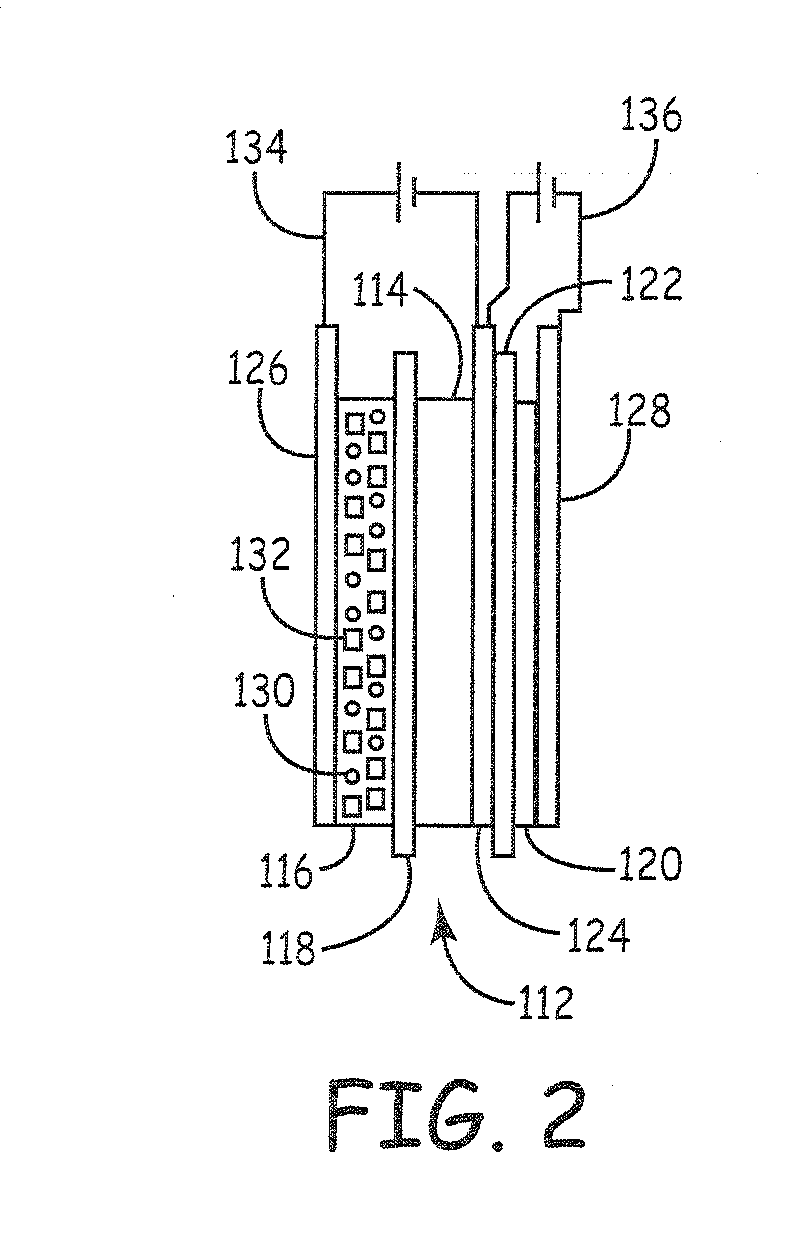

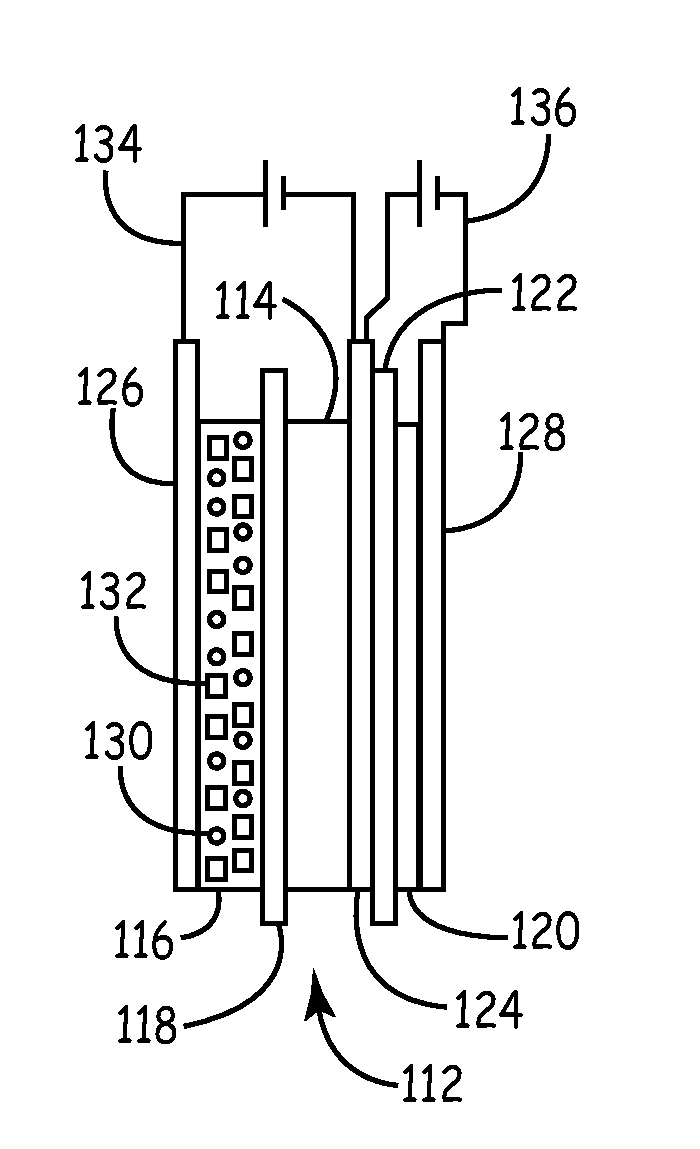

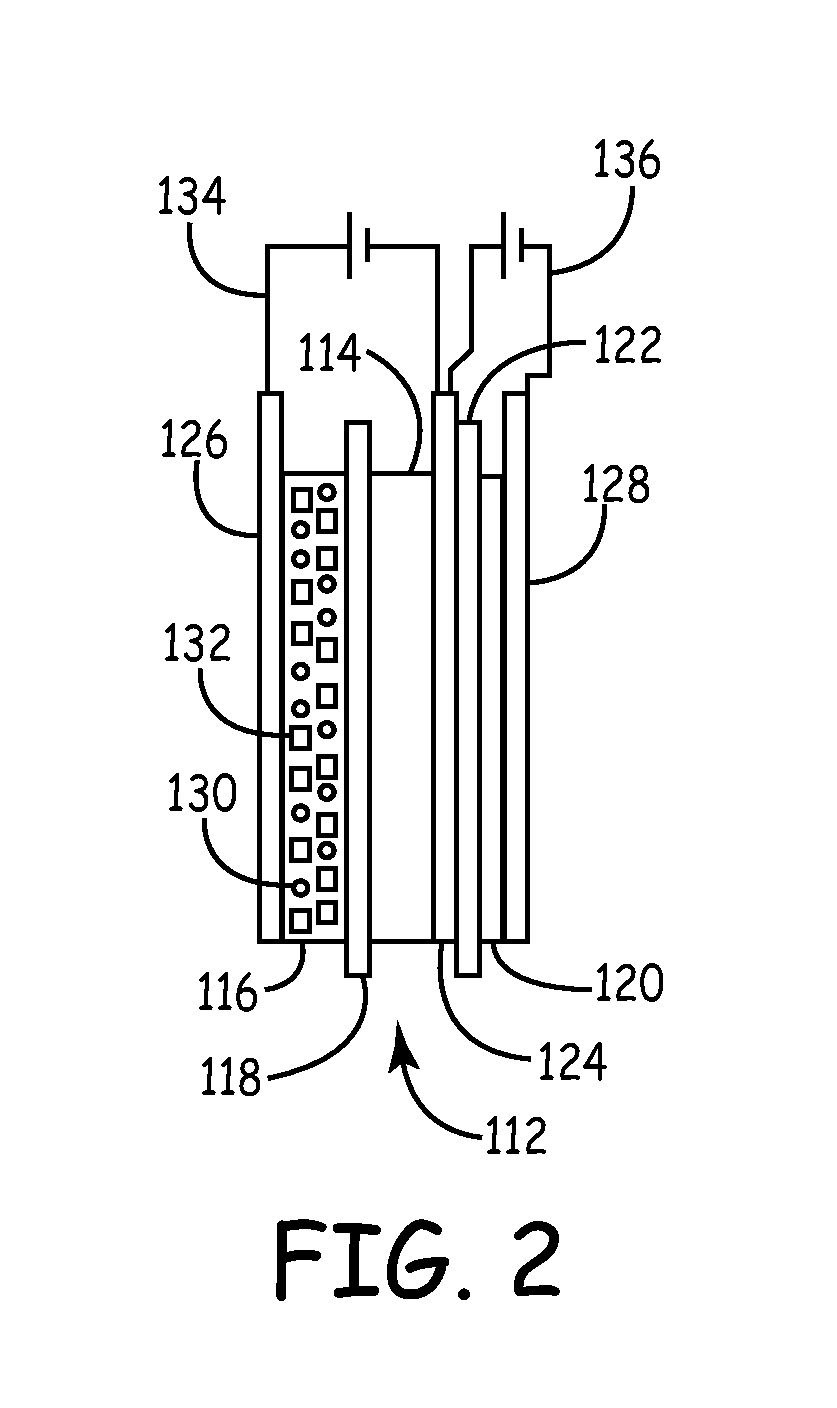

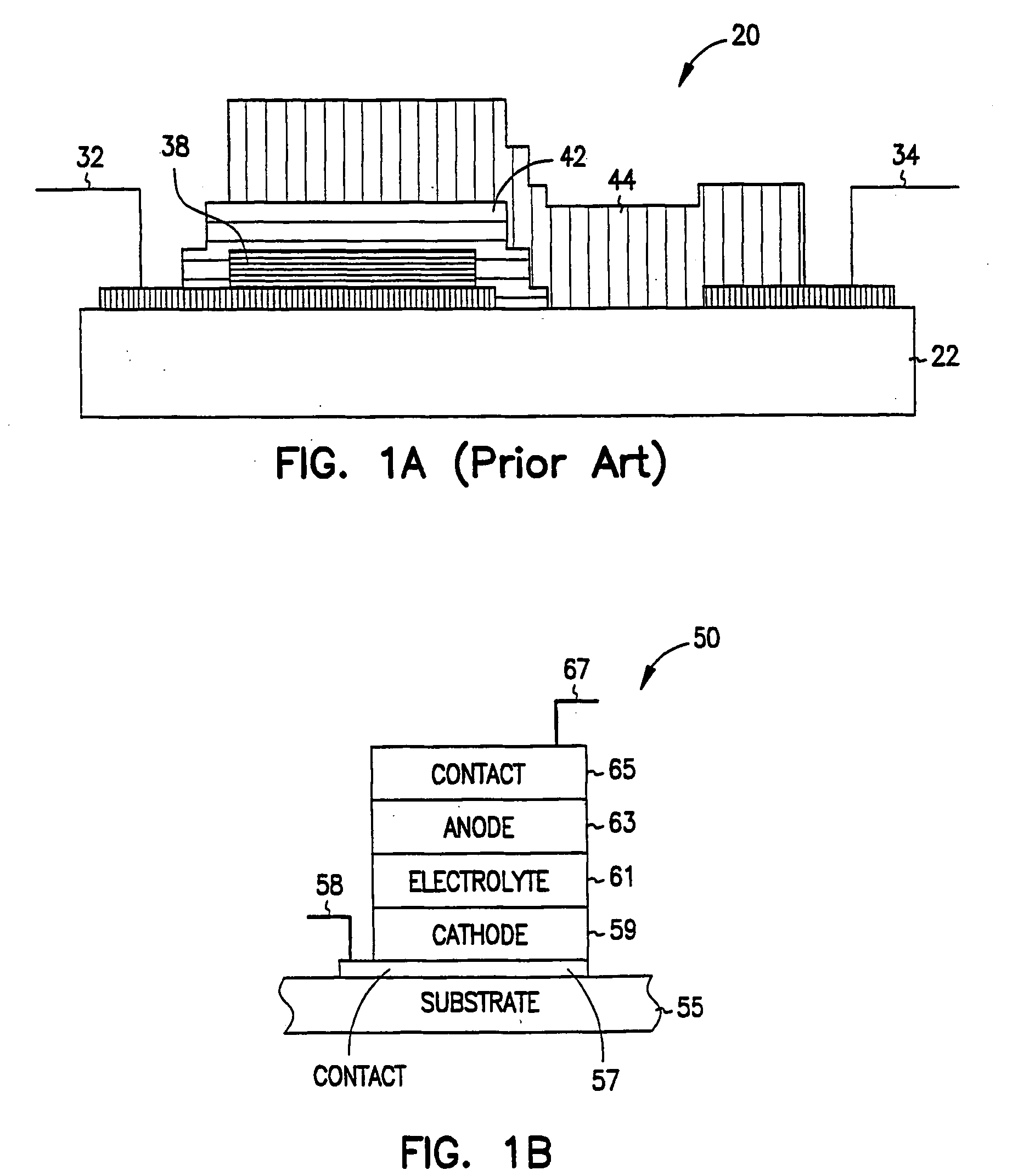

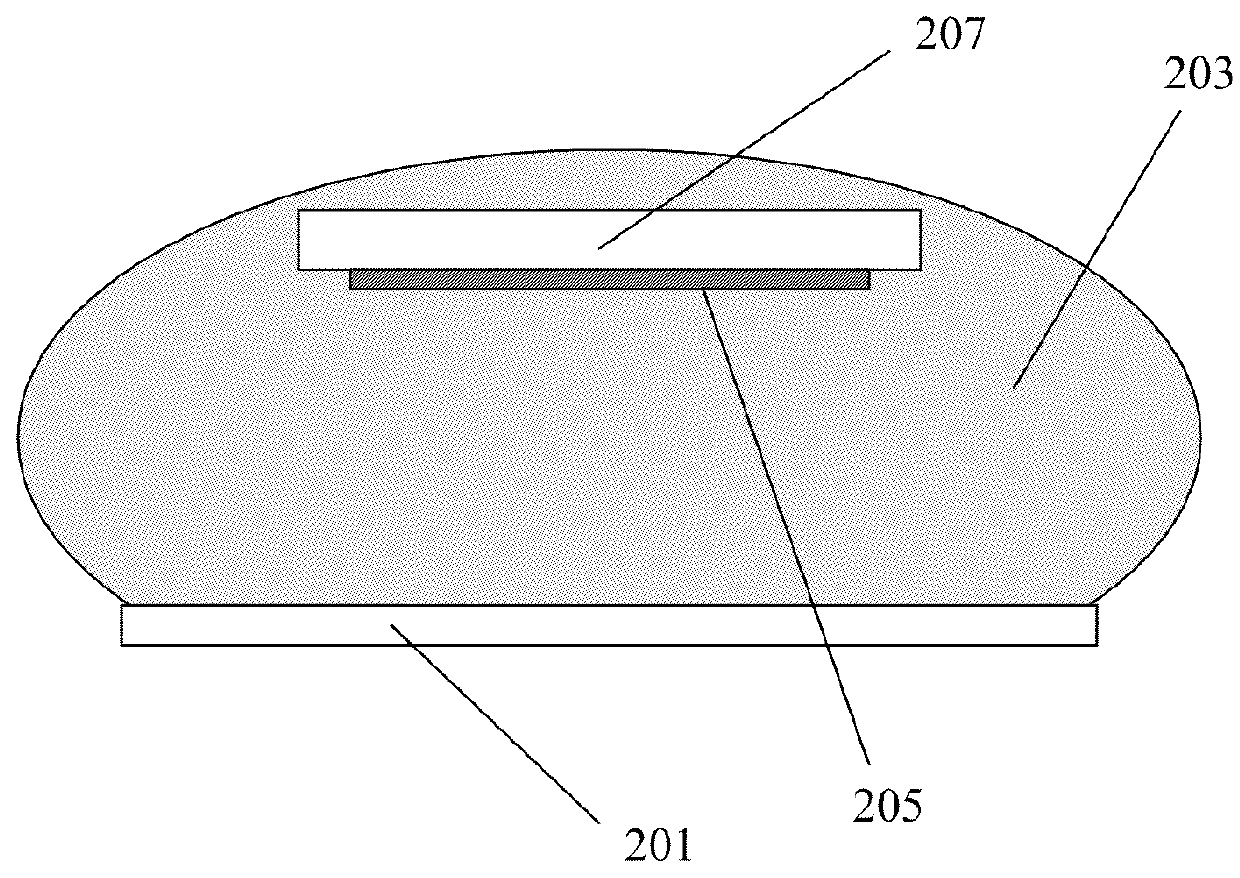

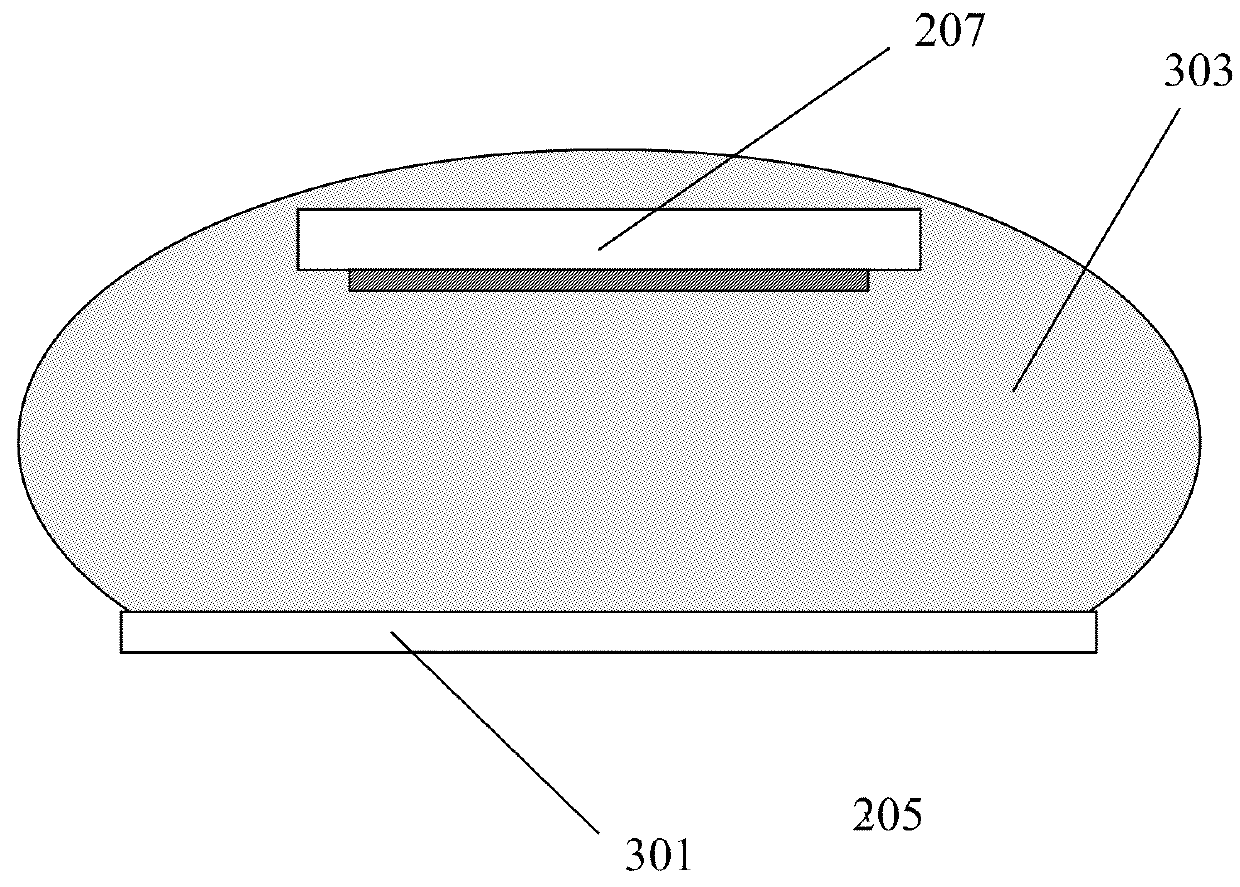

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Aqueous polyvinylidene fluoride composition

ActiveUS20100304270A1Dry fastUseful electrodeLiquid electrolytic capacitorsConductive materialInterconnectivityPolyvinylidene difluoride

The invention relates to an aqueous fluoropolymer, and preferably polyvinylidene fluoride (PVDF), composition for manufacturing electrodes for use in non-aqueous-type electrochemical devices, such as batteries and electric double layer capacitors. The composition contains aqueous PVDF binder, and one or more powdery electrode-forming materials. In one embodiment, the composition is free of fluorinated surfactant In another embodiment, one or more fugitive adhesion promoters are added. The electrode formed from the composition of the invention exhibits interconnectivity and irreversibility that is achieved from the use of aqueous PVDF binder.

Owner:ARKEMA INC

Lithium Ion Batteries with Supplemental Lithium

Supplemental lithium can be used to stabilize lithium ion batteries with lithium rich metal oxides as the positive electrode active material. Dramatic improvements in the specific capacity at long cycling have been obtained. The supplemental lithium can be provided with the negative electrode, or alternatively as a sacrificial material that is subsequently driven into the negative electrode active material. The supplemental lithium can be provided to the negative electrode active material prior to assembly of the battery using electrochemical deposition. The positive electrode active materials can comprise a layered-layered structure comprising manganese as well as nickel and / or cobalt.

Owner:IONBLOX INC

Continuous fiber of single-wall carbon nanotubes

InactiveUS20020127162A1High yieldCarbon compoundsElectrolytic capacitorsFiberElectric power transmission

A method for purifying a mixture comprising single-wall carbon nanotubes and amorphous carbon contaminate is disclosed. The method includes the steps of heating the mixture under oxidizing conditions sufficient to remove the amorphous carbon, followed by recovering a product comprising at least about 80% by weight of single-wall carbon nanotubes. A method for producing tubular carbon molecules of about 5 to 500 nm in length is also disclosed. The method includes the steps of cutting single-wall nanotube containing-material to form a mixture of tubular carbon molecules having lengths in the range of 5-500 nm and isolating a fraction of the molecules having substantially equal lengths The nanotubes may be used, singularly or in multiples, in power transmission cables, in solar cells, in batteries, as antennas, as molecular electronics, as probes and manipulators, and in composites.

Owner:RICE UNIV

Lithium ion batteries with supplemental lithium

ActiveUS20120105007A1Batteries circuit arrangementsElectrode carriers/collectorsManganeseElectrochemistry

Supplemental lithium can be used to stabilize lithium ion batteries with lithium rich metal oxides as the positive electrode active material. Dramatic improvements in the specific capacity at long cycling have been obtained. The supplemental lithium can be provided with the negative electrode, or alternatively as a sacrificial material that is subsequently driven into the negative electrode active material. The supplemental lithium can be provided to the negative electrode active material prior to assembly of the battery using electrochemical deposition. The positive electrode active materials can comprise a layered-layered structure comprising manganese as well as nickel and / or cobalt.

Owner:ZENLABS ENERGY INC

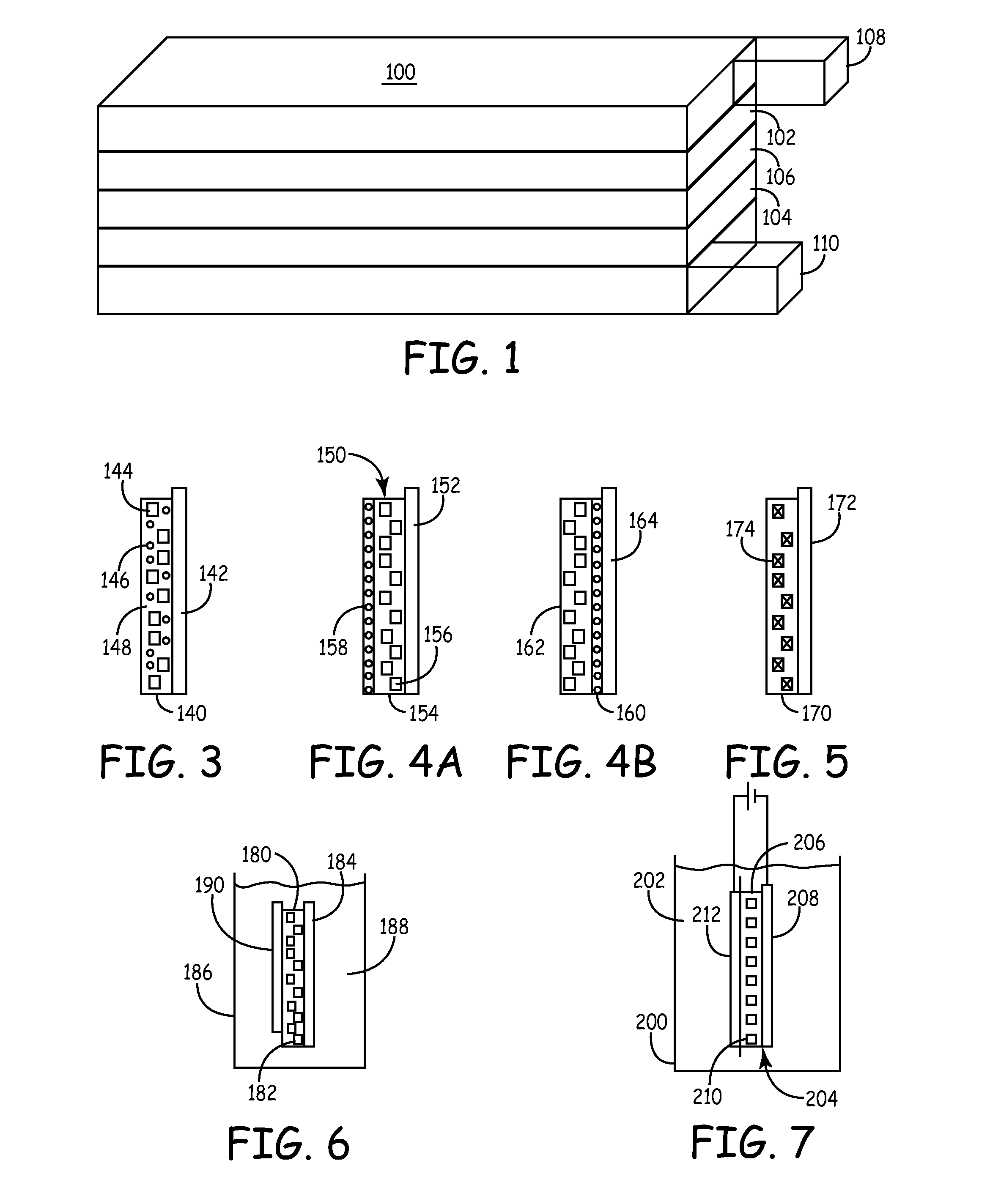

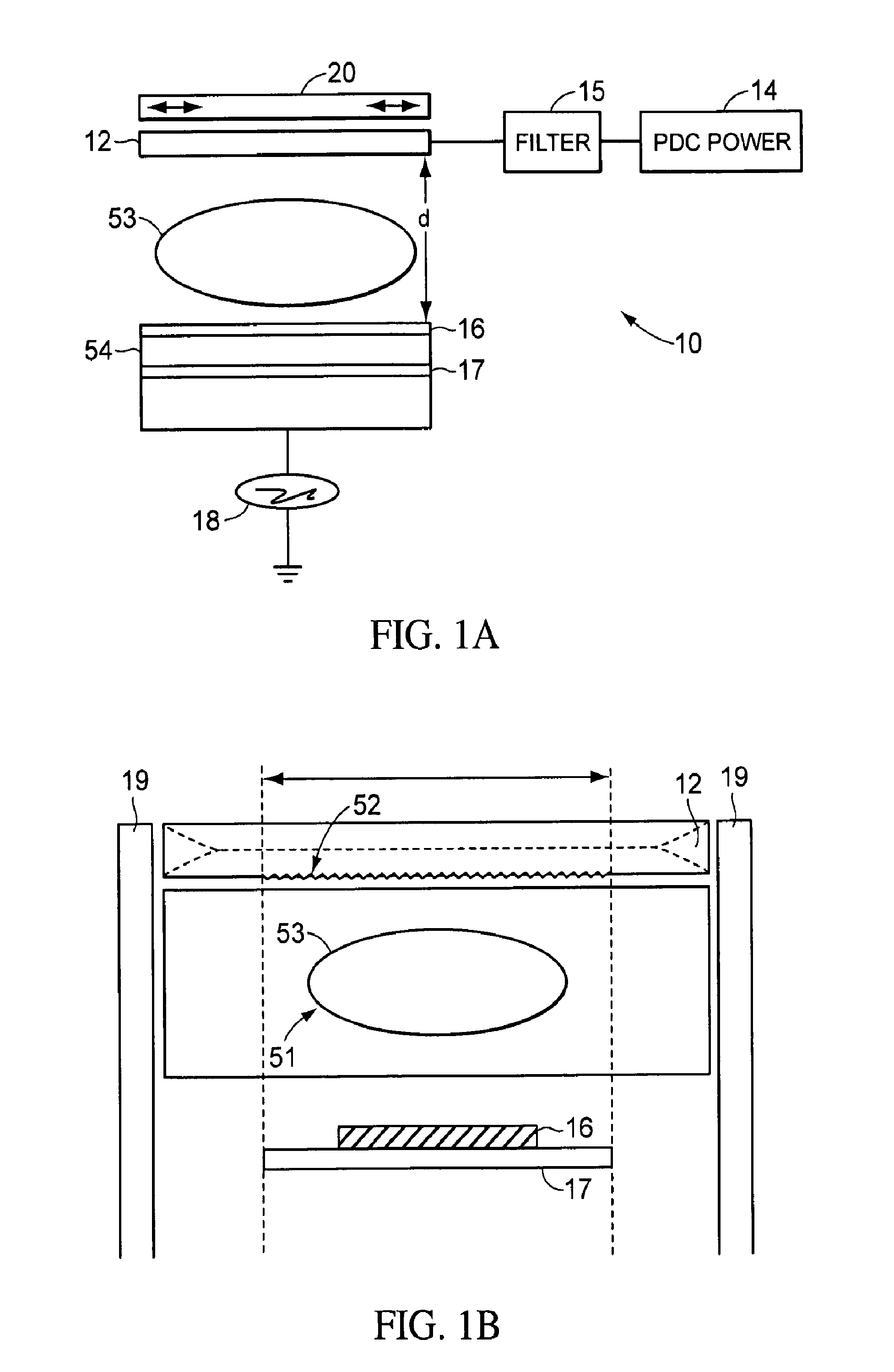

Method of continuous processing of thin-film batteries and like devices

A method of making a thin-film device including a substrate-supply station that supplies a substrate. The substrate has a first layer on the substrate. Also described is a method and device for depositing a second layer onto the first layer, wherein energy supplied to the second layer aids in layer formation without substantially heating the substrate. Some embodiments include depositing a photovoltaic cell. In some embodiments, the substrate is a flexible material supplied from a roll. Some embodiments include attaching an integrated circuit to the substrate and operatively coupling the integrated circuit to charge the battery from the photovoltaic cell.

Owner:CYMBET CORP

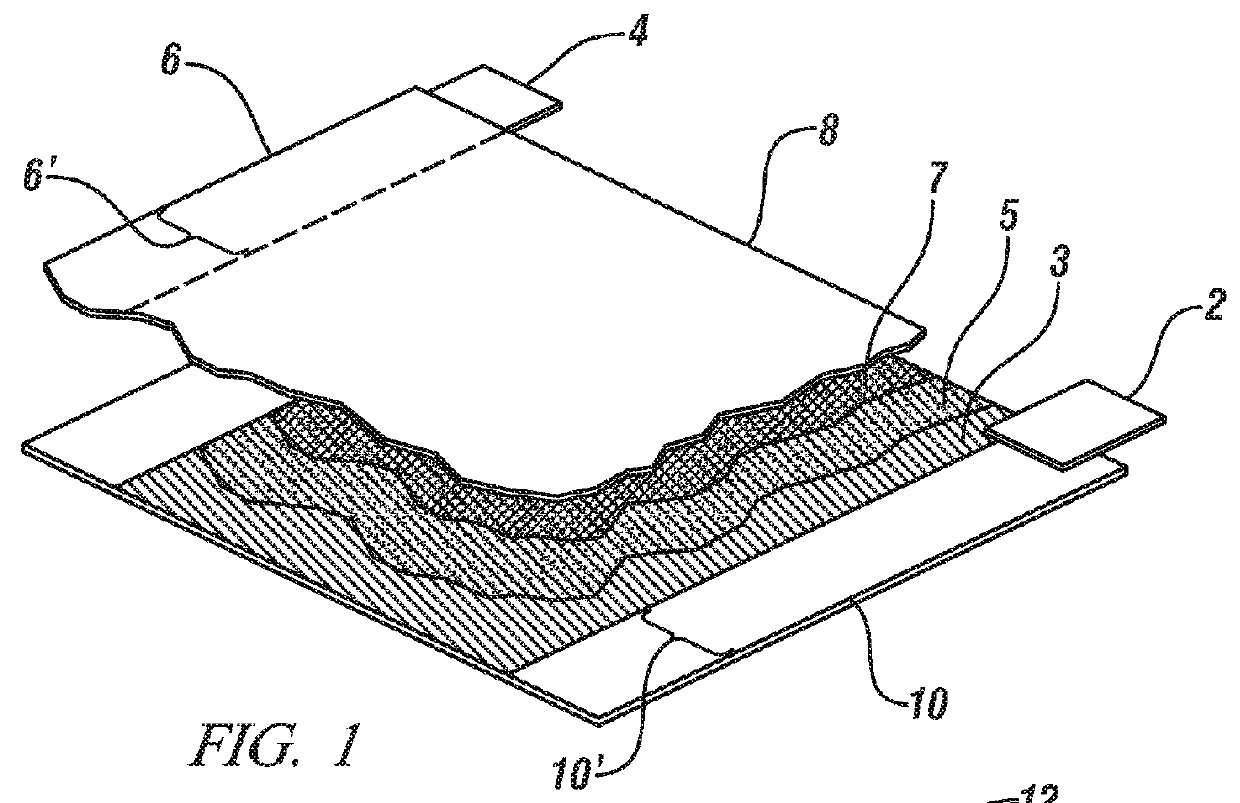

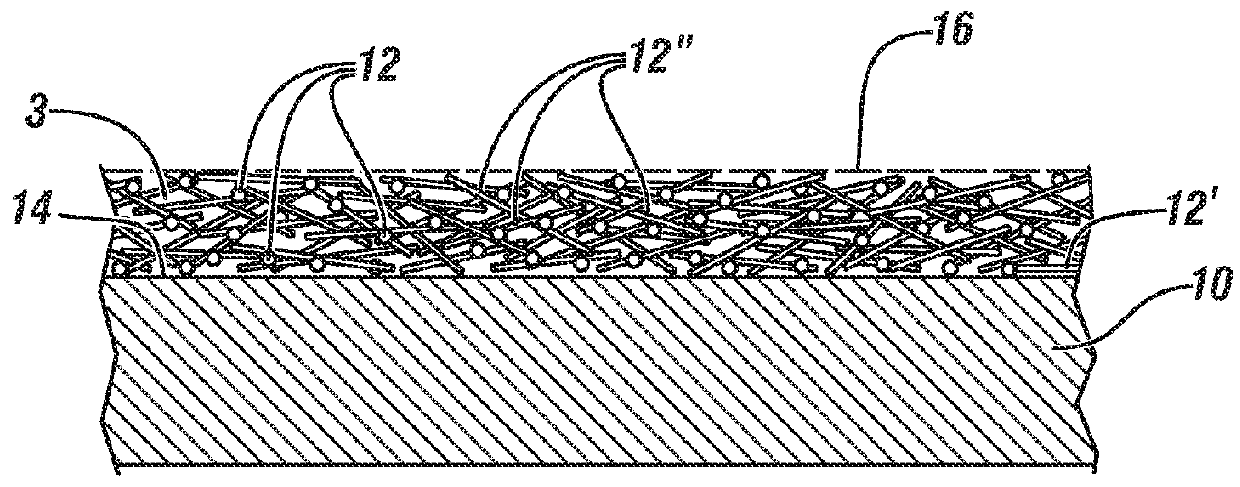

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

Positive electrode material, manufacturing method thereof, positive electrode for non-aqueous rechargeable battery, and non-aqueous rechargeable battery

ActiveUS20120321948A1Reduce moistureReduce capacity dropSecondary cellsPositive electrodesHigh temperature storageProduction rate

A positive electrode material that can form a positive electrode mixture containing composition with reduced changes over time and high productivity, a manufacturing method thereof, a non-aqueous rechargeable battery less likely to swell and having a high storage characteristic during storage at high temperatures, and a positive electrode that can form the battery are provided. The object is solved by providing a positive electrode material having a coating layer of an organic silane compound on a surface of a positive electrode active material made of a lithium nickel composite oxide represented by the general compositional formula (1): Li1+xMO2 where −0.5≦x≦0.5, M represents a group of at least two elements including at least one of Mn and Co and Ni, and 20≦a≦100 and 50≦a+b+c≦100 when the ratios (mol %) of Ni, Mn, and Co in the elements forming M are a, b, and c, respectively.

Owner:MAXELL HLDG LTD

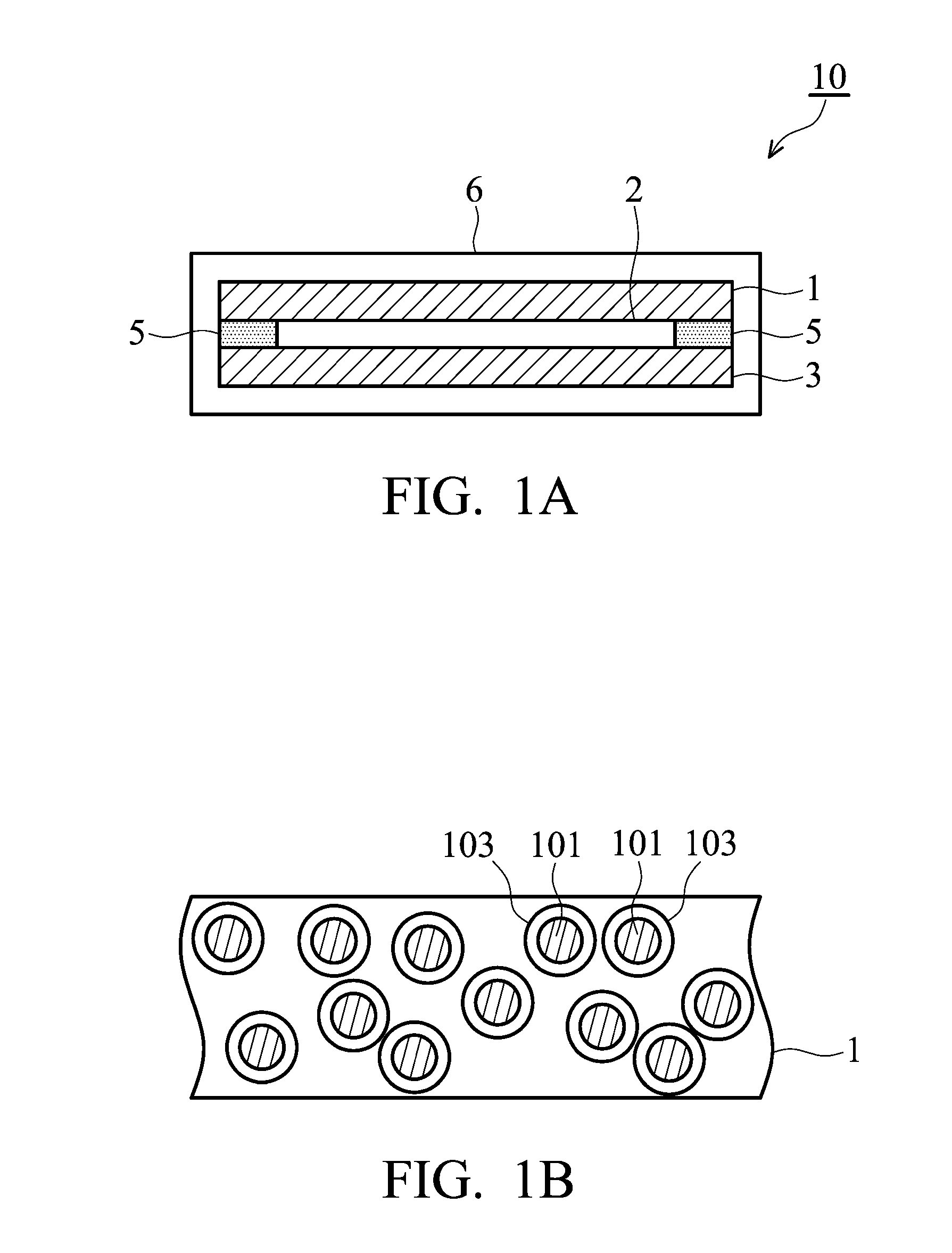

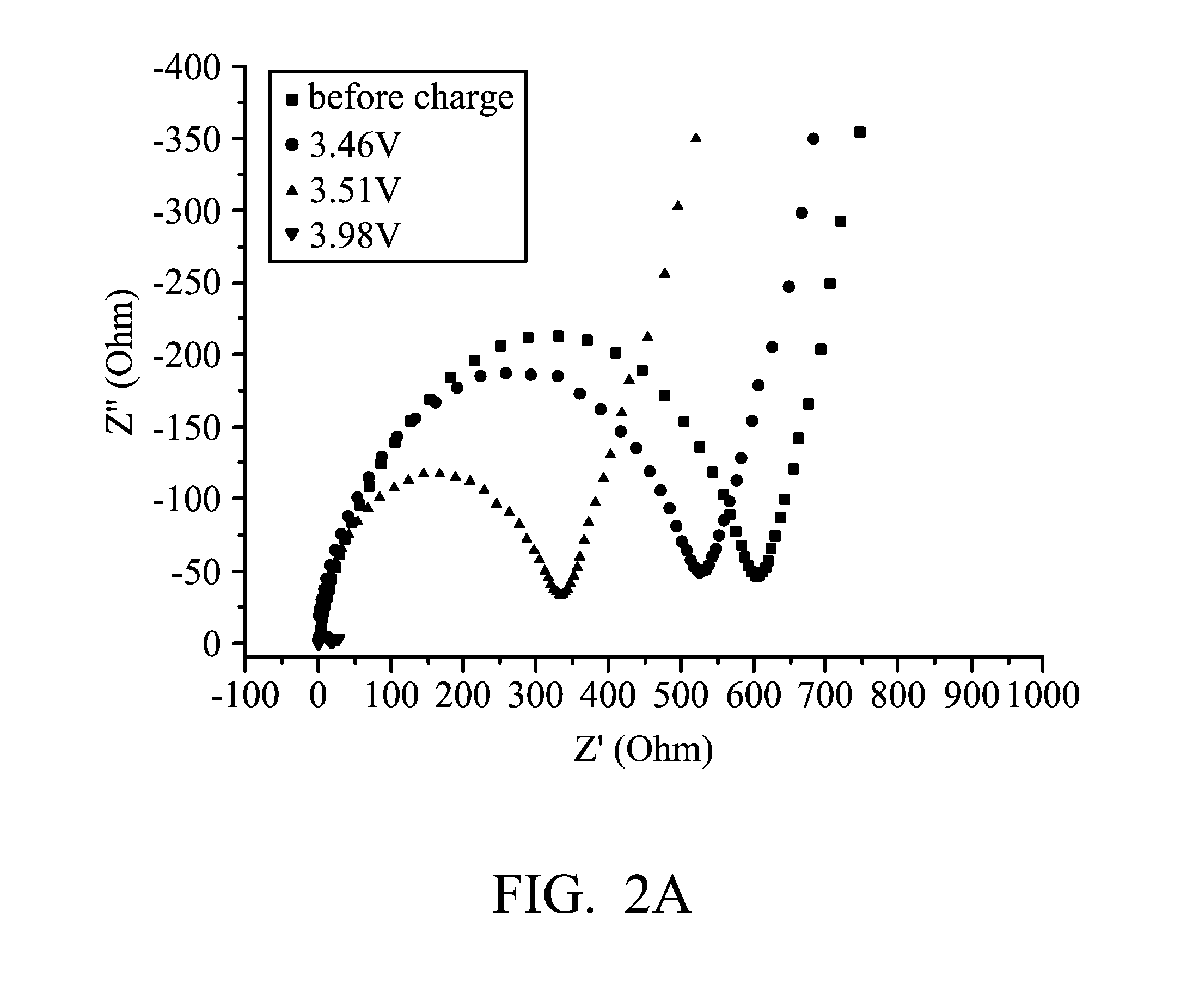

Method for modifying cathode material and lithium battery employing the cathode material

ActiveUS20100167129A1Avoid explosionPrimary cellsElectrode carriers/collectorsLithium-ion batteryBattery cell

The invention provides a lithium battery, including: a cathode plate and an anode plate; a separator disposed between the cathode plate and the anode plate to define a reservoir region; and an electrolyte filled in the reservoir region. A thermal protective film is provided to cover a material of the cathode plate or the anode plate. When a battery temperature rises over an onset temperature of the thermal protective film, it undergoes a crosslinking reaction to inhibit thermal runaway. A method for fabricating the lithium ion battery is also provided.

Owner:IND TECH RES INST

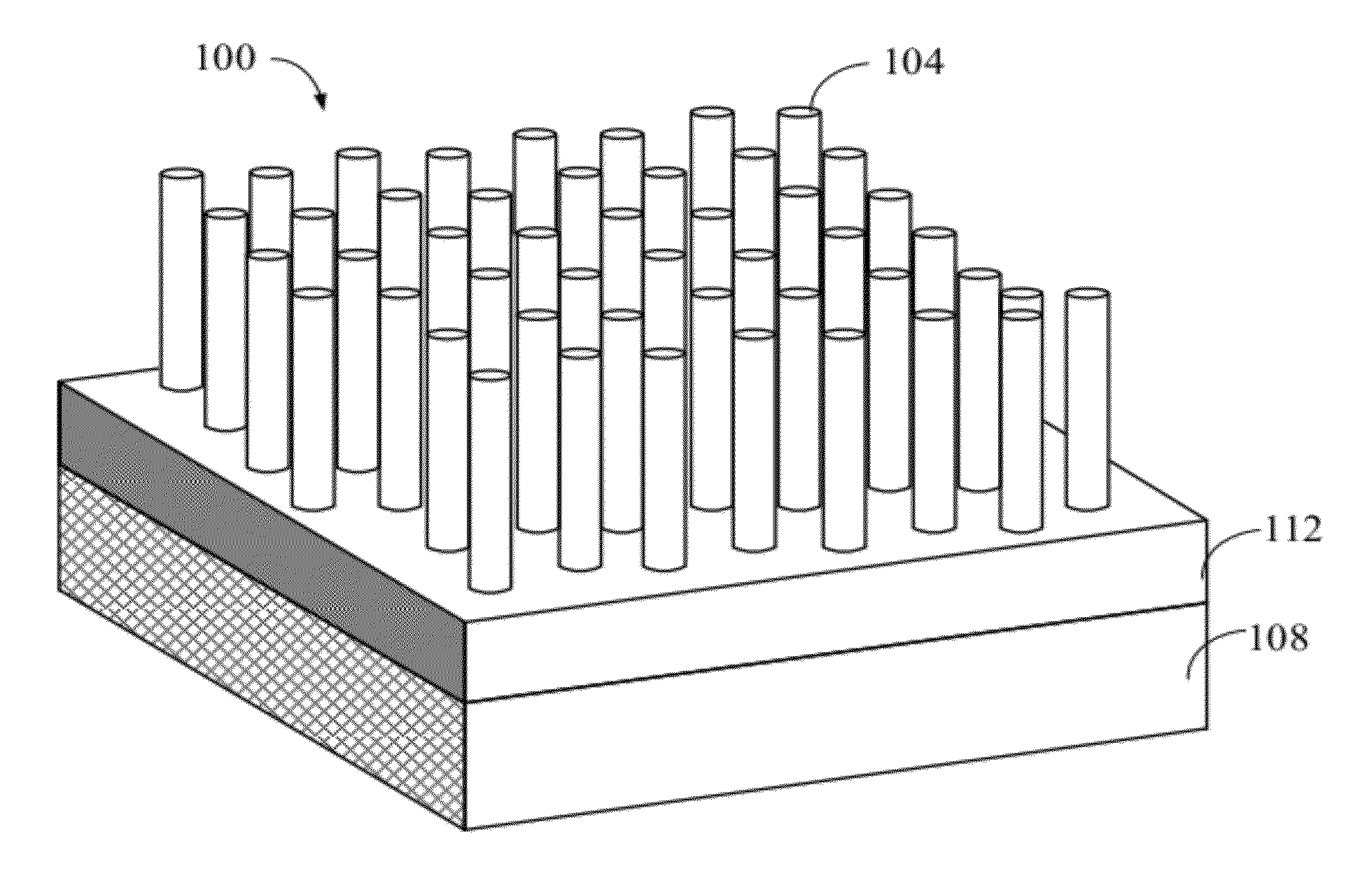

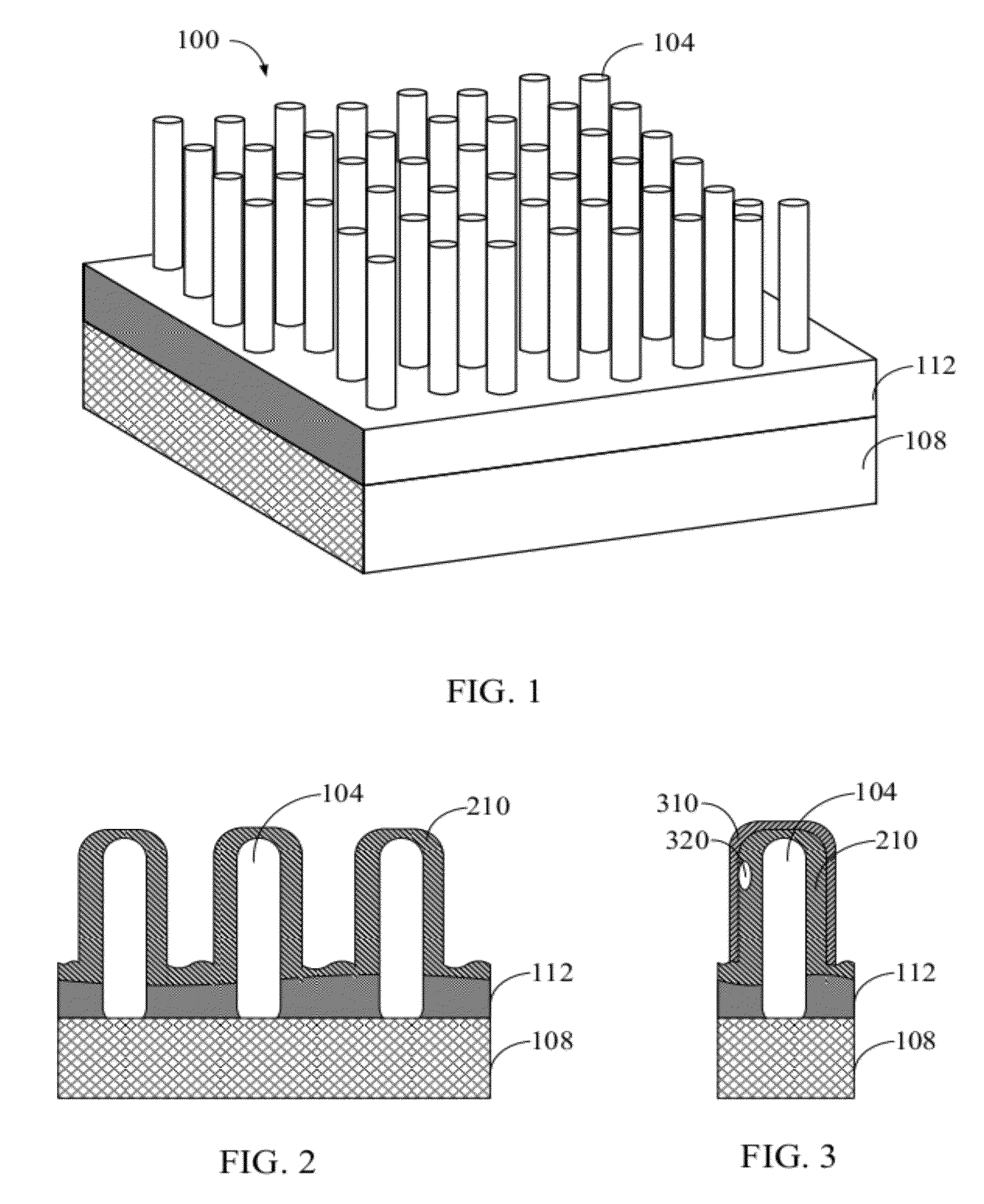

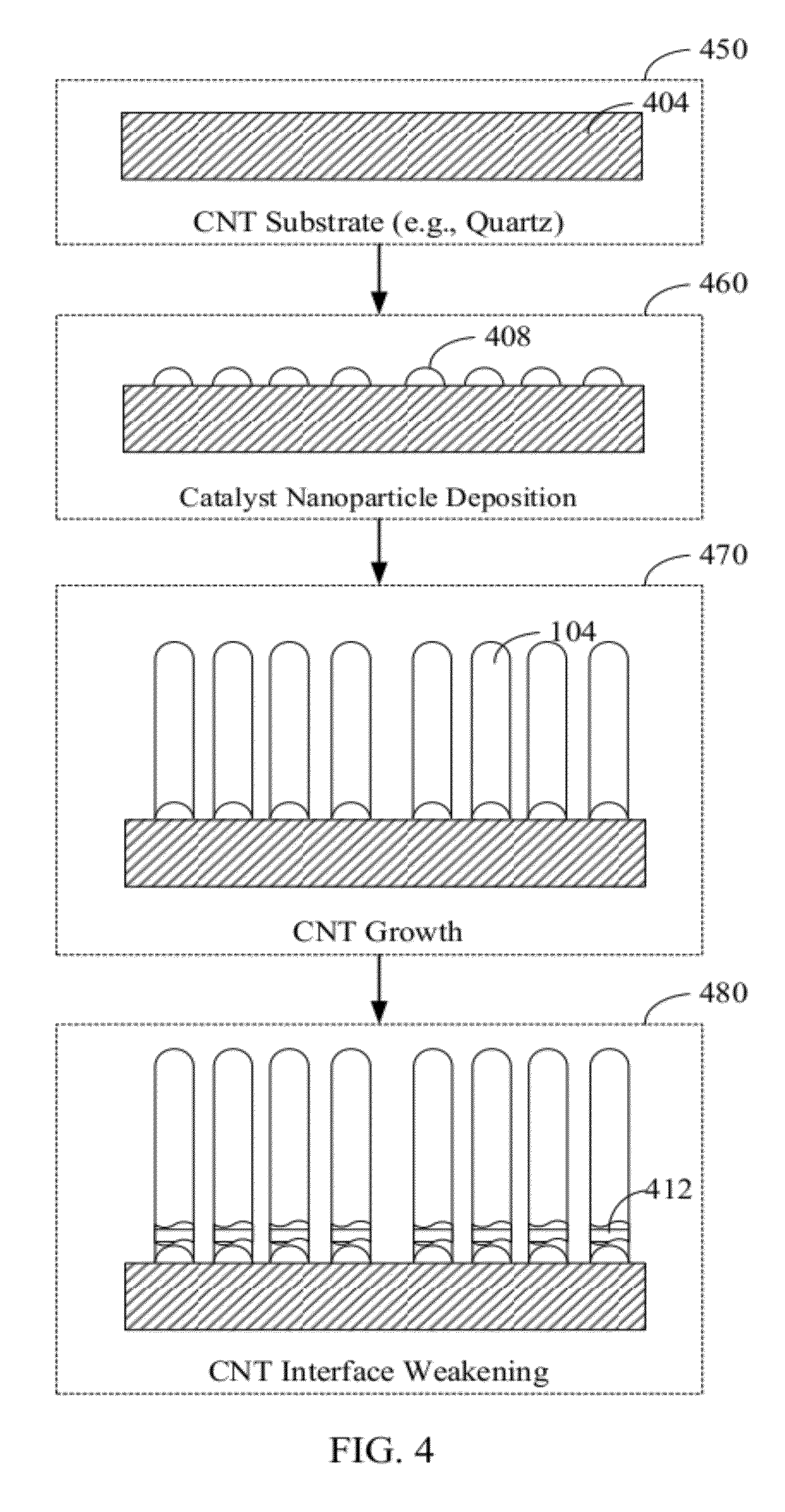

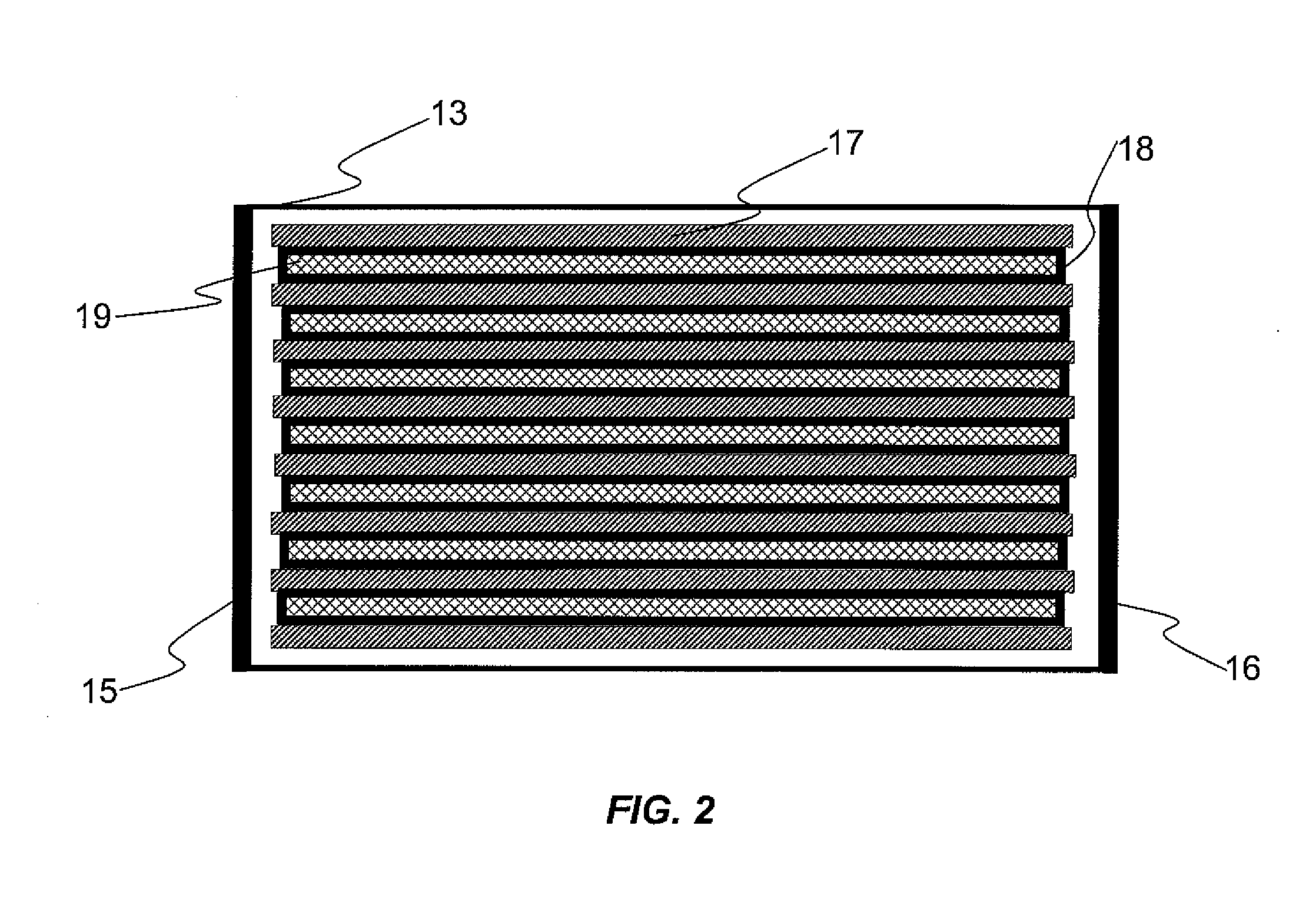

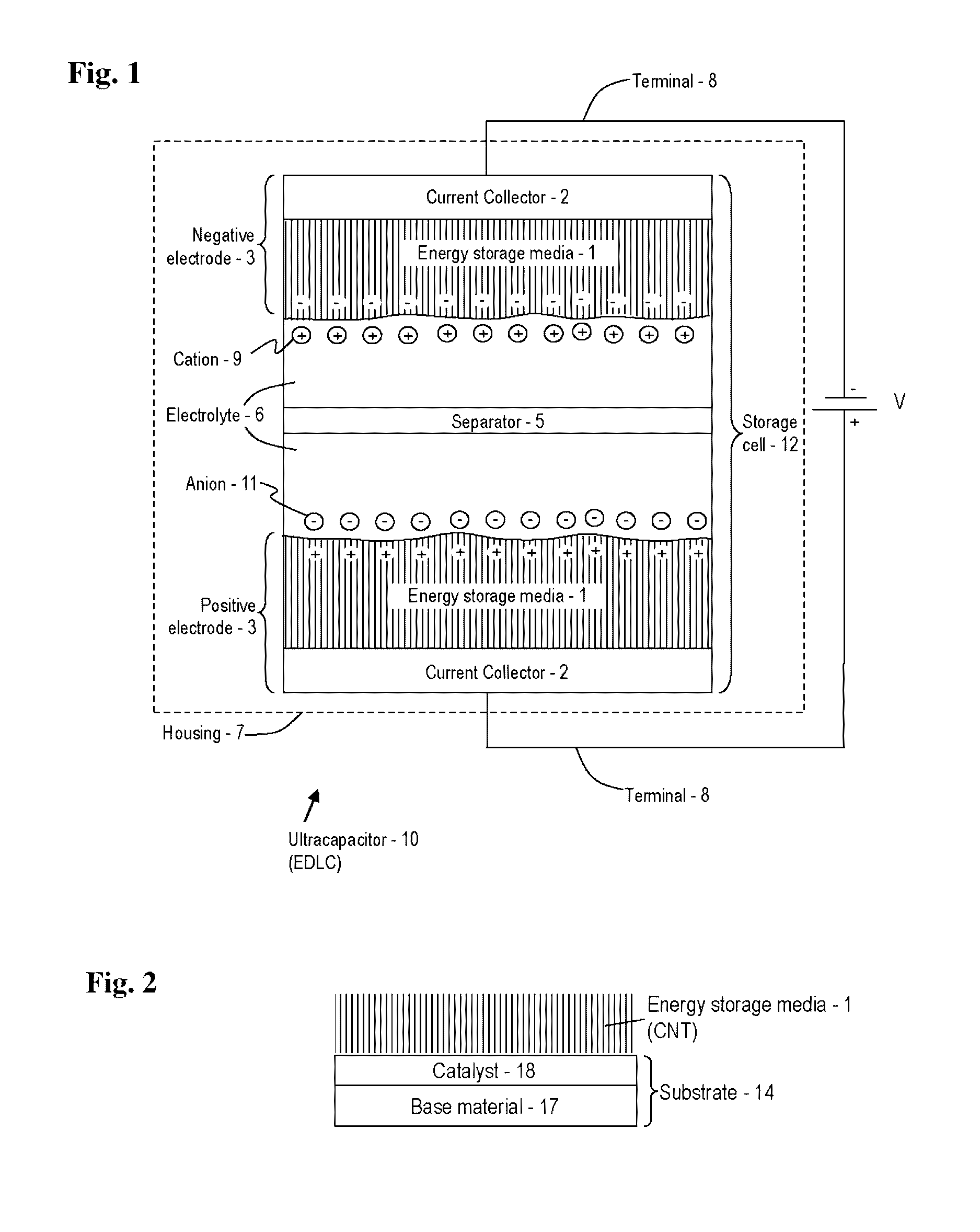

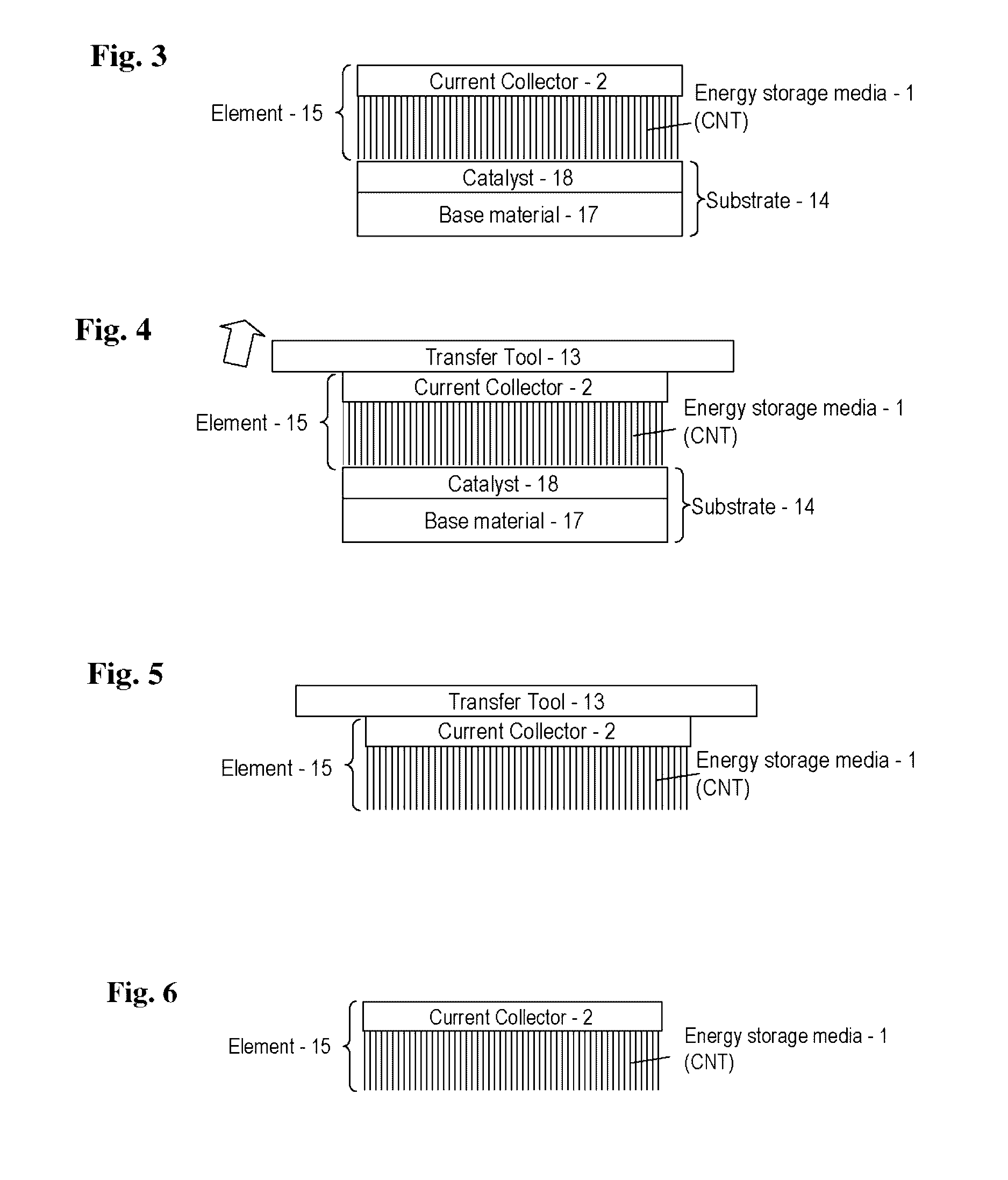

Carbon nanotube array bonding

Material compositions are provided that may comprise, for example, a vertically aligned carbon nanotube (VACNT) array, a conductive layer, and a carbon interlayer coupling the VACNT array to the conductive layer. Methods of manufacturing are provided. Such methods may comprise, for example, providing a VACNT array, providing a conductive layer, and bonding the VACNT array to the conductive layer via a carbon interlayer.

Owner:GEORGIA TECH RES CORP

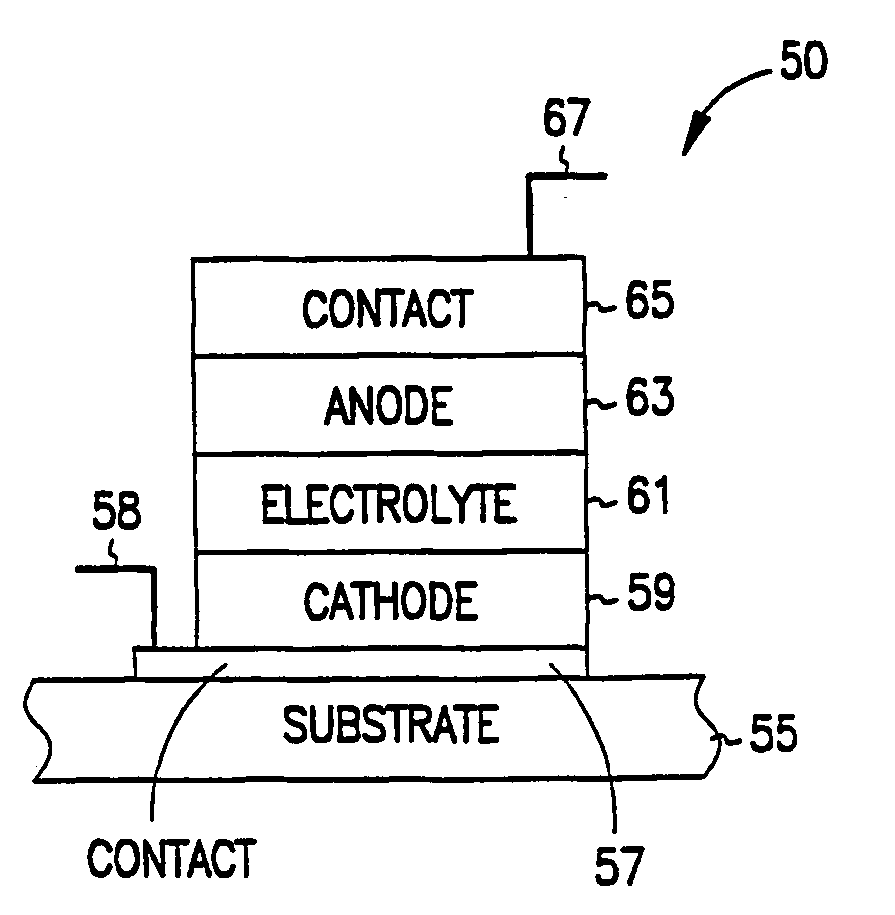

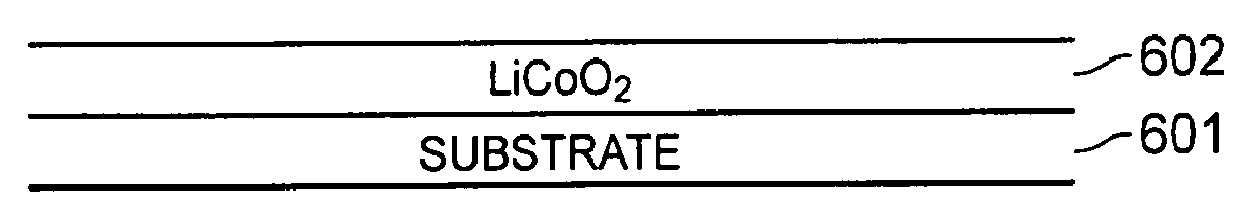

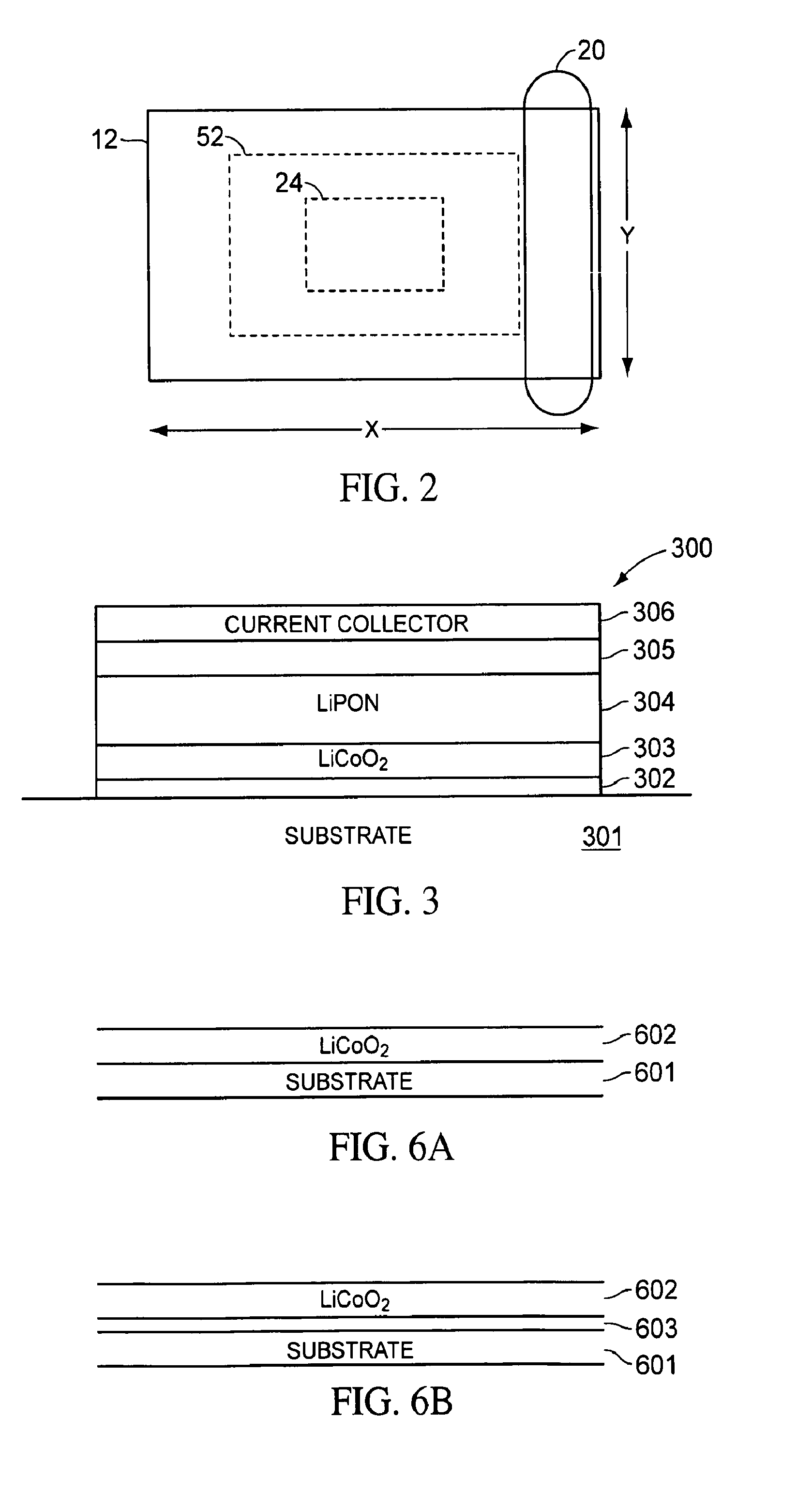

Deposition of LiCoO2

ActiveUS7959769B2Increase deposition rateElectrochemical processing of electrodesElectrode thermal treatmentHigh rateEngineering

In accordance with the present invention, deposition of LiCoO2 layers in a pulsed-dc physical vapor deposition process is presented. Such a deposition can provide a low-temperature, high deposition rate deposition of a crystalline layer of LiCoO2 with a desired (101) or (003) orientation. Some embodiments of the deposition addresses the need for high rate deposition of LiCoO2 films, which can be utilized as the cathode layer in a solid state rechargeable Li battery. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the LiCoO2 layer. Some embodiments of the process can improve a battery utilizing the LiCoO2 layer by utilizing a rapid thermal anneal process with short ramp rates.

Owner:SAPURAST RES

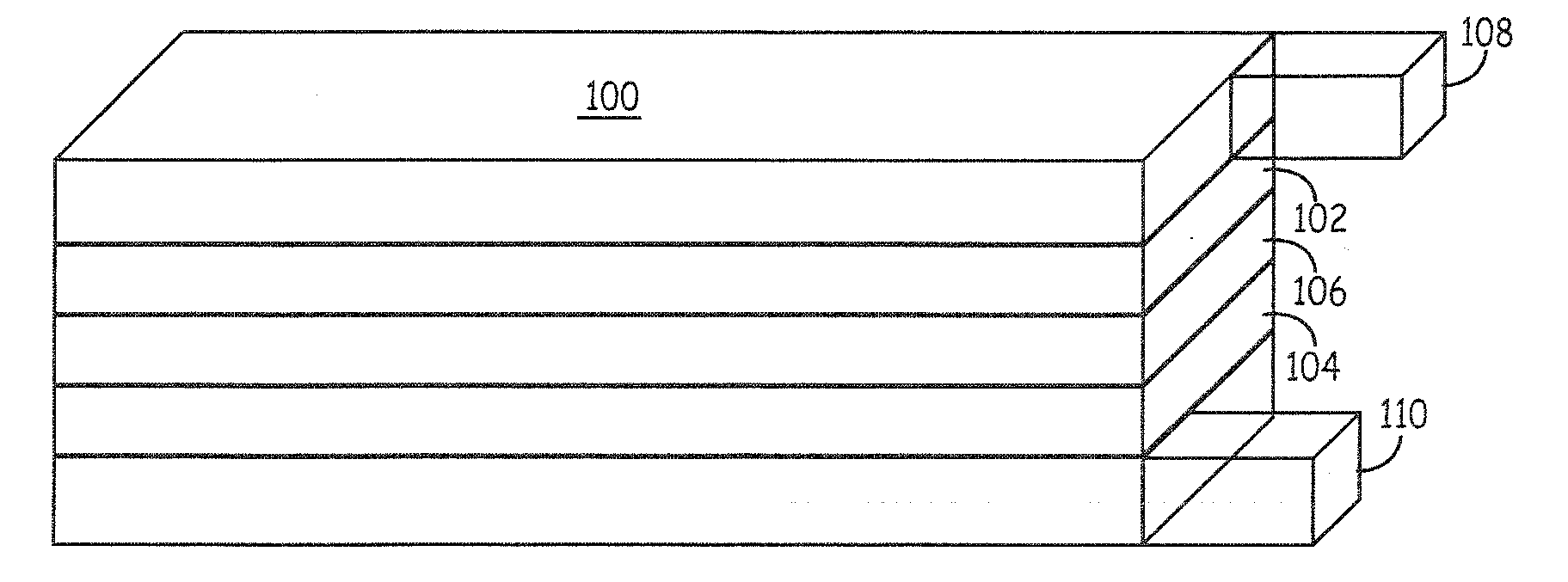

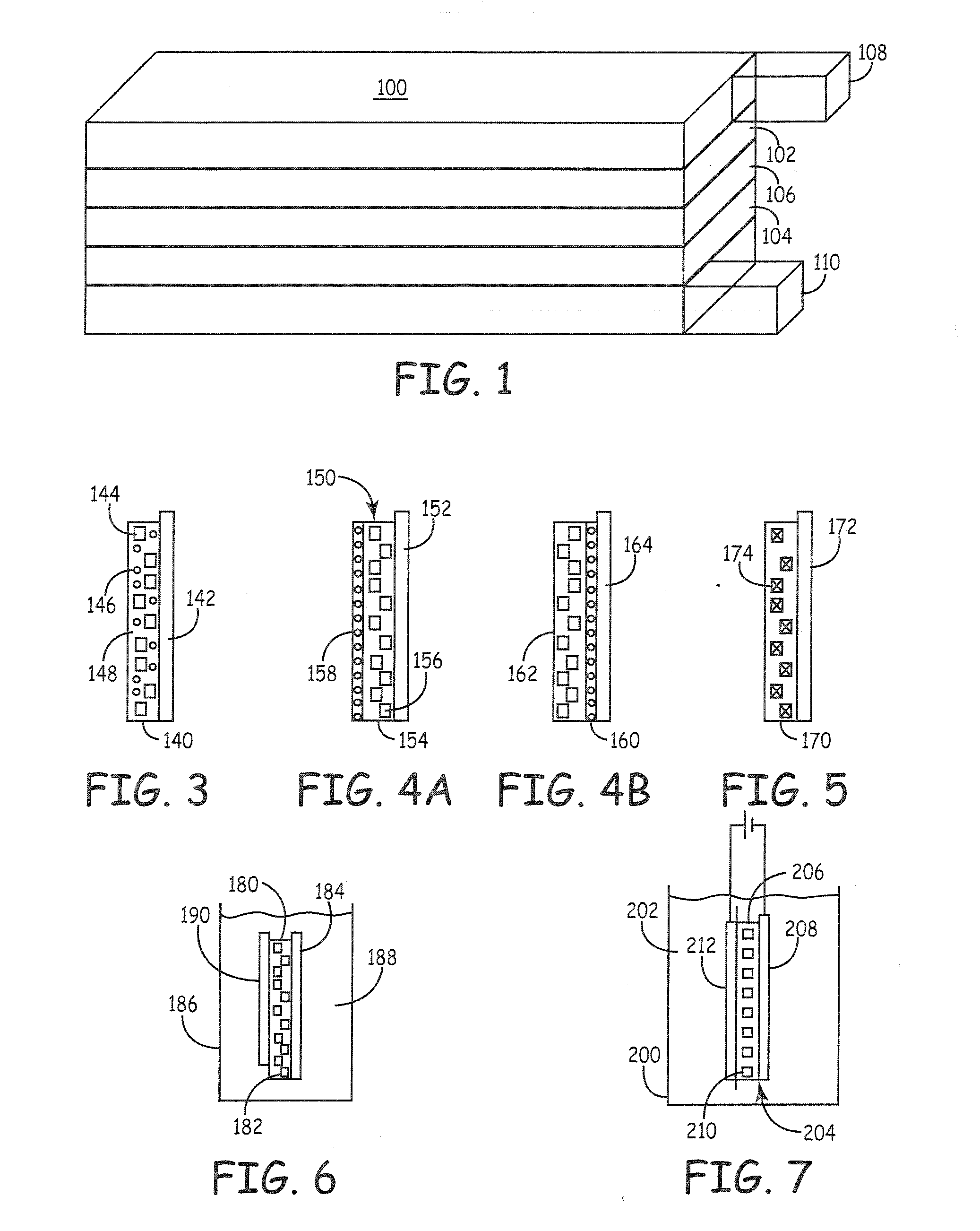

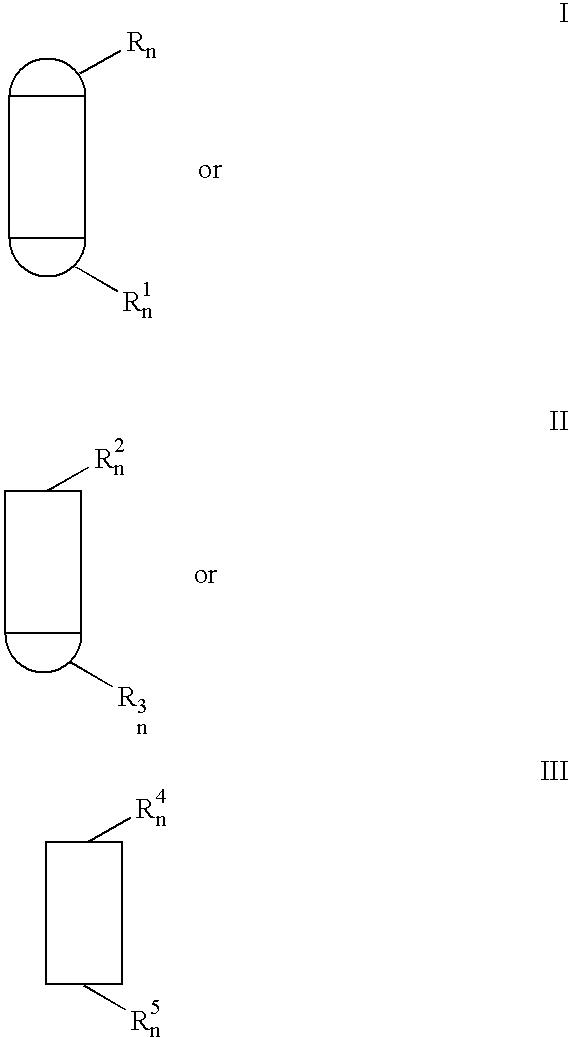

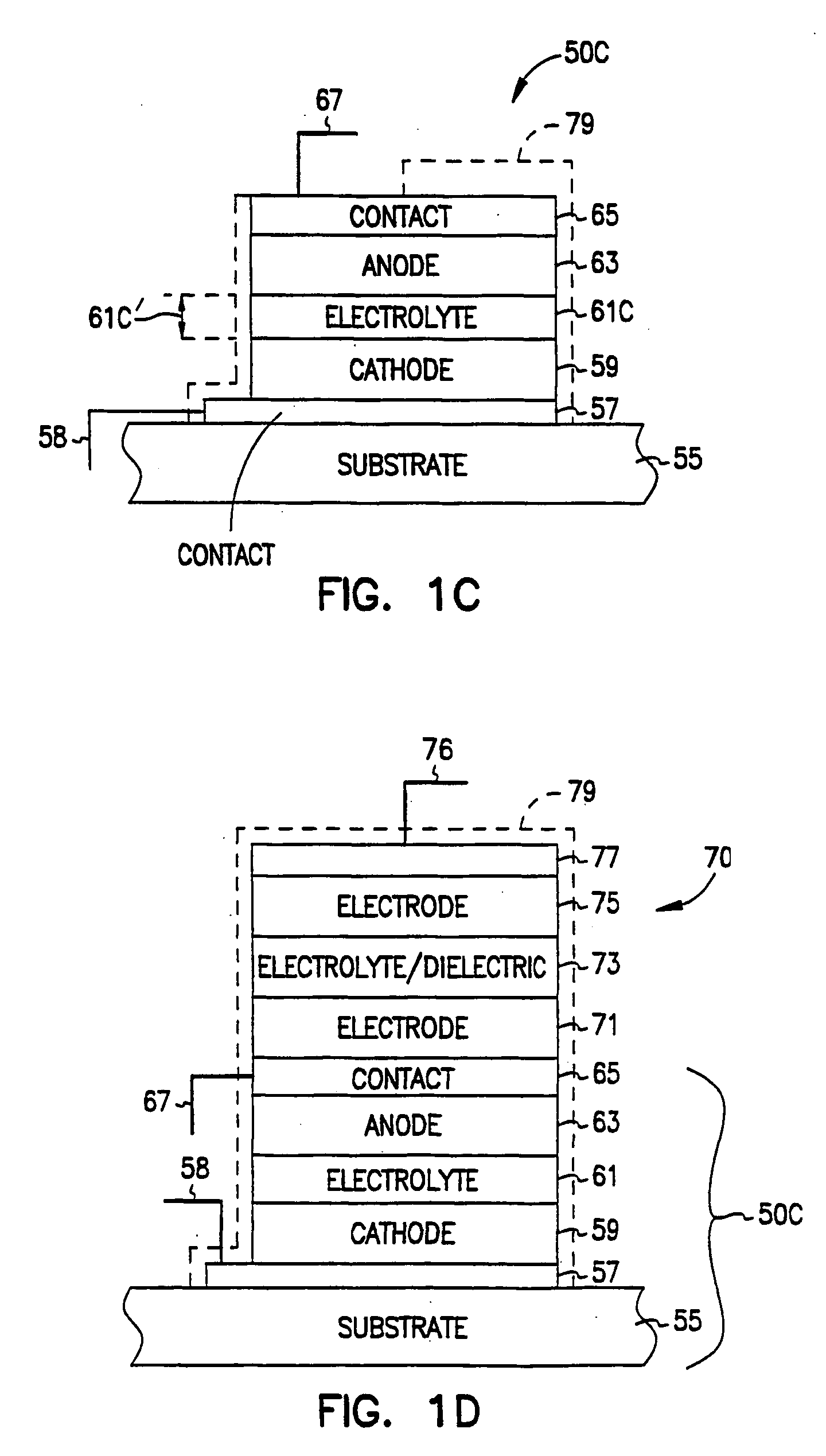

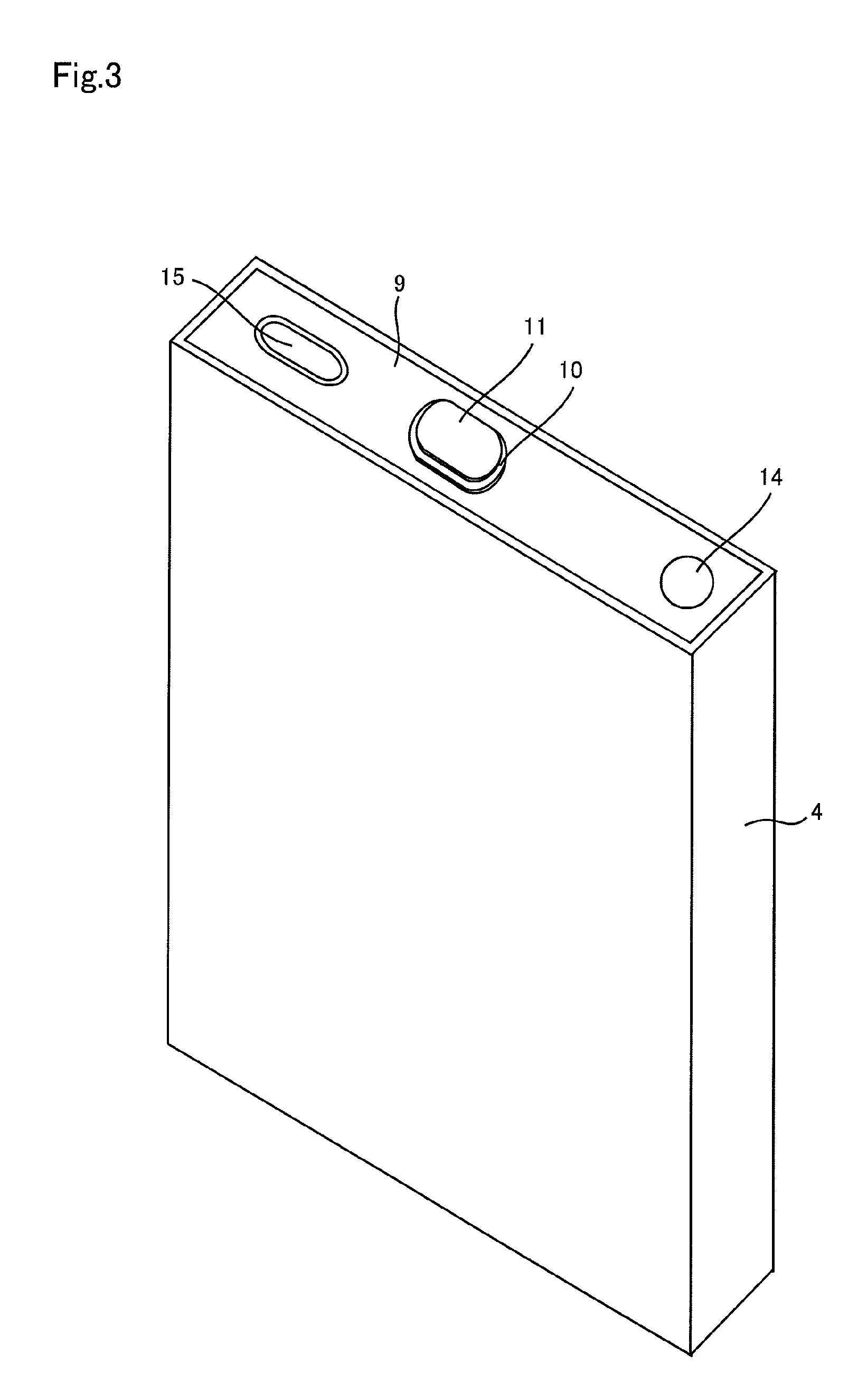

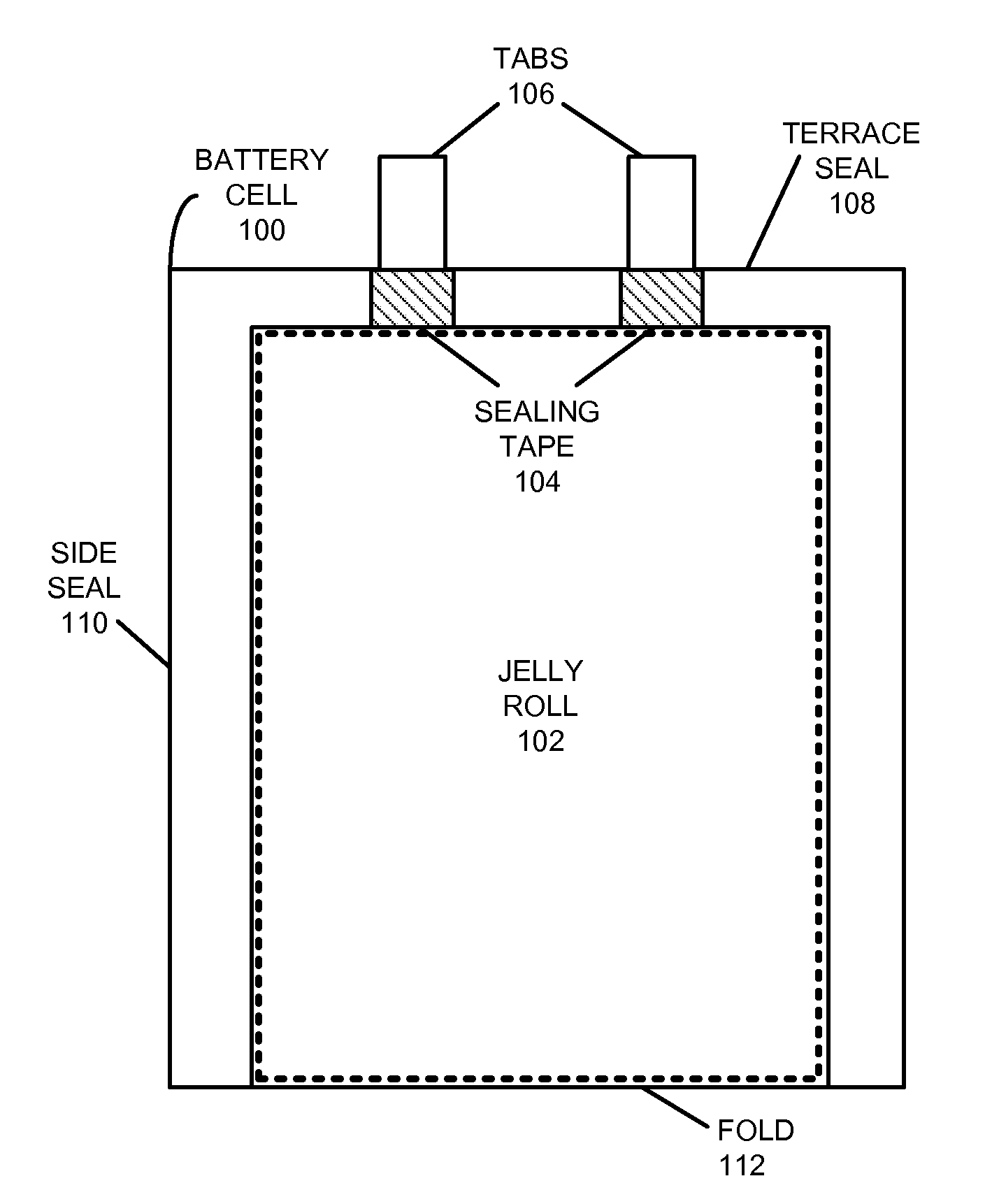

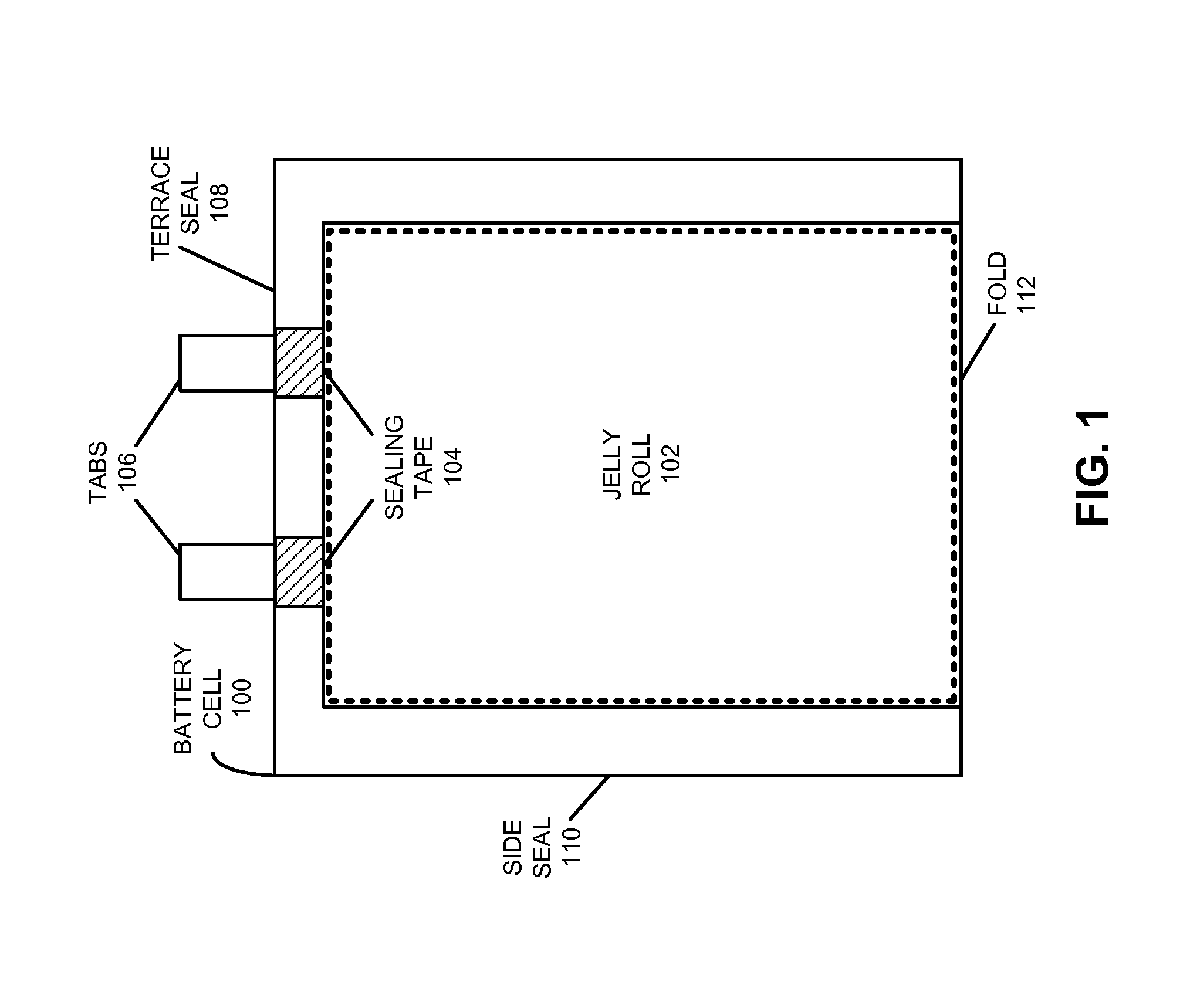

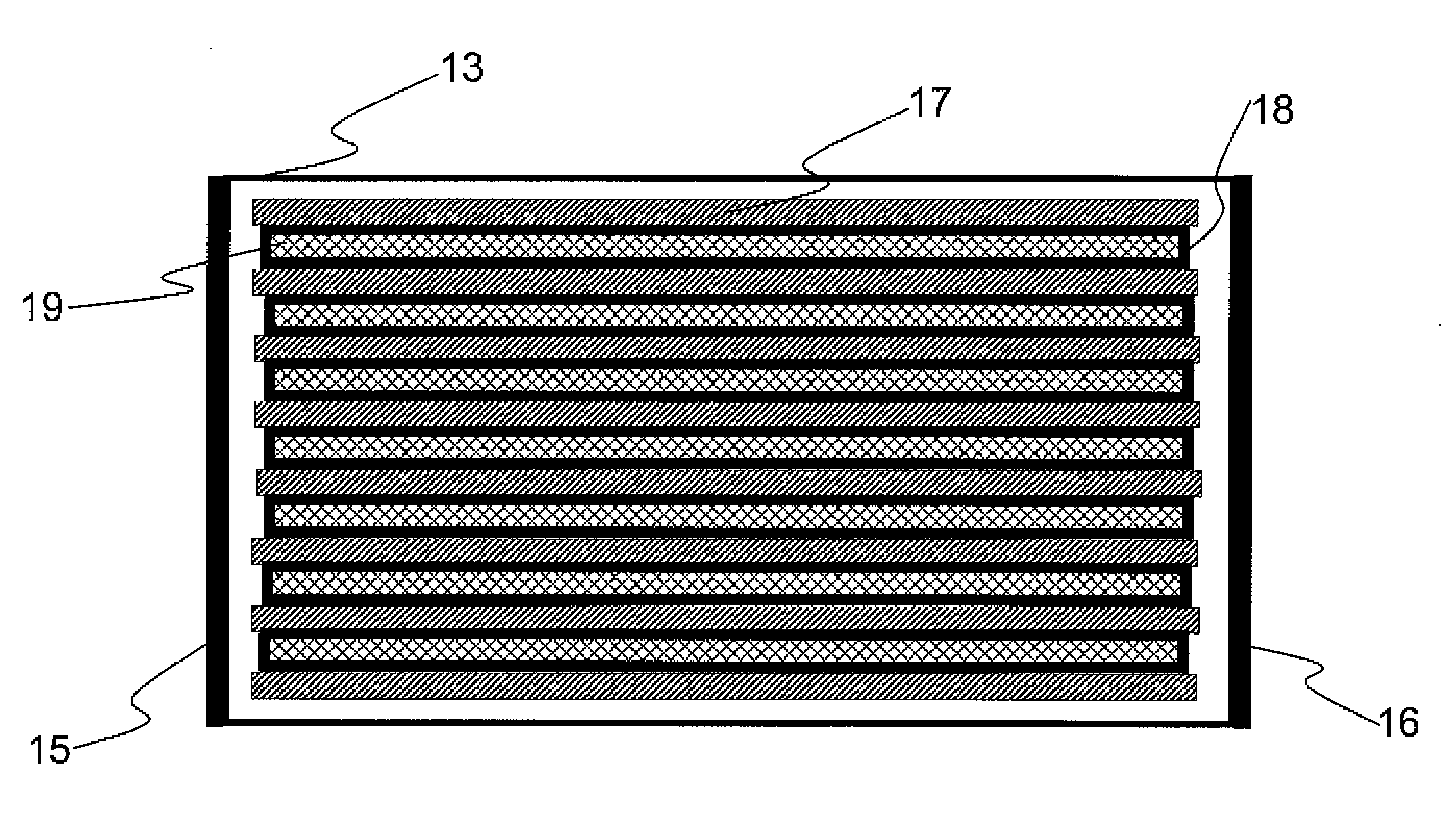

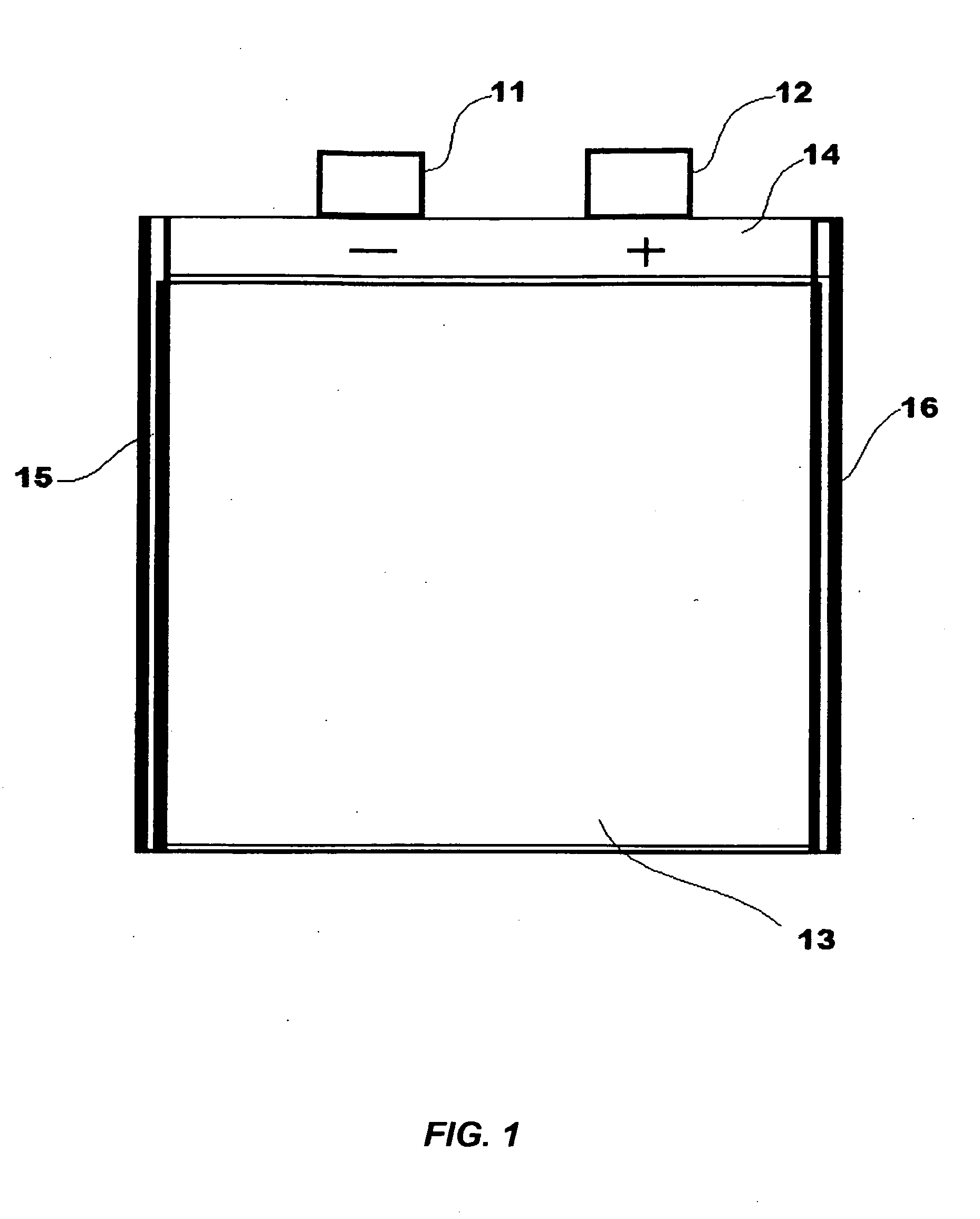

Rechargeable battery with a jelly roll having multiple thicknesses

ActiveUS20120107654A1Facilitate efficient use of spaceContact member manufacturingContact member cases/bases manufactureRechargeable cellEngineering

The disclosed embodiments relate to the design of a battery cell with multiple thicknesses. This battery cell includes a jelly roll enclosed in a pouch, wherein the jelly roll includes layers which are wound together, including a cathode with an active coating, a separator, and an anode with an active coating. The jelly roll also includes a first conductive tab coupled to the cathode and a second conductive tab coupled to the anode. The jelly roll is enclosed in a flexible pouch, and the first and second conductive tabs are extended through seals in the pouch to provide terminals for the battery cell. Furthermore, the battery cell has two or more thicknesses, wherein the different thicknesses are created by removing material from one or more of the layers before winding the layers together.

Owner:APPLE INC

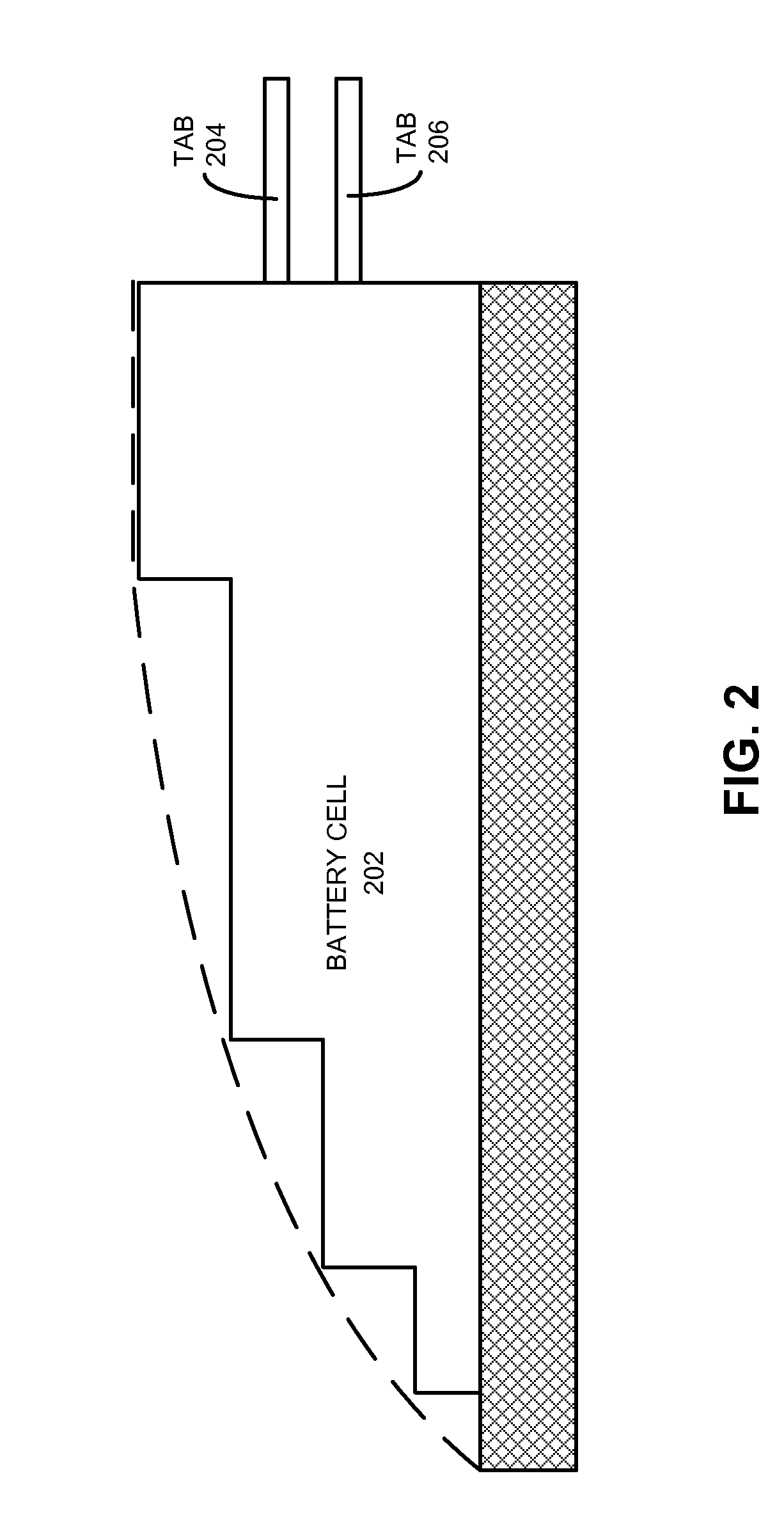

Method for sputter targets for electrolyte films

ActiveUS9334557B2Improve thermal conductivityReduce downtimeVacuum evaporation coatingPrinted batteriesLithiumSputter deposition

Owner:SAPURAST RES

Large format lithium-ion cell and its uses thereof

InactiveUS20080318122A1Primary cell to battery groupingNon-aqueous electrolyte cellsHigh energyEngineering plastic

This invention is directed to a battery pack with a high energy density and a large format prismatic lithium-ion cell comprising (1) at least one positive electrode, (2) at least one negative electrode, (3) a non-aqueous electrolyte, and (4) a homogeneous microporous membrane which comprises (a) a hot-melt adhesive, (b) an engineering plastics, (c) optionally a tackifier and (d) a filler having an average particle size of less than about 50 μm. The resulting battery pack can be used as power source for applications such as electric vehicles (EV), hybrid electric vehicles (HEV), power-assist HEV (P-HEV), and standby power stations.

Owner:POLICELL TECH

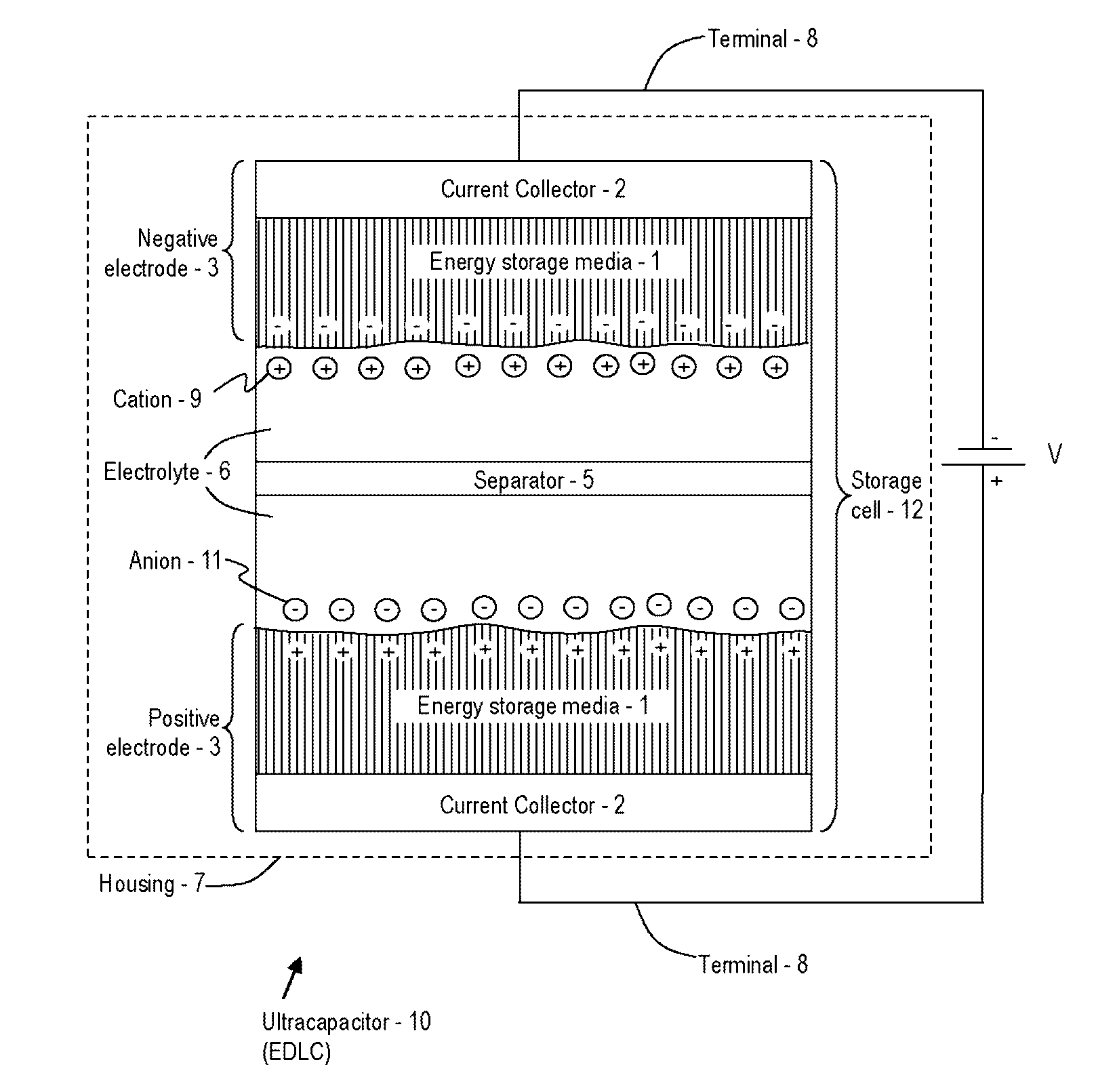

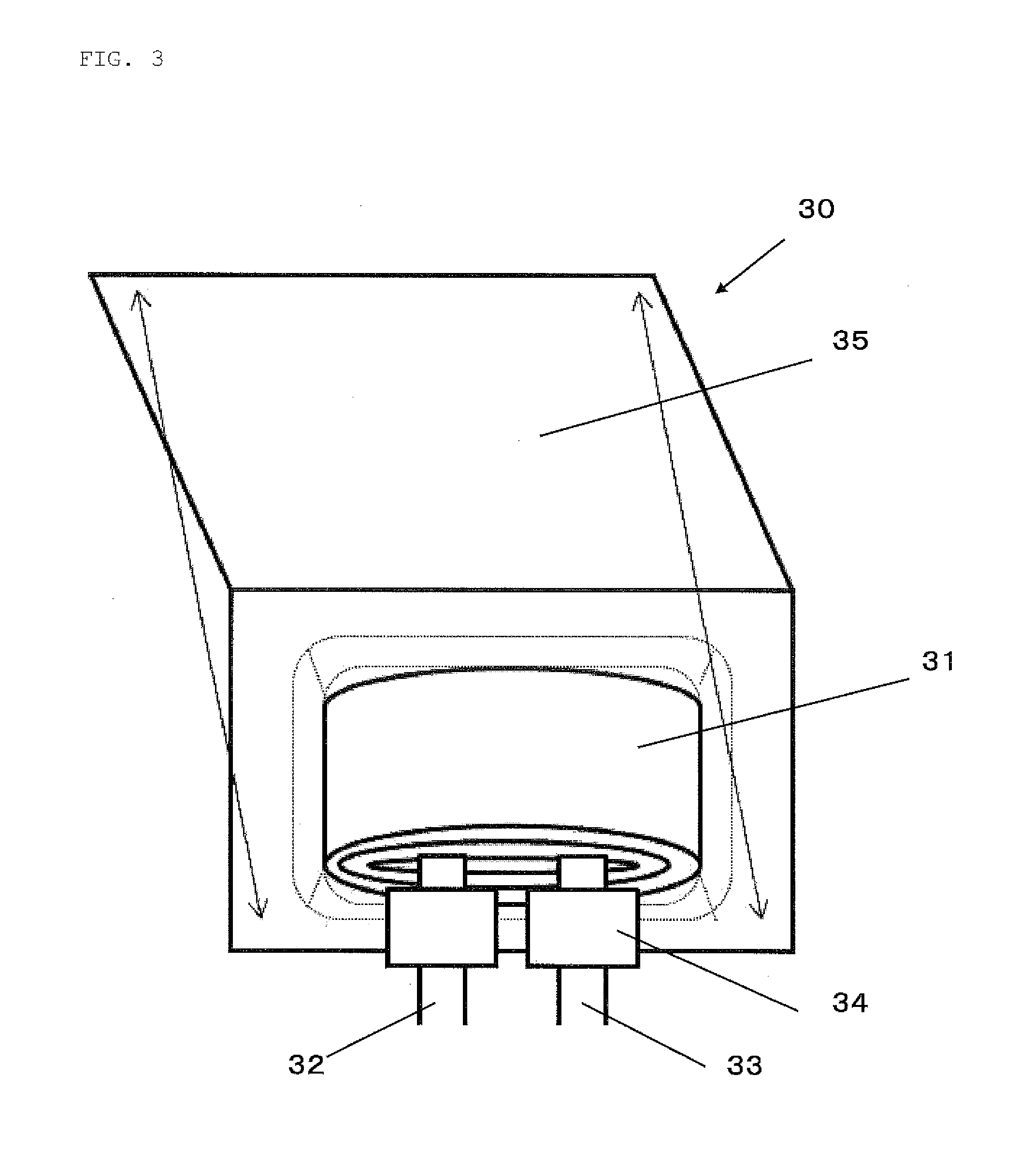

Advanced electrolyte systems and their use in energy storage devices

An ultracapacitor that includes an energy storage cell immersed in an advanced electrolyte system and disposed within a hermetically sealed housing, the cell electrically coupled to a positive contact and a negative contact, wherein the ultracapacitor is configured to output electrical energy within a temperature range between about −40 degrees Celsius to about 210 degrees Celsius. Methods of fabrication and use are provided.

Owner:FASTCAP SYST

Polyimide binder for power storage device, electrode sheet using same, and power storage device

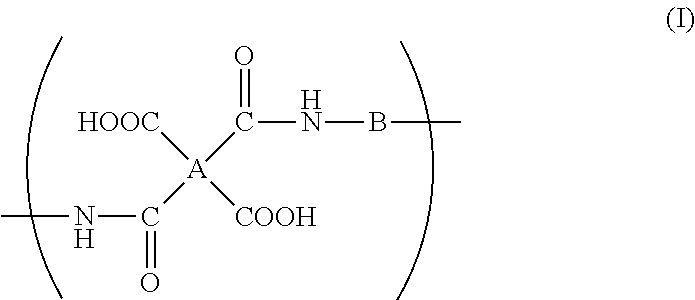

ActiveUS20160233513A1Improve propertiesHybrid capacitor electrolytesHybrid capacitor electrodesCarboxylic acidPolyamic acid

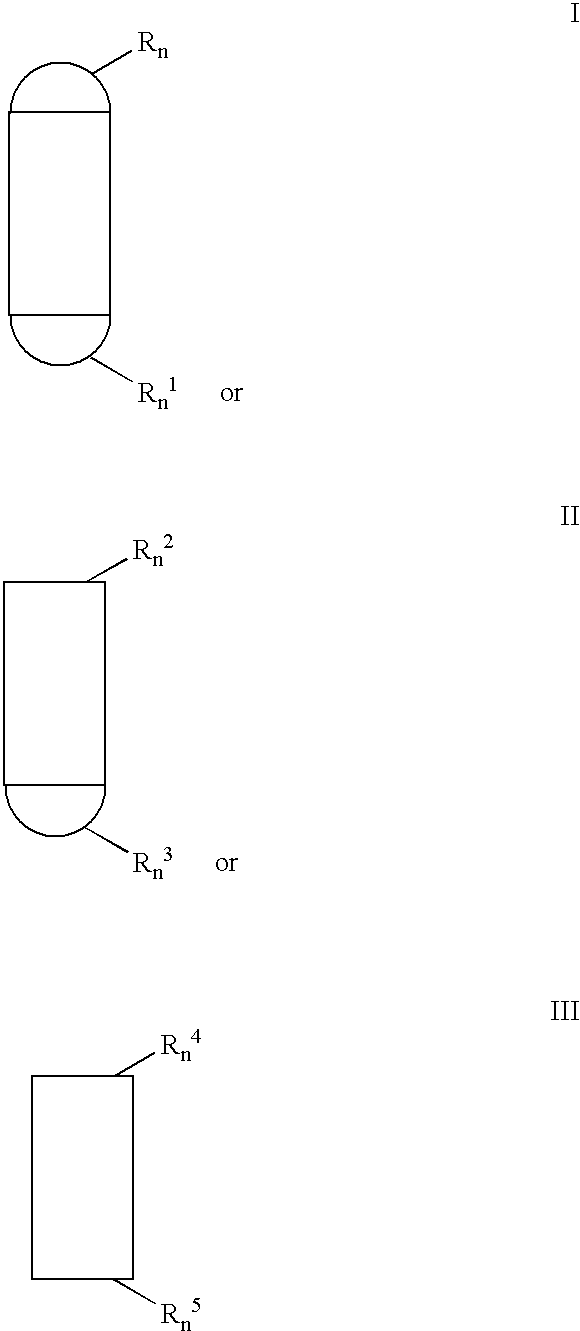

Provided are a polyimide binder for energy storage device capable of improving properties of an energy storage device in a broad temperature range, and an electrode sheet and an energy storage device using the same. The polyimide binder for energy storage device, which is a polyimide obtained by subjecting an aqueous solution of a polyamic acid composed of a repeating unit represented by the following general formula (I) to an imidization reaction, the polyimide having a tensile elastic modulus of 1.5 GPa or more and 2.7 GPa or less.In the formula, A is a tetravalent group resulting from eliminating a carboxyl group from a specified tetracarboxylic acid, and B is a divalent group resulting from eliminating an amino group from a specified diamine, provided that 55 mol % or more of B in a total amount of the repeating unit is the divalent group resulting from eliminating an amino group from an aliphatic diamine having a molecular weight of 500 or less.

Owner:UBE CORP

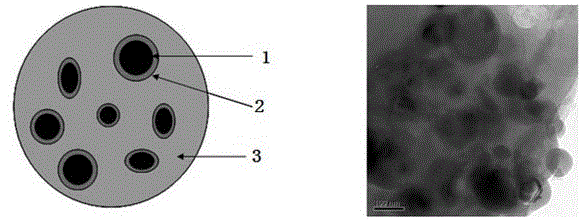

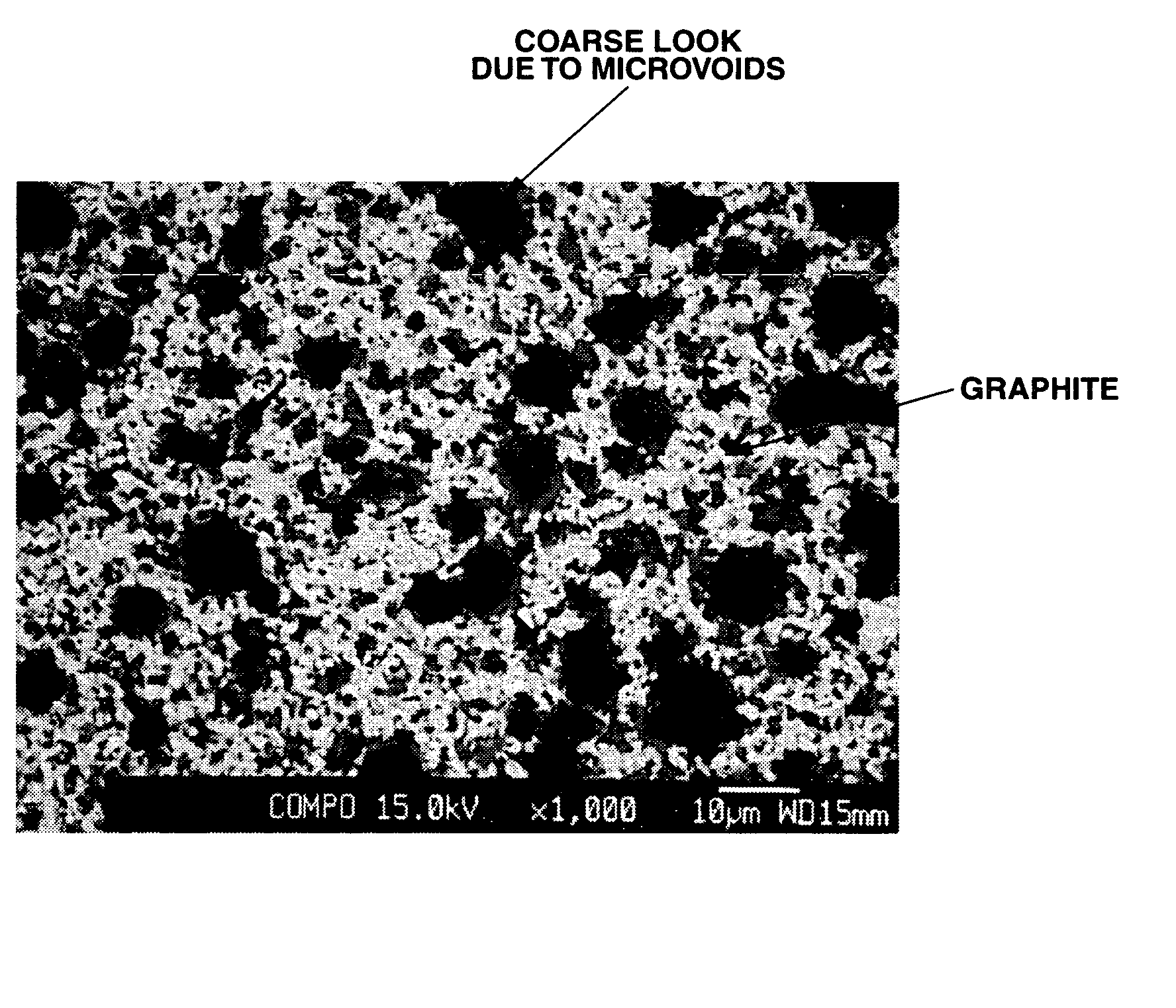

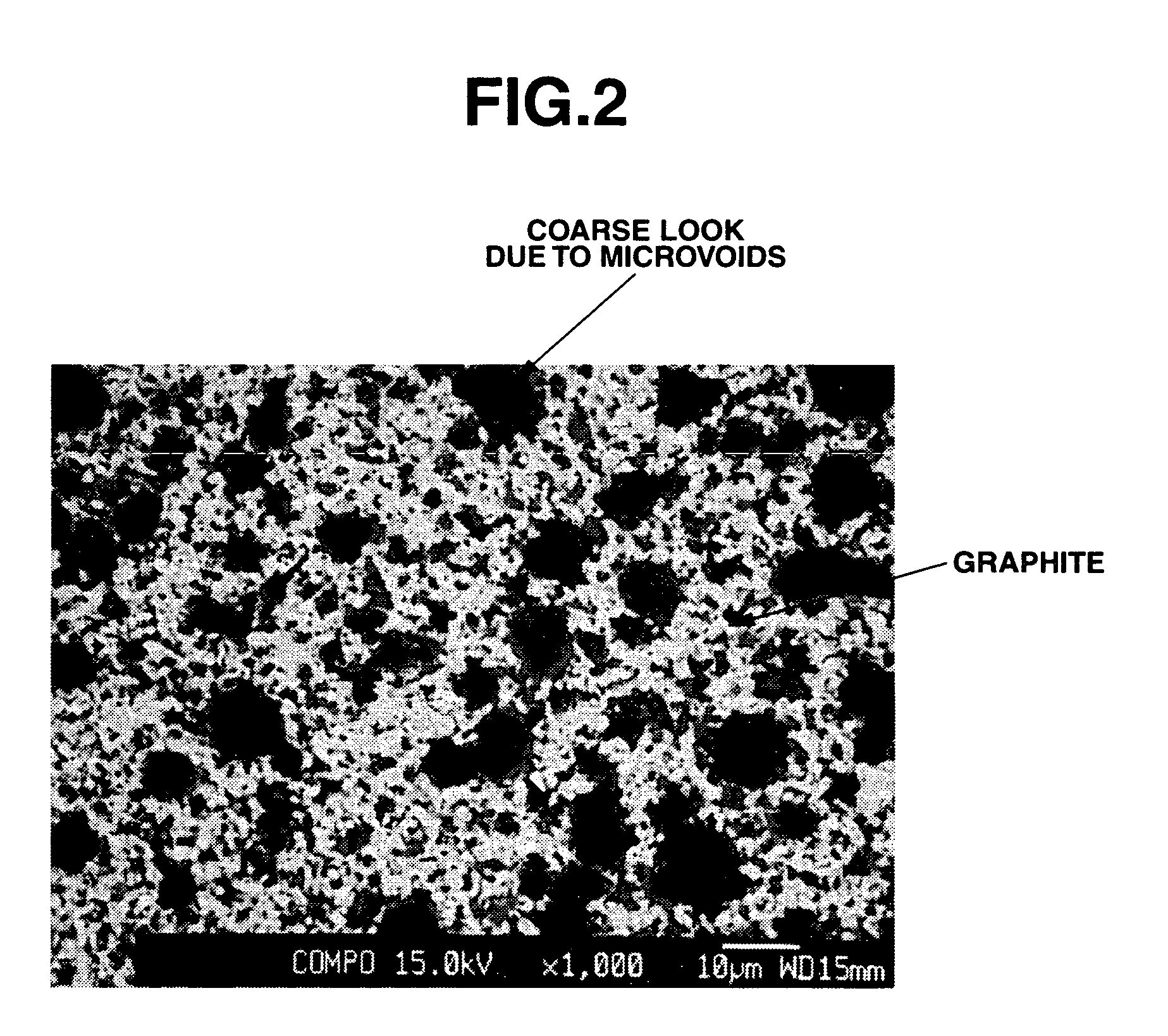

Silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN102509781BHigh specific capacityImprove cycle performanceCell electrodesBatteries manufactureCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAOTONG UNIV

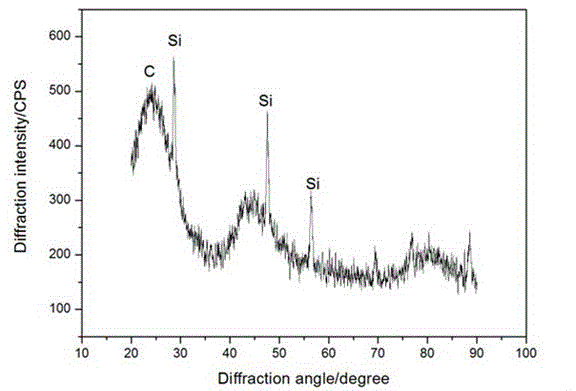

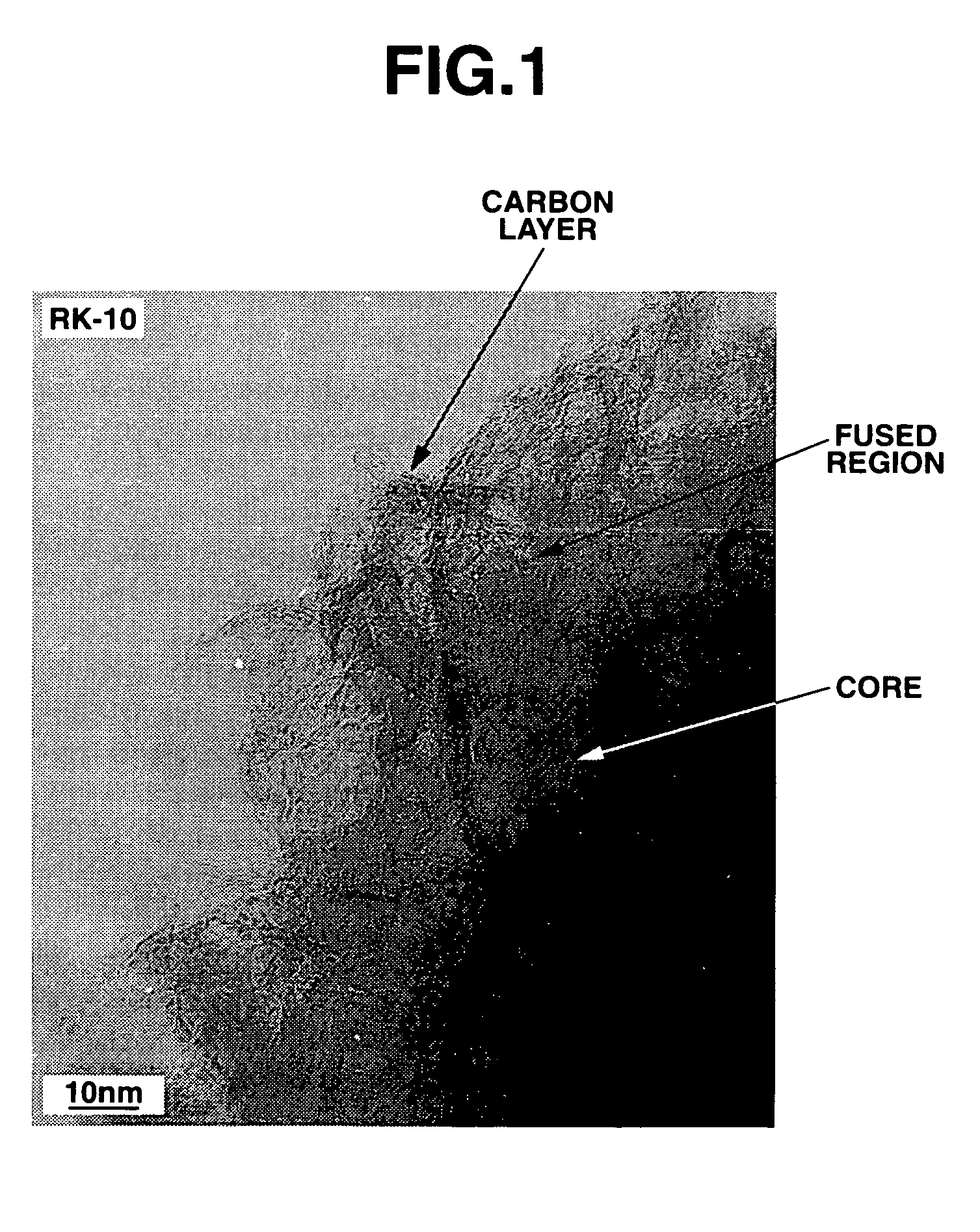

Si-C-O composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

InactiveUS7658863B2Improve cycle performanceInferior capacityCell electrodesPretreated surfacesMetallurgySilanes

A Si—C—O composite powder is obtained by curing a reactive silane or siloxane having crosslinkable groups through heat curing or catalytic reaction into a crosslinked product and sintering the crosslinked product in an inert gas stream at a temperature of 700-1,400° C. into an inorganic state. It exhibits satisfactory cycle performance when used as the negative electrode material for non-aqueous electrolyte secondary cells.

Owner:SHIN ETSU CHEM CO LTD

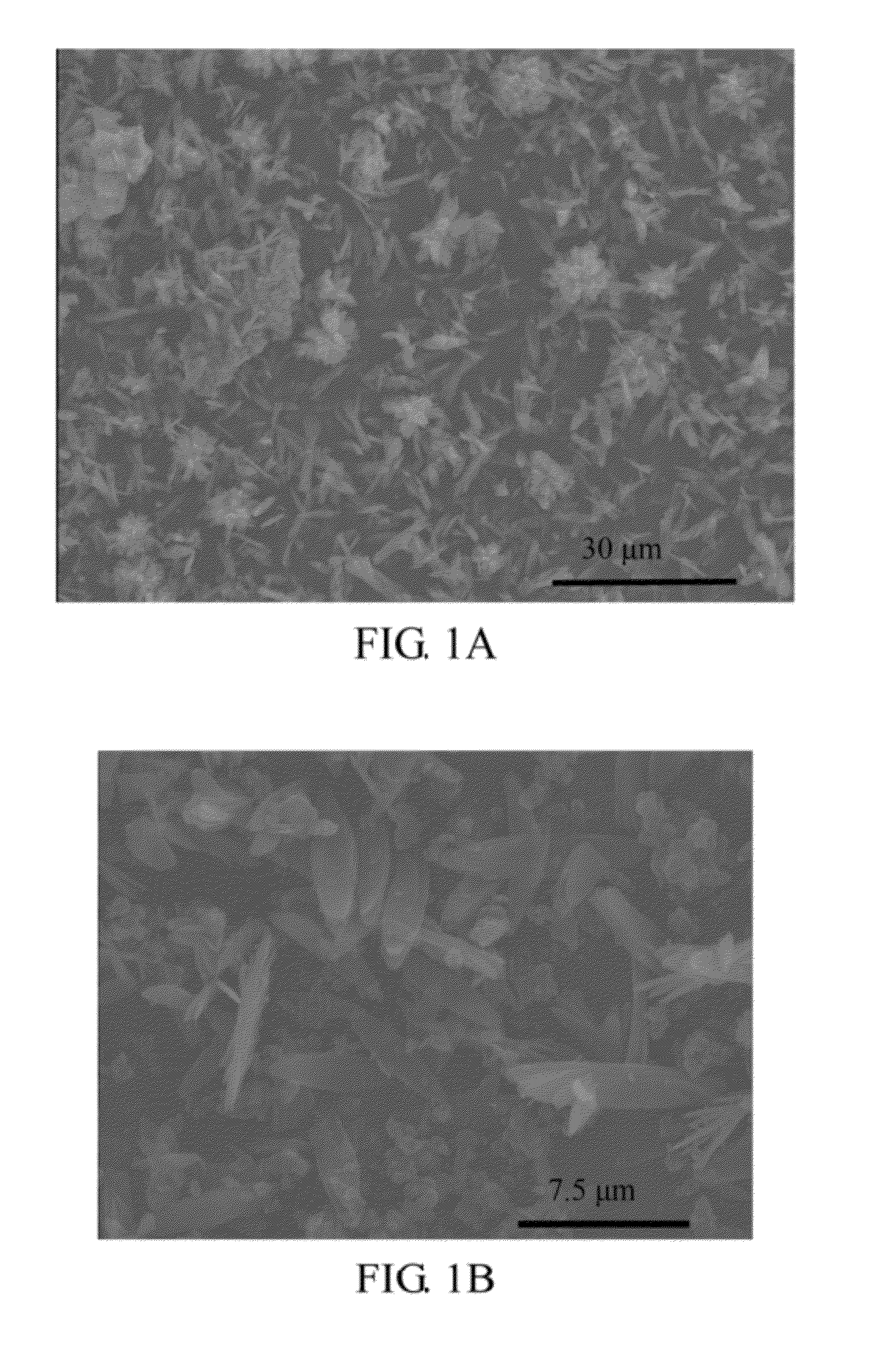

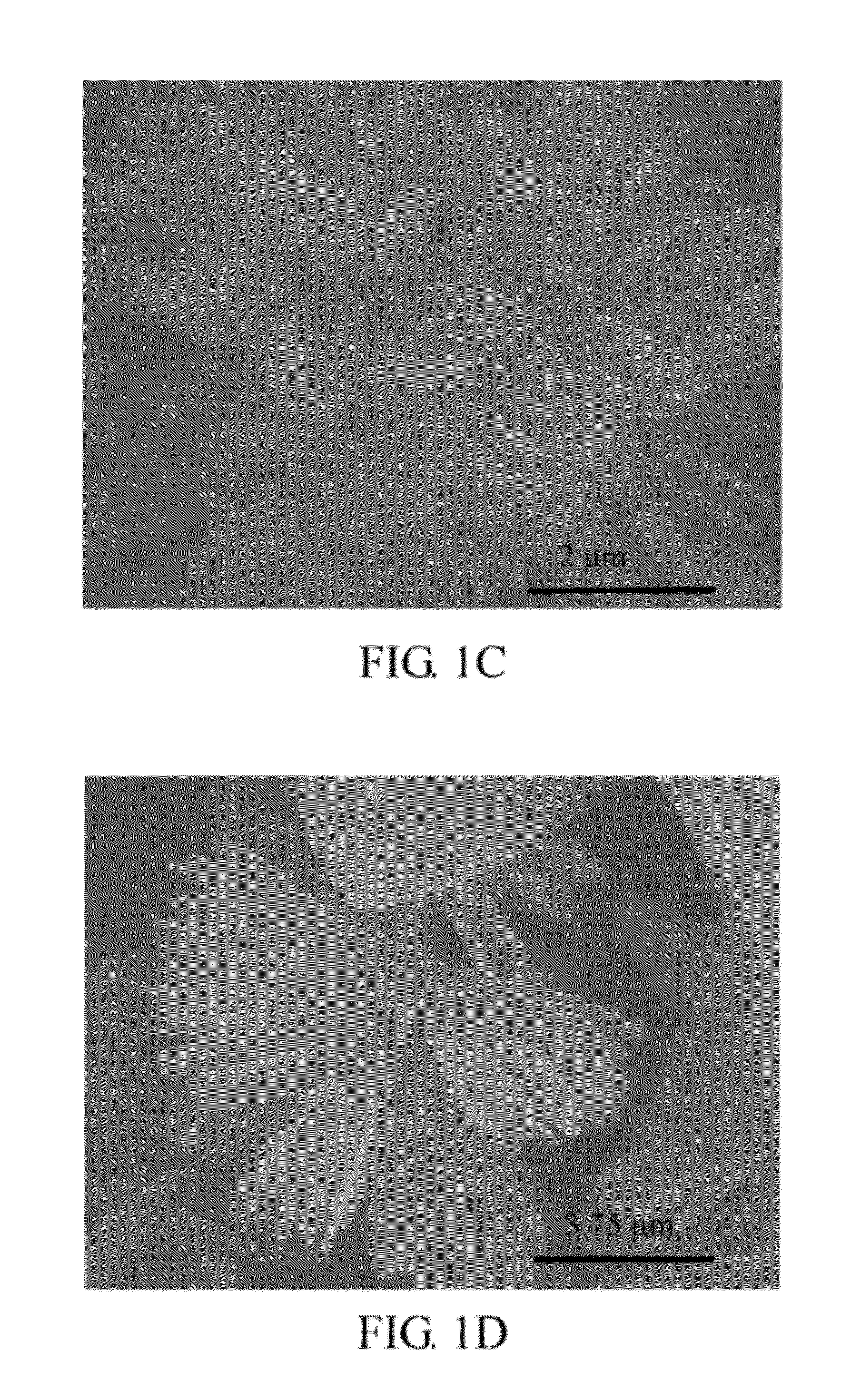

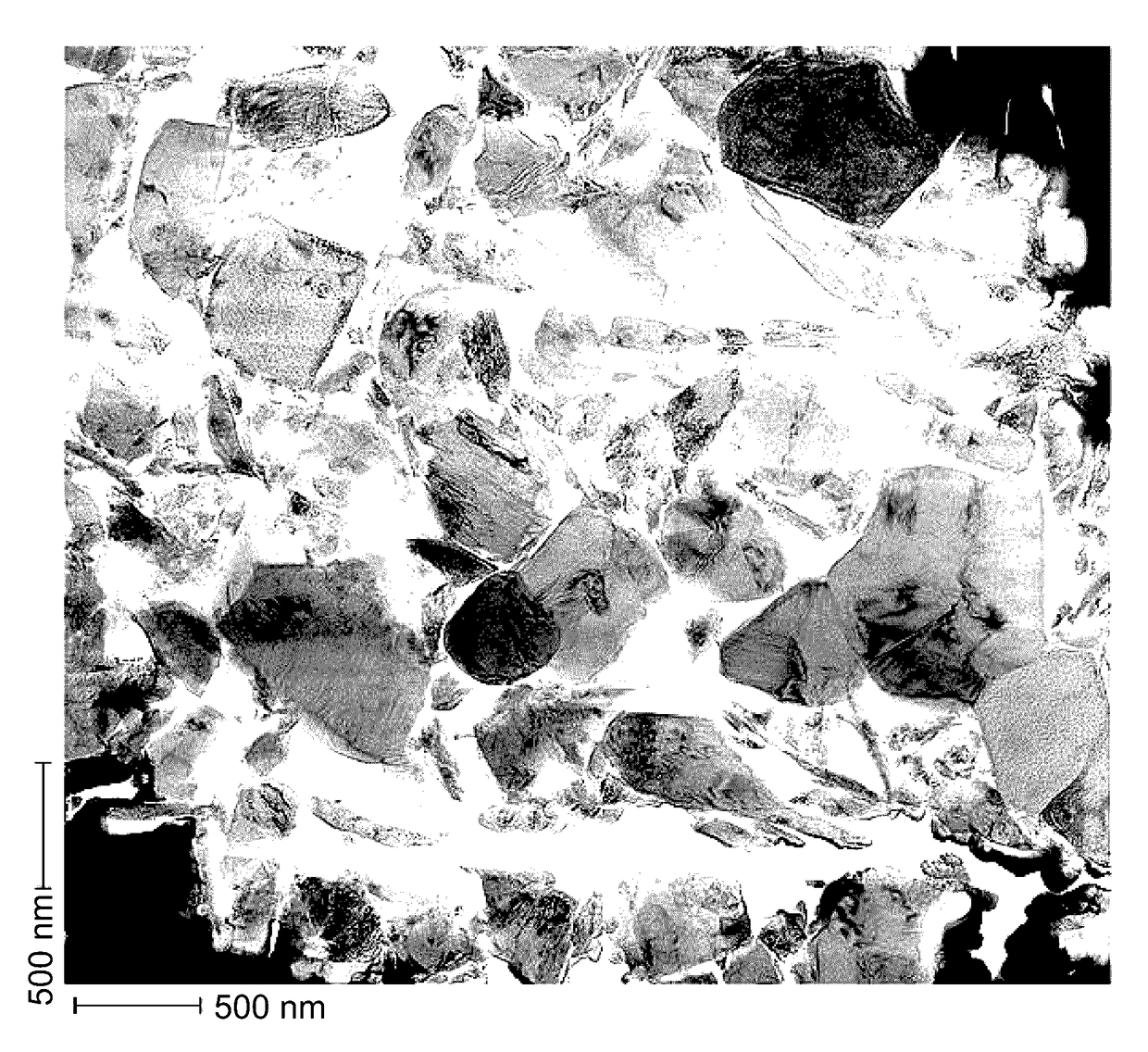

Ferrous phosphate (II) powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20120321958A1Uniform and small grain sizeUniform and small sizePhosphatesConductive materialLithium iron phosphatePhosphate

Ferrous phosphate (II) (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The ferrous phosphate (II) powders are represented by the following formula (I):Fe(3-x)Mx(PO4)2.yH2O (I)wherein, M, x, and y are defined in the specification, the ferrous phosphate (II) powders are composed of plural flake powders, and the length of each of the flake powders is 0.5-10 μm.

Owner:NATIONAL TSING HUA UNIVERSITY +1

Separation membrane and lithium-sulfur battery comprising same

ActiveUS20160233475A1Prevent elutionGrowth inhibitionElectrode carriers/collectorsNegative electrodesLithium–sulfur batteryElution

The present application relates to a separation membrane and a lithium-sulfur battery including the same, and the separation membrane according to the present application prevents elution of lithium polysulfide in a cathode and suppresses growth of a lithium dendrite generated in an anode, and thus has an effect that a life-span and safety of the battery are improved.

Owner:LG ENERGY SOLUTION LTD

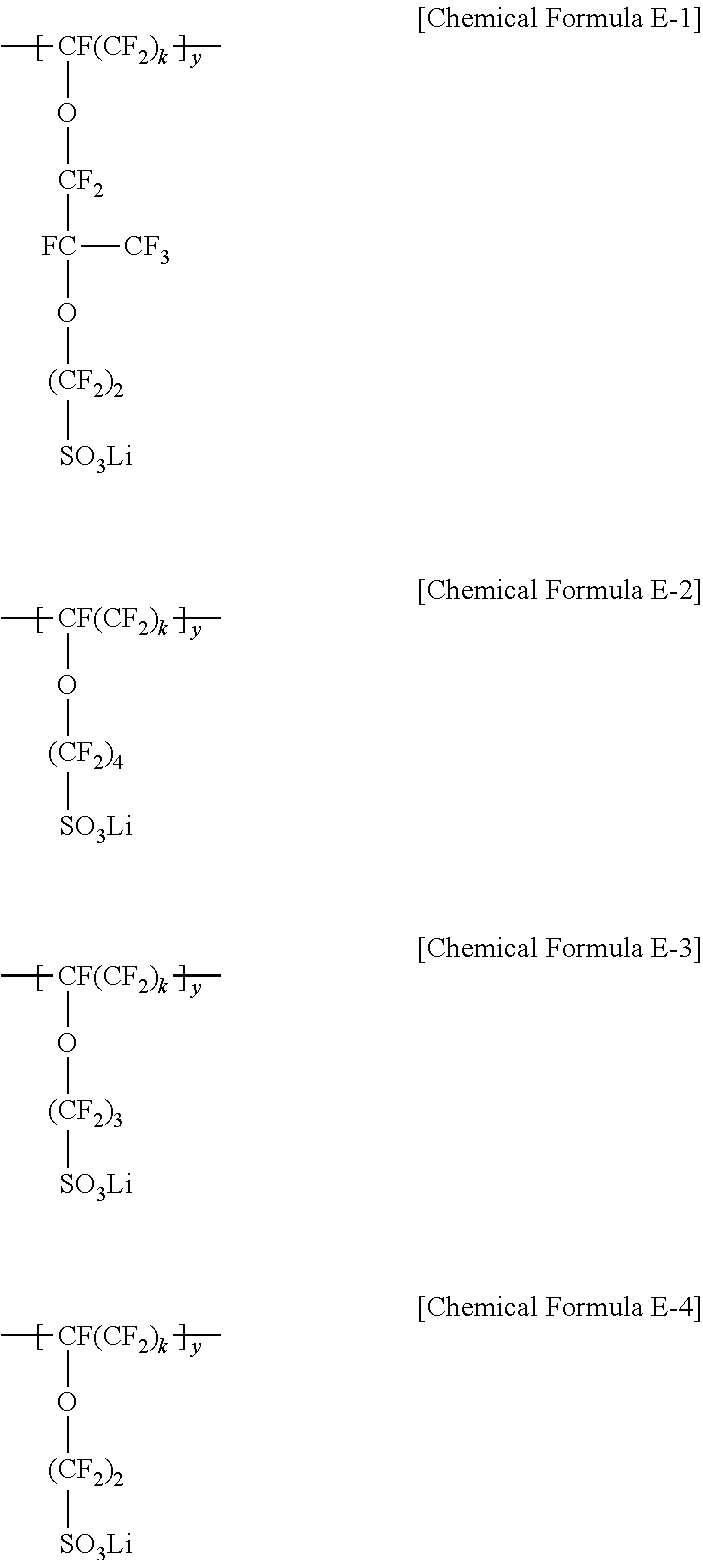

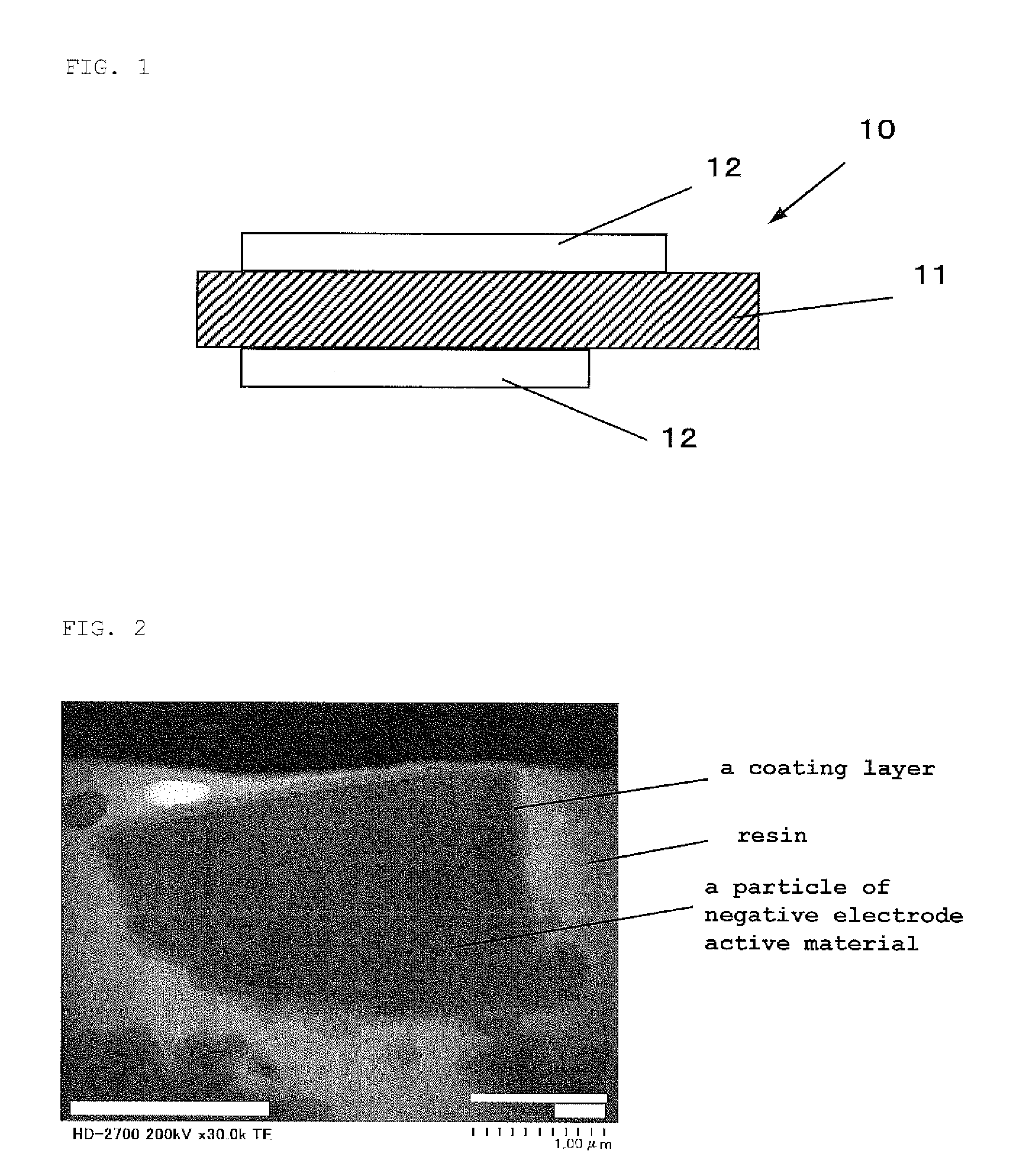

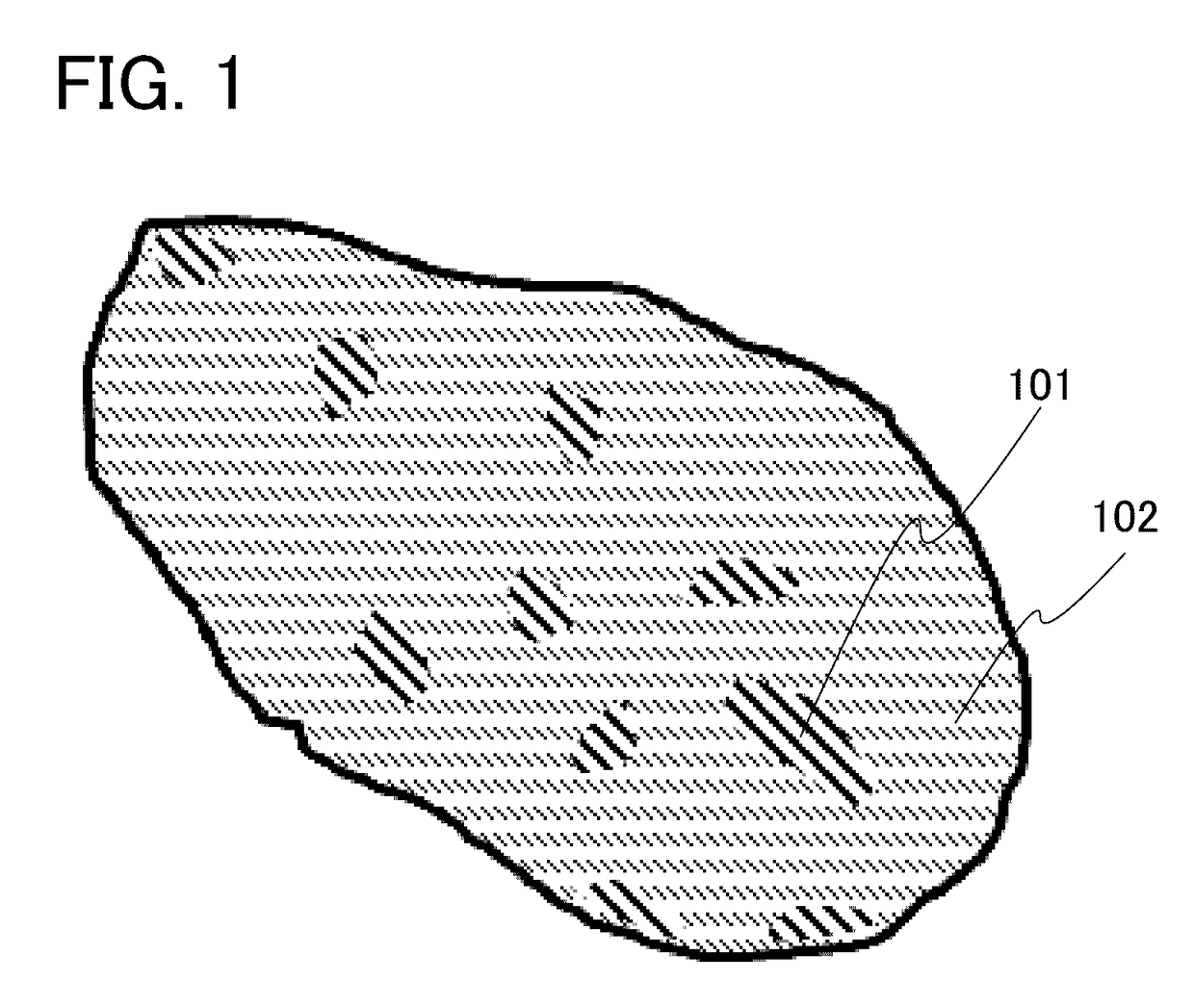

Negative electrode active material, raw material for a negative electrode active material, negative electrode, lithium ion secondary battery, method for producing a negative electrode active material, and method for producing a lithium ion secondary battery

ActiveUS20160233484A1Large capacityImprove featuresNegative electrodesSilicon oxidesLithiumUltimate tensile strength

A negative electrode active material including: a particle of negative electrode active material containing silicon-based material of SiOx (0.5≦x≦1.6); wherein the intensity A of a peak in a Si-region given in the chemical shift region of from −50 to −95 ppm and the intensity B of a peak in a SiO2-region given in the chemical shift region of from −96 to −150 ppm in a 29Si-MAS-NMR spectrum of the silicon-based material satisfy a relationship that A / B≧0.8. This provides a negative electrode active material which can increase a battery capacity, and can improve cycle characteristics and initial charge / discharge characteristics when used as a negative electrode active material for a lithium ion secondary battery.

Owner:SHIN ETSU CHEM IND CO LTD

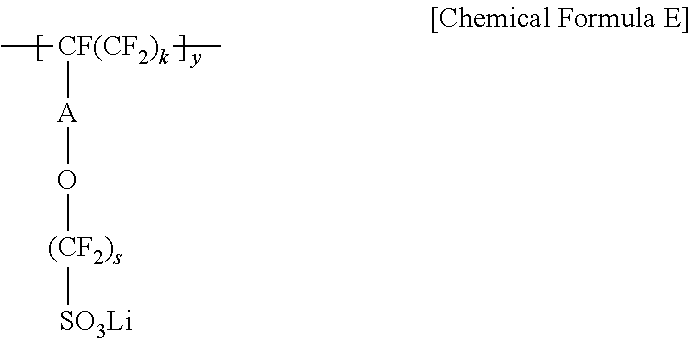

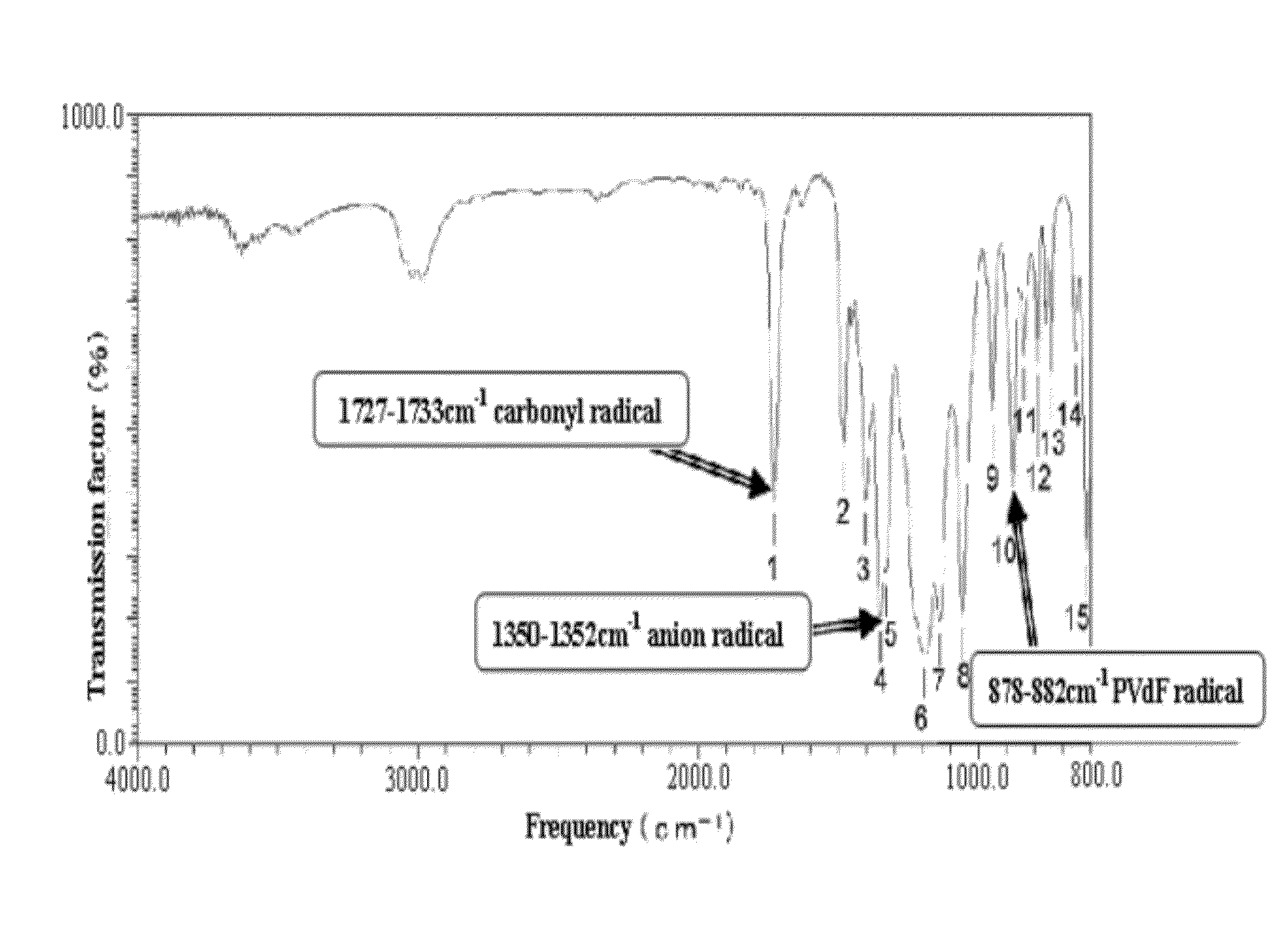

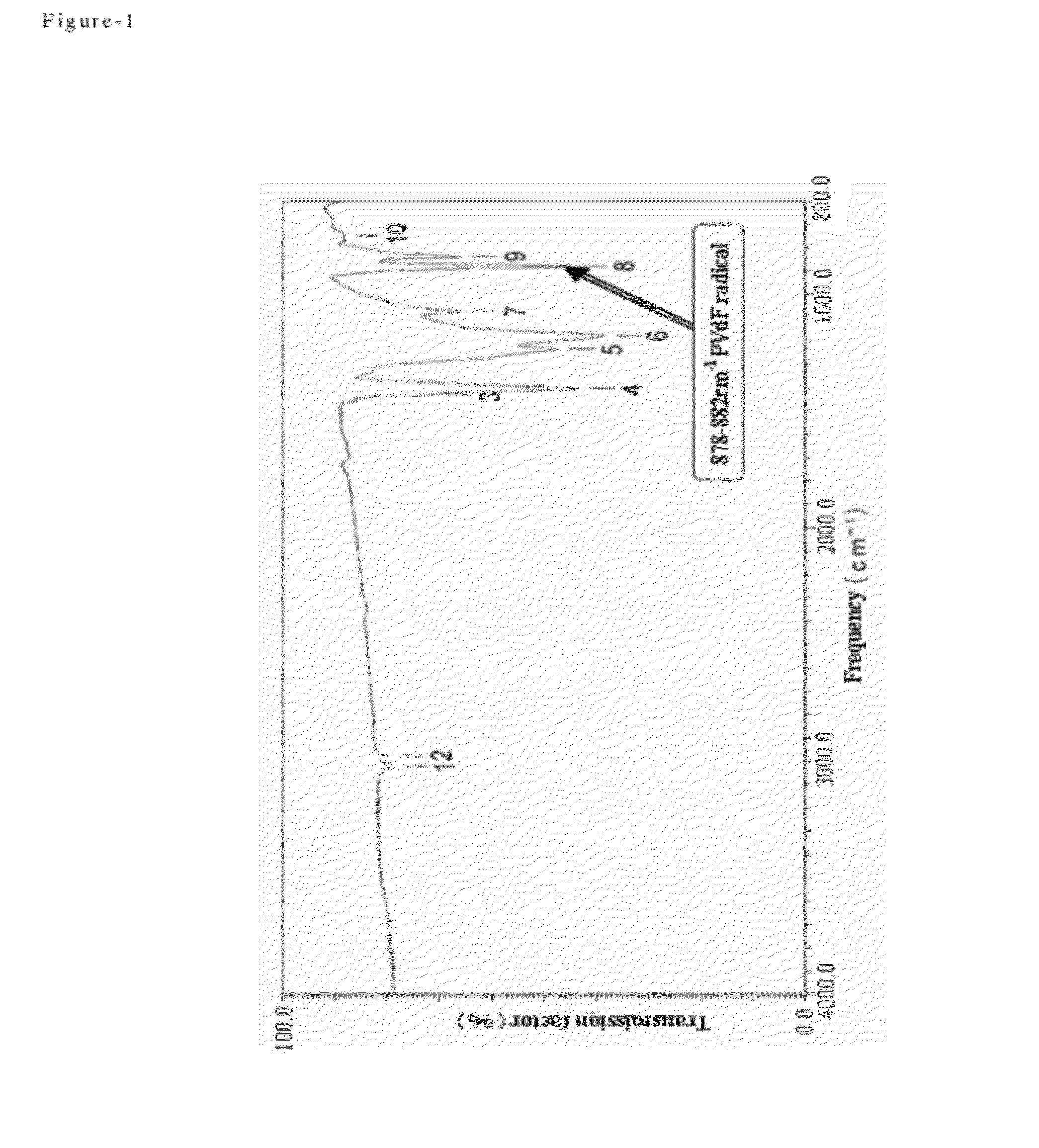

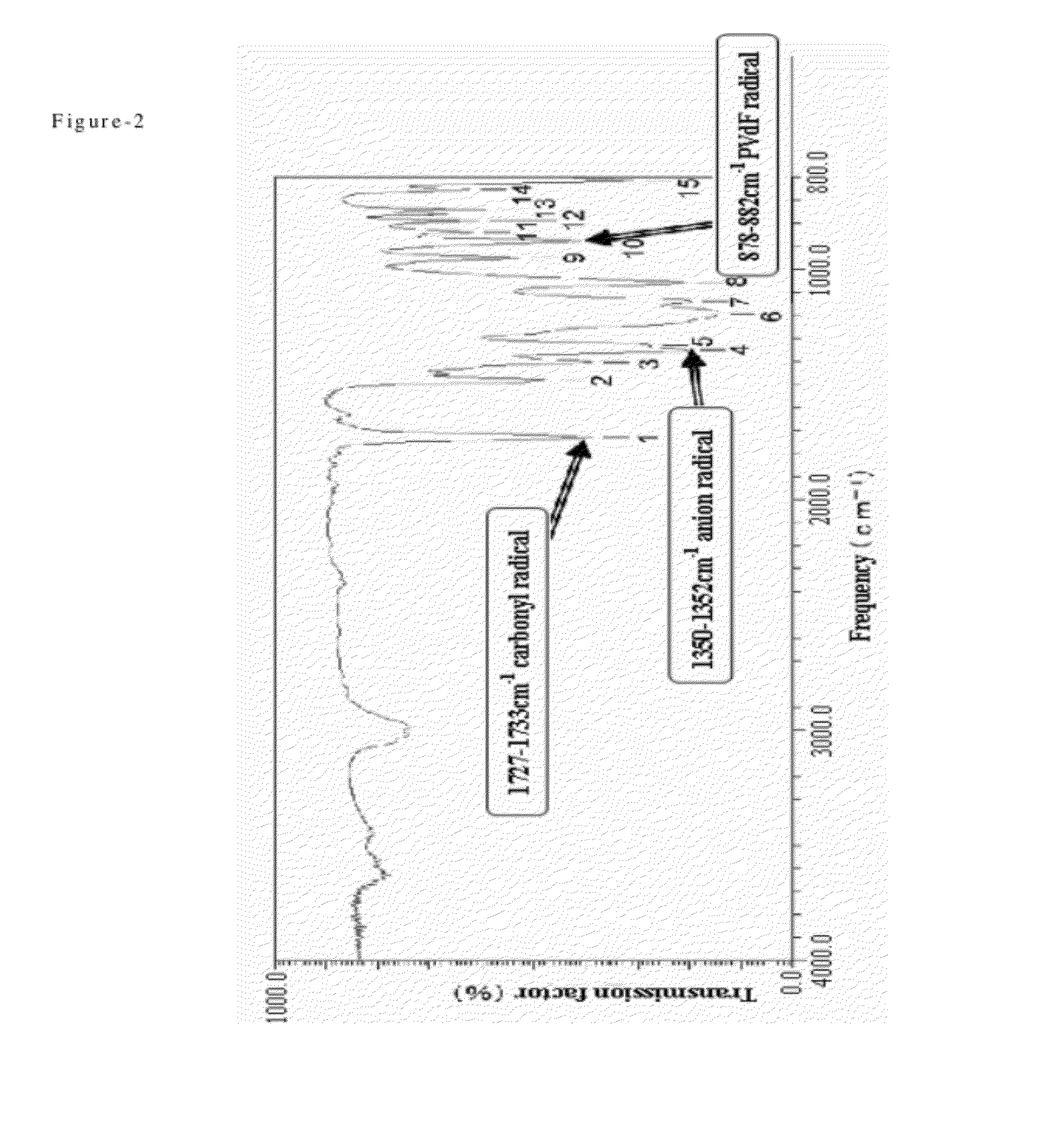

Process for producing fluorine containing polymer

According to this invention, a process for producing fluorine containing polymer to obtain composite polymer electrolyte composition having excellent ion transport number, that is, ion transfer coefficient, for example, excellent transport number of lithium ion, is provided.A process for producing fluorine containing polymer comprising graft-polymerizing a molten salt monomer having a polymerizable functional group and a quaternary ammonium salt structure having a quaternary ammonium cation and anion, with a polymer having the following unit;—(CR1R2—CFX)—X means halogen atom except fluorine atom,R1 and R2 mean hydrogen or fluorine atom, each is same or different atom.

Owner:PIOTREK

Process for manufacturing monolithic all-solid-state battery

ActiveCN105009332AIncrease volumetric energy densitySolid electrolytesElectrochemical processing of electrodesAll solid stateMetallurgy

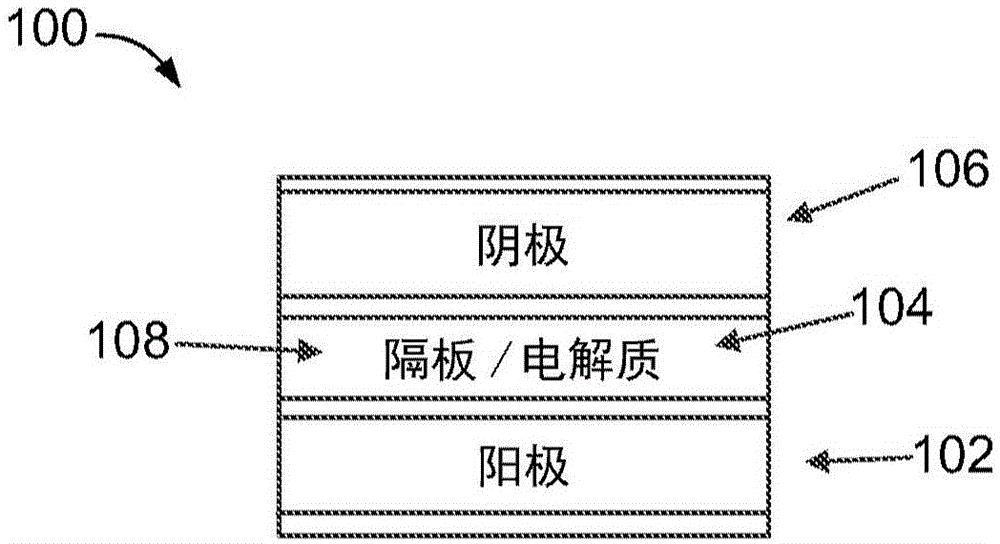

The invention relates to a process for manufacturing all-solid-state batteries, said batteries comprising at least one dense layer containing anode materials ("anode layer") at least one dense layer containing solid electrolyte materials ("electrolyte layer"), and at least one dense layer containing cathode materials ("cathode layer"), in order to obtain an all-solid-state battery consisting of an assembly of a plurality of elementary cells.

Owner:I TEN

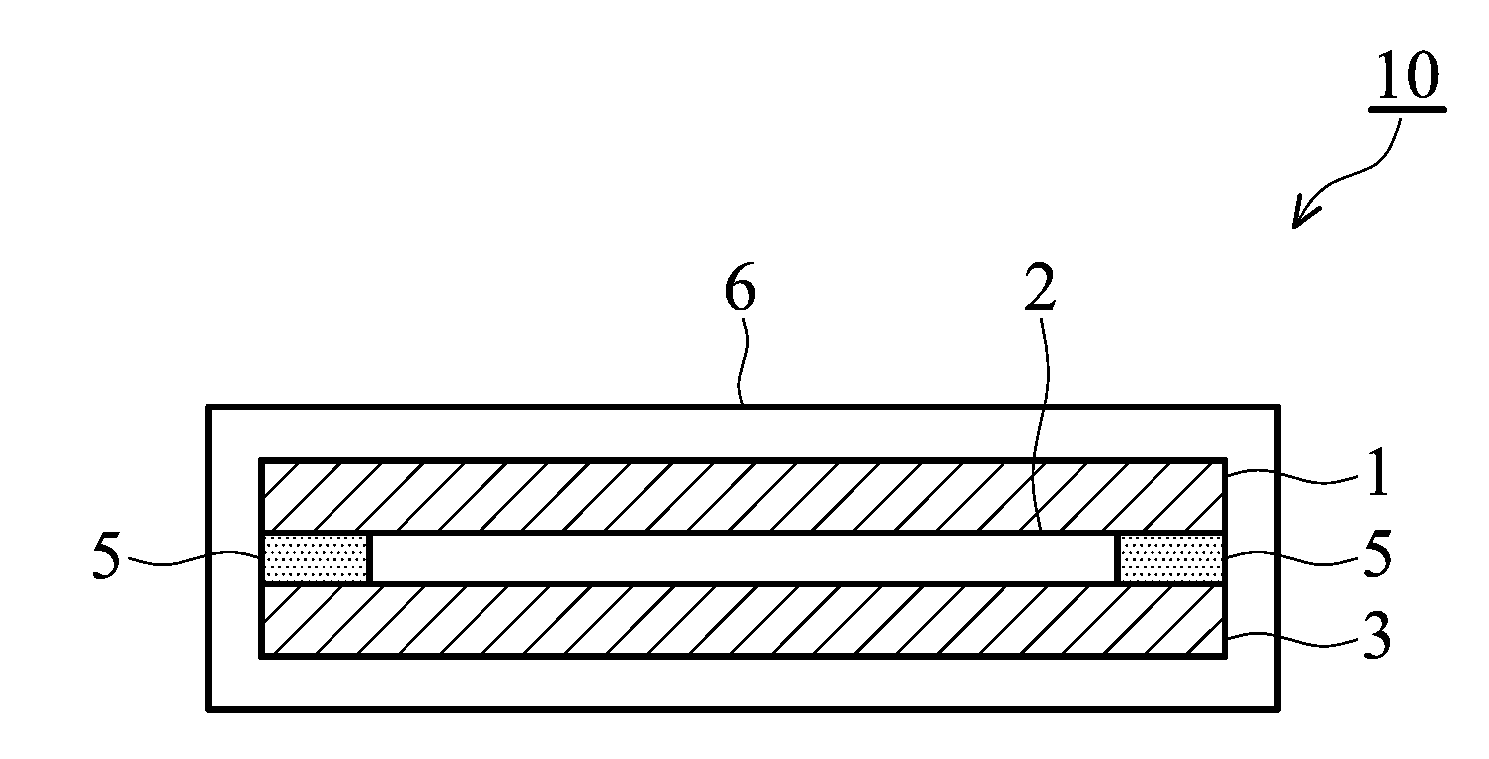

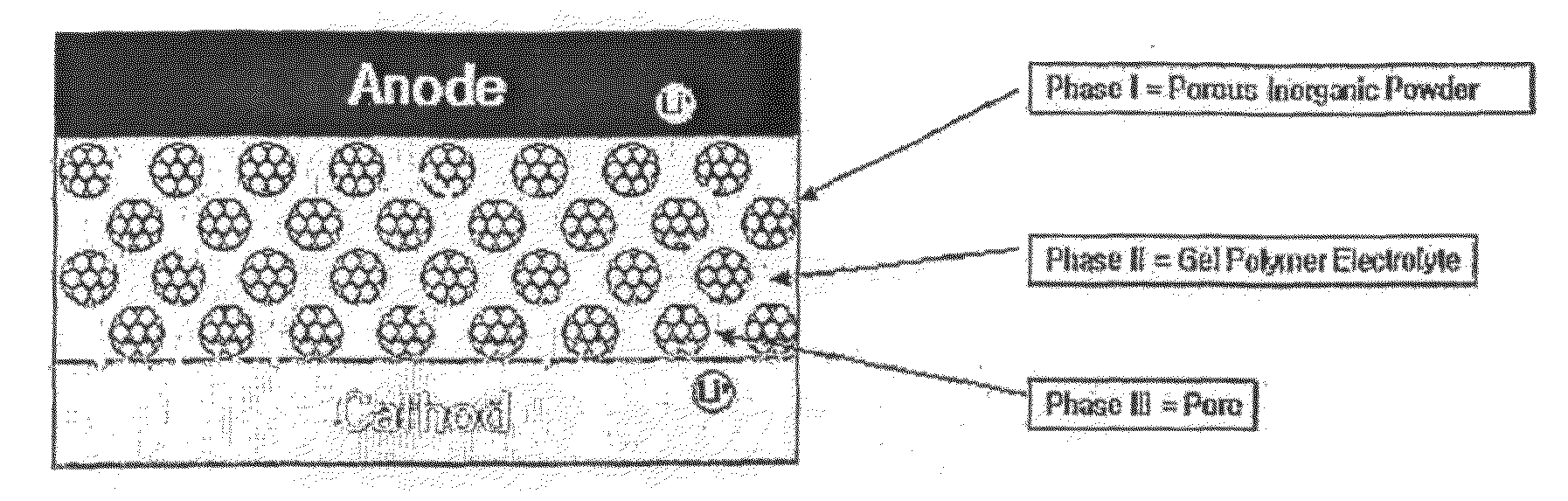

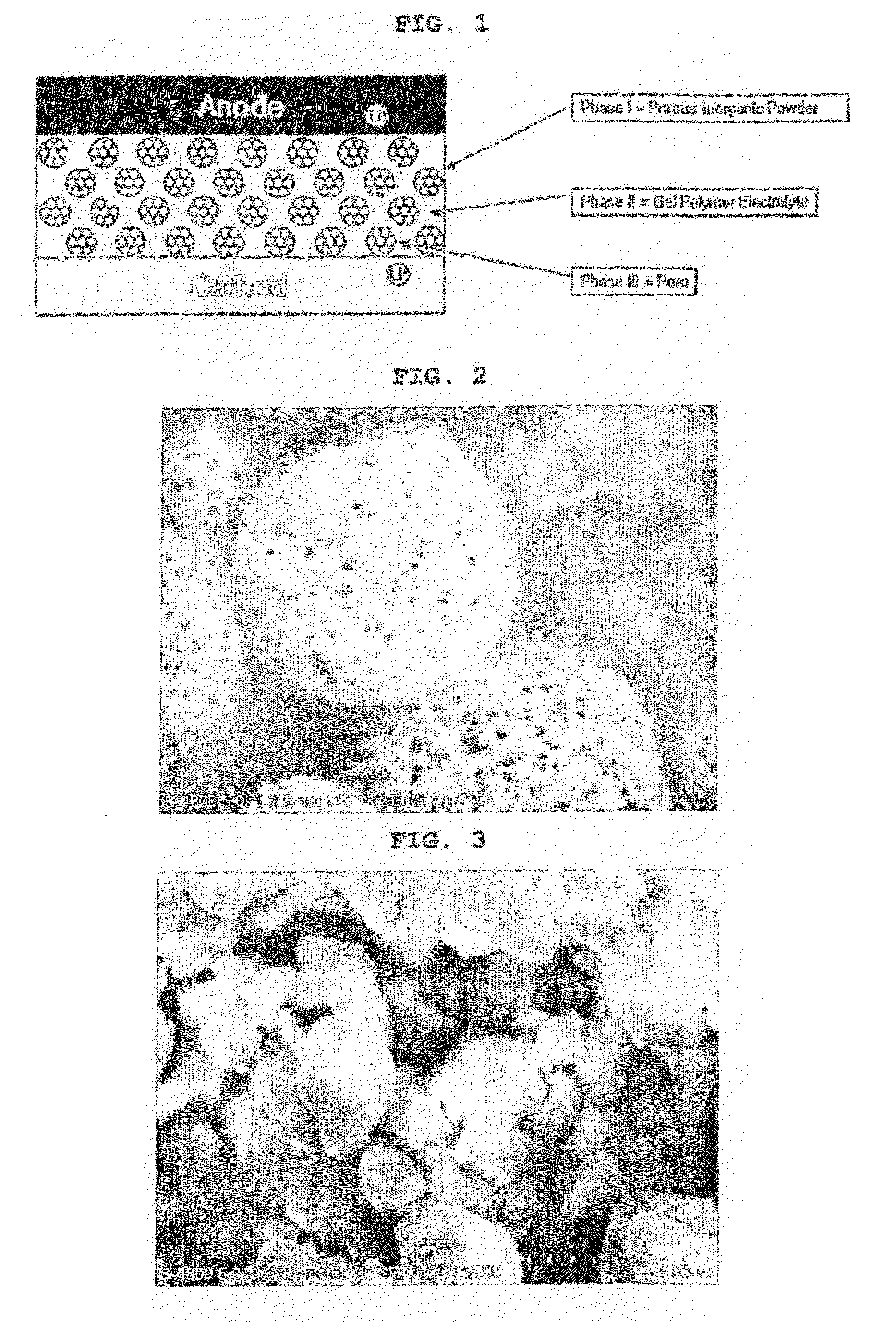

Organic/Inorganic Composite Electrolyte and Electrochemical Device Prepared Thereby

InactiveUS20100167124A1Improve securityInhibit heat shrinkageElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesPorous coatingComposite electrolyte

Disclosed is an electrode whose surface includes an organic / inorganic composite porous coating layer comprising porous inorganic particles and a binder polymer, wherein the porous inorganic particles have pores having such a size that lithium ions (Li+) solvated in an electrolyte solvent can pass therethrough. A method for manufacturing the electrode and an electrochemical device using the electrode are also disclosed. The organic / inorganic composite porous coating layer formed on the electrode according to the present invention provides an additional pathway for lithium ion conduction due to a plurality of pore structures present in the porous inorganic particles. Thus, when the organic / inorganic composite porous coating layer is used instead of a conventional polymer-based separator in a battery, the battery can provide improved quality and an increased energy density per unit weight due to a reduced weight of the organic / inorganic composite porous coating layer.

Owner:LG CHEM LTD

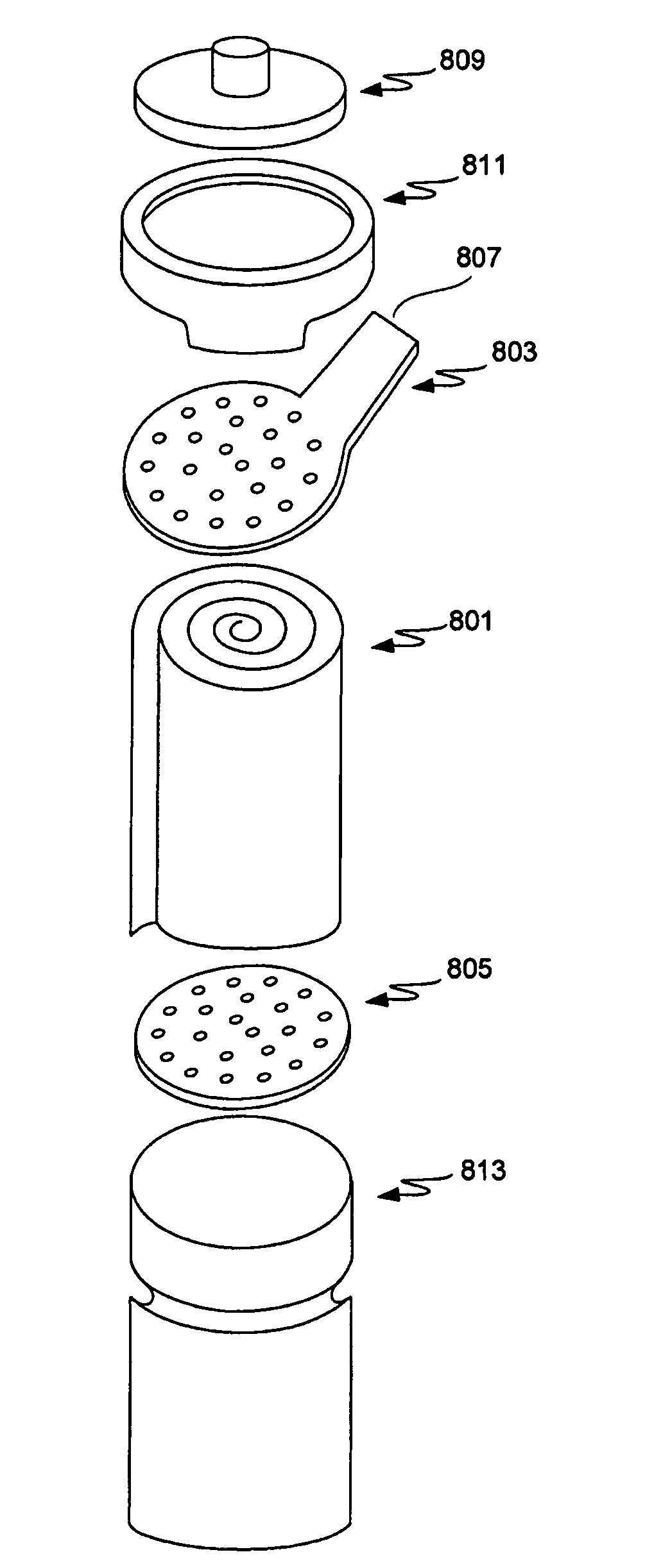

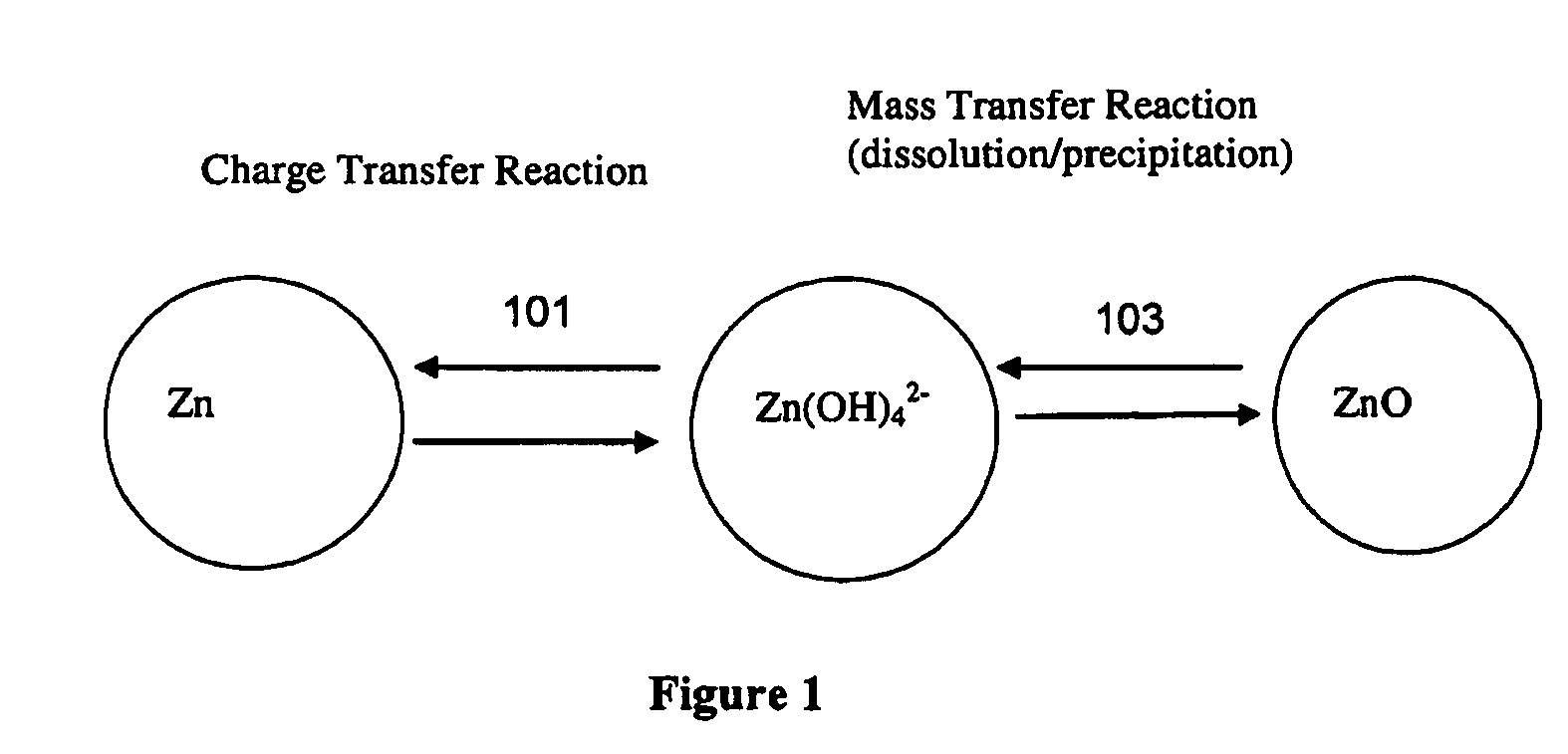

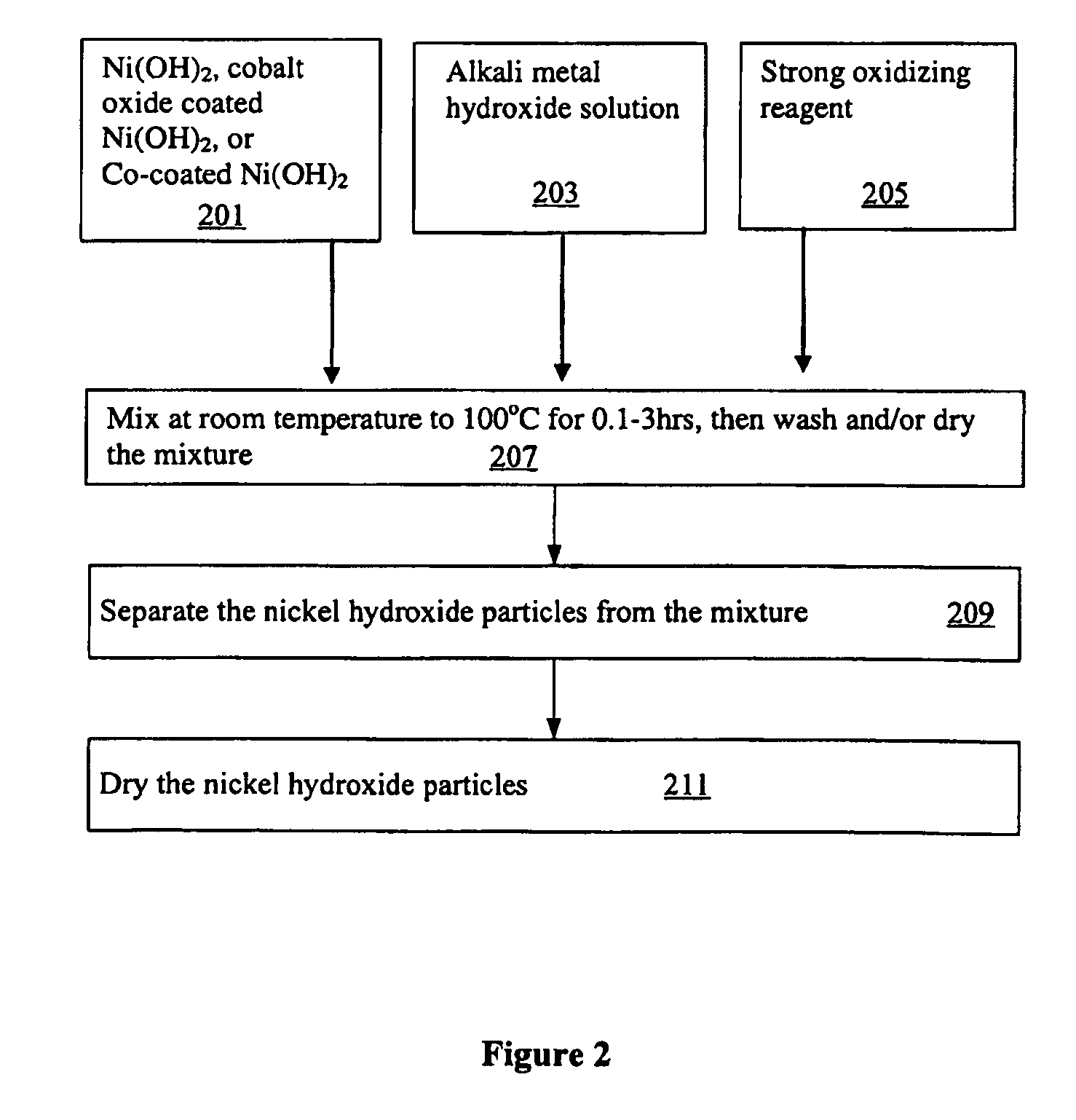

Pasted nickel hydroxide electrode for rechargeable nickel-zinc batteries

ActiveUS8043748B2Improve manufacturabilityMany timesAlkaline accumulator electrodesNon-aqueous electrolyte accumulator electrodesSolubilityHigh rate

Active material for a positive electrode of a rechargeable alkaline electrochemical cell is made with nickel hydroxide particles or cobalt-coated nickel hydroxide particles treated with strongly oxidizing reagents such as alkali metal persulfate in alkaline solution. The active material also may be made with cobalt-coated nickel hydroxide particles having a high percentage of cobalt(III) on a surface or an average cobalt oxidation state of about 3 measured across the particles. The treated nickel hydroxide or cobalt-coated nickel hydroxide decreases the cobalt solubility in the alkaline electrolyte and increases the high-rate charge and discharge capability. The lower cobalt solubility decreases cobalt migration that can increase self discharge and lead to premature failure.

Owner:ZINCFIVE POWER INC

Lithium secondary battery and manufacturing method for same

InactiveUS20120321947A1Excellent battery characteristicsIncrease resistanceActive material electrodesLi-accumulatorsPorosityCobalt

In a lithium secondary battery provided by the present invention, a positive electrode active material is constituted by a lithium composite oxide having at least lithium, nickel, and / or cobalt as main constituent elements, a porosity of a positive electrode active material layer is 30% or more and 40% or less, and a porosity of a negative electrode active material layer is 30% or more and 45% or less. Further, a void volume ratio (Sa / Sb) between a void volume (Sa) per unit area of the positive electrode active material layer and a void volume (Sb) per unit area of the negative electrode active material layer satisfies 0.9≦(Sa / Sb)≦1.4.

Owner:TOYOTA JIDOSHA KK

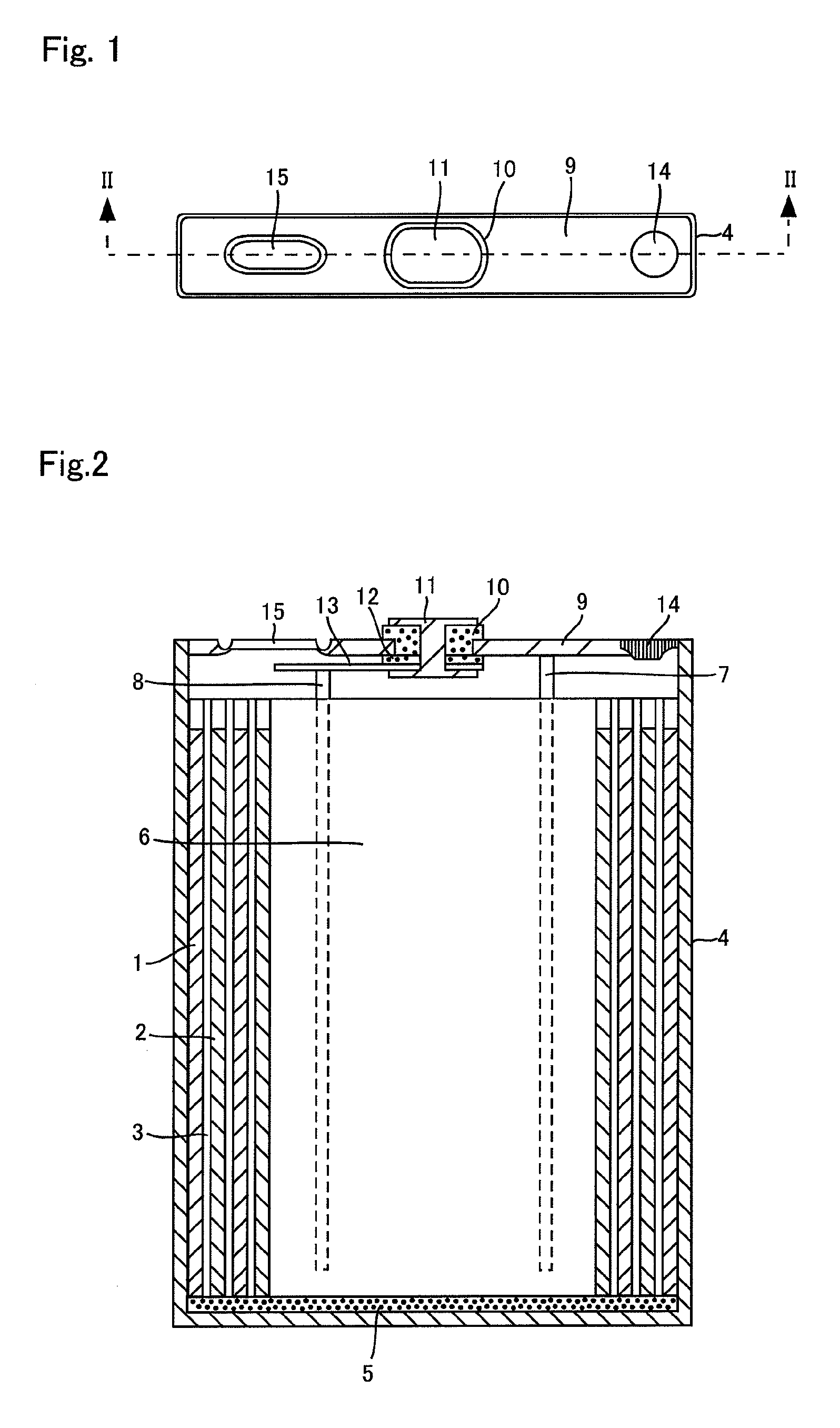

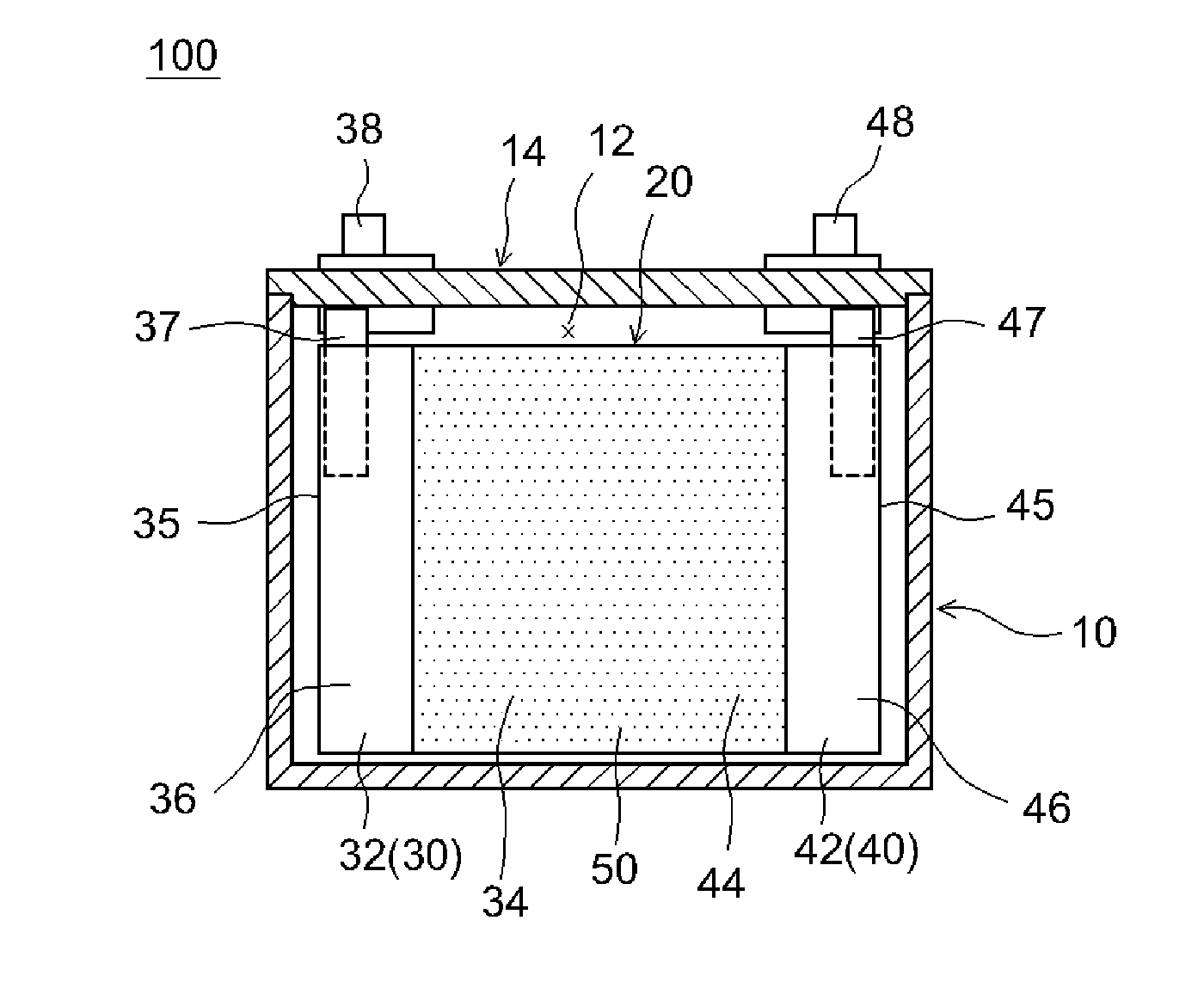

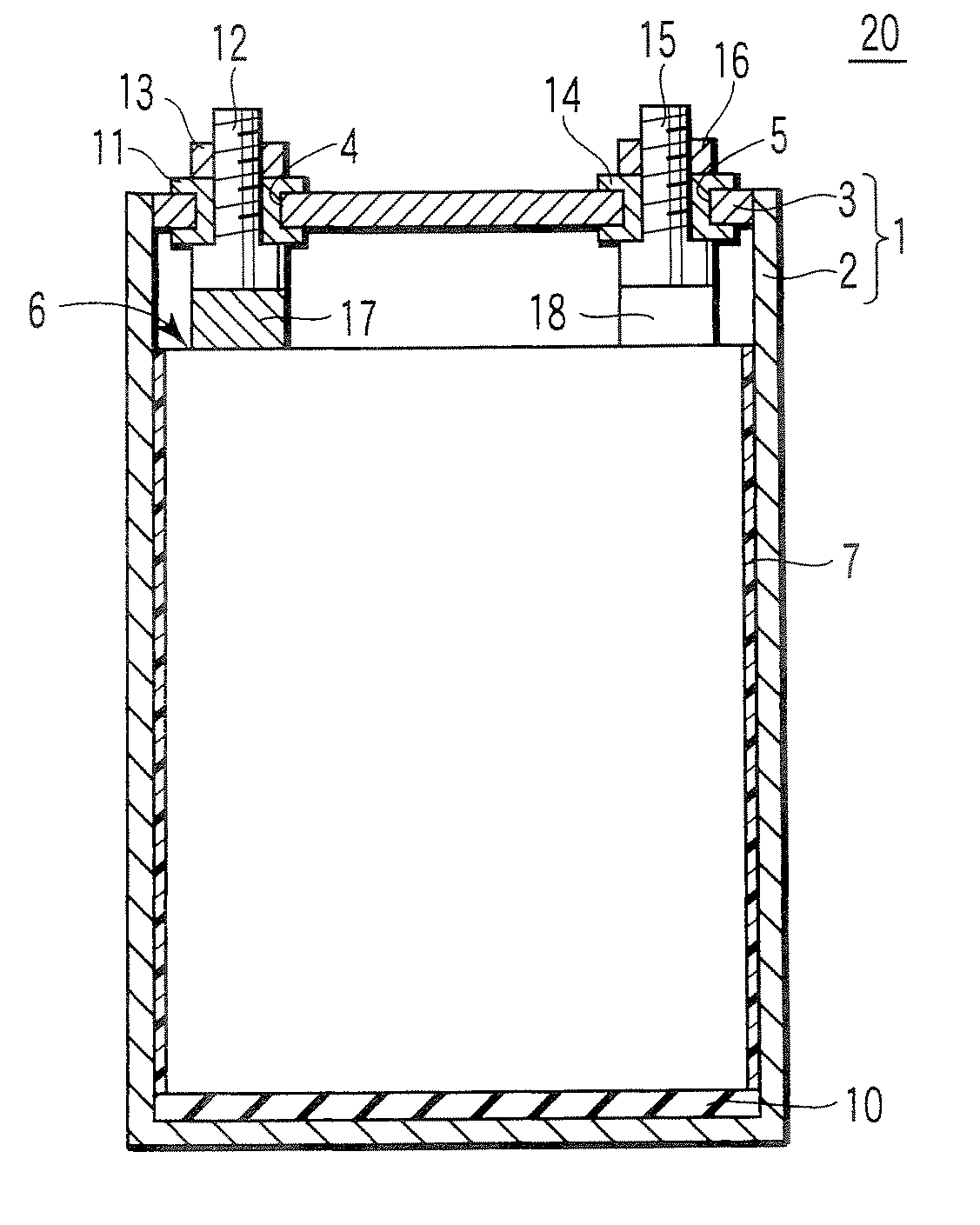

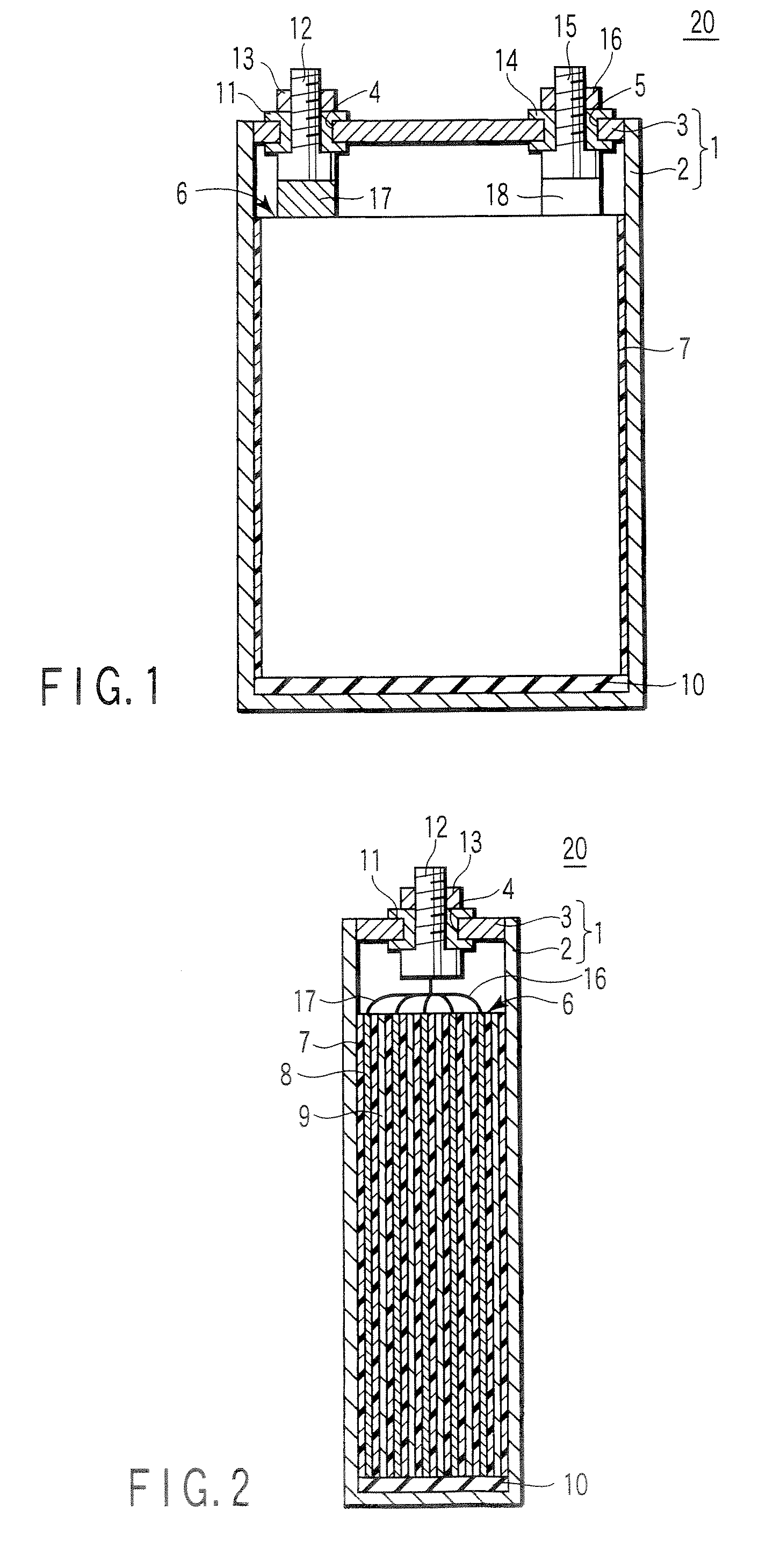

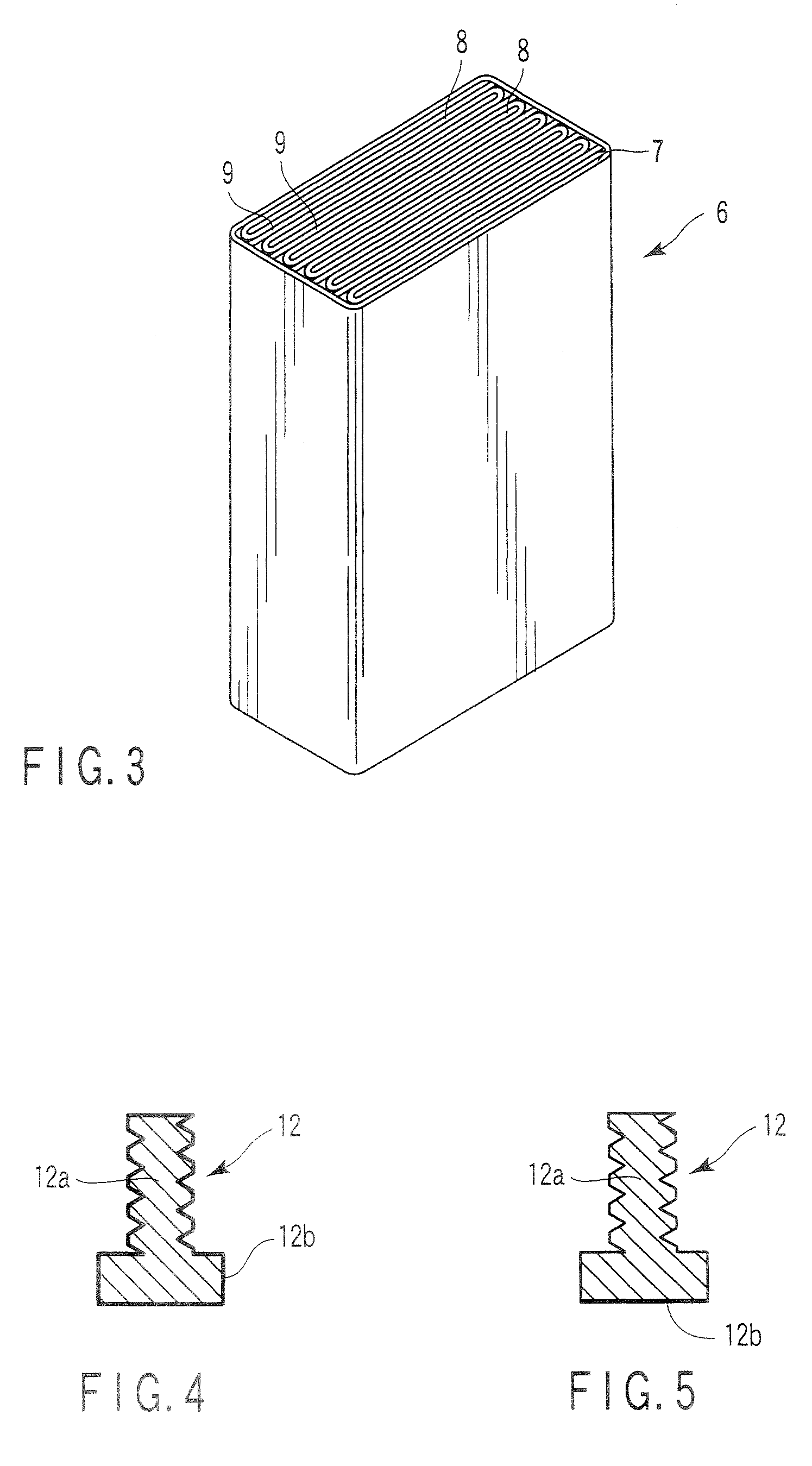

Nonaqueous electrolyte secondary battery and battery module

ActiveUS7892674B2Primary cell to battery groupingElectrode carriers/collectorsInternal resistanceEngineering

A nonaqueous electrolyte secondary battery, having an internal resistance of 10 mΩ or less as an alternating-current impedance value of 1 kHz, comprises a metal outer container, a nonaqueous electrolyte contained in the container, a positive electrode contained in the container, a negative electrode contained in the container, a separator interposed between the negative electrode and the positive electrode, a negative electrode lead having one end connected to the negative electrode, and a negative electrode terminal attached to the outer container so as to be connected electrically to the other end of the negative electrode lead, at least the surface of the negative electrode terminal which is connected to the negative electrode lead being formed of aluminum alloy with an aluminum purity of less than 99 wt. % containing at least one metal selected from the group consisting of Mg, Cr, Mn, Cu, Si, Fe and Ni.

Owner:KK TOSHIBA

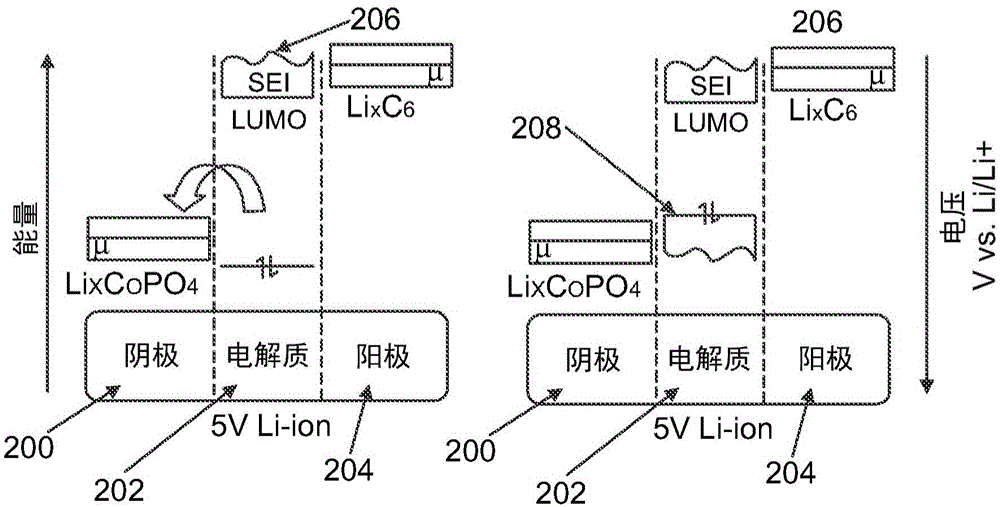

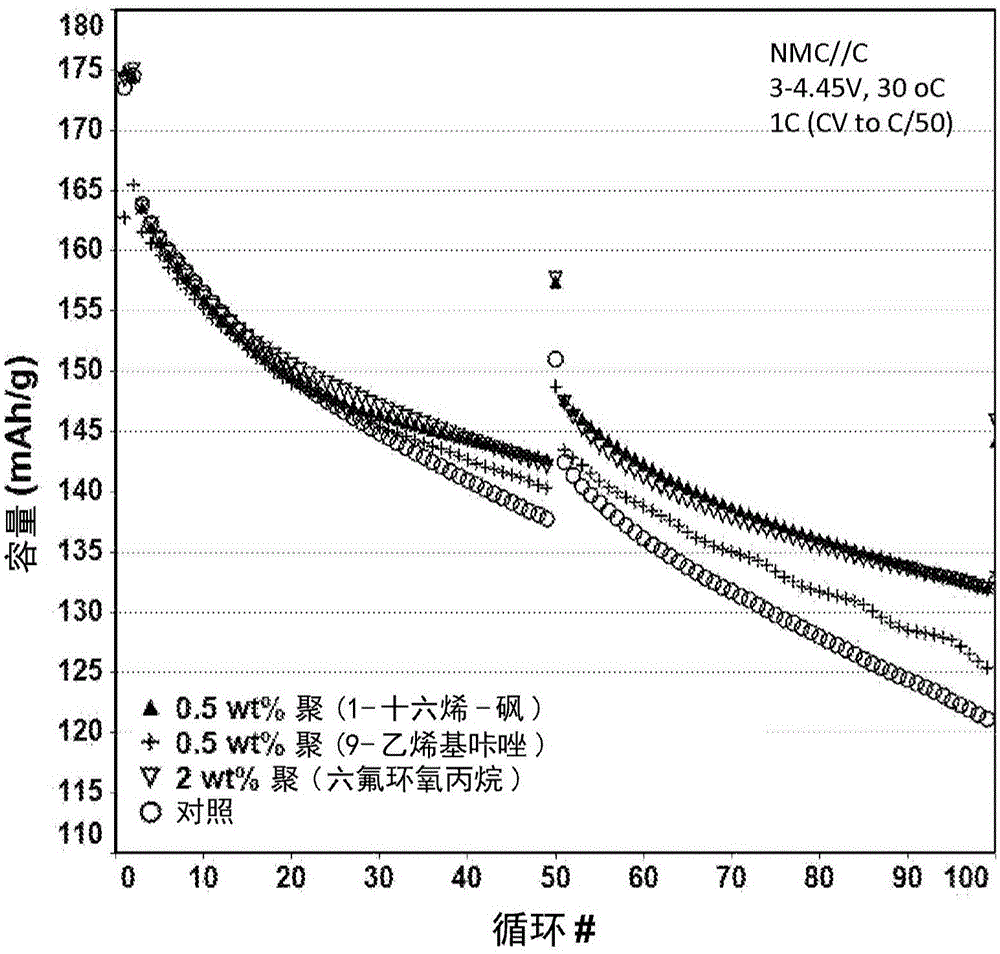

Electrolyte solutions for high energy cathode materials and methods for use

Described herein are materials for use in electrolytes that provide a number of desirable characteristics when implemented within batteries, such as high stability during battery cycling up to high temperatures, high voltages, high discharge capacity, high coulombic efficiency, and excellent retention of discharge capacity and coulombic efficiency over several cycles of charging and discharging. In some embodiments, a high voltage electrolyte includes a base electrolyte and a set of additive compounds, which impart these desirable performance characteristics.

Owner:WILDCAT DISCOVERY TECH

Lithium manganese oxide composite, secondary battery, and manufacturing method thereof

ActiveUS9666326B2Low costInexpensive materialsCell electrodesOxide conductorsHigh energyOxide composite

To increase the amount of lithium ions that can be received and released in and from a positive electrode active material to achieve high capacity and high energy density of a secondary battery. A composite material of crystallites of LiMn2O4 (crystallites with a spinel crystal structure) and crystallites of Li2MnO3 (crystallites with a layered rock-salt crystal structure) is used as a positive electrode active material. The lithium manganese oxide composite has high structural stability and high capacity.

Owner:SEMICON ENERGY LAB CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com